Ferrida FRD-MS2115SE User manual

Miter Saw

FRD-MS2115SE

User Manual

ENGLISH 4

DEUTSCH 18

ČESKY 34

SLOVENSKY 48

MAGYAR 62

WARRANTY & SUPPORT 76

GARANTIE & BETREUUNG 76

ZÁRUKA & PODPORA 76

ZÁRUKA & PODPORA 76

GARANCIA & TÁMOGATÁS 76

4ENGLISH

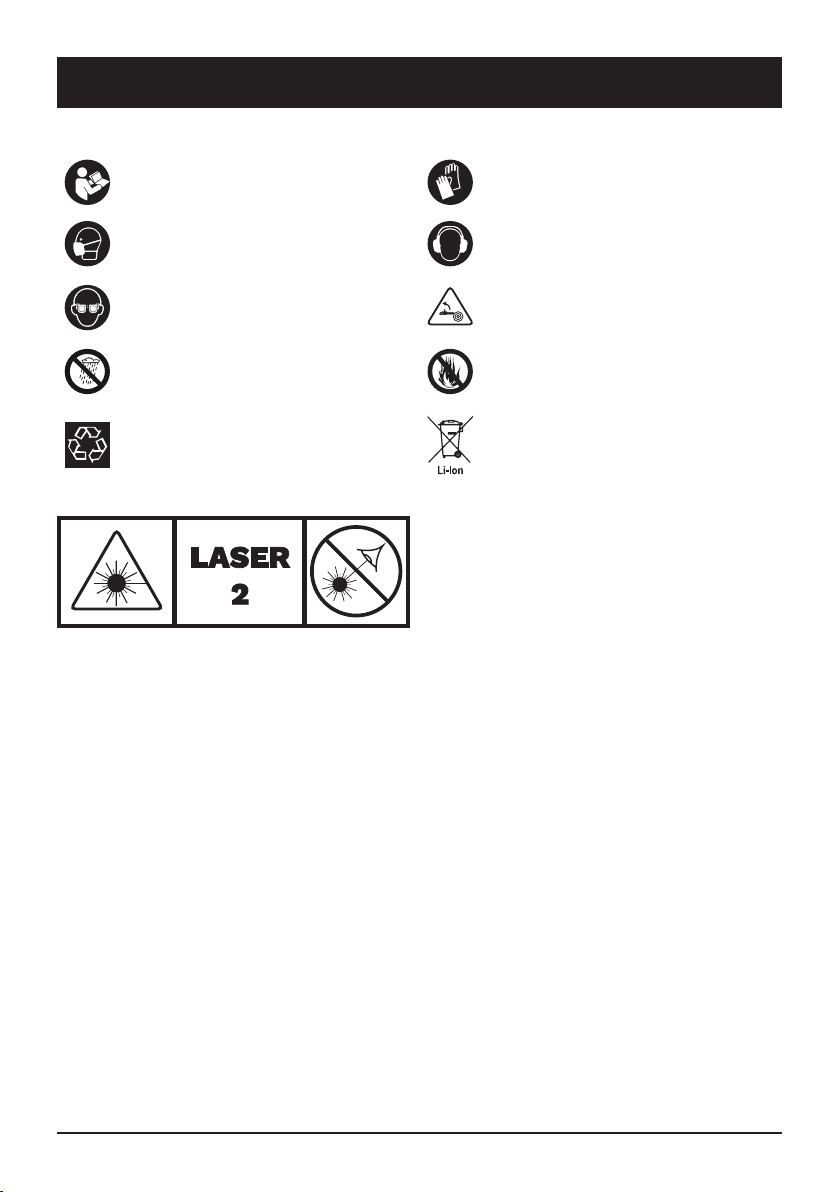

EXPLANATION OF SYMBOLS ON THE PRODUCT PACKAGING/TYPE LABEL

Read the operating instructions careful-

ly before use! Wear protective gloves

Wear mouth and nose protection. Wear noise protection.

Wear protective glasses

Observe the safety instructions con-

cerning recoil and the safety precau-

tions.

Protect from rain and moisture. Protect from heat and fire.

Ensure proper recycling of the product

at the end of its service life and all pack-

aging materials.

Do not dispose of with normal house-

hold waste.

WARNING:

Class 2 laser product. Do not look into the la-

ser beam.

GENERAL SAFETY INSTRUCTIONS FOR POW-

ER TOOLS

WARNING! All safety instructions, user man-

uals, images and regulations supplied with

these tools must be read. Failure to follow all

of the following instructions may result in elec-

tric shock, fire, and/or serious personal injury.

All instructions and the user manual must be

kept for future reference.

Safety of working environment

1. The workplace must be kept clean and well lit.

Untidy and dark spaces are often the cause of

accidents.

2. Power tools must not be used in potentially ex-

plosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools

create sparks that can ignite dust or fumes.

3. Children and other persons must be kept away

when using power tools. If the operator is dis-

turbed, he/she may lose control of the opera-

tion.

Electrical safety

1. The plug on the power tool's flexible lead must

match the power outlet. The plug must never

be modified in any way. No socket adapters

may be used with tools that have a protective

earth connection. Plugs and respective sockets

that are rendered unusable will reduce the risk

of electric shock.

2. The operator must not touch grounded ob-

jects, such as pipes, central heating units,

cookers and refrigerators. The risk of electric

shock is greater if your body is connected to

the ground.

3. Power tools must not be exposed to rain, mois-

ture or wetness. If water enters the power tool,

the risk of electric shock increases.

4. The flexible supply must not be used for oth-

er purposes. The power tool must not be car-

ried or pulled by the cord, nor must the plug

be unplugged from the socket. The inlet must

be protected from heat, grease, sharp edges

or moving parts. Damaged or tangled leads

increase the risk of electric shock.

5. If the power tool is used outdoors, an extension

cord suitable for outdoor use must be used. Us-

ing an extension cord for outdoor use reduces

the risk of electric shock.

6. If the power tool is used in a humid environ-

ment, a residual current device (RCD) must be

SAFETY INSTRUCTIONS

5ENGLISH

used. Using an RCD reduces the risk of electric

shock.

Safety of persons

1. When using a power tool, the operator must

be careful, pay attention to what he/she is do-

ing, and concentrate and think clearly. Power

tools must not be used if the operator is tired

or under the influence of drugs, alcohol or

medication. Momentary inattention while us-

ing a power tool can result in serious personal

injury.

2. Use personal protective equipment. Always

use eye protection. Protective equipment such

as a respirator, non-slip safety shoes, hard hat

and hearing protection, used in accordance

with the working conditions, reduces the risk

of personal injury.

3. Unintentional starting of the machine must be

avoided. Make sure that the switch is in the

off position before plugging in and/or con-

necting the battery pack, lifting or carrying

the tool. Carrying a tool with your finger on

the switch or plugging in a tool fork with the

switch on can cause injury.

4. All adjusting tools or wrenches must be re-

moved before turning on the tool. An adjust-

ing tool or wrench that remains attached to

the rotating part of the power tool may result

in personal injury.

5. The operator must only work where he/she

can safely reach. The operator must always

maintain a stable posture and balance. This

will allow better control of the power tool in

unforeseen situations.

6. Dress appropriately. Do not wear loose cloth-

ing or jewellery. The operator must make sure

that his/her hair and clothing are a sufficient

distance away from moving parts. Loose cloth-

ing, jewellery and long hair can be caught in

moving parts.

7. Where equipment is provided for connecting

dust extraction and collection facilities, care

must be taken to ensure that it is connected

and used correctly. The use of such equip-

ment can reduce hazards caused by dust.

8. The operator must not allow the routine that

results from the frequent use of the tools, to

cause them to become complacent and ig-

nore the principles of tool safety. Careless

activity can cause serious injuries in a split

second.

Use and the maintenance of power tools

1. Power tools must not be overloaded. It is es-

sential to use the correct power tool for the

work being carried out. The correct power tool

will do the work it was designed to do better

and safer.

2. Power tools that cannot be turned on and off

with the switch must not be used. Any power

tool that cannot be operated with the switch is

dangerous and must be repaired.

3. Before making any adjustments, changing ac-

cessories, or storing power tools, unplug the

power tool and/or remove the battery pack

from the power tool if it is removable. These

precautions reduce the risk of accidentally

starting the power tool.

4. Unused power tools must be stored out of the

reach of children. Persons unfamiliar with the

power tool or these instructions must not be

allowed to use the power tool. Power tools

are dangerous in the hands of inexperienced

users.

5. Power tools and accessories must be main-

tained. The adjustment of moving parts and

their mobility must be checked and attention

focused on cracks, broken parts and any other

circumstances that may jeopardize the func-

tion of the power tool. If the tool is damaged, it

must be repaired before use. Many accidents

are caused by poorly maintained power tools.

6. Cutting tools must be kept sharp and clean.

Properly maintained and sharpened cutting

tools are less likely to catch on material or jam

and are easier to control.

7. Power tools, accessories and tool bits etc.

must be used in accordance with these in-

structions and in the manner intended for the

particular power tool, taking into account the

working conditions and the work to be carried

out. Using power tools for activities other than

those for which they are designed can lead to

dangerous situations.

8. Handles and grip surfaces must be kept dry,

clean and free of grease. Slippery handles and

gripping surfaces mean the tool cannot be

held and controlled in unexpected situations.

Service

1. Power tool repairs must be carried out by

SAFETY INSTRUCTIONS

6ENGLISH

SAFETY INSTRUCTIONS

qualified personnel using identical spare

parts. This will ensure the same level of safety

of the power tool as before the repair.

SAFETY INSTRUCTIONS FOR ALL SAWS

When cutting

1. DANGER: The operator must ensure that his/

her hands are at a safe distance from the cut-

ting point and the saw disc. The other hand

must be used to grip the auxiliary handle or

the motor housing. If the saw is held with both

hands, the hands cannot be cut with the disc.

2. Do not touch the workpiece. The protective

cover cannot protect the operator from touch-

ing the disc under the workpiece.

3. The depth of cut must be adapted to the thick-

ness of the workpiece. The visible part of the

saw disc teeth under the workpiece should be

less than the height of one tooth.

4. The workpiece must never be held in the hand

or over the knee when cutting. The workpiece

must be mounted on a solid base. It is impor-

tant that the workpiece is properly supported

and that the risk of touching any part of the

body, the disc jamming, or loss of control is

reduced to the minimum.

5. When performing an operation where the cut-

ting tool may touch a hidden guide or its own

power supply, the power tool must be held

by insulated gripping surfaces. Contact with

a “live” wire will cause the uninsulated metal

parts of the power tool to become “live” and

may cause an electric shock to the user.

6. When cutting longitudinally, it is always nec-

essary to use a longitudinal ruler or a guide

with a straight edge. This improves cutting ac-

curacy and reduces the risk of the disc getting

stuck.

7. Discs with clamping holes of the correct size

and shape (diamond or circular) must always

be used. Saw discs that do not exactly match

the saw's clamping components will not be

centred and will cause a loss of control.

8. Damaged or incorrect washers or screws must

never be used to clamp the disc. The washers

and screws for clamping the disc have been

specially designed for your saw for optimum

performance and work safety.

Causes of recoil and related warnings

Recoil is a sudden reaction of a pinched, blocked

or misaligned saw disc resulting in an uncon-

trolled upward movement of the saw upwards

and away from the workpiece towards the oper-

ator;

• If the saw disc is clamped or completely

blocked by the clamping cut, it stops, and the

reaction force of the motor causes the saw to

be thrown back quickly towards the operator;

• If the saw disc is rotated or misaligned in the

cut, the teeth on the rear edge of the disc may

hit the wood surface from above, the disc will

jump out of the cut and the saw will be thrown

back towards the operator.

Recoil is the result of improper use of the saw

and/or improper work procedures or conditions

and can be prevented by fully complying with

the above precautions.

• The saw must always be held firmly with both

hands and the arms in a position that it can

withstand the force of the recoil. The body

of the operator must be on one side of the

disc, but not in the plane of the disc. Recoil

can cause the saw to be thrown back, but the

force caused by the recoil can be handled by

the user taking the appropriate safety precau-

tions.

• If the saw disc becomes stuck or if it is nec-

essary to interrupt the cut for any reason, the

switch control must be released, and the saw

held in place in the material until the saw disc

comes to a complete stop. The operator must

never attempt to lift the saw from the cut or

pull it back while the saw disc is in motion; in

such cases, recoil may occur. It is necessary to

look for the causes of the saw disc jamming

and ways to eliminate these causes.

• If the saw disc is lowered in the workpiece, the

saw disc must be centred in the cut so that the

saw teeth are not immersed in the material. If

the saw disc jams, the saw may be pushed up-

wards from the workpiece or recoil may occur.

• Large sawn timber must be supported to min-

imize the risk of recoil and the saw disc jam-

ming. Large sawn timber tends to sag under

its own weight. There must be pads on both

sides under the board near the cut and near

the edges.

• Blunt or damaged saw discs must not be used.

Unsharpened or incorrectly adjusted saw discs

7ENGLISH

create a narrow cutting groove and cause ex-

cessive friction, which limits the rotation of the

disc and leads to recoil.

• Before cutting, the levers for adjusting the

depth of the cut and the bevel angle of the

saw disc must be sufficiently and reliably tight-

ened If the disc position changes during cut-

ting, the disc may jam and recoil may occur.

• Extra care must be taken when cutting into ex-

isting walls or other places where you cannot

see. A disc that penetrates the other side of

the material can cut into the object, which can

cause recoil.

SAFETY INSTRUCTIONS FOR MITER SAWS

• Miter saws are designed for cutting wood or

wood-like materials.They cannot be used with

cutting discs to cut ferrous materials such as

rods, screws, etc. Abrasive dust can cause the

lower guard to jam. Grinding sparks can burn

the bottom guard, insert plate or other plastic

parts.

• Use the clamp to secure the workpiece when-

ever possible. When holding the workpiece by

hand, hold it at least 100 mm from both sides

of the saw disc. Do not use the saw to cut

pieces that are too small to clamp or hold. If

you place your hand too close to the saw disc,

there is an increased risk of injury from contact

with the disc.

• You must fasten the workpiece with clamps

or hold it to the stop bar and the table. Never

hold the workpiece "only in your hand" when

cutting. Unattached or moving workpieces can

be dropped at high speed and cause injury.

• Push the saw when cutting with the workpiece.

Never pull the saw through the workpiece. To

make a cut, first lift the saw head and pull it

over the workpiece without cutting. Then you

start the motor, press the saw head and push

to cut the workpiece. If you make a pull cut,

the disc could reach the top of the workpiece

and be thrown sharply toward the machine

operator.

• Never place your hands across the intended

cutting line in front of or behind the saw disc.

Holding the workpiece with the "opposite

hand", i.e. Holding with your left hand on the

right side of the saw disc and vice versa is very

dangerous.

• When the disc is in motion, do not approach

the saw disc on either side by less than 100

mm with your hand behind the stop bar, either

to remove wood chips or for other reasons.

You may not be able to estimate the distance

between your hand and the disc correctly and

you could be seriously injured.

• Inspect the workpiece carefully before cutting.

If it is crooked or bent, attach it to the stop bar

on the outside of the arch. Always check that

there is no gap between the workpiece, the

stop bar and the table along the intended cut.

Curved or warped workpieces can rotate or

shift and can pinch the saw disc when cutting.

There should be no nails or foreign objects in

the workpiece.

• Do not use the saw until you have harvested all

tools, sawdust, etc. from the table and only the

workpiece remains on it. Small pieces of wood

or other material that comes into contact with

the rotating disc can be thrown away at high

speed.

• Always cut only one workpiece. Laminated

workpieces cannot be fastened properly and

can pinch the saw disc or move during cutting.

• Before use, make sure that the saw is mounted

or placed on a firm, level surface. A solid flat

surface reduces the risk of the saw becoming

unstable.

• Plan the work in advance. Each time you

change the inclination and cutting angle set-

tings, make sure that the stop bar sufficiently

supports the workpiece and does not interfere

with the discs or the protection system. With

a tool and no workpiece, make a blank test cut

and make sure that the stop bar does not ob-

struct or damage it.

• If you are cutting a workpiece that is wider or

longer than the top of the saw table, support it

properly with table attachments, wood cutting

goats, etc. Workpieces that are wider or longer

than the miter saw table and are not support-

ed may tip over. If the chip or workpiece is

overturned, it could lift the lower guard or be

dropped by the rotating disc.

• Do not use other people instead of table at-

tachments or as additional support. Insuffi-

cient workpiece support can cause the disc to

pinch or the workpiece to shift during cutting

and can pull you or your assistant toward the

rotating disc.

• The chip must not jam or otherwise be

SAFETY INSTRUCTIONS

8ENGLISH

SAFETY INSTRUCTIONS

pressed against the rotating disc. If the chip is

attached, such as stops, it may jam against the

disc and be thrown off sharply.

• Always fasten round materials such as rods

and tubes. The bars tend to rotate during cut-

ting, which causes the disc to "bite" and pull

your hand and the workpiece under the disc.

• Allow the disc to reach full rotation speed be-

fore cutting the workpiece. This will help re-

duce the risk of the workpiece being dropped.

• If the workpiece or disc jams, switch off the

miter saw. Wait for all moving parts to stop,

pull the plug out of the socket and/or remove

the battery. Only then remove the jammed

material. If you continue to cut through the

jammed workpiece, you could lose control of

the machine or damage the miter saw.

• When you have finished cutting, release the

switch, hold the saw head down and wait for

the disc to stop. Only then remove the clip.

Approaching the running disc with your hand

is very dangerous.

• Keep your workplace clean. Mixtures of mate-

rials are particularly harmful. Light metal dust

may burn or explode.

• Do not use any blunt, cracked, bent or dam-

aged saw discs. Saw discs with blunt or mis-

aligned teeth cause increased friction, pinch-

ing of the saw disc and kickback due to the

narrow cut gap.

• Do not use any high-alloy high-speed steel

(HSS) saw discs. Such saw discs can break eas-

ily.

• Always use saw discs of the correct size and

with a suitable clamping hole (e.g. diamond

or circular). Saw discs that do not match the

saw's mounting parts do not run centred and

lead to a loss of control.

• Never remove cutting residues, wood chips,

etc. from the cutting area while the power tool

is running. First, bring the tool arm to rest and

turn off the power tool.

• Never touch the saw disc before it has cooled

down. The saw disc is very hot during oper-

ation.

9ENGLISH

Electric miter saw

Parameter Value

Voltage 220-240 V, 50 Hz

Power consumption 1,500 W

Idle revolutions 4,500 min-1

Saw disc 210 mm × 30 mm, 24 teeth

Scale of the angle 0° to 45° to both sides

Vertical angle 0° to 45° to the left

Direct cut 0° × 0° 22 × 7 cm

Miter cut 0° × 45° 15.5 × 7 cm

Miter cut 45° × 0° 22 × 3.5 cm

Combined saw 45° × 45° 15.5 × 3.5 cm

Laser class 2

Laser wavelength 650 nm

Laser output <1 mW

Weight 10.5 kg

NOISE AND VIBRATION LEVEL PARAMETERS

Sound pressure level (LpA)93.6 dB(A)

uncertainty KpA 3 dB

Sound power level LwA 106.6 dB(A)

uncertainty KWA 3 dB

VIBRATION AND NOISE INFORMATION

Noise parameters and their uncertainty were measured according to EN62841-1.

Wear noise protection! Actual noise values depend on the conditions of use of the machine and

may differ from those stated, which are far from being safe values.

WAYS TO REDUCE NOISE AND VIBRATION

You can reduce noise and vibration by using tools with reduced vibration, the way you work, reducing

the time of use and wearing protective equipment.

To reduce the risk of shocks and noise, follow these recommendations:

1. Always use the product in accordance with the instructions and intended use.

2. Ensure that the product is always in perfect condition and properly maintained.

3. Use tools designed for this product and in good condition.

4. Hold the handle of the machine firmly, keep the surface clean.

5. Plan the work with regard to the distribution of exposure over a longer period.

TECHNICAL DATA

10 ENGLISH

DESCRIPTION

1 Laser

2 Laser switch

3 Arm of the saw

4 Arm lock

5 Saw handle

6 Upper fixed protective cover

7 Clamp

8 Movable saw disc protection

9 Protective cover rod

10 Saw disc screw cover

11 Bag for saws

12 Vertical angle locking screw

13 Vertical angle scale

14 Stop bar

15 6 mm Allen key

16 Turntable

17 Cutting angle scale

18 Table insert

19 Saw switch

20 Handle with angle fixing screw

21 Fixed angle stop

22 Spindle lock

23 Saw feed

24 Feed lock

25 Depth of cut stop screw

26 Cutting depth stop

27 Depth adjustment screw nut

28 Vertical angle stop 45°

29 Vertical angle stop 0°

30 Switch fuse

31 Side supports (×2)

The package also includes a spare saw disc (not shown).

11ENGLISH

SAWDUST OUTPUT

To reduce dust and increase cutting efficiency, the machine is equipped with a dust outlet. This can

be connected to an extractor or equipped with a sawdust trap.

The relevant bag is included in the accessories. Simply thread it onto the sawdust outlet neck on the

top cover of the saw.

Clean the used bag after removing it from the machine and opening the zipper.

Note: to ensure optimal function, clean the bag no later than when it is 2/3rds full.

ASSEMBLY HOLES

Before use, it is necessary to fasten it to a solid flat surface with 4 screws (not included).

The base of the machine has holes for attaching the machine to a work table or other suitable base.

Proceed as follows:

1. Place the machine in position and mark the position of the mounting holes.

2. Remove the machine and drill 4 holes in the washer.

3. Place the machine back on the holes and fasten it with suitable bolts, nuts and washers.

Attention: make sure the base is not tilted. An uneven and sloping surface leads to jamming of cut

objects and uneven cuts.

CLAMP

The material to be cut should always be fastened with the enclosed clamp.

EXTENSION SUPPORTS

When cutting long materials, slide the supports out of the machine and secure them by tightening

the appropriate elements.

USE

Arm lock

When transporting or storing the machine, the saw arm should be locked in the lower position by

means of a lock. The arm must be released before use: Push the arm down and release the arm lock

(4) by turning it with the other hand. Then release the arm.

The machine must never be used with a secured arm.

To return the machine to the locked position, reverse the procedure: push the arm down and clamp

it with the lock (4), then lock by turning it.

TRANSPORT

• Before transporting the machine, the arm must be locked in the down position.

• It is also necessary to tighten the other locking screws: the angle fixing handle (20), the vertical

angle screw (12) and the feed lock (24).

• The machine must be switched off and the power supply unplugged.

• Lift the machine by the handle or base. Never pull on the protective covers.

TABLE ROTATION LOCK

The handle with the angle fixing screw (2) is used to lock the table at any selected cutting angle. You

can select this angle from 0° to 45° on both sides. Adjust the angle by releasing the handle (20) and

pressing the stop (21) by turning the table to the desired position.

ASSEMBLY

12 ENGLISH

The stop (21) allows quick adjustment of fixed angles 0°, 15°, 22.5°, 30° and 45°.

MITER CUTS

The vertical angle locking screw (12) allows the vertical angle of the saw to be adjusted. This angle

can be adjusted between 0° and 45° to the left. Before adjusting the angle, loosen the screw, adjust

the saw to the desired angle, and then retighten the screw.

SPINDLE LOCK

The spindle lock (22) allows you to stop the motor from rotating when the disc is mounted. First, press

and hold it and rotate the spindle until it clicks. Keep it pressed while loosening and tightening the

saw disc screw.

Never press it while the machine is running!

MOVABLE SAW DISC PROTECTION

The movable disc guard (8) covers both sides of the saw and automatically rises over the top cover

when the arm is pushed into the cut.

SWITCHING ON AND OFF

• To switch on the machine, push the switch lock (30) to the left and press the switch (19).

• The motor stops when the switch (19) is released.

USING THE LASER

Switch the laser (1) on and off with the laser switch (2). Press position "I" to turn on the light, press at

the point marked "0" to turn it off again.

SAW ADJUSTMENT

1. Make sure that the machine is disconnected from the mains.

2. Push the arm (3) down to the lowest position and secure it with the lock (4).

3. Release the handle (20) and press the angle lock (21).

4. Turn the table (16) to the 0° position on the scale.

5. Release the lock (21) and let it lock and tighten the handle (20).

6. Loosen the vertical angle screw (12) and set the vertical arm angle (3) to 0° (90° to the table).Then

tighten the lock (12).

7. Place the angle on the table (16) and rest it on the flat part of the saw disc.

8. Turn the disc by hand and check it is perpendicular at several points. The edge of the angle and

the surface of the disc must be parallel.

9. If the saw disc is not perpendicular to the table, adjust the angle as follows:

10.Use a 10 mm wrench to loosen the 0° vertical angle stop (29). Also, loosen the vertical angle lock-

ing screw (12).

11.Using a 4 mm Allen key, adjust the vertical angle stop 0° (29) so that the saw is perpendicular to

the table.

12.Loosen the vertical angle scale screw (13) and adjust the scale so that the pointer corresponds to

an angle of 0°. Tighten the support screw.

13.Tighten the vertical angle locking screw (12) and the vertical angle stop 0° (29).

USE

13ENGLISH

ADJUSTING THE DISTANCE OF THE STOP RAILS

1. Make sure that the machine is disconnected from the mains.

2. Push the arm (3) down to the lowest position and secure it with the lock (4).

3. Release the handle (20) and press the angle lock (21).

4. Turn the table (16) to the 0° position on the scale.

5. Release the lock (21) and let it lock and tighten the handle (20).

6. Using a 5 mm Allen key, loosen the two screws holding the stop rails (14) to the base.

7. Place the angle on the table (16) and rest it on the stop rails (14) and the flat part of the saw disc.

8. Adjust the stops so that they are perpendicular to the disc.

9. Hold the stop rails (14) and carefully tighten the screws.

10.Loosen the cutting angle scale screw (17) and adjust the scale so that the pointer corresponds to

an angle of 0°. Tighten the support screw.

SAW DISC REPLACEMENT

It is recommended to use thick gloves when replacing.

1. Make sure that the machine is disconnected from the mains.

2. Push the arm (3) down and pull out the lock (4).

3. Raise the arm to the highest position.

4. Release the cover using a cross screwdriver.

5. Turn the movable saw disc guard (8) to the open position above the saw disc cover by pulling. The

wheel bolt is now accessible.

6. Hold down the movable saw disc guard (8) and press and hold the spindle lock (22). Turn the saw

until the lock engages.

7. Loosen and unscrew the saw disc screw with the enclosed 6 mm Allen key (loosen to the right, as

the screw has a left-hand thread).

8. Remove the flat washer, the outer flange of the disc and the disc. Clean sawdust and dirt from the

spindle.

9. Rub a drop of oil into the inner and outer flanges where they touch the disc.

10.Insert the new saw disc into the inner flange and position it on the axle.

11.Install the outer flange.

12.Press the spindle lock (22) and insert the flat washer and screw.

13.Tighten the screw firmly with a 6 mm Allen key (the screw has a left-hand thread, tighten to the left).

14.While still holding, slide the saw disc guard (8) down and replace the saw disc screw cover (10);

fasten it with a screw.

15.Check that the movable disc guard works properly and covers the disc as the arm moves.

16.Plug in the machine and run it to check that the disc is loaded correctly.

CROSS CUTS

Whenever possible, fasten the material to be cut to the base of the saw with the clamp provided.

Always keep your hands out of the saw area when cutting.

Do not remove pieces of cut material while the machine is running; take pieces from the right side

with your left hand.

The cross-sections are made through wood fibres. A vertical cut (90°) is made when the table is set to

the 0° mark. Oblique cuts are made after setting the table to the desired angle.

1. Pull out the lock (4) and raise the arm (3) to its full height.

USE

14 ENGLISH

2. Release the angle fixing handle (20) and press the stop (21). You can now turn the table (16) to the

desired position.

3. Secure the angle by turning the angle fixing handle (20) and releasing the stop (21).

4. Place the material to be cut on the table with one edge pressed against the stop rails (14). If the

material is not level, rest the convex side against the stops (14). In the opposite arrangement, the

material may break during cutting and block the saw.

5. When cutting longer pieces, it is necessary to support them with the help of machine supports or

suitable external support or table in the same height, etc.

6. Before switching on the machine, make sure that the material moves freely and does not hit parts

of the saw, clamp, surrounding objects, etc., and that the saw also reaches freely from the cut.

7. Hold the saw firmly by the handle (5), flip the switch lock (30) and press the switch (19). Let the

engine run at full speed and then gradually lower the saw into the cut.

8. When you have finished cutting, release the switch (19) and let the engine stop before lifting the

saw out of the cut. The disc must be stopped completely before removing the material to be cut.

BEVELLED CUT

Whenever possible, fasten the material to be cut to the base of the saw with the clamp provided.

Always keep your hands out of the saw area when cutting.

Do not remove pieces of cut material while the machine is running; take pieces from the right side

with your left hand.

Bevelled cuts are made through the wood fibres at the angle of the saw in relation to the table and

the stop rails. The cut is made with the table set to the 0° mark and with a vertical disc angle between

0° and 45°.

1. Pull out the lock (4) and raise the arm (3) to its full height.

2. Release the angle fixing handle (20) and press the stop (21). Now turn the table (16) to the 0°

position.

3. Secure the angle by turning the angle fixing handle (20) and releasing the stop (21).

4. Loosen the vertical angle locking screw (12) and tilt the saw arm (3) to the left to the desired angle.

Tighten the locking screw (12).

5. Place the material to be cut on the table with one edge pressed against the stop rails (14). If the

material is not level, rest the convex side against the stops (14). In the opposite arrangement, the

material may crack during cutting and block the saw.

6. When cutting longer pieces, it is necessary to support them with the help of machine supports or

suitable external support or table in the same height, etc.

7. Before switching on the machine, make sure that the material moves freely and does not hit parts

of the saw, clamp, surrounding objects, etc., and that the saw also reaches freely from the cut.

8. Hold the saw firmly by the handle (5), flip the switch lock (30) and press the switch (19). Let the

engine run at full speed and then gradually lower the saw into the cut.

9. When you have finished cutting, release the switch (19) and let the engine stop before lifting the

saw out of the cut. The disc must be stopped completely before removing the material to be cut.

COMBINED ANGLE CUTS

Whenever possible, fasten the material to be cut to the base of the saw with the clamp provided.

Always keep your hands out of the saw area when cutting.

Do not remove pieces of cut material while the machine is running; take pieces from the right side

with your left hand.

Combined angle cuts are made by setting the table to any angle and with a vertical disc angle be-

USE

15ENGLISH

USE

tween 0° and 45°. They are used in the production of picture frames, for carving mouldings, making

boxes with sloping sides and for carpentry work. Always make a test cut on a piece of spare wood

first.

1. Pull out the lock (4) and raise the arm (3) to its full height.

2. Release the angle fixing handle (20) and press the stop (21). Now turn the table (16) to the re-

quired position.

3. Secure the angle by turning the angle fixing handle (20) and releasing the stop (21).

4. Loosen the vertical angle locking screw (12) and tilt the saw arm (3) to the left to the desired angle.

Tighten the locking screw (12).

5. Place the material to be cut on the table with one edge pressed against the stop rails (14). If the

material is not level, rest the convex side against the stops (14). In the opposite arrangement, the

material may break during cutting and block the saw.

6. When cutting longer pieces, it is necessary to support them with the help of machine supports or

suitable external support or table in the same height, etc.

7. Before switching on the machine, make sure that the material moves freely and does not hit parts

of the saw, clamp, surrounding objects, etc., and that the saw also reaches freely from the cut.

8. Hold the saw firmly by the handle (5), flip the switch lock (30) and press the switch (19). Let the

engine run at full speed and then gradually lower the saw into the cut.

9. When you have finished cutting, release the switch (19) and let the engine stop before lifting the

saw out of the cut. The disc must be stopped completely before removing the material to be cut.

Cutting wider material

For longer cuts, release the feed lock (24) and move the saw arm back and forth.

CUTTING DEPTH ADJUSTMENT

You can set the depth of the cut for evenly shallow cuts and repeated cuts.

1. Slide the depth of cut stop (26) to the front position.

2. Loosen the depth adjustment screw nut (27) to loosen the screw (25) and turn it until the saw teeth

reach the specified depth.

3. Hold the saw arm in this position and tighten the nut (27) to secure the position of the screw (25).

4. Check the depth of the cut again by moving the saw head over the entire feed range or making

a test cut.

MAINTENANCE

WARNING: Unplug the power cord before making any adjustments, repairs, or maintenance.

1. After making any adjustments, adjustments, or maintenance, always make sure that all bolts are

securely tightened, the covers, locks, and pins in place, and all wrenches and tools are securely

removed.

2. Keep engine vents clean and uncovered. Sometimes you can see sparks through the holes. This is

normal and does not damage the machine.

3. Regularly check the motor grilles and the switch area and clean any dust, chips and material resi-

dues. Remove dust with a soft brush.

4. Protect your eyes with goggles when cleaning.

5. Clean the machine body with a soft, dry cloth. Remove heavy soiling with a mild detergent solu-

tion. Do not use any chemicals, solvents or alcohol.

16 ENGLISH

MAINTENANCE

6. Clean plastic parts especially carefully, do not use any chemicals.

ATTENTION: Do not clean the motor, metal parts or the saw with water.

7. Keep tools, instructions and accessories in a suitable safe place. You should always have them

available.

REGULAR INSPECTIONS

• Regularly check the tightness of all screws and especially the outer flange of the disc. They can

be released by vibrations.

• Check the power supply and any extension cords. If the power supply is damaged, it must be

replaced immediately. Replacement must only be carried out by the manufacturer, its represent-

ative or an authorized service centre. There is a risk of electric shock or fire. Do not use or replace

any damaged leads.

• Only a qualified person may replace the engine carbons. Always replace both carbons at the

same time.

17ENGLISH

Identification of the manufacturer / importer's authorised representative:

Manufacturer: Alza.cz, a. s.

Registered office: Jankovcova 1522/53, Holešovice, 170 00 Prague 7

Company ID: 27082440

Subject of the declaration:

Name: Miter saw

Model/Type: J1G-ZP8-210 / FRD-MS2115SE

The above product has been tested in accordance with the standard (s) used to demonstrate

compliance with the essential requirements set out in the Directive (s):

Machine directive 2006/42/EC

Electromagnetic compatibility (EMC) directive 2014/30/EU

ROHS directives 2011/65/EU and (EU) 2015/863

Reference to harmonised standards:

EN62841-1: 2015+AC: 15

EN62841-3-9:2015+AC:16+A11:17

EN55014-1:2017

EN55014-2:2015

EN61000-3-2:2014

EN61000-3-3:2013

EC type-examination was carried out on:

Intertek Testing Services Shanghai, Building No. 86,1198 Qinzhou Road (North), Caohejing Develop-

ment Zone, Shanghai 200233, China

Notified Body No. 0012

Certificate number: 180803154SHA-V1

Technical documentation is stored at:

Alza.cz, a. s.

Jankovcova 1522/53, Holešovice, 170 00 Prague 7

The year of manufacture of the machine and the serial number are indicated on the machine.

Ing. Jan Melena

Business Development Manager

Sales and Purchasing; Private Labels

In Prague, 22.9.2021

EC DECLARATION OF CONFORMITY

18 DEUTSCH

ERLÄUTERUNG DER SYMBOLE AUF DER PRODUKTVERPACKUNG/DEM TYPENSCHILD

Lesen Sie vor dem Gebrauch die Bedie-

nungsanleitung durch! Tragen Sie Schutzhandschuhe.

Tragen Sie einen Mund- und Nasen-

schutz. Benutzen Sie Lärmschutz.

Tragen Sie eine Schutzbrille.

Beachten Sie die Hinweise zur Rück-

laufsicherheit und deren Sicherheits-

vorkehrungen.

Vor Regen und Feuchtigkeit schützen. Vor Hitze und Feuer schützen.

Sorgen Sie für ein ordnungsgemäßes

Recycling des Produkts am Ende seiner

Lebensdauer und aller Verpackungs-

materialien.

Entsorgen Sie das Produkt nicht über

den gewöhnlichen Hausmüll.

WARNUNG:

Laserprodukt der Klasse 2. Schauen Sie nicht

in den Laserstrahl.

ALLGEMEINE SICHERHEITSHINWEISE FÜR

ELEKTROWERKZEUGE

WARNUNG! Alle Sicherheitshinweise, Bedie-

nungsanleitungen, Bilder und Vorschriften,

die mit diesem Gerät geliefert werden, müs-

sen gelesen werden. Die Nichteinhaltung der

folgenden Hinweise kann zu Stromschlag,

Brand und/oder schweren Verletzungen füh-

ren.

Alle Anleitungen und Gebrauchsanweisungen

müssen aufbewahrt werden, damit sie zu ei-

nem späteren Zeitpunkt eingesehen werden

können.

Sicherheit im Arbeitsumfeld

1. Der Arbeitsplatz muss sauber und gut beleuch-

tet sein. Unordnung und dunkle Räume sind oft

die Ursache von Unfällen.

2. Elektrowerkzeuge dürfen nicht in explosions-

gefährdeten Bereichen eingesetzt werden, in

denen brennbare Flüssigkeiten, Gase oder

Stäube vorhanden sind. Das Elektrowerkzeug

erzeugt Funken, die Staub oder Dämpfe ent-

zünden können.

3. Kinder und andere Personen müssen an der

Benutzung von Elektrowerkzeugen gehindert

werden. Wenn der Bediener gestört wird, kann

er die Kontrolle über den Vorgang verlieren.

Elektrische Sicherheit

1. Die Gabel des beweglichen Elektrowerkzeugs

muss mit der Steckdose übereinstimmen. Die

Gabel darf in keiner Weise verändert werden.

Es dürfen keine Steckdosenadapter mit Werk-

zeugen verwendet werden, die eine Schutz-

verbindung zur Erde haben. Stecker, die durch

Änderungen entwertet wurden, und entspre-

chende Steckdosen, verringern das Risiko ei-

nes Stromschlags.

2. Der Bediener darf geerdete Gegenstände wie

Rohre, Körper der Zentralheizung, Herde und

Kühlschränke nicht mit seinem Körper berüh-

ren. Die Gefahr eines Stromschlags ist größer,

wenn Ihr Körper mit dem Boden verbunden ist.

3. Elektrowerkzeuge dürfen nicht Regen, Feuch-

tigkeit oder Nässe ausgesetzt werden. Wenn

Wasser in das Elektrowerkzeug eindringt, er-

höht sich das Risiko eines Stromschlags.

4. Das bewegliche Zuleitungskabel darf nicht

für andere Zwecke verwendet werden. Elekt-

rowerkzeuge dürfen nicht am Kabel getragen

oder gezogen werden, auch darf der Stecker

SICHERHEITSHINWEISE

19DEUTSCH

durch Ziehen am Kabel nicht aus der Steck-

dose gezogen werden. Das Zuleitungskabel

muss vor Hitze, Fett, scharfen Kanten oder

beweglichen Teilen geschützt werden. Be-

schädigte oder verhedderte Zuleitungskabel

erhöhen das Risiko eines Stromunfalles.

5. Wenn das Elektrowerkzeug im Freien ver-

wendet wird, muss ein für den Außeneinsatz

geeignetes Verlängerungskabel verwendet

werden. Die Verwendung eines Verlänge-

rungskabels für den Einsatz im Freien verrin-

gert das Risiko eines Stromschlags.

6. Wenn Elektrowerkzeuge in feuchten Berei-

chen verwendet werden, muss eine durch

einen Fehlerstromschutzschalter (RCD) ge-

schützte Stromversorgung verwendet werden.

Der Fehlerstromschutzschalter (RCD) redu-

ziert Stromunfälle.

Sicherheit von Personen

1. Bei der Verwendung von Elektrowerkzeugen

muss der Bediener aufmerksam sein, sich kon-

zentrieren und rational denken. Elektrowerk-

zeuge dürfen nicht verwendet werden, wenn

der Bediener müde ist oder unter dem Ein-

fluss von Drogen, Alkohol oder Medikamen-

ten steht. Ein Moment der Unachtsamkeit bei

der Verwendung von Elektrowerkzeugen kann

zu schweren Verletzungen führen.

2. Tragen Sie eine persönliche Schutzausrüs-

tung. Tragen Sie stets Augenschutz. Schutz-

ausrüstungen wie Schutzmasken, rutschfeste

Sicherheitsschuhe, harte Kopfbedeckungen

oder Gehörschutz, die entsprechend den Ar-

beitsbedingungen verwendet werden, verrin-

gern das Risiko von Personenverletzungen.

3. Ein unbeabsichtigtes Einschalten der Maschi-

ne muss vermieden werden. Vergewissern Sie

sich, dass der Schalter auf „Aus“ steht, bevor

Sie den Stecker in die Steckdose stecken und/

oder den Akku anschließen, das Gerät anhe-

ben oder tragen. Das Tragen des Geräts mit

dem Finger auf dem Schalter oder das Einste-

cken der Werkzeuggabel bei eingeschaltetem

Schalter kann zu Unfällen führen.

4. Vor dem Einschalten des Geräts müssen alle

Einstellwerkzeuge oder Einstellschlüssel ent-

fernt werden. Ein Einstellwerkzeug oder Ein-

stellschlüssel, der an einem rotierenden Teil

des Elektrowerkzeugs bleibt, kann zu Verlet-

zungen führen.

5. Der Bediener darf nur an Stellen arbeiten, die

er sicher erreichen kann. Der Bediener muss

stets eine stabile Körperhaltung einnehmen

und das Gleichgewicht halten. Dies ermög-

licht eine bessere Kontrolle des Elektrowerk-

zeugs in unvorhergesehenen Situationen.

6. Kleiden Sie sich angemessen. Tragen Sie we-

der lose Kleidung noch Schmuck. Der Bedie-

ner muss darauf achten, dass Haare und Klei-

dung von beweglichen Teilen ferngehalten

werden. Lose Kleidung, Schmuck und lange

Haare können von beweglichen Teilen erfasst

werden.

7. Sind Vorrichtungen für den Anschluss von

Staubabsaug- und -sammelgeräten vorhan-

den, so muss sichergestellt werden, dass die-

se Geräte ordnungsgemäß angeschlossen

und verwendet werden. Durch den Einsatz

dieser Geräte können die durch den entste-

henden Staub verursachten Gefahren verrin-

gert werden.

8. Der Bediener darf nicht zulassen, dass er

bei der Routine, die sich aus dem häufigen

Gebrauch des Werkzeugs ergibt, zu selbst-

bewusst wird und er die Grundsätze der

Werkzeugsicherheit ignoriert. Unvorsichtiges

Handeln kann in Sekundenbruchteilen zu

schweren Verletzungen führen.

Verwendung und Wartung von Elektrowerk-

zeugen

1. Elektrowerkzeuge dürfen nicht überlastet wer-

den. Es ist wichtig, die richtigen Elektrowerk-

zeuge für die durchzuführenden Arbeiten zu

verwenden. Das richtige Elektrowerkzeug leis-

tet mehr und ist sicherer bei der Arbeit, für die

es entwickelt wurde.

2. Verwenden Sie keine Elektrowerkzeuge, die

nicht mit einem Schalter ein- und ausgeschal-

tet werden können. Ein Elektrowerkzeug mit

einem defekten Hauptschalter ist gefährlich

und muss repariert werden.

3. Vor jeder Einstellung, jedem Zubehörwech-

sel oder jeder Lagerung des Elektrowerk-

zeugs müssen die Stecker aus der Steckdose

gezogen und/oder der Akku aus dem Elek-

trowerkzeug entfernt werden, wenn er her-

ausnehmbar ist. Diese vorbeugenden Sicher-

heitsmaßnahmen reduzieren das Risiko einer

versehentlichen Inbetriebnahme des Elektro-

werkzeugs.

SICHERHEITSHINWEISE

20 DEUTSCH

SICHERHEITSHINWEISE

4. Unbenutzte Elektrowerkzeuge müssen außer-

halb der Reichweite von Kindern aufbewahrt

werden, und Personen, die nicht mit Elektro-

werkzeugen oder dieser Anleitung vertraut

sind, dürfen sie nicht benutzen. Das Elektro-

werkzeug könnte in den Händen von unerfah-

renen Anwendern gefährlich sein.

5. Elektrowerkzeuge und Zubehör müssen ge-

wartet werden. Die Ausrichtung der beweg-

lichen Teile und ihre Beweglichkeit müssen

überprüft werden, wobei auf Risse, gebroche-

ne Teile und andere Umstände zu achten ist,

die die Funktion des Elektrowerkzeugs be-

einträchtigen könnten. Wenn das Werkzeug

beschädigt ist, muss es vor der weiteren Ver-

wendung repariert werden. Viele Unfälle sind

auf die Anwendung eines falsch gewarteten

Elektrowerkzeugs zurückzuführen.

6. Schneidwerkzeuge müssen scharf und sauber

gehalten werden. Ordnungsgemäß gewartete

und geschärfte Schneidwerkzeuge verfangen

sich seltener im Material oder verklemmen

sich und sind leichter zu kontrollieren.

7. Elektrowerkzeuge, Zubehör, Arbeitsgerä-

te usw. müssen unter Berücksichtigung der

Arbeitsbedingungen und der Art der auszu-

führenden Arbeiten gemäß dieser Anleitung

und in der für das jeweilige Elektrowerkzeug

vorgeschriebenen Weise verwendet werden.

Die Verwendung von Elektrowerkzeugen für

andere Tätigkeiten als die, für die sie konzi-

piert wurden, kann zu gefährlichen Situatio-

nen führen.

8. Griffe und Griffflächen müssen trocken, sau-

ber und fettfrei gehalten werden. Rutschige

Griffe und Griffflächen machen es unmöglich,

das Werkzeug in unerwarteten Situationen si-

cher zu halten und zu kontrollieren.

Service

1. Reparaturen an Elektrowerkzeugen müssen

von einer qualifizierten Person durchgeführt

werden, die identische Ersatzteile verwendet.

Dadurch wird die Sicherheit des Elektrowerk-

zeugs auf dem gleichen Niveau wie vor der

Reparatur gewährleistet.

SICHERHEITSHINWEISE FÜR ALLE SÄGEN

Beim Schneiden

1. GEFAHR : Der Bediener muss sicherstellen,

dass sich seine Hände in einem sicheren Ab-

stand zum Schnittbereich und zur Scheibe

befinden. Greifen Sie mit der anderen Hand

den Hilfsgriff oder das Motorgehäuse. Wenn

die Säge mit beiden Händen gehalten wird,

können die Hände nicht von der Scheibe ge-

schnitten werden.

2. Berühren Sie das Werkstück nicht. Die Schutz-

vorrichtung kann den Bediener nicht davor

schützen, die Scheibe unter dem Werkstück

zu berühren.

3. Die Schnitttiefe muss an die Dicke des Werk-

stücks angepasst werden. Der sichtbare Teil

der Scheibenzähne unter dem Werkstück soll-

te weniger als die Höhe eines Zahns betragen.

4. Halten Sie das Werkstück beim Schneiden

niemals in der Hand oder über dem Knie.

Das Werkstück muss auf einer festen Unterla-

ge befestigt werden. Es ist wichtig, dass das

Werkstück richtig abgestützt wird, um das Risi-

ko zu minimieren, dass ein Körperteil berührt

wird, die Scheibe klemmen bleibt oder es zum

Verlust der Kontrolle kommt.

5. Bei Arbeiten, bei denen das Schneidwerkzeug

mit verdeckten Leitungen oder der eigenen

Stromversorgung in Berührung kommen

kann, muss das elektromechanische Werk-

zeug durch isolierte Griffflächen gehalten

werden. Der Kontakt mit einem stromführen-

den Leiter führt dazu, dass die nicht isolierten

Metallteile des elektromechanischen Werk-

zeugs ebenfalls unter Spannung stehen, was

zu einem elektrischen Schlag für den Benutzer

führen kann.

6. Verwenden Sie beim Schneiden in Längsrich-

tung immer ein Lineal oder eine Schablone

mit gerader Kante. Dadurch wird die Schnitt-

genauigkeit verbessert und die Gefahr des

Verklemmens der Scheibe verringert.

7. Verwenden Sie immer Scheiben mit Spann-

löchern der richtigen Größe und Form (qua-

dratisch oder rund). Scheiben, die nicht genau

zu den Spannkomponenten der Säge passen,

werden nicht zentriert, was zu einem Kontroll-

verlust führt.

8. Verwenden Sie niemals beschädigte oder

falsche Unterlegscheiben oder Schrauben,

um die Scheibe einzuspannen. Die Unterleg-

scheiben und Blattklemmschrauben wurden

speziell für Ihre Säge entwickelt, um optimale

Leistung und Sicherheit zu gewährleisten.

Table of contents

Languages:

Other Ferrida Saw manuals