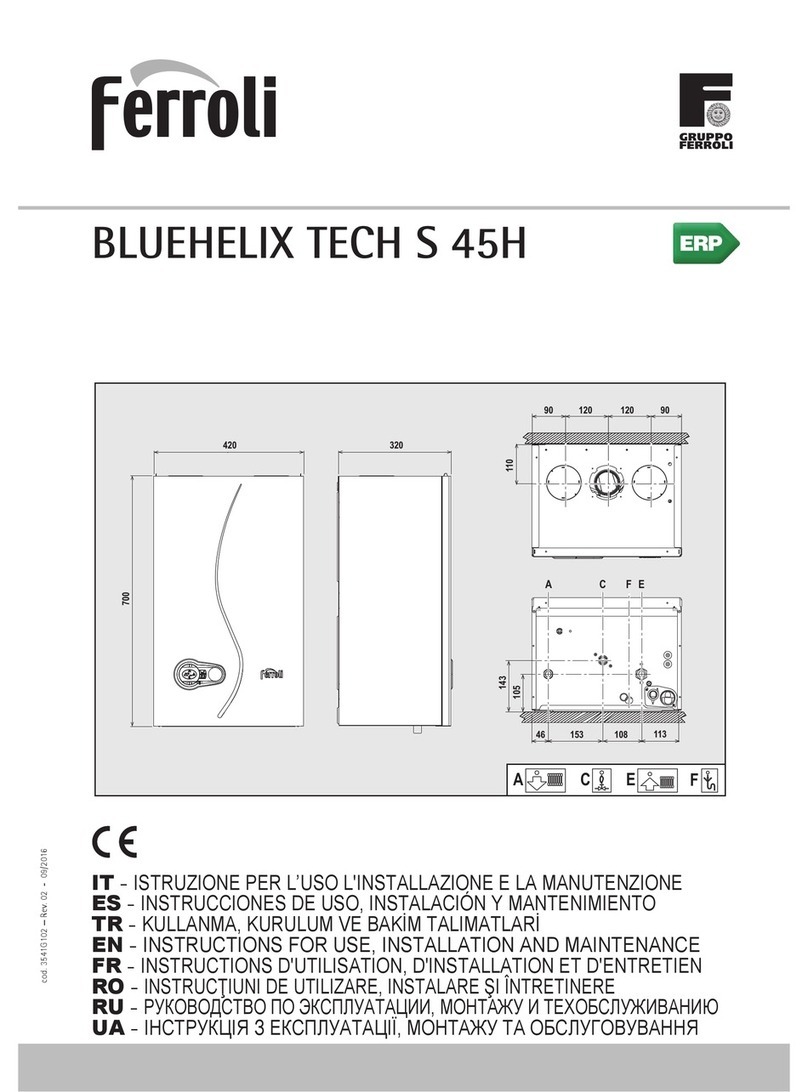

Press the heating buttons (detail 3 - fig. 1) to access parallel curve offset; the display

shows "OF" flashing. Use the DHW buttons (detail 1 - fig. 1) to adjust the parallel curve

offset according to the characteristic (fig. 11).

Press the reset button (detail 6 - fig. 1) again for 5 seconds to exit the "Sliding Temper-

ature" menu.

If the room temperature is lower than the required value, it is advisable to set a higher

order curve and vice versa. Proceed by increasing or decreasing in steps of one and

check the result in the room.

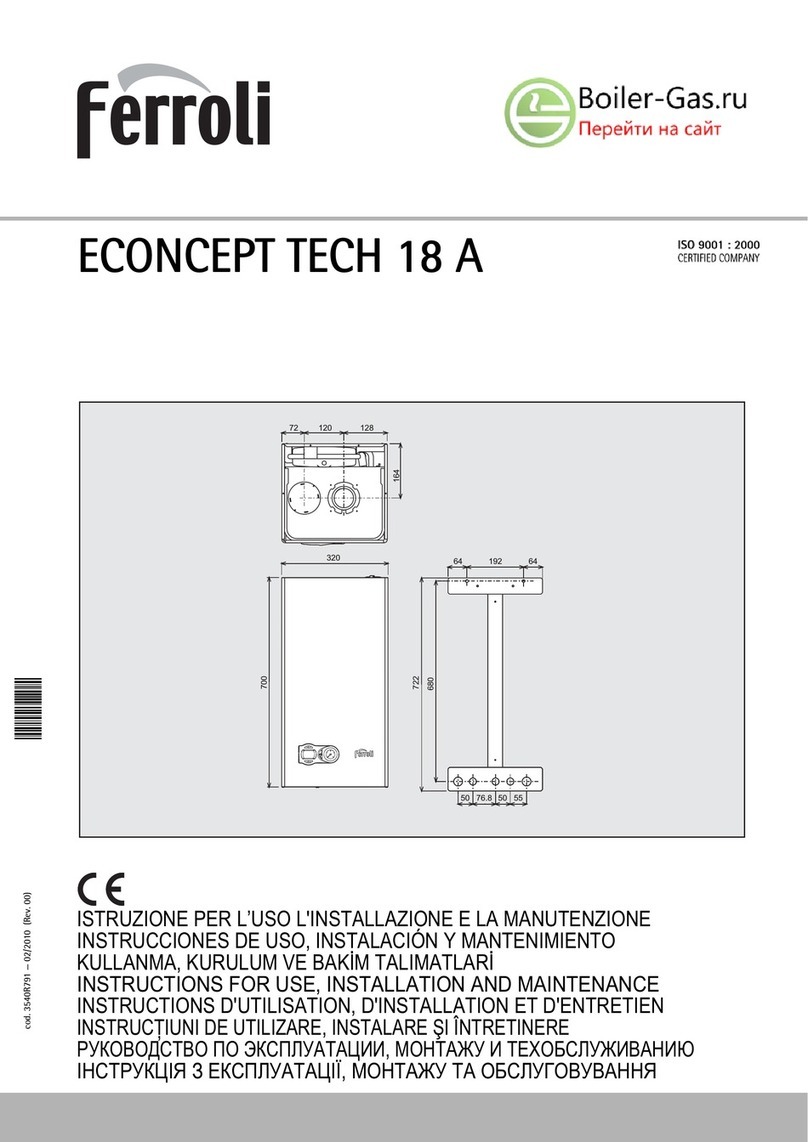

fig. 11 - Example of compensation parallel curve offset

Adjustments from Remote Timer Control

AIf the Remote Timer Control (optional) is connected to the boiler, the above ad-

justments are managed according to that given in table 1.

Table. 1

Plumbing system pressure adjustment

The filling pressure read on the boiler water gauge with the system cold must be approx

1.0 bar. If the system pressure falls to values below minimum, the boiler stops and fault

F37 is displayed. Operate the filling cock, if connected to the water supply system (detail

1 fig. 12 and bring it to the initial value. Always turn it off it afterwards.

Once the system pressure is restored, the boiler will activate the 300-second air venting

cycle indicated on the display by FH.

fig. 12 - System filling cock

3. INSTALLATION

3.1 General Instructions

BOILER INSTALLATION MUST ONLY BE PERFORMED BY QUALIFIED PERSON-

NEL, IN ACCORDANCE WITH ALL THE INSTRUCTIONS GIVEN IN THIS TECHNICAL

MANUAL, THE PROVISIONS OF CURRENT LAW, THE PRESCRIPTIONS OF NA-

TIONAL AND LOCAL STANDARDS AND THE RULES OF PROPER WORKMANSHIP.

The unit is suitable for indoor installation.

The place of installation must be dry, not exposed to rain, snow or frost, and free of flam-

mable dusts, objects and materials and corrosive gases.

AIf the unit is enclosed in a cabinet or mounted alongside, a space must be pro-

vided for removing the casing and for normal maintenance operations.

3.3 Plumbing connections

Important

BThe safety valve outlet must be connected to a funnel or collection pipe to pre-

vent water spurting onto the floor in case of overpressure in the heating circuit.

Otherwise, if the discharge valve cuts in and floods the room, the boiler manu-

facturer cannot be held liable.

BBefore installation, carefully wash all the pipes of the system to remove any re-

siduals or impurities that could affect proper operation of the unit.

In case of replacement of generators in existing installations, the system must

be completely emptied and cleaned of any sludge and pollutants. For that pur-

pose only use suitable guaranteed products for heating systems (see next sec-

tion), that do not harm metals, plastics or rubber. The manufacturer declines

any liability for damage caused to the generator by failure to properly

clean the system.

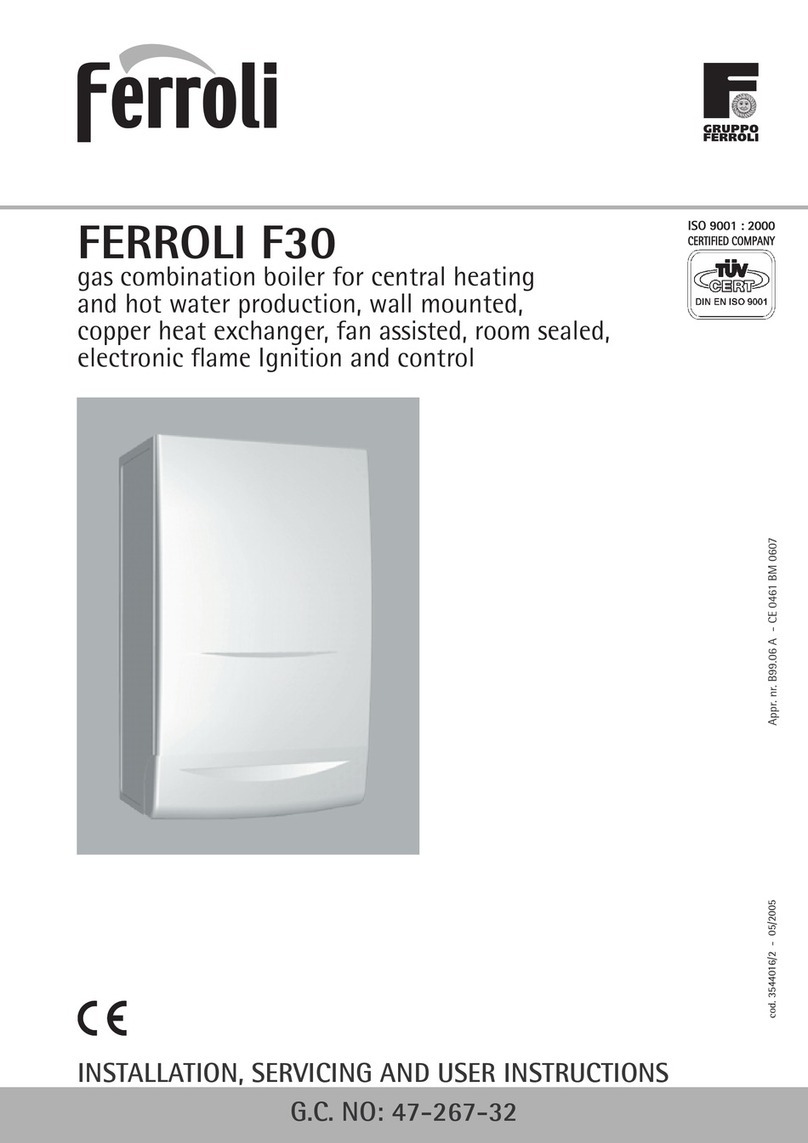

Carry out the relevant connections according to the diagram in fig. 13 and the symbols

on the unit.

fig. 13 - Plumbing connections

Antifreeze system, antifreeze fluids, additives and inhibitors

When necessary, antifreeze fluids, additives and inhibitors can be used only if the man-

ufacturer of such fluids or additives guarantees that they are suitable and do not cause

damage to the exchanger or other components and/or materials of the boiler and system.

Do not use generic antifreeze fluids, additives or inhibitors that are not specific for use in

heating systems and compatible with the materials of the boiler and system.

Water system characteristics

In the presence of water harder than 25° Fr (1°F = 10ppm CaCO3), use suitably treated

water in order to avoid possible scaling in the boiler.

Heating temperature setting

Adjustment can be made from the Remote Timer Control menu

and the boiler control panel.

DHW temperature adjustment

Adjustment can be made from the Remote Timer Control menu

and the boiler control panel.

Summer/Winter Switchover

Summer mode has priority over a possible Remote Timer Control

heating demand.

Eco/Comfort selection

On disabling DHW from the Remote Timer Control menu, the

boiler selects the Economy mode. In this condition, the

eco/com-

fort

button (detail 7 - fig. 1) on the boiler panel is disabled.

On enabling DHW from the Remote Timer Control menu, the

boiler selects the Comfort mode. In this condition it is possible

select one of the two modes with the

eco/comfort

button (detail 7

- fig. 1) on the boiler panel.

Sliding Temperature

Both the Remote Timer Control and the boiler card manage Slid-

ing Temperature adjustment: the boiler card Sliding Temperature

has priority.

20

30

40

50

60

70

80

90

85

20

30

40

50

60

70

80

90

85

1

2

3

4

5

6

8910 7

1

2

3

4

568910 7

OFFSET = 20 OFFSET = 40

1

7

Gas inlet - 1/2”

10

System delivery - 3/4”

11

System return - 3/4”

2"

4& 2#%#0 #0

&

11 10 7

47

BLUEHELIX B S 45

3.2 Place of installation

& ' ( ) * + , - . / 0 * 1 ) 0 2 ) - 0 / 0 . . ( 3 4 ( 5 6 0 / ' 2 ( . 7 ( ) / / * / ' ( 7 4 3 ) ( * 8 0 1 . / 3 4 4 3 / 0 * 1

URRPWKHUHIRUHWKHXQLWFDQEHLQVWDOOHGLQDQ\URRP+RZHYHUWKHSODFHRI

LQVWDOODWLRQPXVWEHDGHTXDWHO\YHQWLODWHGWRSUHYHQWWKHFUHDWLRQRIGDQJH

9

URXVFRQGLWLRQVLQFDVHRIHYHQVPDOOJDVOHDNV7KLVVDIHW\UHJXODWLRQLVODLGGRZQ

E\((&'LUHFWLYHQRIRUDOOJDVXQLWVLQFOXGLQJWKRVHZLWKVHDOHGFKDPEHU

! " # $ $ $ % $