ferrotec Genius II User manual

0101-9031-0

Genius II

Quick Start Guide

Revision B, December 2015

Temescal, a division of Ferrotec (USA) Corporation

4569-C Las Positas Road, Livermore, CA 94551

Tel: 1-800-522-1215; Fax: 925-449-4096

Ferrotec GmbH

Seerosenstr. 1, 72669 Unterensingen,

AG Stuttgart, Germany

Tel.: +49 7022 9270 0

+49 7022 9270 10

Revision History, 0101-9031-0

Rev.

Description

Application/Reason for Change

Date

Approved By

A First released version of document. Applies to all Genius II units sold after

November 2015 Dec.

2015 IA

B Correct internal cross-references on pp. 7

and 8.Also deleted former (and redundant)

Figure 2.

Applies to all Genius II units sold after

November 2015 Dec.

2015 IA

© 2015 Ferrotec (USA) Corp.

Genius II Quick Start Guide i 01010-9031-0, Rev. B

Table of Contents

Page

Section Number and Title Number

1 Genius II Quick Start Guide ........................................................................1

1.1 Contents of Genius II Kits .............................................................................1

1.2 Basic Hardware Installation...........................................................................1

1.3 Making Cable Connections.............................................................................2

1.4 Connecting the AC Power Cable and Powering Up the Genius II ......................9

1.5 Configuring the Control Modules..................................................................10

List of Illustrations

Page

Figure Number and Title Number

Figure 1 Genius II Front Panel, Showing Connections Port for Hand Held Remote Controller ....................1

Figure 2 Connectors on Genius II Rear Panel.........................................................................................2

Figure 3 Genius II Cabling Diagram ......................................................................................................4

Figure 4 Connections To Be Made via Rear Panel Connector X110 ..........................................................6

Figure 5 Sample Circuit Supplying BEAM ON and BEAM OFF Inputs via X110 Pins 5 and 6........................7

Figure 6 Connections to Rear Panel Connector X119, Configuration #1...................................................8

Figure 7 Connections to Rear Panel Connector X119, Configuration #2...................................................8

Figure 8 Genius II Input Power Cable Receptacle and Rear Panel On/Off Switch......................................9

Figure 9 Genius II Start Screen........................................................................................................... 10

Figure 10 Config>Main Screen After Initial Boot-Up............................................................................... 10

Figure 11 Configuration>Main Screen After User Configures All Control Modules as

Remote I/O

...............11

Figure 12 Configuration E-Beam Screen After Initial Boot-Up.................................................................. 11

Figure 13 Config>Turret Screen at Initial Boot-Up.................................................................................12

Figure 14 Config>Turret Screen After User Alters Rotation, Seek Speed, and Index Speed....................... 13

Figure 15 Config>Turret Screen After Turret Configuration Procedure is Completed ................................14

Figure 16 Config>Sweep Screen, Beam Position Limits Unconfigured, Initial State................................... 14

Figure 17 Config>Sweep Screen, Beam Position Limits Unconfigured, Beam Switched On........................ 15

Figure 18 Remote Controller in Config Mode with Menu 1 Selected and Beam on at 5%, ......................... 16

Figure 19 Remote Controller, Beam On @ 5%, Config Mode, Menu 1 and

Pos Adjust

Selected................. 17

Figure 20 Remote Controller in Config Mode with Menu 2 Selected, User Setting the -Lat Position Limit.... 18

Figure 21 Config>Sweep Screen After All Four Limits Are Set.................................................................19

Figure 22 Config>Sweep Screen, Configuration Completed, Auxiliary Menu Displayed..............................20

Figure 23 User Exiting Configuration Mode, Mode Select Popup Displayed............................................... 20

List of Tables

Page

Table Number and Title Number

Table 1 Functional Descriptions of Pins on Rear Panel Connector X110 ......................................................7

Table 2 Functional Descriptions of Pins on Rear Panel Connector X119 ......................................................9

01010-9031-0, Rev. Bii Genius II Quick Start Guide

Liability

The manufacturer's liability for the Genius II is based on the principles of German law. The manufacturer

accepts no liability for damage and losses due to:

•improper use

•operation by unauthorised personnel

•failure to follow safety regulations

•failure to comply with the instructions in this manual.

Translation

If the machine is sold to a country in the EEA, this manual must be translated into the language of the

country in which the machine is to be used. Should the translated text be unclear, the original manual (in

English) must be consulted or the manufacturer contacted for clarification.

Intended Use

This manual is intended for all who may use or work on the Genius II controller, especially the operating

personnel. The mounting instruction contains an exact description of the product, but does not warrant

certain properties or success of use. The instruction handbook was inspected carefully before publication.

The authors guarantee that the mounting instruction does not contain errors that cancel or reduce the value

or suitability of the device for its intended use. The publishers, however, accept neither explicitly nor

implicitly any liability for damage or consequential losses resulting from use of this manual. We are thankful

for notification of errors and for recommendations and criticism. Where not stated otherwise, the technical

state at the time of joint delivery of product and manual is definitive. We reserve the right to make technical

changes without prior notice. All previous revisions of this manual then lose their validity.

The Genius II controller is part of a group of devices for the operation of an electron beam evaporator

installed in a vacuum chamber. This group of devices consists of:

1. a high voltage power supply (HVPS)

2. the Genius II controller, including hand-held remote control

3. a filament power supply (FPS)

4. a grounding rod

Use of the Genius II controller other that in combination with this group of devices is not allowed. The

Genius II is intended solely for the control of this group of devices. Use of the Genius II for any other

purpose requires the approval of the manufacturer. This Manual deals only with the design and operation of

the Genius II. Please see the relevant user manuals regarding operation of the other devices in the group.

These devices were developed, designed, and build solely for commercial/industrial use. Proper use in

accordance with its designated use includes compliance with the manufacturer's operating, maintenance,

and repair instruction.

WARNING!

Access to the electron beam evaporator is to be secured by the unit controller in such a way that it is

possible to ensure that both the rotary crucible movement and the high-voltage power supply are stopped.

To this end, external connection options are available at the high-voltage supply and at the Genius II

controller. The person setting up the entire unit is required to integrate this safety function in accordance

with the performance level determined in the functional safety.

Genius II Quick Start Guide iii 01010-9031-0, Rev. B

DANGER!

The evaporation controller Genius II is intended solely for the purpose described above. Any other use or

modification of the evaporation controller Genius II without the written consent of the manufacturer is

deemed improper. The manufacturer accepts no liability for resultant damage. The risk is borne solely by

the operator.

NOTICE

Per EMC Directive 2004/108/EG in the manufacturer's declaration, the Genius II controller may be

operated only in Industrial environments.

DANGER!

The materials/media required for operation of the electron beam evaporator in compliance with its

intended use are procured and used by the operator of the electron beam evaporator. Proper handling of

these materials/media and the related dangers are the sole responsibility of the operator. The operator

must supply his operating personnel with information and instructions on dangers and disposal. The safety

data sheets of the material/media manufacturers must be observed

Copyright

No part of this publication may be reproduced, transmitted, sold or disclosed without prior permission.

Damages will be claimed for violations. All rights reserved.The controller and this manual are protected by

copyright. Copying of the devices will be prosecuted. All rights to this manual are reserved, including

reproduction in any conceivable form, be it photo mechanical, by printing, on any data carrier whatsoever or

in translated form. Reproduction of this manual, also in excerpts, is permitted only with the written consent

of Ferrotec GmbH.

Publisher

Should you have any questions or problems the installation or initial operation of the

Genius II, please contact us. We will be glad to help you.

Ferrotec GmbH

Seerosenstrasse 1

72669 Unterensingen

phone +49 7022 9270-0

fax +49 7022 9270-10

Explanations of Safety Symbols and Notifications

DANGER!

Warns of dangerous actions situations that could result in severe injury or death. Avoid such actions and

situations.

CAUTION

Warns of actions that could lead to damage to the Genius II or other equipment associated with the

evaporation system. Avoid such actions.

01010-9031-0, Rev. Biv Genius II Quick Start Guide

Indicates danger of burns .

Indicates danger of hands being crushed or injured.

Indicates danger from magnetism.

Indicates danger to people with cardiac pacemakers, poeple with insulin pumps, and people with active or

passive prostheses and ferromagnetic or conductive foreign bodies.

These symbols mark the sites of protective conductor connections.

Environment sign indicates actions to protect the environment.

This symbol reminds personnel to wear personal safety equipment, including safety glasses.

This instruction handbook is an integral part of the deposition controller and must be kept readily at hand

for the operating personnel at all times. The safety instructions contained in it must be obeyed. If the

deposition controller is resold, the instruction handbook must always be delivered along with it.

Genius II Quick Start Guide v 01010-9031-0, Rev. B

Manufacturer’s Warranty

Conditions of the warranty

FerroTec products are produced and inspected in accordance with our quality management

system. Warranty must be claimed immediately after the notice of the failure including the serial

number of the deposition controller. The manufacturer guarantees warranty of the product of 12

months to be free on defects caused by material failure or failures caused by the manufacturing

process. If a fault occurs during this time period the manufacturer guarantees free of charge

repair in regards of parts and labor time.

Warranty exclusions

Damages caused by improper or not intended use or unauthorized alterations into the Genius II

are excluded from this warranty.

01010-9031-0, Rev. Bvi Genius II Quick Start Guide

0101-9031-0, Rev. B 1 Genius II User Manual

1 Genius II Quick Start Guide

1.1 Contents of Genius II Kits

Your Genius II kit contains the following components:

•Genius II Control Unit, containing Ebeam, Turret, and Sweep Control Modules

•Hand-held controller with 10-ft. connection cable

•Mounting hardware for installation in a standard 19-inch rack

•Magnet-connection cable (PN 1-9500003)

•Input power cable (PN 1-9500024)

•Grounding cable (PN 1-9500001)

1.2 Basic Hardware Installation

Step Action

1Using the mounting hardware supplied, install the Genius II controller

in a standard 19-inch rack.

2Plug the connector on the end of the remote controller’s cable into the

port indicated in Figure 1.

Figure 1Genius II Front Panel, Showing Connections Port for Hand Held Remote Controller

Connection Port for Hand

Held Remote controller

On/Off Button

1.3 Making Cable Connections 1.3.1 Cabling Overview

Genius II Quick Start Guide 0101-9031-0, Rev. B

2

1.3 Making Cable Connections

1.3.1 Cabling Overview

Section 1.3.2 describes how to connect the Genius II to the components it controls and to the required

interlock switches. For instructions on making connections between the Genius II and a PLC-based

system controller, see section 1.3.3.

WARNING

Connect the Genius II’s rear panel SWEEPER COILS connector only to e-beam

guns with beam-drive coils of ±3 A capacity in both the longitudinal and lateral

axes.

1.3.2 Basic Cabling Procedure

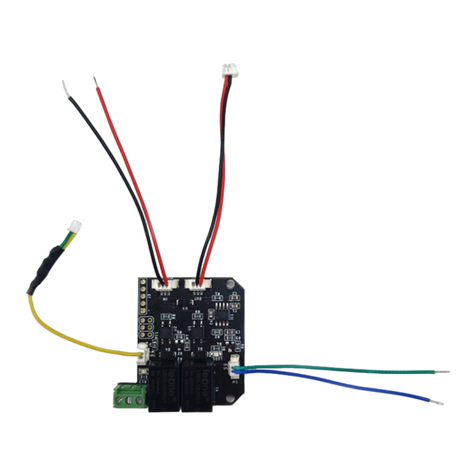

Figure 2 shows the connectors on the Genius II rear panel. The following procedure describes the basic

cabling connections to be made to via those connectors, and Figure 3 illustrates those cabling

connections. For additional details about connections to be made via rear panel connector X110, see

Figure 4 and Table 1. For details about connections to be made via rear panel connector X119, see

Figures 6 and 7.

Figure 2 Connectors on Genius II Rear Panel

Step Action

1Plug the male 9-pin connector on the Y-end of Cable 1-950040 into

Carrera rear-panel connector X302, as shown in Figure 3.

2Plug the female 15-pin connector on the Y-end of Cable 1-950040 into

Carrera rear-panel connector X303.

1.3.2 Basic Cabling Procedure 1.3 Making Cable Connections

0101-9031-0, Rev. B 3 Genius II Quick Start Guide

3Plug the female 15-pin connector on the other end of this cable to the

Genius II rear panel connector X115 (see Figure 3).

4Plug the female 25-pin sub-D connector on one end of cable 1-950013

into Genius II rear-panel connector X116 (see Figure 3).

5Plug the male connector on the other end of this cable into connector

X202 on the rear panel of the filament power supply (see Figure 3).

6Plug the circular connector on one end of the cable 1-950003 into

connector X117 on the Genius II rear panel (see Figure 3).

7Plug the connector on the other end of this cable to the in-atmosphere

end of octal feedthrough mounted on the vacuum system’s source

tray (see Figure 3).

8Plug the male 15-pin connector on one end of cable 1-950054 into

Genius II rear panel connector X118 (see Figure 3).

9Connect the female 15-pin sub-D connector on the other end of this

cable to the male 15-pin connector on the turret-drive unit mounted

beneath the source tray (see Figure 3).

10 Connect one end of the grounding cable (PN 1-9500001) to the

grounding stud on the Genius II rear panel (see Figure 3).

11 Connect the other end of the grounding cable to the system’s central

grounding point.

12 Connect the required water, vacuum, and vacuum chamber door

interlock switches to Genius II rear-panel connector X110, as shown in

Figure 4.

NOTE

To ensure equipment and personnel safety, these interlock switch connections

are required in all Genius II installations. Optionally, Pin A4 may be connected to

an additional user-defined interlock, as shown in Error! Reference source not

found..

13 Connect Pins A2 and B2 on rear panel connector X105 to the poles of

a normally-closed safety switch mounted on the product chamber

door. That switch then prevents turret rotation whenever the door is

open.

NOTE

If X105 Pins A2 and B2 are not connected to a safety switch, as described

above, X105 Pin B1 must be connected to Pin B2. If X102 is not either

connected to a safety switch or jumpered as indicated, the turret cannot rotate.

1.3 Making Cable Connections 1.3.2 Basic Cabling Procedure

Genius II Quick Start Guide 0101-9031-0, Rev. B

4

Figure 3 Genius II Cabling Diagram

1.3.2 Basic Cabling Procedure 1.3 Making Cable Connections

0101-9031-0, Rev. B 5 Genius II Quick Start Guide

1.3 Making Cable Connections 1.3.3 Making Connections to a PLC-Based System Controller

Genius II Quick Start Guide 0101-9031-0, Rev. B

6

1.3.3 Making Connections to a PLC-Based System Controller

Making Connections to Rear Panel Connector X110

When making connections between rear panel connector and a deposition controller, perform the

procedure described below.

NOTE

Before performing this procedure, complete the basic cabling procedure

described in section 1.3.2.

Step Action

1Using the BNC cable provided with the deposition controller, connect

Genius II rear-panel connector X111 to the BNC connector on the

deposition controller rear panel which outputs the emission current

request. If you are connecting the Genius II to either an Inficon

XTC/3S or an XTC/3M, connect the BNC connector to the XTC’s

SOURCE 1 connector. If a BNC cable was not supplied with your

deposition controller, use a standard 50-ohm coaxial cable.

2Make connections between the PLC-based higher-level controller and

Genius II rear panel connector X110 rear-panel, as shown in 4. Table

1provides functional definitions of the I/Os shown in that illustration.

Figure 4 Connections To Be Made via Rear Panel Connector X110

1.3.3 Making Connections to a PLC-Based System Controller 1.3 Making Cable Connections

0101-9031-0, Rev. B 7 Genius II Quick Start Guide

Table 1 Functional Descriptions of Pins on Rear Panel Connector X110

Pin No. Functional Description

A1 Input 1: Status of water interlock (1 = OK); connect to water interlock switch.

A2

Input 2: Status of vacuum interlock (1 = OK); connect to vacuum interlock switch.

A3 Input 3: Status of vacuum chamber door interlock (1 = OK); connect to vacuum chamber door interlock switch.

A4

Input 4: Status of auxiliary interlock (1 = OK); connect to optional user-defined interlock switch.

A5 Input 5: BEAM ON input (Positive slope). Within the Genius II, this input, when true, switches on the HV and the

gun. Connect Pin A5 to a user-determined output from the higher-level controller. For example, if you are using

the Genius II in a system equipped with an XTC/3M deposition controller, you can create a circuit similar to that

shown in Figure 5, which illustrates the use of the XTC/3M’s IN LAYER output to provide both the BEAM ON

and BEAM OFF inputs.

A6 Input 6: BEAM OFF input (HV OFF = 1). When, this input switches off the HV and the gun. Connect Pin A6 to a

user-determined output from the higher-level controller. Figure 5 shows how this input could be supplied by an

XTC/3M deposition controller, using its IN LAYER output.

A7

Output K1: Relay contact with Pin B7; default function = HV ON status (HV ON = 1).

A8 Output K2: Relay contact with Pin B7; default function = Genius II ERROR indicator (ERROR = 1).

B1 Ground reference for Pin A1; jumper to Pin B5.

B2 Ground reference for Pin A2; jumper to Pin B5.

B3

Ground reference for Pin A3; jumper to Pin B5.

B4 Ground reference for Pin A4; jumper to Pin B5.

B5

0 V reference for Pins A1-A5

B6 24 V, 80 mA output; can be used as control voltage for Inputs 1-4.

B7 Relay contact with Pin A7; jumper to Pin B6.

B8

Relay contact with Pin A8; jumper to Pin B6.

Figure 5 Sample Circuit Supplying BEAM ON and BEAM OFF Inputs via X110 Pins 5 and 6

Making Connections to Rear Panel Connector X119

When making connections from rear panel connector X119 and a higher-level controller (i.e., either a

deposition controller or a PLC-based system controller), perform the procedure described below.

NOTE

Before performing this procedure, complete the basic cabling procedure described in section 1.3.2.

Step Action

1If you have not already done so, make the connections between the

higher-level controller and connector X110 shown in Figure 4.

.

.

In Layer signal from

deposition controller

.

.

.

.

Relay

1.3 Making Cable Connections 1.3.3 Making Connections to a PLC-Based System Controller

Genius II Quick Start Guide 0101-9031-0, Rev. B

8

2Make the required connections between the higher-level controller and

rear panel connector X119. This wiring can follow either of two

configurations, as shown in Figures 6 and 7. Table 2 provides

functional descriptions of the I/Os exchanged via connector X119.

Figure 6 Connections to Rear Panel Connector X119, Configuration #1

Figure 7 Connections to Rear Panel Connector X119, Configuration #2

1.3.3 Making Connections to a PLC-Based System Controller 1.4 Connecting the AC Power Cable and Powering Up the Genius II

0101-9031-0, Rev. B 9 Genius II Quick Start Guide

Table 2 Functional Descriptions of Pins on Rear Panel Connector X119

Pin

Functional Description

A1 Input 1: Data-set-selection Bit 1

A2

Input 2: Data-set-selection Bit 2

A3 Input 3: Data-set-selection Bit 3

A4 Input 4: Data-set-selection Bit 4

A5 Input 5: Data-set-selection Bit 5

A6 Input 6: Data-set-selection Bit 6

A7

COM IN; ground reference for inputs 1-6

A8 24 V, 1.5 A output; can be connected to Pin B5 to provide control voltage for outputs K1-K4.

B1 Output K1: Relay contact with B5; function = POCKET IN POSITION output.

B2 Output K2: Relay contact with B5; function = POS 0 (BCD bit 0)

B3

Output K3: Relay contact with B5; function = POS 1 (BCD bit 1)

B4 Output K4: Relay contact with B5; function = POS 2 (BCD bit 2)

B5 COM OUT: Function: Either 0 V reference for Outputs K1-K4, if jumpered to Pin B8, or 1.5-A control voltage for the

same outputs, if jumpered to Pin A8

B6

Output T1: Transistorized output not implemented on Genius II

B7 Output T2: Transistorized output not implemented on Genius II

B8

Internally connected to ground; can be connected to Pin B5 to provide 0 V reference for outputs K1-K4

1.4 Connecting the AC Power Cable and Powering Up the Genius II

Perform the following procedure to supply AC power to the Genius I.

Step Action

1Make sure that the rear-panel On/Off switch (see Figure 8) is in the

Off position.

Figure 8 Genius II Input Power Cable Receptacle and Rear Panel On/Off Switch

1Plug the unit’s power cable into the rear-panel input power receptacle

and into an appropriate source of AC power.

On/Off Switch

Receptacle for

Input Power Cable

1.5 Configuring the Control Modules 1.5.1 Configuring All Module Control Modules for Remote Control

Genius II Quick Start Guide 0101-9031-0, Rev. B

10

2Put the rear-panel On/Off switch in the On position.

3Press the front-panel On/Off button (see Figure 1). The unit will then

boot up and display the Start screen (see Figure 9).

1.5 Configuring the Control Modules

1.5.1 Configuring All Module Control Modules for Remote Control

Step Action

1When the Genius II is first booted up, the main controller screen

displays the Start screen (see Figure 9). To put the unit into

Configuration Mode, touch this screen’s Configuration button. The

unit will then display the Configuration>Main screen (see Figure 10).

Figure 9 Genius II Start Screen

Figure 10 Config>Main Screen After Initial Boot-Up

Note that Hardware Deactivated is displayed on the E-Beam, Sweep, and

Pocket buttons on the command button bar. This is because all three control

modules are factory-configured as Offline.

1.5.2 Configuring the EBeam Control Module 1.5 Configuring the Control Modules

0101-9031-0, Rev. B 11 Genius II Quick Start Guide

2Touch the buttons opposite Ebeam modules, Sweeper Module,

and Turret Module twice each to select Remote I/O for all three

control modules. The Config>Main screen will then appear as shown

in Figure 11

Figure 11 Configuration>Main Screen After User Configures All Control Modules as Remote I/O

1.5.2 Configuring the EBeam Control Module

Step Action

1Touch the Menu Bar’s E-Beam button to display the Config>E-Beam

screen (see Figure 12).

Figure 12 Configuration E-Beam Screen After Initial Boot-Up

2Select the desired power supply, if it is not already selected. To do so,

touch the Carrera Type button to toggle between the four power

supply options.

3Leave EXTERNAL selected opposite Emis Control.

4If desired, you can change the default kV value. To do so:

a) Touch the kV Set button to display a numeric keypad.

b) Use that keypad to enter the desired default value.

c) Touch Enter to close the keypad. The value you entered will then

appear on the kV Set button.

1.5 Configuring the Control Modules 1.5.3 Configuring the Turret Control Module

Genius II Quick Start Guide 0101-9031-0, Rev. B

12

5If desired, you can also change the filament current bias level. To do

so:

a) Touch the Fil Bias button to display a numeric keypad.

b) Use that keypad to enter the desired bias value.

c) Touch Enter to close the keypad. The value you entered will then

appear on the Fil Bias button.

6Enter the desired values for Emis Kp, Emis Ki, and Emis Kd,

following the procedure analogous to that described in sub-steps 5a),

5b), and 5c) above.

Configuration of the E-Beam PS parameters is now complete. If you have made all the configuration

changes you wish to make at this time, exit Configuration Mode to save the configuration (see section

1.5.5 for detailed instructions). If not, proceed to section 1.5.3.

1.5.3 Configuring the Turret Control Module

Overview of the Config>Turret Screen

Figure 13 shows the Configuration>Turret screen as it appears when the Genius II is first booted up.

Figure 13 Config>Turret Screen at Initial Boot-Up

The features on this screen enable the user to configure the essential turret-related parameters,

including:

•Rotation direction, either clockwise (CW) or counterclockwise (CCW).

•Number of pockets (3-8)

•Motor seek speed, in percentage terms.

•Motor indexing speed, also as a percentage.

Setting the Turret Drive Parameters

Perform the following procedure to set the required turret drive parameters from the Genius II’s touch

screen. This procedure is most easily accomplished with the source tray lowered and swung out from the

system.

Table of contents