5

iso685_D00022_06_Q_CNEN/10.2016

ISOMETER® iso685...-CN

报警和它的影响

报警的原因

•绝缘故障

绝缘电阻有下列 2 组响应值

LEDs ALARM 1 ALARM 2

闪烁。

•设备故障

LED SERVICE 闪烁。

•激活绝缘故障定位

LED PGH ON 在故障电流通道闪烁。

设备信号报警或设备故障

•显示指示的错误以及应用的测量值。

•在发生 "ALARM 1" 或 "ALARM 2" 的情况下,相关 LED 等闪

烁。

•如果分配,会间隔发出报警哔哔声。

•开关分配的报警继电器。

•开关分配的数字输出。

重置报警信息 ( 重置 )

要求 : 不再存在报警的原因。 绝缘电阻必须至少高于响应值

25 % 。

选择 : "RESET" > "RESET" > "OK".

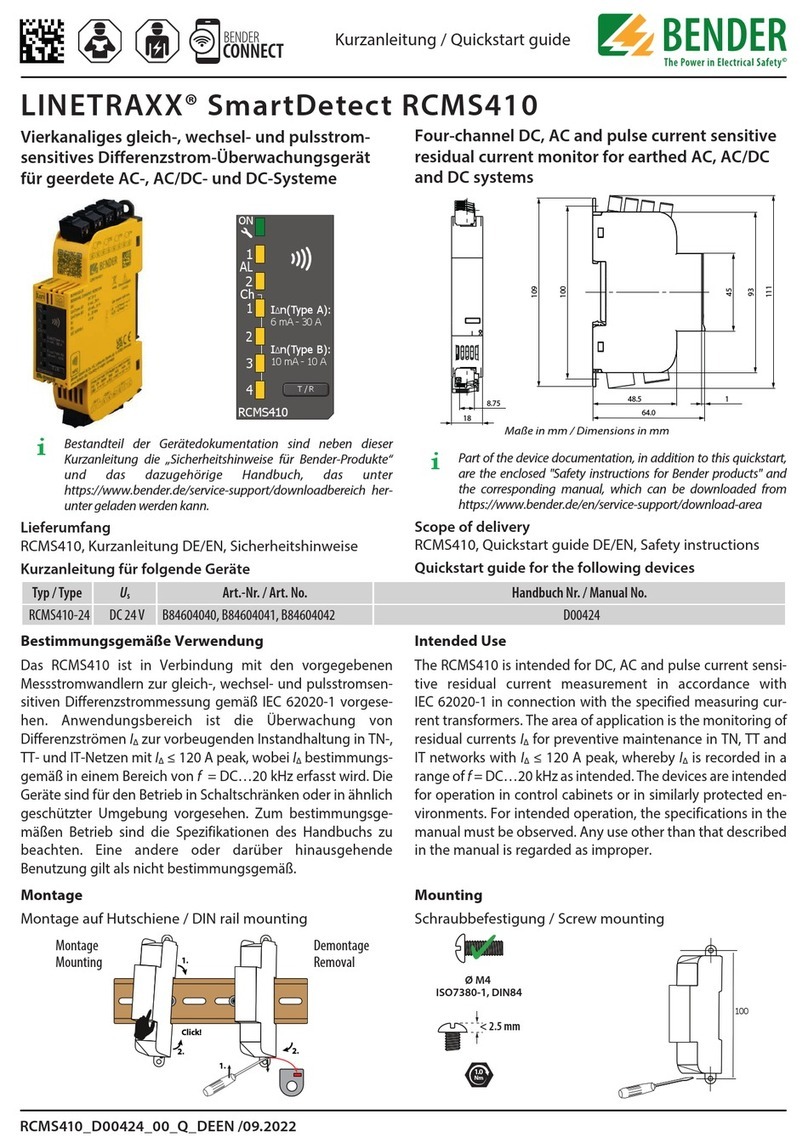

技术数据

( )* = 出厂设置

绝缘协调性 (IEC 60664-1/IEC 60664-3)

额定电压.......................................................................................................................................... 1000 V

过电压分类 (OVC).................................................................................................................................III

额定脉冲电压 (IEC 60664-1) ....................................................................................................... 8 kV

额定绝缘电压 (IEC 60664-1) .................................................................................................. 1000 V

污染等级 (Un< 690 V) .......................................................................................................................... 3

污染等级 (Un< 1000 V) ........................................................................................................................ 2

保护隔离介于 (≤ 2000 m NN) 和......................................................... (L1/+,L2,L3/-) 之间 –

........................................................................ (A1,A2) – (11,12,14) – (21,22,24) – (E, KE), (X1, ETH, X3, X4)

电压测试、常规测试 (IEC 61010-1) .......................................................................... AC 2.2 kV

电源电压

电源电压范围 Us.................................................................................................. AC/DC 24…240 V

Us的公差 ............................................................................................................................. -20…+15 %

Us的频率范围 ........................................................................................................... DC, 50…400 Hz

功耗,典型地 50 Hz (400 Hz)...........................................................≤12 W/21 VA (≤12 W/45 VA)

被监视的 IT 系统

标称系统电压范围 Un.................................................................. AC 0…690 V, DC 0…1000 V

Un的公差 ..............................................................................................................................AC/DC+15%

Un的频率范围 ............................................................................................................. DC, 1…460 Hz

响应值

响应值 Ran1 (Alarm 1) ......................................................................................... 1 kΩ…10 MΩ (40 kΩ)*

响应值 Ran2 (Alarm 2) ......................................................................................... 1 kΩ…10 MΩ (10 kΩ)*

操作的不确定性 (符合 IEC 61557-8)...................相关的配置 , ±15 %, min. ±1 kΩ

时间相应

响应时间 tan 在RF= 0.5 x Ran (Ran= 10 kΩ) 和Ce= 1 μF

符合 IEC 61557-8 .............................................................................. 相关的配置 , 典型 4 s

测量回路

测量电压 Um................................................................................. 相关的配置 , ±10 V, ±50 V

测量电流 Im.................................................................................................................................≤ 403 μA

内部电阻 Ri, Zi.............................................................................................................................≥ 124 kΩ

允许外部直流电压 Ufg.....................................................................................................≤ 1200 V

允许系统泄露电容 Ce............................................. 取决于相关配置 , 0…1000 μF

接口

现场总线 : 接口 / 协议 ....................................................... web server/Modbus TCP/BCOM

Alarm and its effect

Cause of the alarm

•Insulation fault

The insulation resistance is below both response values

LEDs ALARM 1 and ALARM 2 flash.

•Device error

LED SERVICE flashes.

•Active insulation fault location

LED PGH ON blinks according to the locating current.

Device signals alarm or device error

•Display indicates error and, where applicable,

the measured value.

•In the event of "ALARM 1" or "ALARM 2", the associated LEDs

flash.

•A warning sound beeps at intervals, if assigned.

•Assigned alarm relays will switch.

•Assigned digital outputs will switch.

Reset alarm messages (Reset)

Requirement: The cause of the alarm is no longer present. The in-

sulation resistance must be at least 25 % higher than the re-

sponse value.

Select: "RESET" > "RESET" > "OK".

Technical data

( )* = factory setting

Insulation co-ordination (IEC 60664-1/IEC 60664-3)

Rated voltage ............................................................................................................................................. 1000 V

Overvoltage category (OVC) ............................................................................................................................... III

Rated impulse voltage (IEC 60664-1) .......................................................................................................... 8 kV

Rated insulation voltage (IEC 60664-1) ................................................................................................... 1000 V

Pollution degree (Un< 690 V) .......................................................................................................................... 3

Pollution degree (Un< 1000 V) ........................................................................................................................ 2

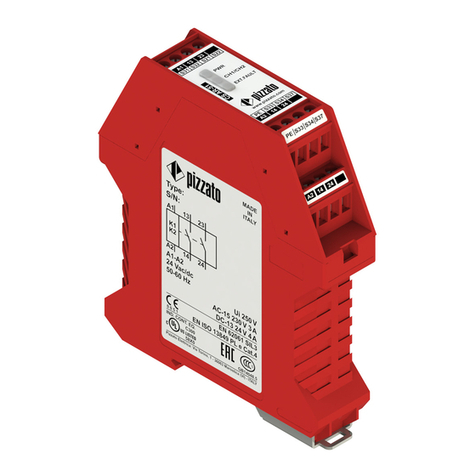

Protective separation (≤ 2000 m NN) between......................................................................(L1/+,L2,L3/-)–

........................................................................ (A1,A2) – (11,12,14) – (21,22,24) – (E, KE), (X1, ETH, X3, X4)

Voltage test, routine test (IEC 61010-1) ............................................................................................. AC 2.2 kV

Supply voltage

Supply voltage range Us....................................................................................................... AC/DC 24…240 V

Tolerance of Us............................................................................................................................. -20…+15 %

Frequency range of Us............................................................................................................. DC, 50…400 Hz

Power consumption typically 50 Hz (400 Hz)..................................................≤12 W/21 VA (≤12 W/45 VA)

IT system being monitored

Nominal system voltage range Un..................................................................... AC 0…690 V, DC 0…1000 V

Tolerance of Un...............................................................................................................................AC/DC+15%

Frequency range of Un............................................................................................................... DC, 1…460 Hz

Response values

Response value Ran1 (Alarm 1) .................................................................................... 1 kΩ…10 MΩ (40 kΩ)*

Response value Ran2 (Alarm 2) .................................................................................... 1 kΩ…10 MΩ (10 kΩ)*

Operating uncertainty (acc. to IEC 61557-8)......................................profile-dependent, ±15 %, min. ±1 kΩ

Time response

Response time tan at RF= 0.5 x Ran (Ran= 10 kΩ) and Ce= 1 μF

acc. to IEC 61557-8 .................................................................................................. profile-dependent, typ. 4 s

Measuring circuit

Measuring voltage Um.................................................................................. profile dependent, ±10 V, ±50 V

Measuring current Im.............................................................................................................................≤ 403 μA

Internal resistance Ri, Zi..........................................................................................................................≥ 124 kΩ

Permissible extraneous DC voltage Ufg .................................................................................................≤ 1200 V

Permissible system leakage capacitance Ce........................................ dependent on the profile, 0…1000 μF

Interfaces

Field bus:Interface/protocol.............................................................................. web server/Modbus TCP/BCOM