ferrotec CARRERA User manual

Operation manual

High-voltage power supply unit

Type: CARRERA

Serial no:

FERROTEC GmbH

Postfach 33

Seerosenstraße 1

72669 Unterensingen

Telefon: +49 7022 - 9270-0

Telefax: +49 7022 - 9270-10

Internet: www.ferrotec-europe.com

E-Mail: ebgun@de.ferrotec.com Version 1.3_15

Translation of the original Operation manual

Electron Beam Evaporator

Types: EV M –6; EV M –8; EV M –10

Rev 1.3_15

1

NOTICE

This instruction handbook is an integral part of the high voltage

power supply and must be kept readily at hand for the operating

personnel at all times.

The safety instructions contained in it must be obeyed.

If the machine is resold, the instruction handbook must always be

delivered with it as well.

Liability

The manufacturer's liability for the CARRERA power supply is

based on the principles of German law.

The manufacturer accepts no liability for damage and losses due

to:

improper use;

operation by unauthorised personnel;

failure to follow safety regulations;

failure to heed the information in the instruction handbook.

Translation

If the machine is sold to a country in the EEA, this instruction

handbook must be translated into the language of the country in

which the machine is to be used.

Should the translated text be unclear, the original instruction

handbook (German) must be consulted or the manufacturer

contacted for clarification.

Copyright

No part of this publication may be reproduced, transmitted, sold or

disclosed without prior permission. Damages will be claimed for

violations.

All rights reserved.

Version 1.3_15 EN

2

High Voltage Power Supply

Type: CARRERA

1 Table of Content

1.1 Table of content

1Table of Content 2

1.1 Table of content 2

1.2 Table of pictures 4

1.3 Manufacturer's Declaration 5

2Overview and Intended Use 6

2.1 Overview CARRERA-System 6

2.2 Intended Use 7

2.3 Explanation of terms 8

2.4 Technical specifications 9

2.4.1 Dimensions and weight 9

2.4.2 Specification 9

2.4.3 General specifications 9

3Safety 10

3.1 Notes / Explanations 10

3.1.1 Explanation of used safety symbols 11

3.1.2 Machine Identification 12

3.2 Integrated Safety Systems 13

3.3 Overview of electrical connections 16

3.4 Safety Precautions (by the Operator) 17

3.5 Responsibilities of the Operator 19

3.6 Safety Inspections and Tests 22

4General Warnings 23

4.1 Dangers 23

4.2 Operating Areas and Danger Zones at the

Machines 24

4.3 Operating and Maintenance Personnel 25

4.4 Spare and Wearing parts 26

4.5 Shutdown Procedure 27

5Installation 28

5.1 Delivery package 28

5.2 Transport and Packaging 29

5.2.1 Delivery (also for Spare and replacement

Parts) 29

5.3 Intermediate Storage 30

Version 1.3_15 EN

3

High Voltage Power Supply

Type: CARRERA

5.4 Transportation to the point of Installation

( by Operator) 30

5.5 Assembly, Installation (only for trained

personnel) 31

5.5.1 Assembly 31

5.5.2 Electric Connection 31

5.5.3 Overview of the electrical connectors and

fuses 34

5.5.4 Connection of the high-voltage power supply

unit 35

6Functional description 39

6.1 Putting in operation for the first time (for

specialized personnel only) 41

7Operation 43

7.1 Operation and displaying elements 43

7.2 Operation modes 44

7.2.1 Operation 44

7.2.2 Switching on 44

7.2.3 Switching off 45

8Cleaning/Maintenance 46

8.1 Complete Daily Cleaning 48

8.2 Cleaning 48

8.3 Maintenance 48

8.3.1 Function test plan 49

8.3.2 Inspections 49

8.4 Inspection of the machine 51

9Troubleshooting 52

10 Emergency 53

11 Dismantling/Disposal 54

12 Appendix; Options 55

12.1 Appendix 1; Control unit GENIUS 55

12.2 Appendix 2; Filament Power Supply FPS 56

Version 1.3_15 EN

4

High Voltage Power Supply

Type: CARRERA

1.2 Table of pictures

Fig. 1 Overview CARRERA system 6

Fig. 2 Electrical connections of the high voltage

power supply ( front side) 16

Fig. 3 Electrical connections of the high voltage

power supply ( back side) 16

Fig. 4 Delivery package 28

Fig. 5 Wiring diagram of the CARRERA 3/5/6 high

voltage power supply 33

Fig. 6 Wiring diagram of the CARRERA 10/12 high

voltage power supply 33

Fig. 7 Overview of electrical connectors and fuses 34

Fig. 8 Interlock connector 37

Fig. 9 Harting plug, connector assignment of the

power supply cable 38

Fig. 10 Overview high voltage power supply 39

Fig. 11 Overview of operation and display elements 43

Version 1.3_15 EN

5

High Voltage Power Supply

Type: CARRERA

1.3 Manufacturer's Declaration

Version 1.3_15 EN

6

High Voltage Power Supply

Type: CARRERA

2 Overview and Intended Use

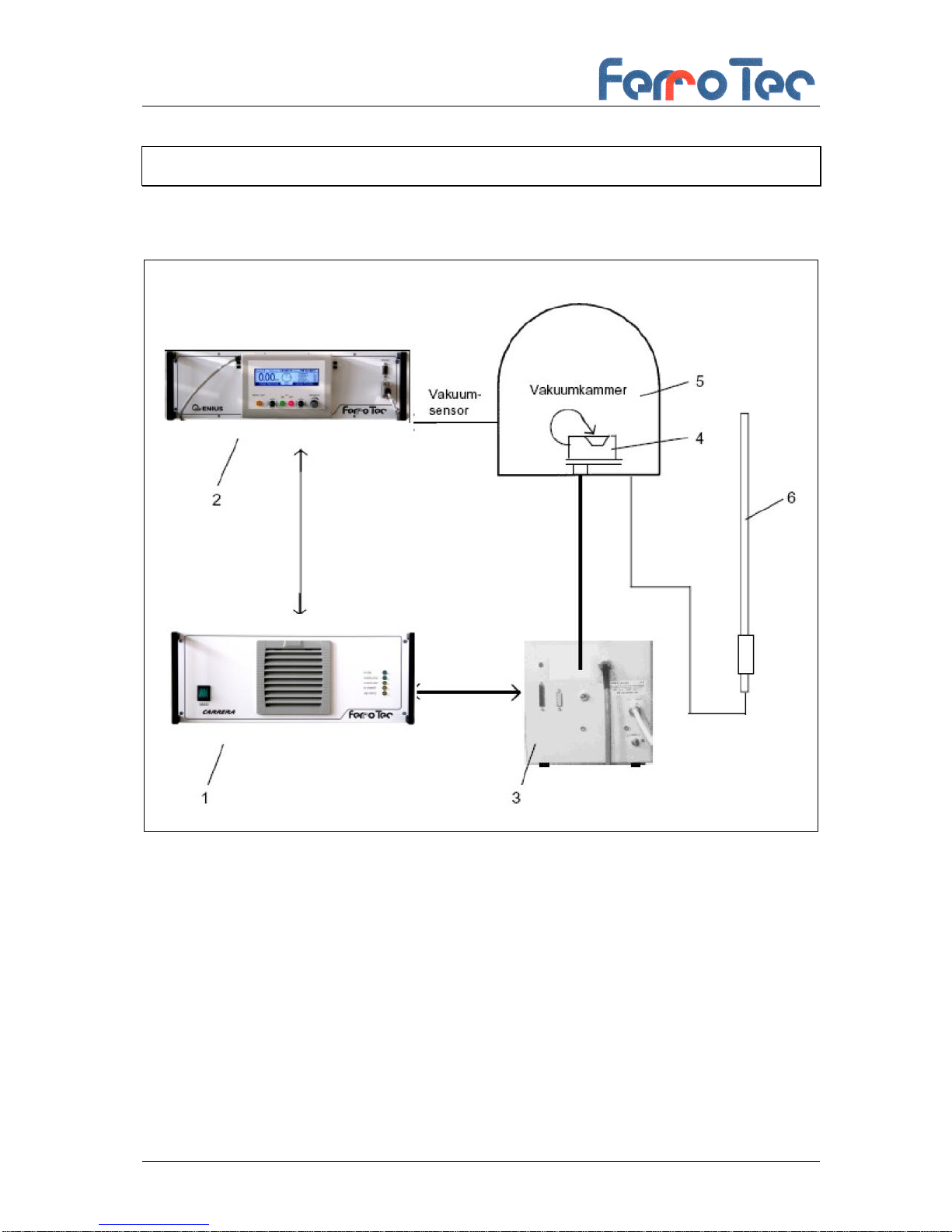

2.1 Overview CARRERA-System

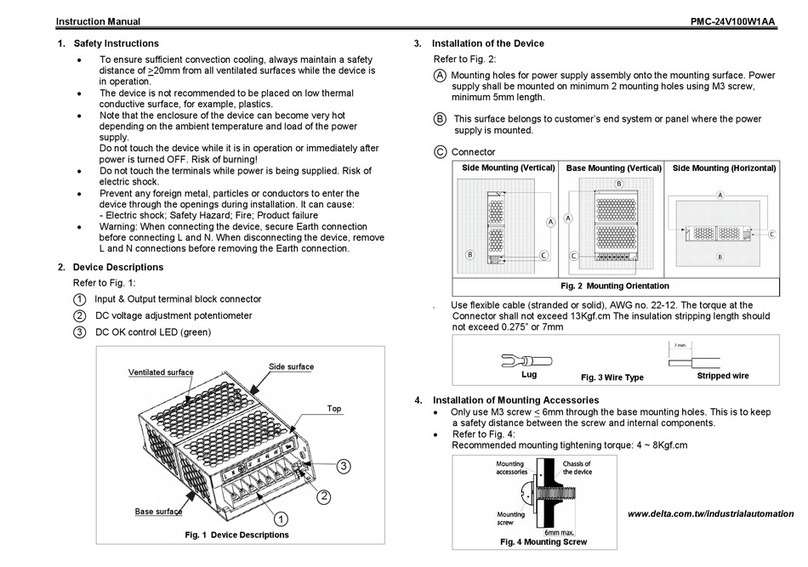

Fig. 1 Overview CARRERA system

The complete evaporator package consist of the following:

1 High voltage power supply HVP

2 Electron beam evaporator controler GENIUS with hand

remote control

3 Filament power supply (FPS)

4 Electron beam evaporator

5 Vacuum chamber

6 Grounding rod

Version 1.3_15 EN

7

High Voltage Power Supply

Type: CARRERA

2.2 Intended Use

The high voltage power supply HVP is part of a group of devices

for the operation of an electron beam evaporator installed in a

vacuum chamber..

The group of devices consists of:

- High voltage power supply (HVP)

- Electron beam evaporator controller GENIUS with integrated

remote control

- Filament power supply (FPS)

- Grounding rod

Use of the high voltage power supply for any other purpose

requires the approval of the manufacturer.

The high voltage power supply HVP generates the high voltage

needed to operate an electron beam evaporator. Other fields of

application are only permitted with the written authorization of the

manufacturer.

This operating manual deals solely with the design and operation

of the high voltage power supply. Please see the relevant

operating manuals for operation of the other devices in the group

(see table of contents and figures, appendices 1 + 2).

These devices were developed, designed and built solely for

commercial/industrial use.

DANGER

The high voltage power supply HVP is intended solely for the

purpose described above. Any other use or modification of the

high voltage power supply HVP without the written consent of

the manufacturer is deemed improper. The manufacturer

accepts no liability for resultant damage. The risk is borne

solely by the operator.

The high voltage power supply HVP may only be put into

operation when it has been ensured that all safety equipment is

operative and the total installation of the vacuum system

comply with EU directives.

Version 1.3_15 EN

8

High Voltage Power Supply

Type: CARRERA

Proper use of the machine in accordance with its intended use

includes compliance with the manufacturer's operating,

maintenance and repair instructions. The use is restricted to

rooms in a building or halls.

HINWEIS

Notice on application of the EMC Directive 2004/108/EC in the

manufacturer's declaration:

The high voltage power supply HVP is only allowed to be

operated in Industrial environment.

2.3 Explanation of terms

HVP - High voltage power supply unit

GENIUS - Electron beam evaporation controller

FPS - Filament Power Supply

Version 1.3_15 EN

9

High Voltage Power Supply

Type: CARRERA

2.4 Technical specifications

2.4.1 Dimensions and weight

Width: 483 mm

Height ( 3, 5 und 6 kW units): 175 mm

Height (10 und 12 kW units): 350 mm

Depth: 550 mm

Weight: approx. 28,5 kg kg

2.4.2 Specification

Power:

3 kW

5 kW

6 kW

10 kW

12 kW

Mains power supply:

EU Version:

3 x 400V

+/-10 %

US Version:

3 x 208V

+/-10 %

EU Version:

3 x 400V

+/-10 %

US Version:

3 x 208V

+/-10 %

EU Version:

3 x 400V

+/-10 %

US Version:

3 x 208V

+/-10 %

EU Version:

2X 3 x 400V

+/-10 %

US Version:

2X 3 x 208V

+/-10 %

EU Version:

2X3 x 400V

+/-10 %

US Version:

2X3 x 208V

+/-10 %

Frequency:

50/60 Hz

50/60 Hz

50/60 Hz

50/60 Hz

50/60 Hz

Control Volage:

4 - 10 kV

4 - 10 kV

4 - 10 kV

4 - 10 kV

4 - 10 kV

High voltage set point:

4 bis 10 V,

DC (entspr.

4 - 10 kV)

4 bis 10 V,

DC (entspr.

4 - 10 kV)

4 bis 10 V,

DC (entspr.

4 - 10 kV)

4 bis 10 V,

DC (entspr.

4 - 10 kV)

4 bis 10 V,

DC (entspr.

4 - 10 kV)

Emission current:

0 -300 mA

0 - 500 mA

0 - 600 mA

1.000 mA

1.200 mA

Emission current actual

valuet:

0 -10 V, DC

(0 -300 mA)

(0 - 500 mA)

(0 - 600 mA)

(0–1000 mA)

(0–1.200 mA)

Electrical connection:

(see chap.5.5.2)

EU Version :

3 x 16 A

slow blow

US Version:

3 x 25 A

slow blow

EU Version :

3 x 16 A

slow blow

US Version:

3 x 25 A

slow blow

EU Version :

3 x 16 A

slow blow

US Version:

3 x 25 A

slow blow

EU Version :

2X3 x 16 A

slow blow

US Version:

2X3 x 25 A

slow blow

EU Version :

2X3 x 16 A

slow blow

US Version:

2X3 x 25 A

slow blow

2.4.3 General specifications

Ambient temperature :

Lower limit: -10 bis 35 °C

Upper limit : + 40° C

Air humidity max: 65 %

Noise level: LPA = < 70 dB (A)

Version 1.3_15 EN

10

High Voltage Power Supply

Type: CARRERA

3 Safety

3.1 Notes / Explanations

DANGER

“DANGER” warns of dangerous situations. Avoid these

dangerous situations! Otherwise they could result in severe

injury or death.

WARNING

“WARNING” warns of dangerous situations. Avoid these

dangerous situations! Otherwise they could result in severe

injury or death.

CAUTION

“CAUTION” in connection with this warning symbol warns of

dangerous situations. Avoid these dangerous situations!

Otherwise they could result in severe injury or death.

NOTICE

“NOTICE” gives you recommendations for action, and there is

no risk of injury if you fail to comply with them. However, follow

these recommendations for action to avoid damage and

annoyance.

NOTICE

Instruction manual mandatory;

framed and marked with a book symbol.

NOTICE

„NOTICE“are marked with the word "NOTICE" . This informs

you about further literature.

Version 1.3_15 EN

11

High Voltage Power Supply

Type: CARRERA

3.1.1 Explanation of used safety symbols

DANGER

Danger from electric current

framed and marked with the symbol shown opposite.

DANGER

Danger of burns

framed and marked with the symbol shown opposite.

DANGER

Danger of your hands being crushed or injured

framed and marked with the symbol shown opposite.

DANGER

Danger from magnetism

framed and marked with the symbol shown opposite.

DANGER

Danger for people with cardiac pacemakers (and with insulin

pumps and people with active or passive prostheses and

ferromagnetic or conductive foreign bodies) are marked with

the symbol shown opposite.

NOTICE

Protective conductor connection

marked at the connection points by the symbol shown opposite.

NOTICE

Environment sign

marks actions to protect the environment.

Version 1.3_15 EN

12

High Voltage Power Supply

Type: CARRERA

3.1.2 Machine Identification

Seriel-Nummber

The information in this instruction handbook only applies to the

High voltrage power supply whose type designations are given

on the title page

The identification plate including the serial number is attached on

the back of the high voltage power supply.

It is important that the type designation and the serial number is

stated correctly when consulting us.

We can only process your query properly and quickly if this

information is correct.

Version 1.3_15 EN

13

High Voltage Power Supply

Type: CARRERA

3.2 Integrated Safety Systems

The integrated safety systems must be checked at regular

intervals (d= daily, w = weekly, m = monthly, ½ y = half-yearly,

y= yearly).

The test methods that are to be applied are:

V= visual inspection, F= function test, M= measurement.

The operator must implement the following in the overall

plant:

Mains Isolator (Main Switch)

The high voltage power supply is

connected to the main power supply

system. The electron beam evaporator

is connected to and disconnected from

the power supply with the main switch

for this power supply system.

DANGER

When the main switch is switched off for cleaning, maintenance

and repair work, it must be locked with a padlock to prevent

unauthorised switching on.

Emergency Stop System

The high voltage power supply has to

be integrated in a master emergency

stop system that immediately puts the

high voltage power supply into a safe

operating state when actuated.

Safety System

Discharge rod,

Safety switch at the vacuum

chamber for the evaporator,

Safety latch for interlocks

Flow controller

Vacuum monitor,

Test

Interval

Method

m

F

Test

Interval

Method

m

F

Test

Interval

Method

y

F

Version 1.3_15 EN

14

High Voltage Power Supply

Type: CARRERA

Stop valve for the cooling water

supply.

Internal Interlock circuit

Using the plug X304 the CARRERA

high voltage power supply hast o be

integrated into the emergency shut off

circuit of the complete vacuum system

Machine Control System

The machine control system has to be

equipped internally with a three-phase,

five-wire supply system with current-

carrying mid-point conductor and

separate ground conductor (with

YELLOW/GREEN insulation).

DANGER

The owner is required to ensure that the unauthorized persons

( i.e., who are not operating or maintenance personnel) are

prevented from entering the operating area.

The operating and maintenance personnel are trained in the use

of the machine at its point of installation by personnel from

FERROTEC GmbH. Should you have any questions or be

uncertain about anything, please contact FERROTEC GmbH.

.

NOTICE

It is strictly forbidden to render any of the safety systems

inoperative or to modify their action.

NOTICE

This instruction handbook is an integral part of the electron

beam evaporator and must be kept readily at hand for the

operating personnel at all times. The safety instructions

contained in it must be obeyed.. If the electron beam

evaporator is resold, the instruction handbook must always be

delivered with it as well.

Test

Interval

Method

m

F

Test

Interval

Method

y

V, F, M

Version 1.3_15 EN

15

High Voltage Power Supply

Type: CARRERA

NOTICE

The type, scope and action of the safety systems were

arranged with the operator.

Version 1.3_15 EN

16

High Voltage Power Supply

Type: CARRERA

3.3 Overview of electrical connections

Fig. 2 Electrical connections of the high voltage power supply ( front side)

Front side of the high voltage power supply:

1 Transportation handle

2 ON/OFF switch

3 Air filter inlet

4 LED-Display

13

Fig. 3 Electrical connections of the high voltage power supply ( back side)

Back side of the high voltage power supply:

5 High voltage output

6 Interlock connection

7 Digital interface (connection to Control unit)

8 Analoginterface (connection to Control unit)

9 Fuses

10 Grounding

1 2 3 4 1

5 6

7 12 8

9

10

11

Version 1.3_15 EN

17

High Voltage Power Supply

Type: CARRERA

11 Mains supply

12 Connection Master/Slave: Control signal

13 Connection Master/Slave: Interlock signal

3.4 Safety Precautions

(by the Operator)

The operator must:

- instruct his operating and maintenance personnel in the use

of the safeguards of the electron beam evaporator and

- ensure the safety precautions are being observed including

the use of personal protective equipment.

- The owner must ensure that entry to the hazard area of the

machine (into which the high voltage power supply has been

built) by unauthorized persons (no operating and

maintenance personnel) is prevented. The minimum

clearances stated in DIN EN ISO 13857 are to be complied

with when installing the high voltage power supply.

- The high voltage power supply may only be operated when

the safety devices of the machine into which the high voltage

power supply has been built have been activated. The person

setting up the entire machine must ensure that through

suitable technical measures.

- The cutting off of the energy sources is to be done in such a

way technically that the switching-off procedure described

under section 4.5 can be complied with.

This instruction handbook must be kept in a safe place for future

reference. The frequency of inspections and checks must be

observed.

The work described in this instruction handbook is explained in

such a way that

-the chapters on operation and modes of operation can be

understood by an instructed person and

-those on transport, installation and assembly, maintenance

and troubleshooting by a skilled person.

The chapters on transport, installation and assembly,

maintenance and troubleshooting are intended for skilled

persons only. Work described in these chapters may only be

carried out by such skilled persons.

Version 1.3_15 EN

18

High Voltage Power Supply

Type: CARRERA

Instructed Person

A person familiarised with and, if applicable, trained in his or her

particular duties by a skilled person and advised of the risks of

improper conduct and about the necessary safeguards and

safety precautions.

Skilled Person

A person with relevant technical training, know-how, experience

and knowledge of applicable standards to enable him or her to

assess the work assigned to him or her and to perceive potential

risks.

Definitions based on EN 60204-1:2006

Version 1.3_15 EN

19

High Voltage Power Supply

Type: CARRERA

3.5 Responsibilities of the Operator

NOTICE

In the EEA (European Economic Area) national implementation

of the framework directive 89/391/EEC and corresponding

individual directives, in particular the directive 2009/104/EEC

concerning the minimum safety and health requirements for the

use of work equipment by workers at work, as amended, are to

be observed and adhered to. In Germany the Plant Safety

Ordinance of October 2002 must be observed (translation of

the above-mentioned directive into national law).

The operator must (where necessary) obtain any local operating

permits required and observe the provisions contained therein

In addition to this he must observe local laws and regulations on

- personnel safety (accident prevention regulations)

- safety of work materials and tools (safety equipment and

maintenance)

- disposal of products (laws on wastes)

- disposal of materials (laws on wastes)

- cleaning (cleaning agents and disposal)

- environmental protection.

In addition, the owner must note:

A constant hazard evaluation of the workplaces (danger of

hands being crushed, danger of stumbling) is to be carried

out. The measures are to be defined in work instructions and

the working personnel are to be instructed accordingly

The supervisors must check compliance with the measures

stated in the work instructions.

Ensure that the operating personnel are suitably trained.

Work on electrical equipment is only to be carried out by

suitably trained persons. The connecting cables and

terminals must be properly insulated and covered.

It is only possible to ensure optimal functioning of the

elements if the machine controller is working perfectly. The

switching states of the limit switches must be properly

incorporated into the machine controller and the signal cables

must be in perfect condition.

Table of contents

Other ferrotec Power Supply manuals