Ferrovac RECOMEC13 User manual

Operating Instructions

[Product Title]

Page 2of 20

Important!

It is the sole responsibility of all users to carefully read the operating instructions and keep

them safe. Read and follow all safety instructions carefully before using the product described

in this document. Ferrovac declines all responsibility and liability for any damage/injuries

resulting from incorrect use/adjusting/controlling or programming of the product.

Warranty

Ferrovac warrants this product to be free of defects in material and workmanship for 24 months from

the date of shipment. In the case of any defects, Ferrovac will either repair or replace the product at

our discretion.

Warranty limitations

The warranty for this product does not apply to defects resulting from the following:

•Non-observance of operational- and safety instructions

•Natural wear of components

•Consumables

•Modifications to our products without our written consent

•Misuse of any product or part of the product

This warranty stands in place of all other warranties, implied or expressed, including any implied

warranty of implied merchantability or fitness for a particular use. The remedies provided herein are

the buyer’s sole and exclusive remedies.

Neither the company Ferrovac nor any of its employees shall be liable for any direct, indirect,

incidental, consequential or special damages arising out of the use of its products even if Ferrovac has

been advised of the possibility of such damages. Such excluded damages shall include but are not

limited to costs of removal and installation, losses sustained as the result of injury to any person, or

damage to property.

Copyright

Copyright 2023 Ferrovac. All rights reserved. All information in this document is the sole property of

Ferrovac and protected by Swiss copyright laws and international conventions. Ferrovac grants the

right for reproduction for the purchaser’s own use. No part of this manual may be reproduced or

transmitted by any third party in any form or by any means and for any purpose without the written

permission of Ferrovac.

Operating Instructions

[Product Title]

Page 3of 20

Contents

1. General Information....................................................................................................................4

1.1 Designated Use....................................................................................................................4

2.1 Non-Designated Use ............................................................................................................4

2. Terms and Symbols .....................................................................................................................5

3. General Safety Information.........................................................................................................5

3.1 Specific Safety Precautions for the Products RECOMEC13 / RECOMCREC13V2 .....................7

4. About..........................................................................................................................................8

4.1 Dimensions..........................................................................................................................8

4.2 Product Configurations ........................................................................................................8

4.3 Specifications ............................................................................................................................9

4.4 Technical Data (all versions):................................................................................................9

4.5 Specifications of individual Versions........................................................................................10

Technical Data:..........................................................................................................................10

5. Unpacking.................................................................................................................................12

6. Installation................................................................................................................................13

6.1 Mounting ................................................................................................................................13

6.2 Wiring .....................................................................................................................................13

7. Operation..................................................................................................................................14

7.1 RECOMEC13.......................................................................................................................14

7.2 RECOMCREC13V2 ..............................................................................................................16

8. Options and Upgrades...............................................................................................................18

9. Return of Defective Items..........................................................................................................20

10. Downloads.........................................................................................................................20

Operating Instructions

[Product Title]

Page 4of 20

1. General Information

This manual covers information about installation, commissioning, and operation of your Ferrovac

Product. It also provides essential safety information, maintenance- and fault-finding procedures.

Products covered in this manual are:

•RECOMEC13 Sample Receiver with 13 electrical contacts, room temperature version

•RECOMCREC13V2 Sample Receiver with 13 electrical contacts, cryogenic version

The product described was manufactured in accordance with the applicable national standards and

guidelines. The information in this document represents the state of the product at the date of print.

Technical changes may be made without notice. Ferrovac makes no warranties or representations with

respect to accuracy or completeness of the contents of this publication. Figures and photos are not

binding. The product names used are for identification purposes and may be trademarks of their

respective companies.

1.1 Designated Use

The product described in this document may only be used for its designated application. Designated

use of the product is defined by the following rules:

The product is:

•Used with original cable sets supplied by Ferrovac which are explicitly specified for the use

with the product described in this publication.

•Used in an indoor research laboratory environment or an industrial production or processing

facility.

•Operated by personnel qualified for the operation of delicate scientific equipment.

•Used in accordance with all related manuals.

2.1 Non-Designated Use

Non-designated use is given if any of the following are true:

•The product is used with other equipment not explicitly acknowledged by Ferrovac in writing.

•The product is used outdoors or at ambient conditions exceeding the values given in the

product specification.

•If non-qualified persons use the product.

•Operation of the product in disregard of the safety instructions.

•Operation of the product with disabled, modified, removed, or damaged safety equipment

and devices.

Important!

Carefully read all safety instructions and relevant manuals before using the product and any

related equipment!

Operating Instructions

[Product Title]

Page 5of 20

2. Terms and Symbols

Symbol

Term

Meaning

Danger!

Risk of mortal danger when

not observed

Warning!

Risk of severe injury or danger

to life when not observed

Caution!

Slight risk of injury or damage

to product when not observed

High voltage!

Potentially lethal voltages are

present

Caution, hot surface!

Potential burn hazard if safety

precautions are not followed

Cryogenic Substances!

Potential cold burn hazard if

safety precautions are not

followed

Important!

Important information for

proper operation of the

product

Info, hint!

Useful hints, tips and clues

3. General Safety Information

Read the safety instructions very carefully. All safety precautions must be observed strictly while using

the product described in this manual and any associated instrumentation.

Study this document to learn how to operate your product correctly. Keep this instruction manual in

a safe place close to the described product and inform all other users of the manual’s location. Always

include this manual when handing the product over to third party persons.

Responsible body is the individual or group of persons that are responsible for the proper use and

maintenance of the product, ensuring that the product is being used within its specifications and

operating limits. The responsible body must ensure that users of the product are adequately trained.

Operators must use the product for its intended purpose. Users must be trained in electrical safety,

handling of cryogenic liquids (if applicable) and adequate use of scientific instrumentation. They must

be protected from electric shock and other potentially dangerous situations.

Operating Instructions

[Product Title]

Page 6of 20

Maintenance Personnel perform routine tasks on the product to keep it in proper operating

conditions, i.e., setting up the line voltage or replacing consumables. Maintenance procedures

described in this manual must be followed.

Service Personnel are trained to work on live circuits and to work cryogenic liquids (if applicable) as

well as perform fault finding measurements and repair work to the product. Only fully trained service

personnel qualified to manage potentially lethal voltages may perform servicing and repair.

Shock hazard: The American National Standards Institute states that a shock hazard exists when

voltage levels are greater than 30 V RMS, 42.2 V peak or 60 VDC. A good safety practice is to assume

that hazardous voltages are present in any unknown circuitry.

Warning!

Always check for correct mains voltage before connecting any equipment!

Mains supply voltage fluctuation must not exceed ±10% of the nominal voltage.

Warning!

• Always observe and strictly follow the safety notes and regulations given in this document

• Always use the originally delivered cables with the product for all electrical connections.

• Always switch off the device before disconnecting cables.

• Never operate the device outside its dedicated environment.

• DO NOT OPEN the device unless you fulfill the requirements of a fully trained service

personnel, and you are familiar with live circuits and potentially lethal voltages.

Important! Ambient conditions and environment:

This product may only be used indoors, in locations meeting the following requirements:

• Room temperature lies between 5°C/41°F and 40°C/104°F

• Humidity up to maximum of 80%

• Altitudes up to 2000m

• Pollution Degree 2 environments

Operating Instructions

[Product Title]

Page 7of 20

3.1 Specific Safety Precautions for the Products RECOMEC13 / RECOMCREC13V2

Only qualified personnel who recognize shock hazards and are familiar with the precautions

necessary to avoid injury shall use the products described in this manual.

Warning: Potentially Lethal Voltages!

This Product, depending on its application can operate at potentially lethal voltages of up to

300VRMS.

Any adjustment, fault-finding procedure, installation and maintenance of the product

described in this manual must be carried out only by authorized service personnel.

• In case of malfunction, immediately disconnect the unit from any power supply

• Do not touch any electrical terminals, connectors or wires

• Report damaged cabling immediately to service personnel

• Always wear electrically isolating safety shoes when performing maintenance

Warning: Liquid Nitrogen (LN2), Nitrogen Gas (N2)

• Nitrogen is a colorless, odorless, and tasteless non-toxic substance. LN2 is a clear liquid.

1 liter of liquid N2 expands to about 700 liters of gas when warming up which causes a large

pressure build-up in a closed container. Make sure to take precautions against overpressure.

• LN2/N2 can cause rapid suffocation without noticing. Therefore, these substances must be

stored and used in areas with adequate ventilation. Be aware that N2 gas accumulates on the

ground. If any symptoms such as drowsiness, dizziness, headache, unconsciousness or even

vomiting occur, bring victim to fresh air, provide oxygen or artificial respiration if needed. Call

for professional medical help.

• LN2 can cause severe frostbite. In case of injury, warm up exposed parts, but do not use hot

water. Seek medical assistance.

• The handling of liquid nitrogen is restricted to authorized and trained personal respecting the

general safety precautions for cryogenic liquids. Always use appropriate personal protective

equipment (PPE), i.e., wear safety glasses and gloves as well as closed stable shoes and long

sleeves/pants.

• Read all safety instruction given by your supplier of liquid nitrogen and storage vessels

carefully.

Operating Instructions

[Product Title]

Page 8of 20

4. About

4.1 Dimensions

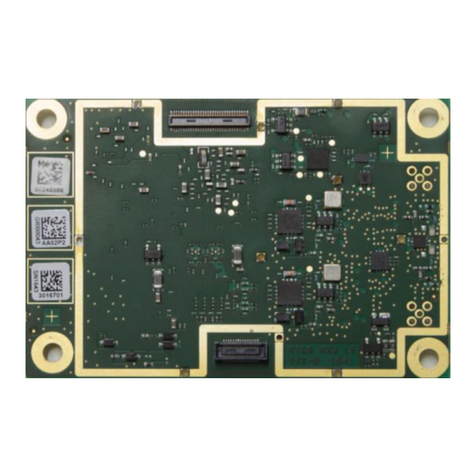

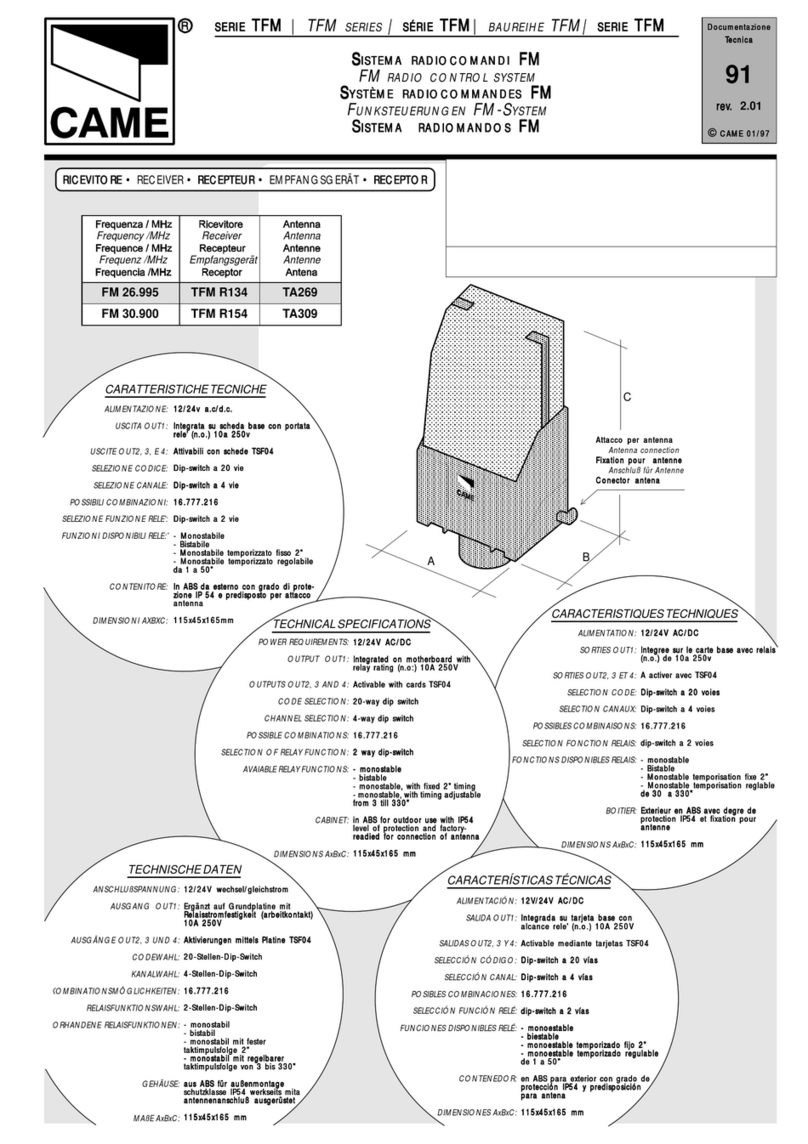

Figure 1: RECOMEC13 Figure 2: RECOMEC13V2

4.2 Product Configurations

The exact product configuration may vary depending on your order and your technical requirements.

Ferrovac strongly recommends ordering pre-wired configurations, normally equipped with UHV

compatible coaxially shielded cables of your specified length and termination.

Figure 3: RECOMEC13 room

temperature version wired up with

0.5mm OD 50 Ohm coax cables.

Figure 4: RECOMCREC13V2 low

temperature version with clamping

mechanism for improved thermal contact

Operating Instructions

[Product Title]

Page 9of 20

4.3 Specifications

The RECOMEC13 and RECOMCREC13 sample holders are designed to apply multiple electrical signals

to flag style sample holders of our product range SHOM, in particular SHOMEC13.

Compatibility with sample holders:

For details of sample holders with electrical contacts, please refer to the Manual_SHOMEC13.

RECOMEC13 sample receivers can also accept “normal” flag style plates such as the slotted 3S-

version for reproducible positioning or the plates with tapped holes metric M1.4.

4.4 Technical Data (all versions):

•Number of electrical contacts: 13

•Max diameter of contact wires/ coax cable central conductor: 0.2mm

•Max coax shield diameter: 0.65mm

•Max coax OD of outer jacket: 0.8mm

•Featuring 3 positioning spheres made of Ruby.

•Contact spring material: CuBe2 coated with 1-2µm gold over non-magnetic diffusion barrier.

•Electrical isolators: PEEK

•Cable strain release material: CuBe2

•UHV compatible adhesives: Epotek H70 and H20

•Safe operating voltage range: Depends on wiring. Please contact us for details

•Max current per contact: Depends on wiring. Please contact us for details

•Max operation temperature: 180°C

•Min operation temperature: <10K

Figure 5: SHOMEC13

available in varied materials

Figure 6: SHOMEC13(DTMO)

with pre-installed DT670 Si-

diode temp. sensor

Figure 7: Possible application

example with CERNOX and

integrated heating

Figure 8: SHOM(3S) available

in a variety of materials

Figure 9: SHOM(3T) available

in a variety of materials

Operating Instructions

[Product Title]

Page 10 of 20

Note: Factory wiring with a preconfigured set of cables is mandatory. Cable sets must be ordered as

separate items and can be tailored to your required configuration and length.

Coax cable reference:

https://www.rotronik-kabel.com/app/download/8837411/01.09.01_Datenblatt_Extern_Miniatur_Koax_PTFE_PFA_01012022.pdf

•Inner conductor: Cu-strand, silver plated, 0,014 mm2, (7 x 0,050 mm)

•Dielectric: PFA (Teflon®)

•Shield: Cu-braid, silver plated

•Outer jacket: PFA (Teflon®)

•Temperature range -200°C bis +180°C

•Max. voltage: 250 V (VAC)

•Impedance: 50 Ohm

Ferrovac Part No.: 60498

Set of 13 coax cables, Ferrovac reference: IVWCOAXEC13UNT1000

4.5 Specifications of individual Versions

Technical Data:

RECOMEC13(ST):

Sample receiver with 13 electrical contacts for common room temperature applications in UHV.

•Housing material: Stainless steel 1.4301 (AISI304)

•Cover plate with leaf spring: Stainless steel 1.4310

•Contact block cover: Stainless steel 1.4310

•Fasteners: Molybdenum and stainless steel A4

•Magnetic properties: Can be slightly ferromagnetic.

•Max bakeout temperature: 180°C

RECOMEC13(CB):

Non-magnetic sample receiver with 13 electrical contacts for variable temperature applications in

UHV.

•Housing material: CuBe2 (2.1247)

•Cover plate with leaf spring: CuBe2 (2.1247)

•Contact block cover: CuBe2 (2.1247)

•Fasteners: Molybdenum

•Magnetic properties: nonmagnetic

•Max bakeout temperature: 180°C

Operating Instructions

[Product Title]

Page 11 of 20

RECOMCREC13V2:

Cryo sample receiver with 13 electrical contacts featuring a clamping mechanism for improved

thermal contact of the sample plate.

•Housing material: CuBe2 coated with 1-2µm gold over non-magnetic diffusion barrier.

•Cold plate material: Cu-OFE CuBe2 coated with 1-2µm gold over non-magnetic diffusion

barrier.

•Cover plate with leaf spring: CuBe2 coated with 1-2µm gold over non-magnetic diffusion

barrier.

•Contact block cover: CuBe2 coated with 1-2µm gold over non-magnetic diffusion barrier.

•Compression bracket: CuBe2 coated with 1-2µm gold over non-magnetic diffusion barrier.

•Locking Screw: Titanium Grade 2

•Fasteners: Molybdenum and stainless steel A4

•Max bakeout temperature: 180°C

Caution!

The specification may change if upgrades or accessories are mounted to the main product.

Operating Instructions

[Product Title]

Page 12 of 20

5. Unpacking

Before unpacking, optically inspect the parcel. If any damage is found, take pictures of the parcel, and

send them to Ferrovac immediately. Check package contents for completeness according to the

delivery note or commercial invoice. Any damage or missing items must be reported to Ferrovac within

one week of delivery.

Caution!

• Ensure enough workspace on a clean table for unpacking and inspection

• Some Ferrovac products are shipped under UHV! Sudden uncontrolled venting can cause

damage to pumps and valves

• Read manuals carefully before using any device

• Never expose any component of the product/system to physical shock or aggressive

chemicals

• CF-Flange knife edges and edge-welded bellows are particularly vulnerable, any damage to

these parts may result in a complete failure of the vacuum integrity

Caution!

This product is designed for use in an ultra-high vacuum environment and is cleaned to UHV

standards.

• Never touch the product with bare hands or unclean gloves.

• Explicitly place the product on adequately clean surfaces and use ultrasonically cleaned tools

free of any fat or grease to work on the product.

• Do not leave the product unprotected from dust under atmospheric conditions for a prolonged

period of time.

You are receiving your RECOMEC13 product in a shockproof, transparent plastic box (Figure 10)

Before removing the sample receiver from its

box, visually inspect it for any signs of damage

that may have occurred during transport.

Watch out for loose parts. Before unpacking,

take photographs to document the condition

of the product upon receipt.

Figure 10

Operating Instructions

[Product Title]

Page 13 of 20

Caution!

RECOMEC13 sample receivers are delicate scientific equipment and should be handled by

personnel skilled in the field. It is strongly recommended to keep the product in its original

shockproof foil box until you are fully prepared for installation.

6. Installation

6.1 Mounting

You can mount RECOM(CR)EC13 sample receivers to their support in two ways:

•From the top using the two countersunk through holes for metric M2 screws (Figure 11)

•From the bottom using the two threaded holes for metric M2 screws (Figure 12)

6.2 Wiring

Ferrovac sells RECOMEC13 and RECOMCREC13 sample receivers prewired with a set of 50 Ohm

coaxial cables.

Wiring of these sample receivers requires special “watchmakers’ skills” and experience in assembling

very small devices.

IVWCOAXEC13: Bespoke set of cables must be ordered seperately - factory wiring is however

mandatory.

Caution!

Ferrovac denies all warranties and liabilities for damaged parts resulting from an attempt to

self-wire RECOM(CR)EC13 sample receivers. Any modifications or attempts to self-repair leads

to a cancellation of warranties.

Please contact Ferrovac in case of any failure of the unit or required modification of the wiring.

Figure 11: top mounting

Figure 12: bottom mounting

Operating Instructions

[Product Title]

Page 14 of 20

7. Operation

The following instructions apply under the assumption that the sample receiver was installed inside a

UHV system equipped with a sample transfer system for flag style plates (SHOM).

As the insertion and extraction of flag style sample holders with electrical contacts is a delicate

operation in general, Ferrovac recommends performing this operation only with superior quality

Ferrovac wobble sticks. Case by case, well aligned MD-Series miniature linear rotary feedthroughs may

also be a viable solution.

Caution!

•Handling flag style plates with wobble sticks or other suited transfer arms always

requires good visibility to the sample exchange positions!

•Make sure that the chamber flange for the wobblestick is well aligned to the flag of the

sample plate!

7.1 RECOMEC13

Sample handling with WM40 single shaft wobble stick and GRABSHOM end effector:

Insert the sample holder into the RECOMEC13.

Push gently forward until you feel the snap-in of

the slits on the ruby spheres.

The sample is in correct position when the rear

edge of the plate is flush with the receiver

housing.

Perform a 90° rotation in either direction to

unlock the sample holder from the grabber.

Withdraw the wobble stick carefully.

Figure 13: Sample insertion

Figure 14: Unlocking sample

Figure 15: Releasing sample.

Operating Instructions

[Product Title]

Page 15 of 20

Figure 16: Angular misalignment

Please note: The deviation error of the wobble stick axis relative to the insertion direction of the

sample receiver must be <1° when using the GRABSHOM end effector.

Sample handling with WMG40 dual shaft wobble stick and PGWMS(OM) pincer

Insert the sample holder into the RECOMEC13.

Push gently forward until you feel the snap-in of

the slits on the ruby spheres.

The sample is in correct position when the rear

edge of the plate is flush with the receiver

housing.

Open the pincer to release the sample holder.

Withdraw the wobble stick carefully.

Please note: The deviation error of the wobble stick axis relative to the insertion direction of the

sample receiver must be <3.5° when using the PGWMS pincer.

Figure 17: Inserting sample.

Figure 18: Releasing sample.

Figure 19: Retract pincer.

Operating Instructions

[Product Title]

Page 16 of 20

7.2 RECOMCREC13V2

Please perform sample insertion and extraction in the exact same way as described on pages 14/15.

How to lock the sample in a cryo-receiver using a single shaft wobble stick equipped with a

GRABSHOM end effector:

Slide the grabber over the handle of the

locking screw without applying force.

Do not push the grabber in fully. You should

find the position as indicated in Figure 20.

Tighten the locking screw clockwise for 1 full

turn. Do not apply excessive torque or you

might break the locking screw’s handle.

For accessing both, the sample’s

handle and the locking screw, the

flange axis must be aligned 3.875

+-1mm above the mounting

surface of the sample receiver,

i.e., in the middle between the

two handles.

The angular deflection of the

wobble stick axis must be <1°

when using the GRABSHOM end

effector.

The angular deflection of the wobble

stick axis must be <1° when using the

GRABSHOM end effector.

Figure 20: accessing the locking

screw.

Figure 21: locking the sample.

3.875mm

Figure 22: wobble stick axis position

Figure 23: angular deviation

Figure 24: angular deviation, top view

Operating Instructions

[Product Title]

Page 17 of 20

How to lock the sample in a cryo-receiver using a dual shaft wobble stick equipped with a

PGWMS(OM) pincer:

Engage the pincer on the locking screw

without applying force.

Tighten the locking screw clockwise for 1 full

turn. Do not apply excessive torque or you

might break the locking screw’s handle.

Open the pincer to release the locking screw

and retract the wobble stick.

For accessing both, the

sample’s handle and the

locking screw, the flange

axis must be aligned

3.875 +-1mm above the

mounting surface of the sample receiver, i.e., in the middle between the two handles.

The angular deflection of the wobble stick axis must be <3.5° when using the PGWMS pincer.

Figure 25: fetch the locking screw.

Figure 26: fetch the locking screw.

Figure 27: release locking screw

3.875mm

Figure 28: axis position

Figure 29: angular deviation

Operating Instructions

[Product Title]

Page 18 of 20

8. Options and Upgrades

IVWCOAXEC13UNT Set of 13 coaxial cables, white, OD=0.8mm, PFA (Teflon®), unterminated

The EC13 cable kit includes wiring and mounting of 13 miniature coaxial cables for any type of

RECOMEC13 sample receiver.. The basic cable kit has unterminated ends. Choose your cable length

and a preferred connector from the list of options of the RECOMEC13 product.

Figure 30: coax cable Figure 31: fully wired RECOMCREC13V2

UPGRADERECOMCREC13(+DB15F) DB15 female in-vacuum connector for RECOM(CR)EC13 including

assembly

•Connector for use in UHV:

•Material: Peek

•Dimension: 37x12.5x17.5mm

•Temperature range: -50°C to 230°C

•Number of female contacts: 15

•Compliance: Sub-D, DIN 41652, MIL-C-24308

•Including crimp and push connectors

Figure 31: DB15 connector

EFCF40DSUB15 Electrical Feedthrough D-Sub 15 Pin

•Compliance: Sub-D, DIN 41652,

•Pin-Ø: 1.0mm

•Number of pins: 15

•Pin-Material: NiFe, (Au plated)

•Seal: Glass ceramic

•Flange: stainless steel 316L:

•Max. current: 5A per pin

•Continuous current: 3A per pin, all pins

connected.

•Temperature range: -200°C to 230°C

•Leak rate: <5x10-10 mbar-l/s He

Figure 32: Electrical feedthrough DN40CF

Operating Instructions

[Product Title]

Page 19 of 20

SHOMEC13(MO) Sample Holder with 13 Electrical Contacts

The SHOMEC13 features a total of thirteen high-quality spring contacts mounted into an AlN-isolator.

The shape and opening of the top plate and shield cover can be customized to your needs.

•Features three slits for snap-in

•Contact stroke: 0.235mm

•Shield cap widow size: □6x6mm

•Max. temperature: 180°C

Materials:

•Isolators: Shapal M

•Base plate: molybdenum (other materials on request)

•Shield cap: molybdenum (other materials on request)

•Contacts: CuBe2, Gold plated over Ni, slightly

ferromagnetic

•Fasteners: molybdenum (other materials on request)

Figure 33: SHOMEC13

SHOMEC13(MO-DT) Sample Holder 13 Electrical Contacts including DT-670 Si-Diode Temperature

Sensor

The SHOMEC13(MO-DT) in ist standard version features a DT-670 silicon diode placed underneath

the sample mounting plate. To further improve temperature measurement accuracy, the sample

mounting plate can be re-machined to enable direct contact between the temperature sensor and

the sample. This modification can be made at our factory if the customer provides detailed

information about the sample and the planned experiments.

•Features three slits for snap-in

•Contact stroke: 0.235mm

•Shield cap widow size: □6x6mm

•Max. temperature: 180°C

•Including a DT-670 silicon diode temperature sensor

Materials:

•Isolator: Shapal M

•Base plate: Molybdenum

•Contacts: CuBe, Gold plated over Ni, slightly

ferromagnetic

•Shield cap: Molybdenum

Operating Instructions

[Product Title]

Page 20 of 20

9. Return of Defective Items

Please contact Ferrovac before returning any equipment to our Factory. We will provide all necessary

information on how to proceed with the return of defective items.

Important!

Do not return any equipment to our factory without a return of materials authorization!

You are obliged to provide a completed Declaration of Contamination form.

Note: Parcels will not be opend if the Declaration of Contamination is missing.

We will require a completed Declaration of Contamination form and you will be issued a Return of

Materials Authorization (RMA).

10. Downloads

Download the latest version of this manual from www.ferrovac.com. For any suggestions or

questions concerning this manual, please do not hesitate to contact us.

This manual suits for next models

1

Table of contents