2.3 Operation with general DP master . . . . . . . . . . . . . . . . . . . . . 2-32

2.3.1 Starting the bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.3.2 Sending parametrizing data . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

2.3.3 Sending configuration data. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.3.4 Requesting diagnostic information . . . . . . . . . . . . . . . . . . . . . 2-36

2.3.5 Cyclic exchange of data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2.3.6 Summary of implemented functions and

service access points (SAP) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

2.3.7 Bus parameters/reaction times. . . . . . . . . . . . . . . . . . . . . . . . . 2-39

2.3.8 Transmission times on the PROFIBUS-DP . . . . . . . . . . . . . . . 2-39

2.4 Type file and device master file (GSD) . . . . . . . . . . . . . . . . . . 2-40

3. Diagnosis

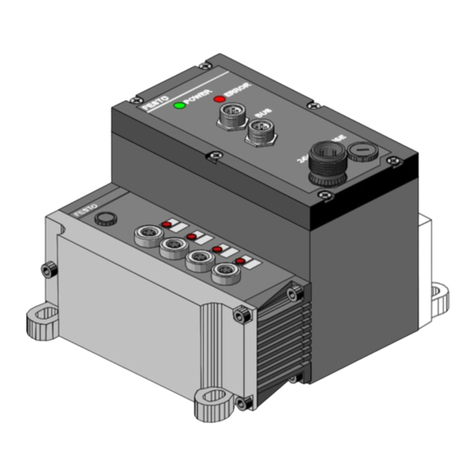

3.1 LED displays on the bus node . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.1 Normal operating status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.1.2 Diagnosis operating voltage POWER or POWER V . . . . . . . . . 3-5

3.1.3 Diagnosis LED BUS ERROR. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2 Testing the valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3 Diagnosis via PROFIBUS-DP. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.3.1 Diagnostic words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.3.2 Diagnostic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.4 Error treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.4.1 General DP master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.4.2 Siemens SIMATIC S5/S7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.5 STEP 7 V4.x - Online diagnosis via diagnostic buffer. . . . . . . 3-21

3.6 Short circuit/overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.6.1 Output module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.6.2 Sensor supply at an input module . . . . . . . . . . . . . . . . . . . . . . 3-25

A. Technical specifications

A.1 Technical specifications of fieldbus node CP FB13-E. . . . . . . . A-3

A.2 Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Contents and general safety instructions

IV CP FB13-E 9904b