4

E213252 2 X 3.0 kW 200-240 1 2+G Terminal Block 4.2 – 6.1 21.3—25.5 14.0 gal/53 lit

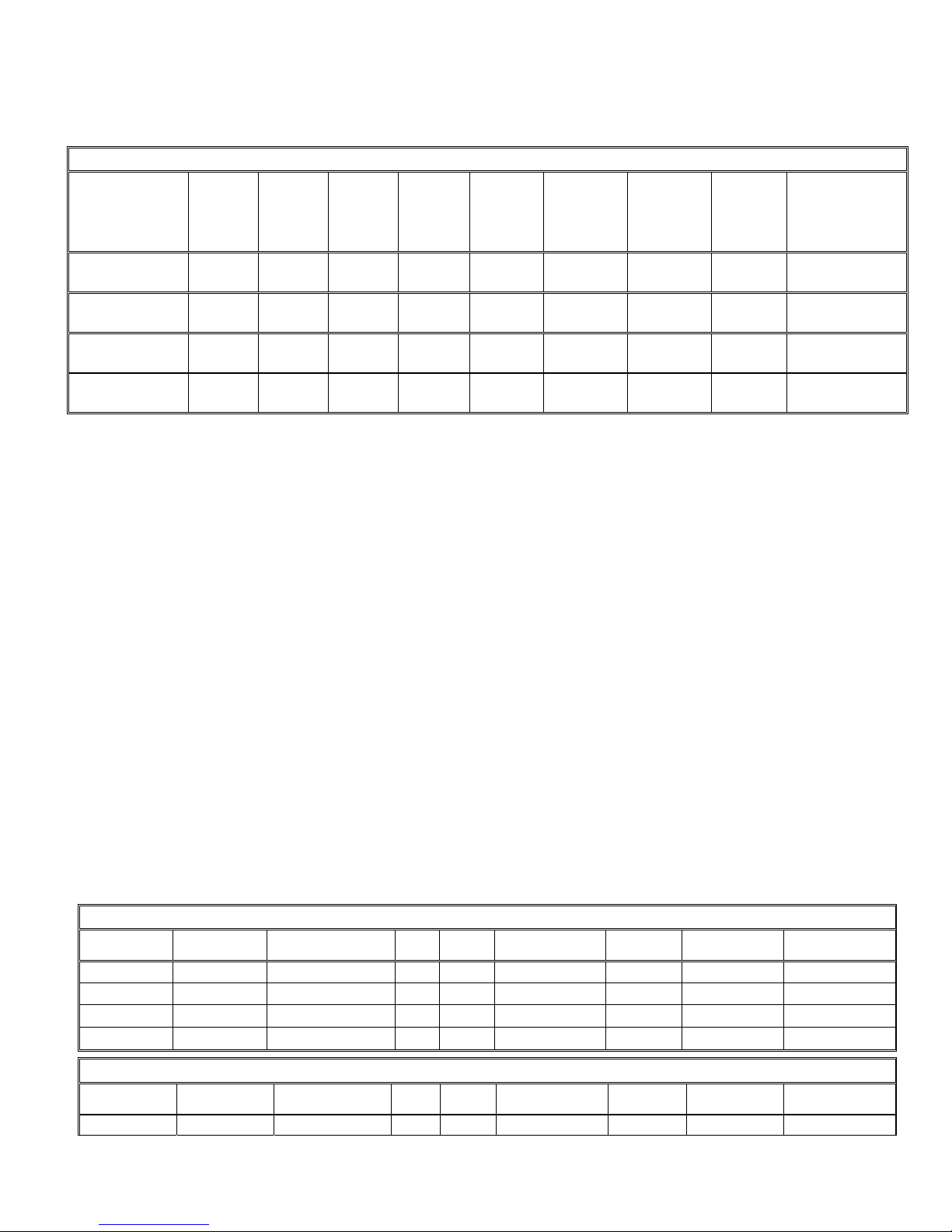

3-liter airpot version, Optional Stainless Steel Brew Basket

Electrical Configurations CBS_2131XTS—Single 3 liter airpot version [Optional: Stainless Steel Brew Basket]

Configuration

Code

Heater

Configuration Voltage Phase Wires

Electrical

Connection KW Maximum Amp

Draw

Gallon/Hour

(3 liters per batch)

E213153M 1 X 1.5 kW 100 - 120 1 2+G NEMA 5-15P 1.1 – 1.6 10.9 – 13.0 3.9 gal/14.8 lit

E213154M 1 X 1.7 kW 100 - 120 1 2+G NEMA 5-15P 1.3 – 1.8 12.3 - 14.7 4.4 gal/16.7 lit

E213151M 1 X 2.3 kW 100 - 120 1 2+G NEMA 5-20P 1.7 – 2.4 16.5 - 19.7 5.8 gal/22 lit

E213157M 1 X 3.0 kW 200 - 240 1 2+G Cord/No Plug 2.2 – 3.1 10.9 – 13.0 7.7 gal/29.1 lit

Electrical Configurations CBS_2132XTS—Dual 3 liter airpot version [Optional: Stainless Steel Brew Basket]

Configuration

Code

Heater

Configuration Voltage Phase Wires

Electrical

Connection KW Maximum

Amp Draw

Gallon/Hour

(3 liters per batch)

E213251M 2 X 2.3 kW 200-240 1 2+G Terminal Block 3.3 – 4.7 16.5 - 19.7 11.5 gal/43.5 lit

E213252M 2 X 3.0 kW 200-240 1 2+G Terminal Block 4.2 – 6.1 21.3—25.5 14.0 gal/53 lit

1-gallon airpot version, Standard Polymeric Brew Basket

Electrical Configurations CBS_2131XTS—Single 1 gallon airpot version [STANDARD: Polymeric Brew Basket]

Configuration

Code

Heater

Configuration Voltage Phase Wires

Electrical

Connection KW Maximum

Amp Draw

Gallon/Hour

(1 gallon per batch)

E213152 1 X 2.3 kW 100 - 120 1 2+G NEMA 5-20P 1.7 – 2.4 16.5 - 19.7 5.8 gal/22 lit

E213158 1 X 3.0 kW 200 - 240 1 2+G Cord/No Plug 2.2 – 3.1 10.9 – 13.0 7.7 gal/29.1 lit

Electrical Configurations CBS_2132XTS—Dual 1 gallon airpot version [STANDARD: Polymeric Brew Basket]

Configuration

Code

Heater

Configuration Voltage Phase Wires

Electrical

Connection KW Maximum

Amp Draw

Gallon/Hour

(1 gallon per batch)

E213253 2 X 3.0 kW 200-240 1 2+G Terminal Block 4.2 – 6.1 21.3—25.5 14.0 gal/53 lit

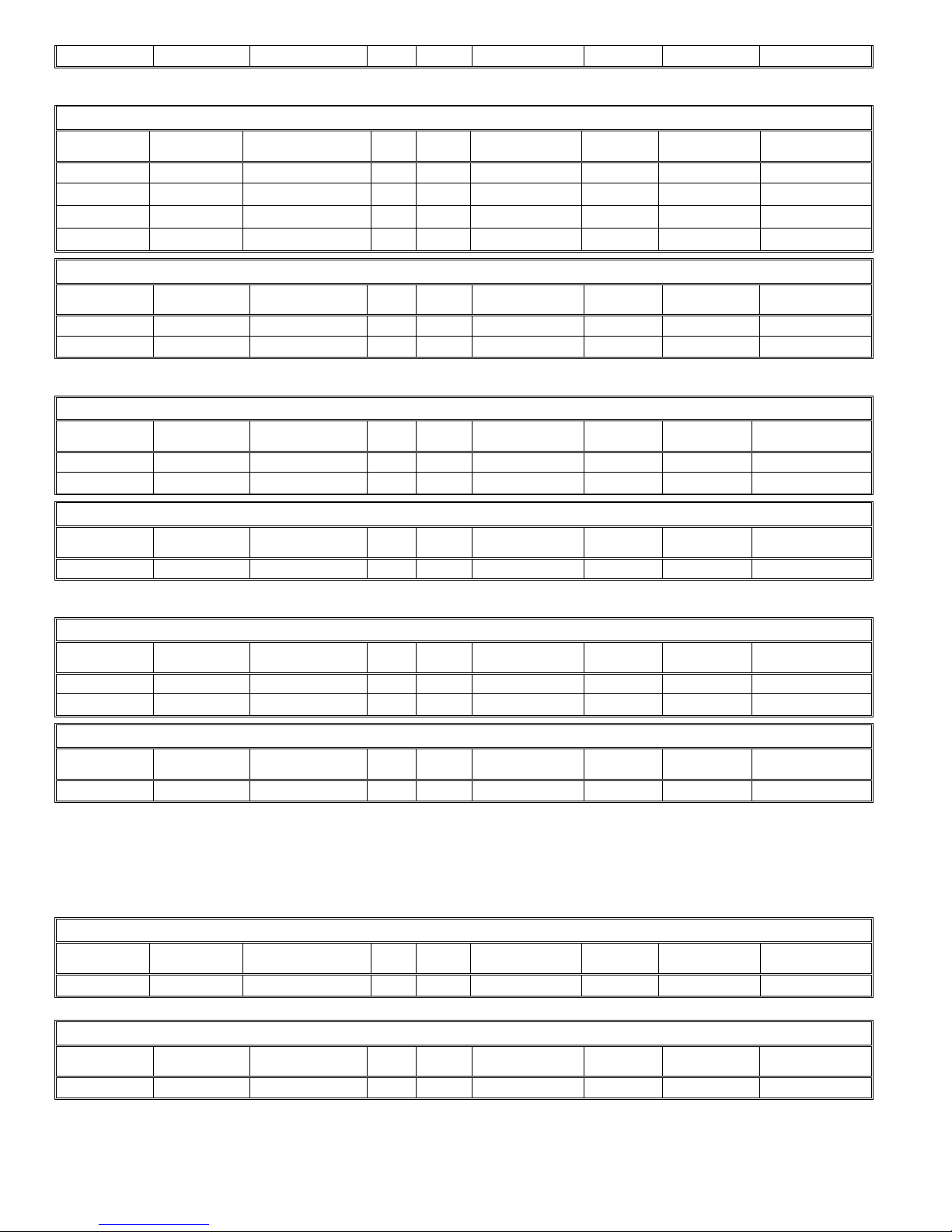

1-gallon airpot version, Optional Stainless Steel Brew Basket

Electrical Configurations CBS_2131XTS—Single 1 gallon airpot version [Optional: Stainless Steel Brew Basket]

Configuration

Code

Heater

Configuration Voltage Phase Wires

Electrical

Connection KW Maximum

Amp Draw

Gallon/Hour

(1 gallon per batch)

E213152M 1 X 2.3 kW 100 - 120 1 2+G NEMA 5-20P 1.7 – 2.4 16.5 - 19.7 5.8 gal/22 lit

E213158M 1 X 3.0 kW 200 - 240 1 2+G Cord/No Plug 2.2 – 3.1 10.9 – 13.0 7.7 gal/29.1 lit

Electrical Configurations CBS_2132XTS—Dual 1 gallon airpot version [Optional: Stainless Steel Brew Basket]

Configuration

Code

Heater

Configuration Voltage Phase Wires

Electrical

Connection KW Maximum

Amp Draw

Gallon/Hour

(1 gallon per batch)

E213253M 2 X 3.0 kW 200-240 1 2+G Terminal Block 4.2 – 6.1 21.3—25.5 14.0 gal/53 lit

Designs, materials, specifications, physical dimensions, firmware and software protocol for equipment or replacement parts are subject to review and change by FETCO

without notice

Specifications-CE

3-liter airpot version, Standard Polymeric Brew Basket

Electrical Configurations CBS_2131XTS—Single 3 liter airpot version [STANDARD: Polymeric Brew Basket]

Configuration

Code

Heater

Configuration Voltage Phase Wires

Electrical

Connection KW Maximum Amp

Draw

Gallon/Hour

(3 liters per batch)

E213157 1 X 3.0 kW 200 - 240 1 2+G Cord/No Plug 2.2 – 3.1 10.9 – 13.0 7.7 gal/29.1 lit

Electrical Configurations CBS_2132XTS—Dual 3 liter airpot version [STANDARD: Polymeric Brew Basket]

Configuration

Code

Heater

Configuration Voltage Phase Wires

Electrical

Connection KW Maximum

Amp Draw

Gallon/Hour

(3 liters per batch)

E213252 2 X 3.0 kW 200-240 1 2+G Terminal Block 4.2 – 6.1 21.3—25.5 14.0 gal/53 lit

3-liter airpot version, Optional Stainless Steel Brew Basket