Go to fetco.com for the latest versions of all information Page 7User Guide & Operator instructions MBS-1221 P202Re0August 2021

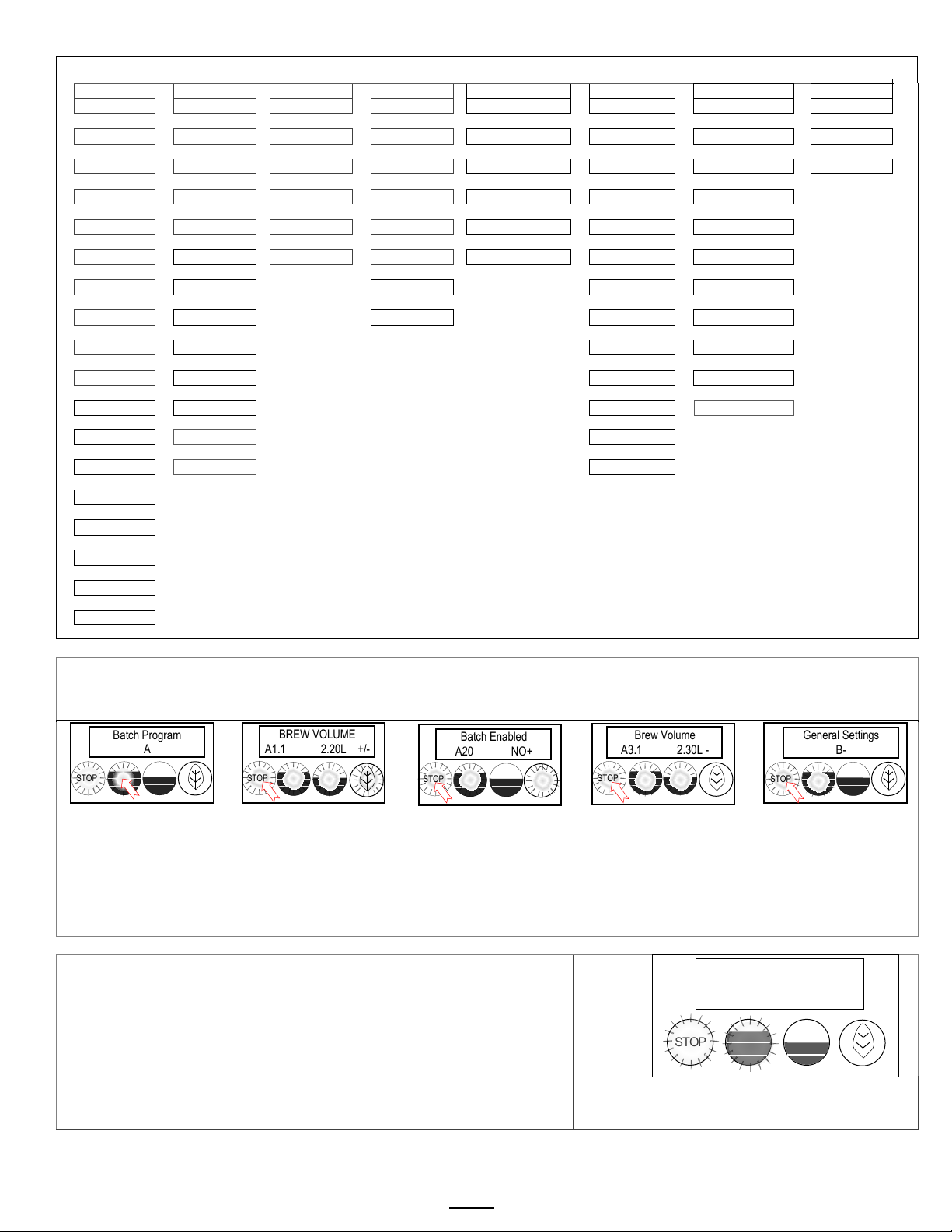

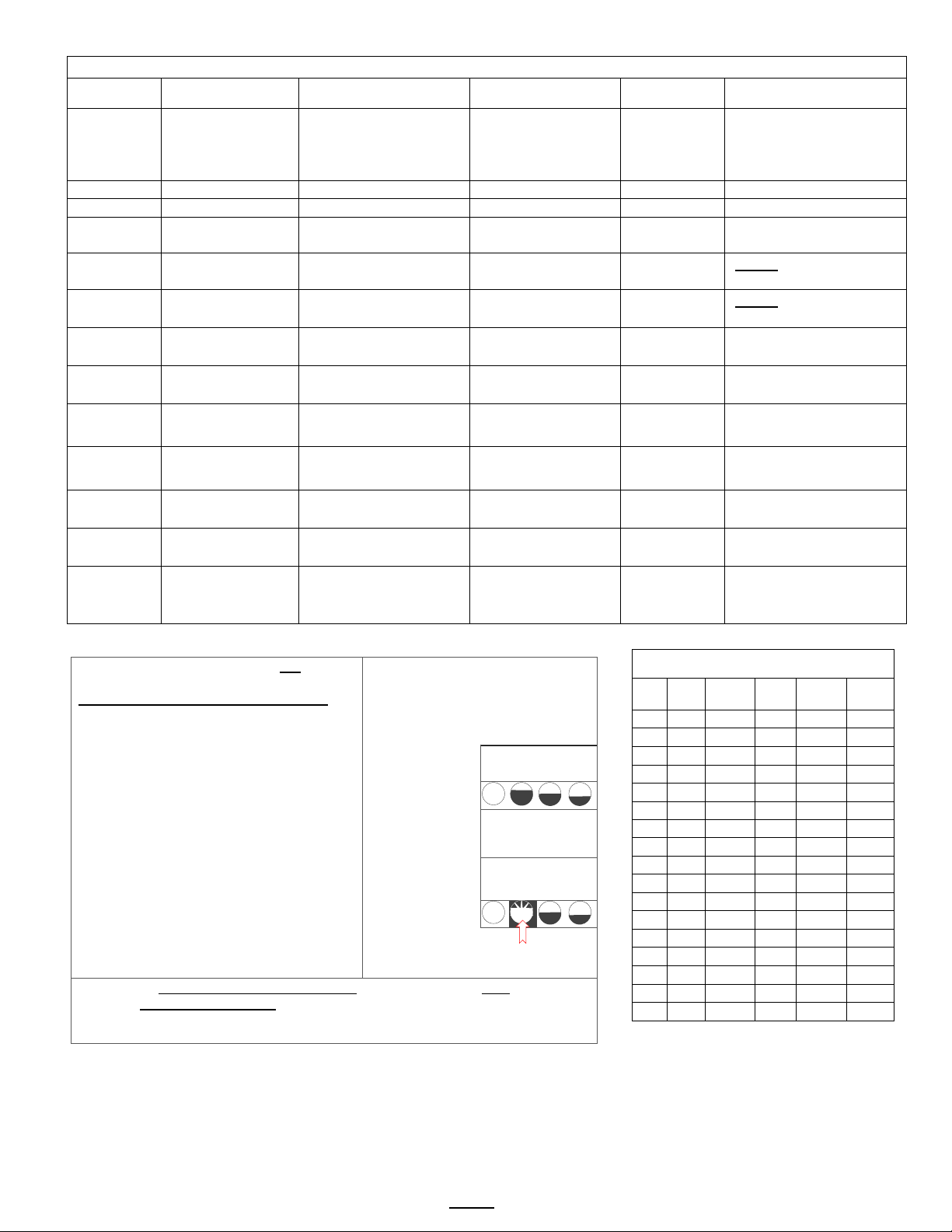

Brewer Operation Control Settings, Adjust Brew Flow Rate

POSITION Program Items Factory set Default Programming Range

Increments Notes

B1 Tank Temp.

NOTE:

Units are Celsius by

170° to 207°F

77° to 97°C

1.0°F

0.5°C

Chart to correct for high

altitude below

B4

YES YES/NO

To display HW tank

temperature on screen

B5

Units of Measure

TEMPERATURE

° Fahrenheit Fahrenheit/Celsius C/F

NOTE: Overwrites user

settings (see page 9)

B6

L LITERS Liters/Gals/Ounces L/Gal/Oz

NOTE: Overwrites user

settings

(see page 9)

B7 Customer Name Off NO or YES For name on screen

B7 Customer Name (only if above is “ON)

A-Z;a-z;0-9 16 characters total

B9 Demo Mode OFF DEMO ON/OFF

Demonstrates the controls for

training. Disables all

B10 Eco Mode Off ON/OFF YES/NO

If Selected: Lowers hot water

tank temperature after preset

B11 Eco Idle Time

(turns on if B10 active) 1Hr 1-6 hours 1 hour Time of inactivity to go into

ECO Mode

B12 Eco Idle Temp

(turns on if B10 active) 169°F 158-176°F 1 degree Temperature that hot water

tank is lowered to

B13 Filter Life OFF ON/OFF YES/NO

Water filter life is accessed in

G-Counters. This is user set

and will display indicator to

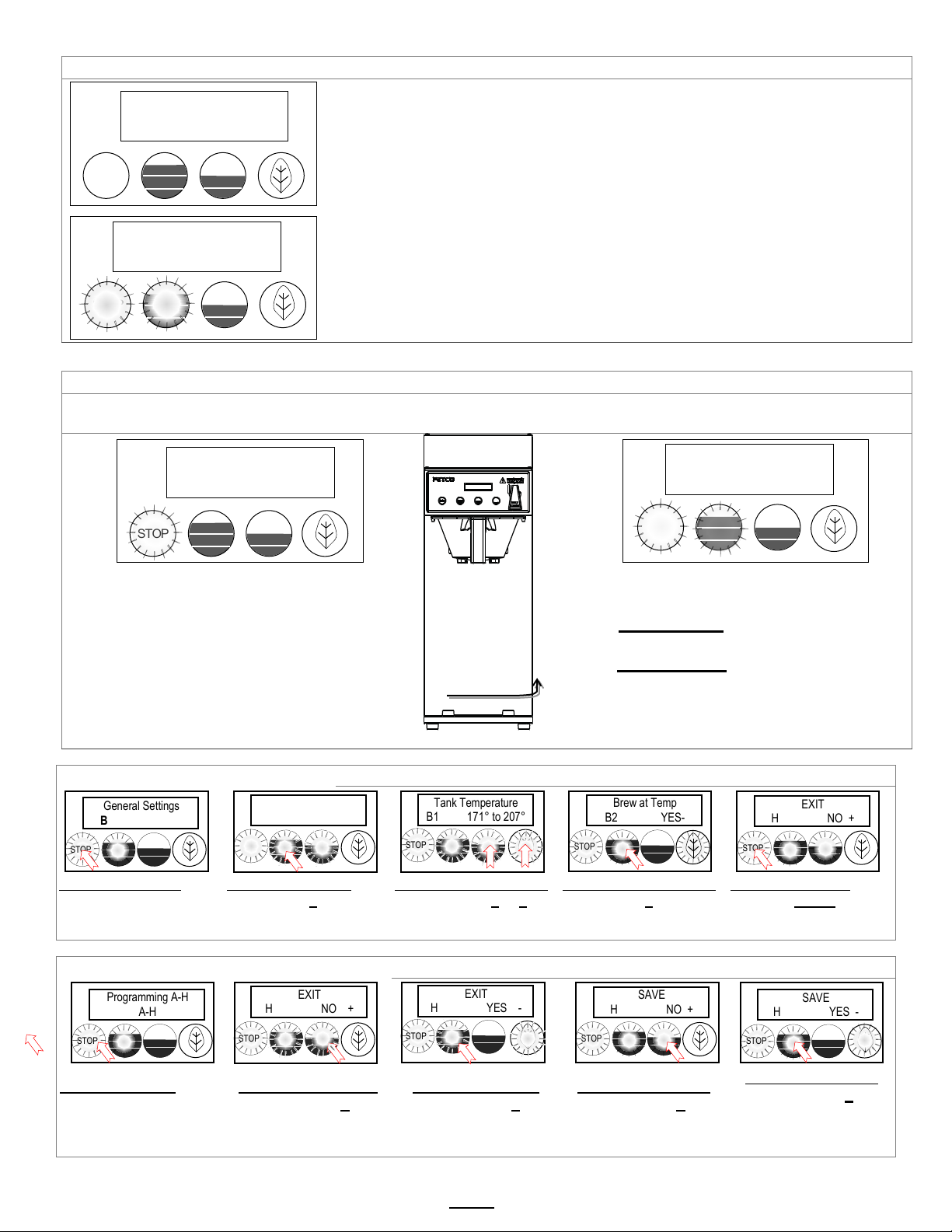

BREW AT TEMPERATURE DEFINITIONS

DEFAULT: BREW AT TEMP: “ON”

(FACTORY DEFAULT FOR BREWER)

“BREW at TEMP:

-Batch will not start if tank temperature

is below set point.

-Display will show “HEATING”

and hot water tank temperature

The “BREW START” entry buttons will not

illuminate until the hot water tank reaches the

selected temperature.

Notifications shown on screen:

TEXT: HEATINGTank above 87°C/189°F-

will allow brew at low temperature.

Extracted tea flavor may be affected

TEXT: L. HEATTank above 76°C/169°F-

will allow brew at low temperature.

Tea flavor will be noticeably affected

Tank temp

STOP is not lit

& BREW START

buttons not lit.

and are disabled.

Batch menu

button(s ) will

illuminate and

“READY”

on screen when hot

water tank

temperature is at

brew temp setpoint.

FETCO

Ready to Brew

USER SELECTABLE OPTION: BREW AT TEMP: OFF

(Not recommended) Unit will operate at reduced temperature

Allows brewing at any temperature above 169°F/76°C

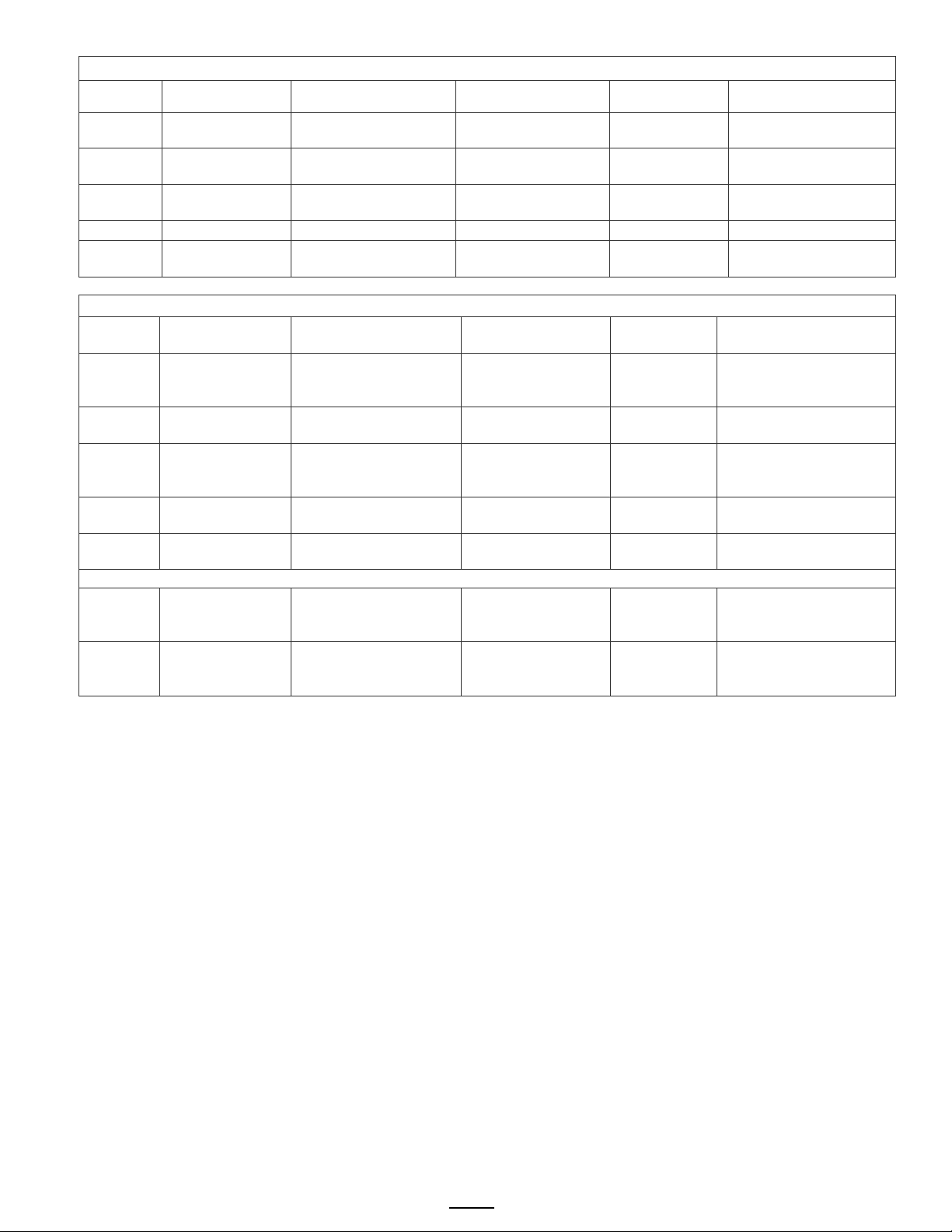

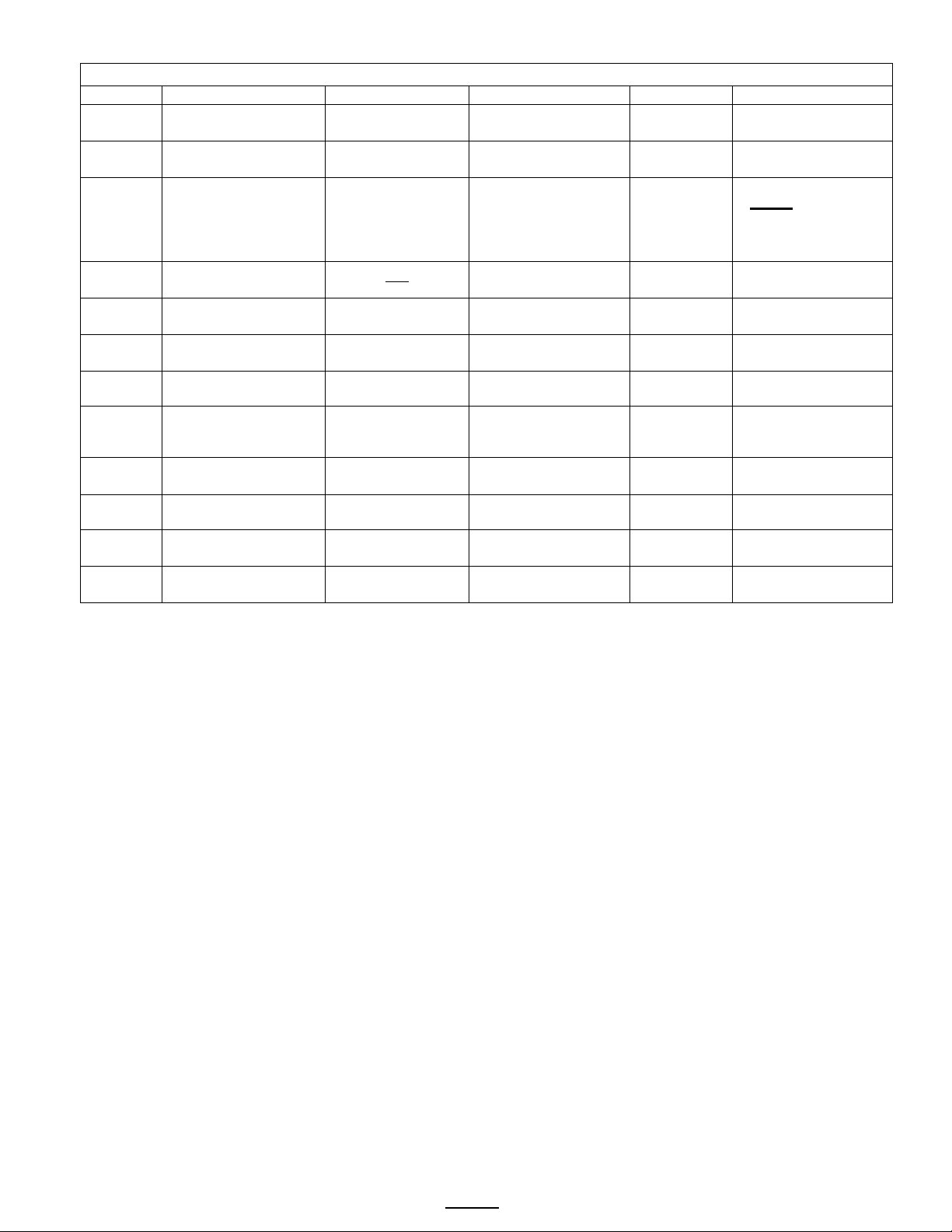

Chart to correct for altitude for boiling point

in tank water temperature.

[ft] [m] Suggested

Setting[°F]

Boiling

point[°F]

Suggested

Setting[°C]

Boiling

point [°C]