FFE Fireray 5000 Specification sheet

Fireray 5000

Technical notes

1. Versions of System Controller

There are 3 versions of the System Controller:

Mark 1, this has 5 LEDs above the LCD window. It can only support 1 Detector. This can be identified by

the fact there are 3 empty ports on the top of the First Fix PCB. These were only made for about a year

and if you come across any, it is a good idea to replace them, whether they are faulty or not. They have

a ‘flexi cable’ which connects the Controller to the First Fix PCB which is very flimsy and easily damaged.

Needs to be set to ‘Hi A’ to do an alignment (it can take over 20 minutes in Lo A), does not have the ‘Find’

function, used to pick up the number of Detectors fitted and has a temperature function (which is in the

Detector). There isn’t an Event Log on this Controller. Do not press the ‘Spanner’ function when in the

Engineering menus as this will un-align the Detector.

Mark 2, this has 5 LEDs above the LCD window. It can support 4 Detectors, but there are only one set

of relay outputs, Fire and Fault, for all the Detectors, so the engineer will not know which Detector gave

an activation unless that Detector is still in Fire or Fault. There isn’t an Event Log on this Controller and you

need to use ‘Hi A’ to do a commissioning. If you get random faults on this Controller, the comms between

the Controller and Detector can get out of Sync and fail for a few seconds, before starting again. Fitting the

Mark 3 Controller will fix this issue. As with the Mark 1 Controller, there is a Temperature function (which

is in the Detector). Do not press the ‘Spanner’ function when in the Engineering menus as this will un-align

all the Detectors connected to the Controller.

Mark 3, this has 3 LEDs above the LCD window. It can support 2 Detectors and has a Fire and a Fault

relay for each of the 2 Detectors. The Controller selects ‘Hi A’ when in a commissioning mode and has an

Event Log. It does not support the Temperature Function which is on the older Detectors.

There are also Simplex and Apollo Analogue Addressable Mark 3 System Controllers. These can be

connected straight to a Simplex or Apollo Loop Bus (which comes from the Fire Panel) without an

interface. The customer selects the Address of the Controller (between 1 and 127), but the rest of the

commissioning is the same as with the Standard F5000s.

There are 2 versions of the Detector:

Mark 1, this Detector can be identified by two ‘prongs’ which protrude from the bottom of the Detector

and connect to the First Fix PCB. This Detector has a Software Version which is lower than 3. It is

compatible with the Mark 3 version of the Controller.

Mark 2, this Detector can be identified by the ‘flying lead’ which connects to the First Fix PCB. This

Detector as a Software Version of above 3. It is compatible with the older Controllers, but if used with

the Mark 1 or 2 Controller, the Temperature function will read -40 (this will not affect the operation of the

Detector). There have been two Software Versions, 3.5 and 3.6 (the current version). 3.5 does not work

with the older Controllers, it will give a comms (E-01) after a short period of time. 3.5 was only made for

about 6 months, so there shouldn’t be any of these Detectors left that have not been installed.

The Controller will indicate (assuming it will power up) which Detector is not working correctly.

2. Fault Codes explained:

1. E-00: (Code Green)

The System Controller is faulty. There is a comms fault between the Mother and Daughter boards inside

the Controller and it will need to be replaced.

2. E-01: (Code Amber)

There is a comms failure between the Detector and the Controller. If possible, it is a good idea to

work out if the Detector or the Controller is faulty, purely so the engineer does not have to replace the

Detector if it is not necessary.

Tests:

1. Can you see an LED flashing (Red or Amber) on the ‘faulty’ Detector? If Yes, then the cable to the

Detector is OK. If No, either the Detector (or the channel to it) has totally failed or the cable to it

could be broken/damaged. In my experience, I’ve only had cable issues during commissioning.

2. Check the voltage at the appropriate channel on the First Fix PCB. It should be between 11V and

13.5V. If the voltage is less than 11V, then disconnect the cable to the Detector and see if the voltage

goes up (to between 11V and 13.5V). If it goes up, then the fault could be on either the Detector or

Controller (you can work out whether it’s the Detector or Controller which is faulty, but I don’t think

it’s worth going that deep), so both should be replaced.

3. If the voltage stays low after removing the Detector, then the Controller is faulty and only that needs to

be replaced. The alignment data is stored in the Detector, so all the engineer must do is run the ‘find’

function and the Controller will pick up the Detector

Note: If the Controller needs to be replaced and it has 3 or 4 Detectors connected to it, then,

unfortunately, you will need to fit 2 Controllers.

3. E-02: (Code Green)

The ‘find’ function has not been run. You will see this at the commissioning stage and it will follow on from

E-01 (and you may also see E-05).

4. E-03: (Code Amber)

The AGC (Automatic Gain Compensation) has been reached. All Beams have AGC, on the F5000 it

ranges between -50 and +205 (the Detector will automatically re-align itself at +75). A re-alignment will

re-set the AGC to 0 (clearing the fault), but what you need to find out is the reason the AGC limit was

reached.

1. +205 AGC means that the Infra-Red Signal has been dropping and the Detector has boosted the IR

Signal +205 times to try and keep the Signal at 100%. The reason for the IR Signal going down could

be poor installation (at the Detector or Reflector end) or a large amount of air born contamination for

example.

2. -50 AGC means the IR Signal has gone up and had to be reduced -50 times. This is a rare event but

means that the Detector is picking up extra IR Signal. This can be because a shiny object has been

placed very close to or in the Beams ‘Line of Sight’, and this is reflecting signal back to the Detector.

5. E-04: (Code Amber)

If the voltage (measured at the First Fix PCB) going to the Detector is less than 11V use the E-01 tests to

determine with the Detector or Controller is faulty. If you get a voltage between 11V and 13.5V DC, the

Detector is faulty.

6. E-05: (Code Green)

The Detector is not aligned.

Note: Aligned Detectors should not become unaligned but seem to do so for no apparent reason. This

may be a Software bug.

7. E-06: (Code Amber)

Something has blocked the Beam and caused the IR Signal to drop to 0%.

Note: This is a ‘common’ fault in warehouses or buildings where the Beams have a process which can

break the IR Signal during normal operations. It can also happen during commissioning or servicing when

testing the Beams.

8. E-07: (Code Amber)

Something reflective (and this doesn’t always have to be shiny) is either in or near the Beams path and this

has added a small amount of Infra-Red Signal to be added to the IR Signal coming back from the Reflector.

9. E-08: (Code Amber)

AGC (Automatic Gain Control) was not at ‘0’ after an alignment. This should never happen, but if it does,

re-align the Beam or power down for 2 minutes before re-aligning.

10.E-09, E-10 and E-11: (Code Amber)

These failure modes are very rare and are all very similar in cause. Either the Reflector(s) have not been

found due to the wrong number of reflectors being fitted, the Detector trying to align onto the wrong

surface, the wrong distance has been selected (8-50M being the default distance when the range may

need to be set to 100M). If there is no apparent reason for the failure, the Detector may well be faulty.

11.E-12: (Code Red)

The reflector(s) may not have been covered when the ‘tick’ button on the Controller was pressed or the

Infra-Red Signal may not have dropped low enough.

Note: When in ‘Hand’ mode, the signal must drop below 500 when the reflector(s) are blocked. When

the reflector(s) are uncovered you should have a value of over 800 but less than 1200 when in ‘Hand’

mode.

The ‘Hand’ values will never be steady.

12.E-13: (Code Amber)

The reflectors may not have been uncovered when the ‘tick’ button was pressed on the Controller.

Note: When you are at the ‘Set’ function, it is always good to confirm that the person at the reflector(s)

end has covered or uncovered them as required. This is main reason for a failure at this point.

13.E-14: (Code Amber)

This is the most common error when aligning a F5000 and there are several potential reasons which can

give an E-14 error. E-14 basically means the Detector has tried to align onto something other than or as

well as the Reflector(s).

1. Poor ‘line of sight’. Ideally the F5000 needs a 1M diameter clearance down the whole of the Beams

path to align through (and without shiny surfaces near the reflector(s) or that the Beam passes

through).

2. Windows or surfaces which are reflective near the Reflector(s) can cause alignment failures. Passing

close to a shiny surface such as ‘Cling Film’ can cause E-14.

3. A strong Infra-Red source (which can be a light directly above the Detector, the Sun or another Beam)

can cause alignment failure.

A large amount of air born contamination, such as dust, could prevent alignment and result in E-14.

Note: You can overcome an E-14 alignment error by doing a Manual Alignment (which will be explained

in training). If you get E-14 errors, switch on the laser and see where it ends up. If you do successive

alignments the laser always ends up in the same place, it could be that something is drawing the Beam to

that part of the building. Try starting the laser starting the laser offset from the reflector(s). Some lasers are

not very accurate and may be pointing the Detector in the wrong direction, so if the laser always ends up

in the top right position in relation to the reflector(s), try starting it from the bottom left. In the worst-case

scenario, the Detector and or Reflector(s) may need to be moved to a better ‘line of sight’.

14.E-21: (Code Amber)

This error indicates that the power supply to the Controller is too low (typically less than 12V). However,

this rarely happens other than when powering down the Controller. The typically scenario is that you

have E-21 on the screen but with +24V connected. If this occurs, there is an internal power fault on the

Controller and there is nothing that can be done other than replace it (this might also cause E-01 errors to

occur to).

15.E24 and E26: (Code Green)

I’ve not come across E-24 which means the Detector and Controller are not compatible. In theory, this

could only happen when connecting very old and brand-new Detectors and Controllers together. With

E-26, this would be the same as with E-00, there is nothing the customer can do other than replace the

Controller.

Table of contents

Other FFE Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

A-Collection

A-Collection 6302618 installation instructions

BTR

BTR 60.300 Assembly, Installation and Commissioning Instructions

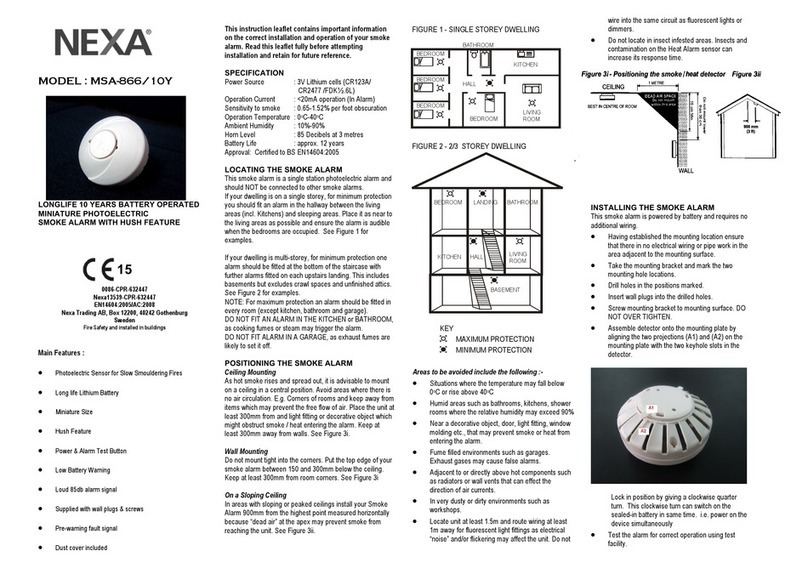

Nexa

Nexa MSA-866/10Y Instruction leaflet

Vega Absolute

Vega Absolute SMART-SS0102 user manual

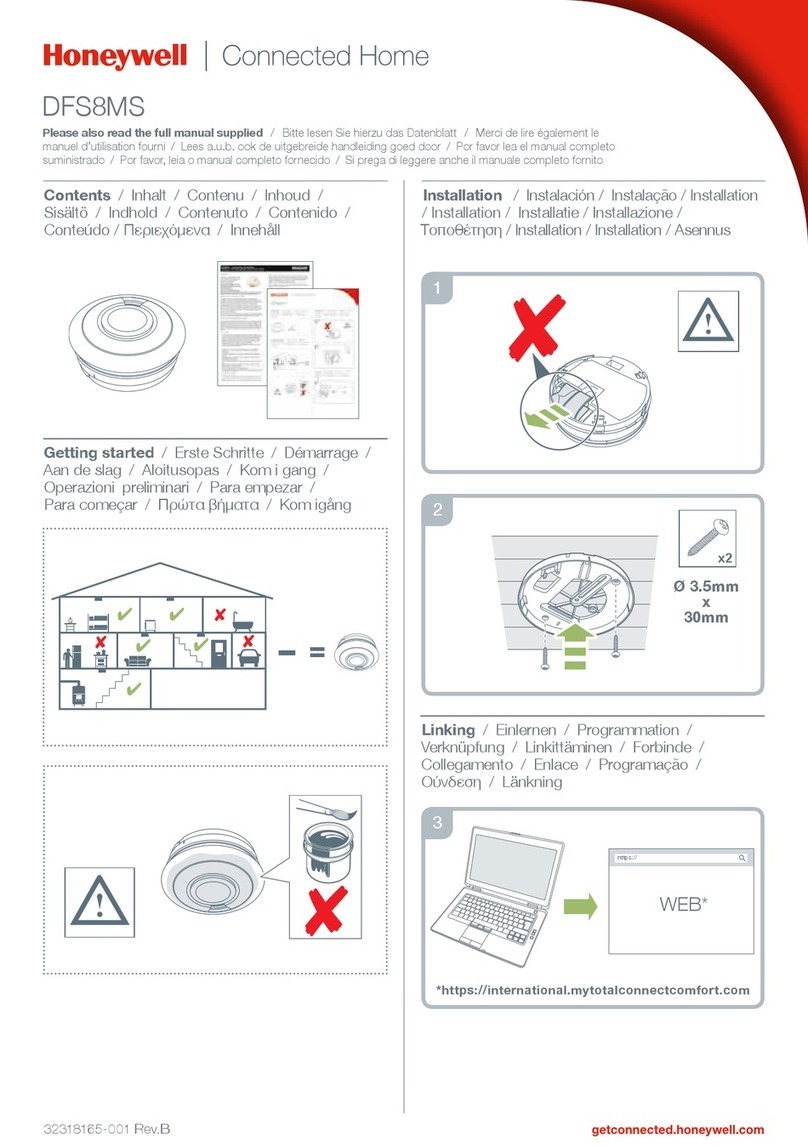

Honeywell

Honeywell MORLEY-IAS MI-LPB2-S2I Installation and maintenance instructions

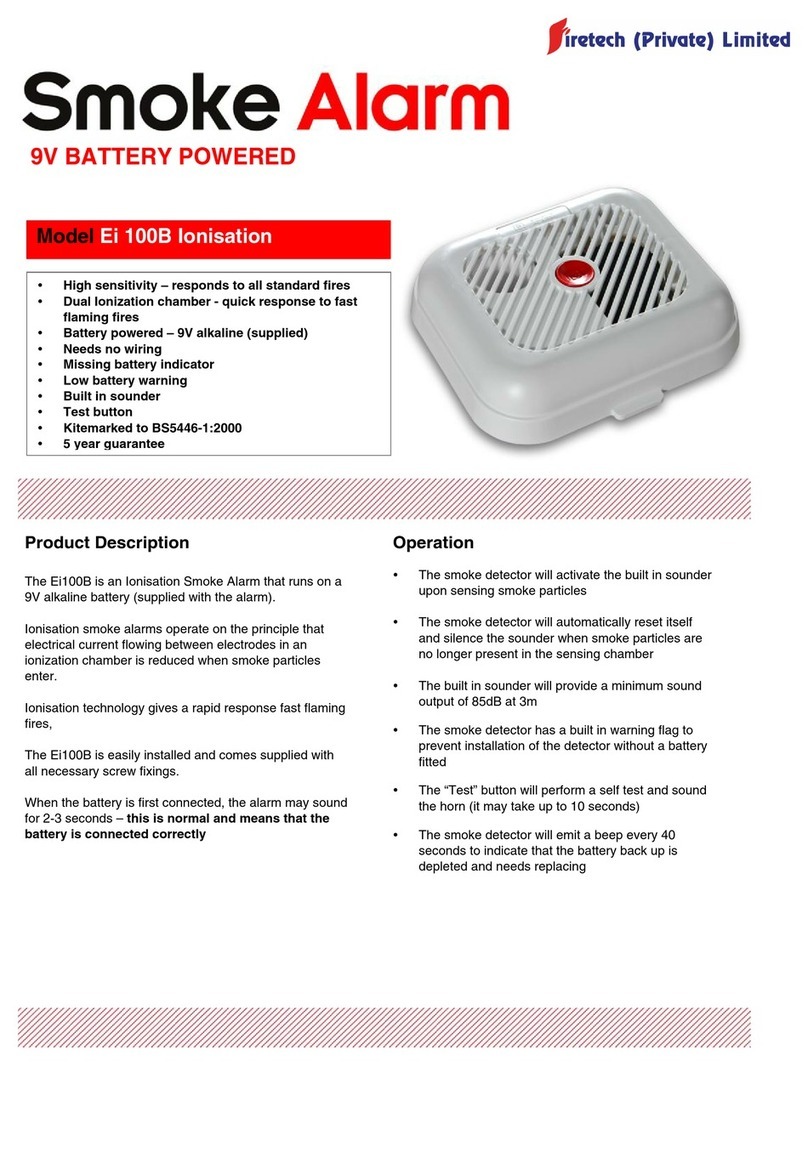

Ei Electronics

Ei Electronics BROOKS EIB160e Series instruction manual