FHP CA CONSOLE series User manual

970-293 Revised 05-12

CA CONSOLE SERIES

Table of Contents

Model Nomenclature......................................................................................................1

Introduction .......................................................................................................................2

Safety Considerations.....................................................................................................2

Inspection, Moving & Storage.....................................................................................2

Installation..........................................................................................................................2

Piping ...................................................................................................................................3

Electrical ..............................................................................................................................3

Cooling Tower/Boiler Applications ...........................................................................3

Earth Coupled Applications ........................................................................................4

Maintenance ......................................................................................................................4

System Checkout .............................................................................................................4

Unit Start-Up......................................................................................................................4

Typical Wiring Diagram..................................................................................................5

Operating Temperatures & Pressures .......................................................................6

Unit Check-Out Sheet.....................................................................................................9

CUC Solid State Controller .........................................................................................10

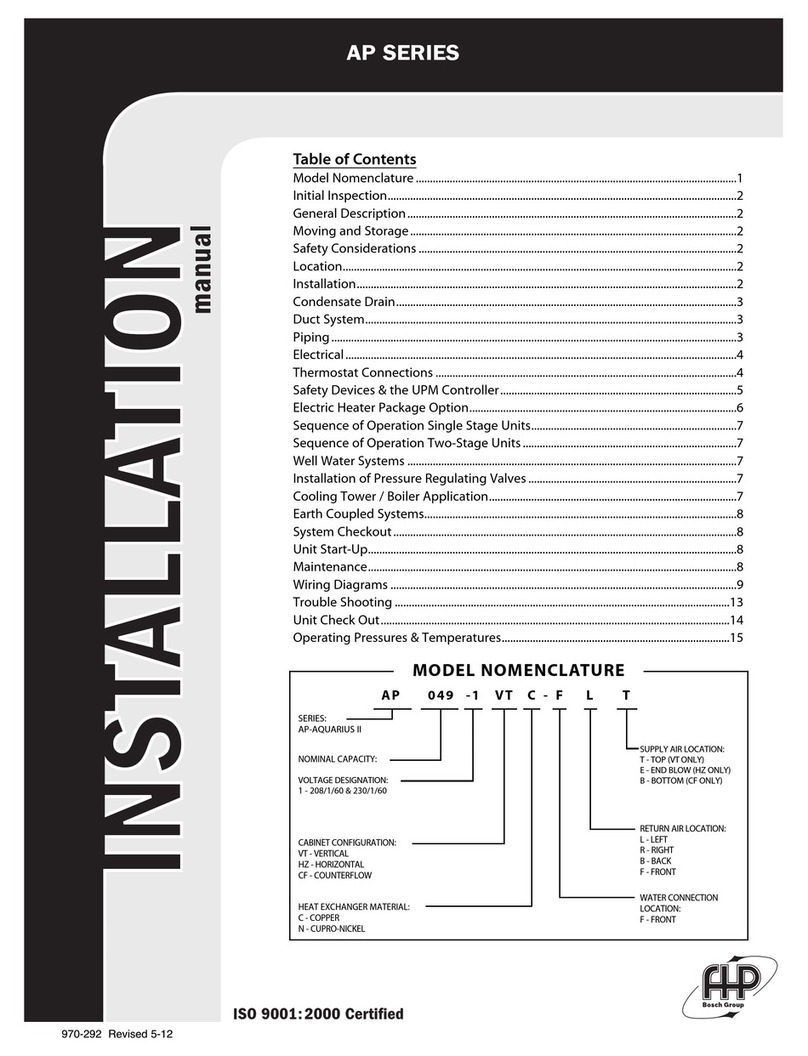

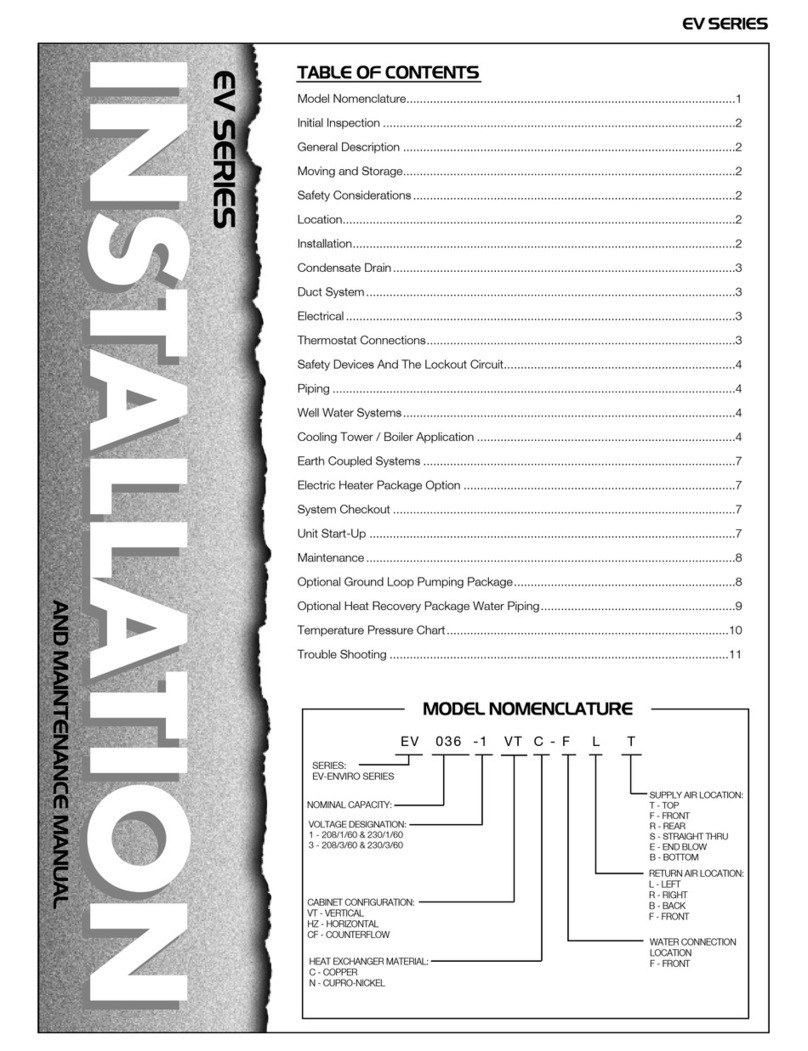

MODEL NOMENCLATURE

SERIES:

CA - R-410A Refrigerant Slope Top

NOMINAL CAPACITY:

VOLTA E DESI NATION:

0 - 115/1/60

1 - 208/1/60 & 230/1/60

2 - 265/1/60

8 - 8-220-240/1/50

CONTROLS:

U - Manual/Auto Change Over (Unit Mounted)

R - Remote Thermostat

S - Master/Slave with Remote Thermostat

NOT USED

HEAT EXCHAN ER

C - Copper

N - Cupro-Nickel

WATER CONNECTION:

L - Left (Standard)

R - Right (Optional)

CA 012 -1UL C- XXX

970-293 Revised 05-12

INTRODUCTION:

The FHP console water source heat pumps are designed

for use as decentralized room terminals that are field

connected to a closed-circuit piping loop within a

structure. Typically these units are installed in perimeter

zones and are ideal for installations where ducted systems

are impractical.

All FHP Console Series units are designed for boiler/tower

systems geothermal closed loop applications and can

operate with fluid temperatures as low as 25°F in heating

and as high as 110°F in cooling. Units are available in 3/4,

1, 1-1/4 and 1-1/2 tons nominal capacity in cooling. Refer

to the unit specification sheet for precise performance

figures at various entering air and water conditions.

NOTE: Console units are designed for indoor installation

in the conditioned space only. Do not install outdoors, in

attics or in any other location that would subject the unit to

extreme temperature or humidity or to corrosive

environments. Doing so will inhibit performance, reliability

and service life of the unit.

SAFETY CONSIDERATIONS:

Installation and servicing of this system can be hazardous

due to system pressure, electrical components and

moving parts. Only trained and qualified service

personnel should install and service this equipment.

Untrained personnel can perform basic maintenance such

as cleaning coils/cabinet or replacing filters.

WARNING: Before performing service or maintenance

operations on system, turn off main power to unit. On

units with unit mounted controls, the On/Off switch DOES

NOT disconnect the unit from main power. High voltage

components or moving parts can cause injury or death.

When working on this equipment, always observe

precautions described in the literature, tags and labels

attached to the unit. Follow all safety codes. Wear safety

glasses and work gloves. Use a quenching cloth for

brazing operations and place a fire extinguisher close to

the work area.

This unit is designed to be operated with the cabinet,

subbase and filter in place. Never operate unit without the

cabinet and filter in place or with open access panels.

Doing so can expose the operator to hazardous voltage

and moving parts and can damage the equipment.

INITIAL INS ECTION, MOVING

AND STORAGE:

Inspect the carton or packaging of each console unit as it

is received at the job site and before signing the freight

bill. Note any damage or shortage on all copies of the

freight bill. Concealed damage must be reported to the

carrier within 24 hours of receipt.

Unit wiring diagrams and Installation/Operation manuals

are provided with each unit. Read these manuals prior to

start up to become familiar with the unit and its

operation.

Note that an Installation/start-up checklist is provided at

the end of this manual to encourage thorough unit check-

out at start-up.

Take care when moving the unit as most of the unit's

weight is located on the left (compressor) end. Always

store and move unit in an upright position. Take care to

protect the unit cabinet and subbase when moving or

storing. Never move or lift unit by its water connections.

If the equipment is not needed for immediate installation,

it should be stored in its original packaging in a clean, dry

area. Units must be moved and stored in an upright

position, never lay the unit on it's side. When storing, do

not stack units.

INSTALLATION:

Before installing the unit, examine each pipe, fitting and

valve; remove any dirt or debris found on or in these

components. Use care when installing the system

components to avoid damage to the cabinet finish or

chassis.

1. After removing the console unit from its packaging

remove the cabinet by removing the cabinet screws

on either side of the unit and lifting the cabinet off

the chassis. Set the cabinet aside and cover it (the

console unit’s packaging can be used for this

purpose).

2. Position the sub base directly on the finished floor.

Make sure the sub base is level (use shims if

necessary). The sub base has a frame that supports

the cabinet and may be secured to wall.

3. Position the chassis onto the sub base. Check and align

electrical, water and condensate connections and

secure to the sub base with 4 screws.

4. Before connecting the unit to water, make sure that

the loop has been properly flushed. After flushing the

system, connect piping or hoses to the proper supply,

return and condensate connections. Refer to the

piping section of this manual for more information

5. Make all necessary electrical connections to the unit.

Refer to the unit wiring diagram and the Electrical

section of this manual.

CAUTION: When making electrical connections to

the unit make sure that the power is disconnected.

Failure to do disconnect power before connecting

power wiring to the unit can result in serious injury or

death and damage to the unit.

6. Make sure the unit’s washable filter is clean and

installed in the subbase. Also make sure that the filter

clip is in place.

7. Reinstall the unit cabinet via locating pins at the top

of the chassis and two screws in the unit subbase.

2CA CONSOLE SERIES

970-293 Revised 05-12

I ING:

SU LY AND RETURN I ING:

The following items should be adhered to in addition to

applicable piping codes.

• A drain valve at the base of each riser to enable

proper flushing of the system at startup and during

servicing.

• Shut-off/Isolation ball valves at the supply and return

connections and unions at each unit to permit proper

flow balancing and unit servicing.

• Strainers at the inlet of each circulating pump.

• Use of teflon tape on threaded pipe fittings to

eliminate water leaks and insure against air entering

the system.

• Flexible hose connections between the unit and the

rigid system to eliminate the possibility of vibration

transmission through the piping.

• Insulation is not normally required on supply and

return piping for boiler tower installations except in

unheated sections or outdoor runs.

• Insulation is required for closed-loop geo-thermal

installations as loop temperatures may fall below the

dew point and can even fall below the freezing point

of water during heating season.

CONDENSATE I ING:

Console units are designed with a blow-through

configuration in the air handling section. This means that

there is positive pressure at the unit drain pan and thus

trapping is not required. Condensate is routed from the

drain pan via a 5/8" non-pressure rated vinyl hose that is

located below the supply and return water connections.

Though horizontal runs of condensate piping are usually

too short to pose problems, horizontal runs should be

pitched at least 1 inch for every 10 feet of piping. Avoid

low spots or unpitched piping, as these areas can collect

sediment and eventually block condensate flow.

Always inspect both internal and external condensate

piping for kinks that could block condensate flow.

HOSE KITS:

When using optional hose kits follow the manufacturer's

recommendations for installation. Never stretch or twist

hoses and never use hoses that show external wear or

damage or are suspected of having damage. Never exceed

the manufacturer's maximum working pressure

recommendations.

ELECTRICAL:

CAUTION: Use only copper conductors for field installed

electrical wiring. Always make sure that the power

disconnect is open before performing service on the

unit's electrical circuits.

Field wiring must comply with local and national fire,

safety and electrical codes. Power to the unit must be

within the operating voltage range indicated on the unit

chassis nameplate or the performance data sheet.

Properly sized fuses or HACR breakers must be installed

for branch circuit protection. See unit chassis name plate

for maximum size.

Each chassis is supplied with a 2 x 4 junction box for

power connection. Inside this box there are 2 pigtail leads

for power wiring. The field ground is to be connected to

the ground connection on the junction box.

On remote thermostat and master/slave units there are

also 5 position terminal blocks for low voltage thermostat

or slave unit connection. On remote thermostat units,

connect the thermostat wires to the low voltage terminal

block. On master/slave units connect the thermostat to

the “Master” terminal block of the lead unit and the “Slave”

terminal block to the “Master” terminal block of the next

unit, daisy chaining the units together as required. Note

that there is no limit to the number of units that can be

connected together in this manner as each unit provides

it's own low voltage power supply.

NOTE: All 208/230 volt (-1 voltage code) units are factory

wired to 230 volts unless ordered otherwise. In 208

voltage applications the transformer wiring may need to

be switched from the 230 volt tap to the 208 volt tap. Cap

all unused leads.

COOLING TOWER/BOILER A LICATIONS:

The cooling tower and boiler water loop temperature is

usually maintained between 50°F and 100°F to assure

adequate cooling and heating performance.

In the cooling mode, heat is rejected from the console

unit into the water loop. A cooling tower provides

evaporative cooling to the loop water thus maintaining a

constant supply water temperature to the unit. When

utilizing open cooling towers chemical water treatment is

mandatory to ensure the water is free from corrosive

elements. A secondary heat exchanger may also be used

between the unit and the cooling tower water. In closed

loop systems such as this it is imperative that all air be

removed from the closed side of the system to insure

against fouling of the heat pump water-to-refrigerant

heat exchanger.

In the heating mode, heat is absorbed from the loop by

the console unit. A boiler may be used to maintain the

loop at the desired temperature.

No unit should be connected to the supply or return

piping until the water system has been completely

cleaned and flushed to remove any dirt, piping chips or

3

CA CONSOLE SERIES

970-293 Revised 05-12

other foreign material. Supply and return hoses should be

connected together during this process to ensure the

entire system is properly flushed. After the cleaning and

flushing has taken place the unit may be connected to the

water loop and should have all valves wide open.

EARTH COU LED SYSTEMS:

Closed loop and pond applications require specialized

design knowledge. No attempt at these installations

should be made unless the contractor has received

specialized training.

Anti freeze solutions are utilized when low evaporating

conditions are expected to occur (I.E.: low loop

temperatures in heating). Typical temperatures are 30°F

fluid temperature in heating and 100°F in cooling.

MAINTENANCE:

1) Filter changes or cleanings are required at regular

intervals. The time period between filter changes will

depend upon type of environment the equipment is

used in. In a single family home, that is not under

construction, changing or cleaning the filter every 60

days is sufficient. In other applications, such as

motels, where daily vacuuming procedures a large

amount of lint, filter changes may need to be as

frequent as biweekly.

2) An annual “checkup” is recommended by a licensed

refrigeration mechanic. Recording the performance

measurements of volts,amps, and water temperature

differences (both heating and cooling) is

recommended. This data should be compared to the

information on the unit's data plate and the data

taken at the original startup of the equipment.

3) Lubrication of the blower motor is not required.

4) The condensate drain should be checked annually by

cleaning or flushing to insure proper drainage.

5) Periodic lockouts almost always are caused by air or

water flow problems. The lockout (shut down) of the

unit is a normal protective measure in the design of

the equipment. If continual lockouts occur call a

mechanic immediately and have them check for:

water flow problems, water temperature problems, air

flow problems or air temperature problems. Use of

the pressure and temperature charts for the unit may

be required to properly determine the cause.

SYSTEM CHECKOUT:

• After completing the installation, and before

energizing the unit, the following system checks

should be made:

• Verify that the supply voltage to the heat pump is in

accordance with the nameplate ratings.

• Make sure that all electrical connections are tight and

secure.

• Check the electrical fusing and wiring for the correct

size.

• Verify that the low voltage wiring between the

thermostat and the unit is correct.

• Verify that the water piping is complete and correct.

• Check that the water flow is correct, and adjust if

necessary.

• Check the blower for free rotation, and that it is

secured to the shaft.

• Verify that vibration isolation has been provided.

• Unit is serviceable. Be certain that all access panels

are secured in place.

UNIT START-U :

1. Set the thermostat to the highest setting.

2. Set the thermostat system switch to "COOL", and the

fan switch to the "AUTO" position. The reversing valve

solenoid should energize. The compressor and fan

should not run.

3. Reduce the thermostat setting approximately 5

degrees below the room temperature.

4. Verify the heat pump is operating in the cooling

mode.

5. Turn the thermostat system switch to the "OFF"

position. The unit should stop running and the

reversing valve should deenergize.

6. Leave the unit off for approximately (5) minutes to

allow for system equalization.

7. Turn the thermostat to the lowest setting.

8. Set the thermostat switch to "HEAT".

9. Increase the thermostat setting approximately 5

degrees above the room temperature.

10. Verify the heat pump is operating in the heating

mode.

11. Set the thermostat to maintain the desired space

temperature.

12. Check for vibrations, leaks, etc...

FREEZE SENSOR

This is optional and can be set to ignore or monitor a freeze

sensor.There are 2 configurable freeze points, 35°F & 15°F.

The unit will enter a soft lock out until the temperature

climbs above the set point and the anti-short cycle time

delay has expired. The freeze sensor may not provide

protection in the case of loss of flow in the heating mode.

A flow switch or pressure differential switch is

recommended to prevent unit operation in case of loss of

flow.

4CA CONSOLE SERIES

970-293 Revised 05-12

UNIT ROTECTION MODULE (U M)

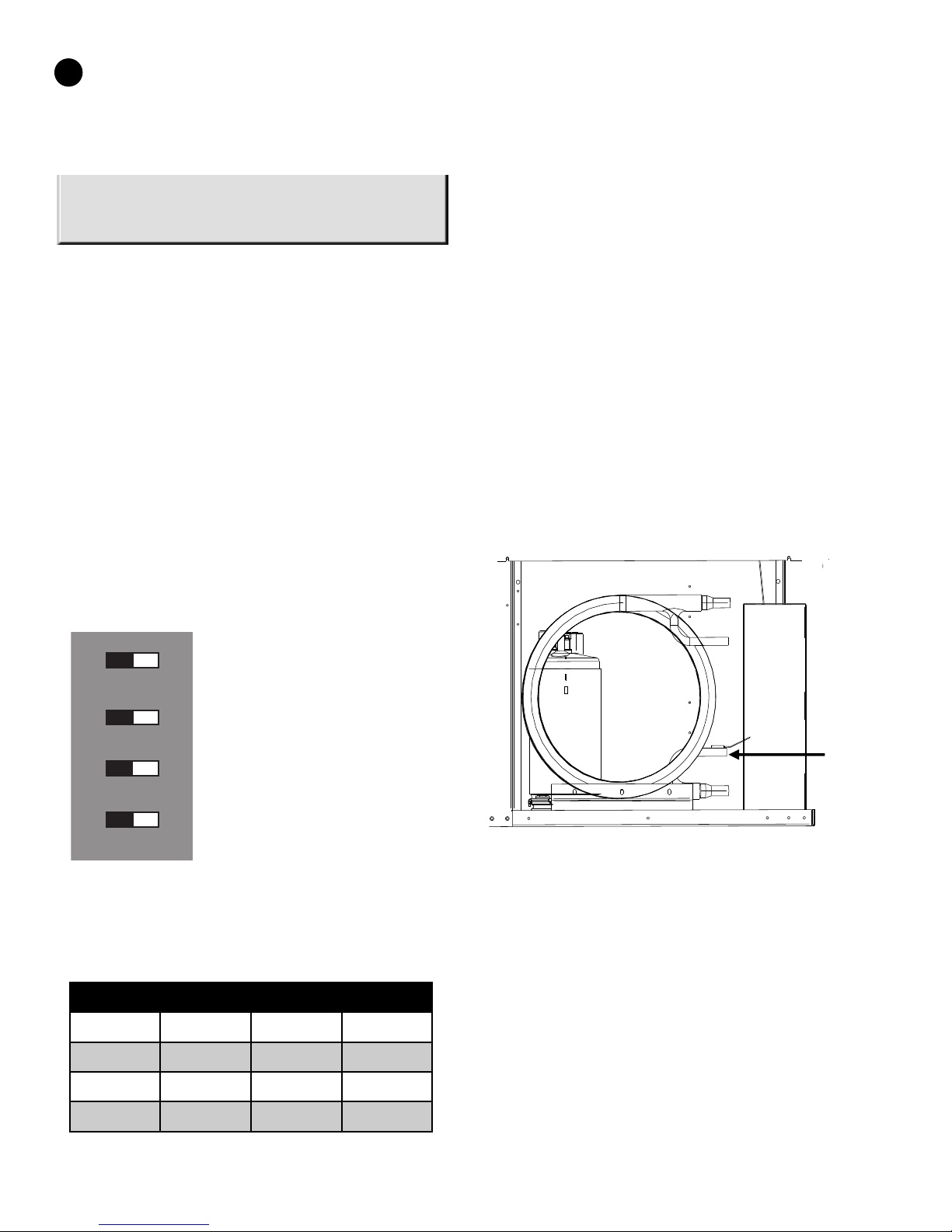

The Unit Protection Module (UPM) as shown in figure 1, is

a printed circuit board (PCB) that interfaces with the

thermostat or the digital direct controller.

The main purpose of this device is to protect the

compressors by monitoring the different states of switches

and sensors of each refrigerant circuit, this device provides

time delays and protects the unit against freezing of the

water and refrigerant heat exchangers as well as condensate

overflow when the appropriate sensors are installed.

Figure1

t

Figure 1

Alarm output is Normally Open (NO) dry contact. If 24 VAC

output is needed R must be wired to the ALR-COM

terminal; 24VAC will be available on the ALR-OUT terminal

when the unit is in alarm condition. If pulse is selected the

alarm output will be pulsed.

OWER RANDOM START U

This feature prevents multiple units sharing same

electrical circuit or network from starting at the same

time.

It assures that Heat Pumps sharing the same electrical

circuit do not demand high inrush currents

simultaneously when starting back up after a power

failure.

If the controller has been completely powered down for

more than 28 milliseconds, a random delay is initiated

typically the unit will start between the time range of 270

and 300 seconds, this only if the controller is set to

normal operation (test switch set to NO).

In order for the random sequence to initiate the unit

power must be removed completely.

IM ORTANT: If the board is set to “TEST” mode through

the “TEST” DIP switch SW1 delay will be 10 seconds.

ANTI SHORT CYCLE DELAY

This feature protects the compressor short cycling if the Y

call is set and removed.

The anti short cycle delay is 300sec delay on break during

normal operation.

NOTE: If the board is set to test mode through the “TEST”

DIP switch the delay will be 5 seconds.

Y CALL

The UPM will energize the compressor’s output (CC) in an event

of a “Y” call from a thermostat or controller (after the random

start up and/or the anti short cycle delays have elapsed). Y

input terminal must be energized with a 24 VAC signal.

HIGH AND LOW RESSURE ROTECTION

The UPM monitors the state of the High and Low pressure

Switch inputs of each refrigerant circuit, HPC and LPC on the

board respectively, these switches must be closed in order

for the controller to energize the compressor output (CC).

The CC output will only be energized when the switches are

closed and the anti short cycle (and /or random start up

when applicable) has expired.

HIGH RESSURE ROTECTION

If the HPC switch is open upon a Y call the UPM will not

energize the CC output and therefore the compressor will

remain off, the fault LED will flash one (1) time for the HPC

and the alarm contact will remain off.

If the compressor is running in normal mode on a Y call

and the high pressure switch opens, the UPM will shut

down the compressor output and will keep it off until the

switch closes and the anti short cycle has expired. The

controller will keep track of the number of times the

switch opens, if within one (1) hour period the switch

opens the number of times set via the DIP switch the

controller will shut the compressor down and perform a

hard lockout condition under this condition the alarm

contact will be energized.

The UPM allows the user to configure the counts that the

HPC will be allowed to open within one hour before the

UPM performs a hard lockout on the compressor. The user

can select either two or four times by changing switch

four (4) on the DIP switch SW1 (shown on table 3) on the

UPM board.

LOW RESSURE ROTECTION

If the LPC switch is open upon a Y call the UPM will not

energize the CC output and therefore the compressor will

remain off, the fault LED will flash two (2) times for the LPC

and the alarm contact will remain off.

If the compressor is running in normal mode on a Y call and

the low pressure switch opens, the UPM will keep the

compressor running for two (2) minutes if the condition

remains after this period of time the compressor will shut

down and the UPM will start a soft lockout. The UPM will flash

two (2) times for the LPC. And the alarm contact will remain off.

5

CA CONSOLE SERIES

970-293 Revised 05-12

If the switch closes, the UPM will start the compressor

after the anti short cycle has expired UPM will energize

the compressor output.

IM ORTANT: To exit the hard lockout the controller must

be reset from the Y or R terminal by removing the power

from the selected terminal. The user can choose which will

be the reset point via the DIP switch SW1.

GROUND

The UPM controller takes its ground reference from the

unit chassis which is connected to the controller via the C-

ND spade terminal.

DI SWITCH SETTINGS

The DIP switch is used to configure most of the available

features of the UPM as follows:

• Alarm mode, Constant or Pulse

• Reset mode, Y signal or R signal

• Lockout mode, two (2) or four (4) Strikes

• Test mode, Normal or Test operation

The settings shown below are factory default for most

heat pump applications, however the Unit wiring diagram

is the ultimate guide for factory DIP switch default

settings (Figiure 2).

Figure 2

The following table is available on the UPM board as well

and it depicts the switch position and its associated

functionality.

Figure 3

SELECTABLE ALARM MODE

The UPM controller can be configured to have either a

constant signal or a pulse.

If constant (CONT) is selected the UPM will provide a

closed contact until the alarm is cleared.

If pulsed (PULSE) is selected the UPM will sequence the

alarm contact with the fault LED flashes.

FREEZE ROTECTION

The default setting for the freeze limit trip is 30°F, however

this can be changed to 15°F by cutting the R42 resistor

located on top of the DIP switch SW1.

The UPM controller will constantly monitor the refrigerant

temperature with the sensor mounted close to the

condensing water coil between the thermal expansion

valve and water coil as shown in figure 4. If temperature

drops below or remains at the freeze limit trip for 30

seconds, the controller will shut the compressor down and

enter into a soft lockout condition. Both the status LED

and the Alarm contact will be active. The LED will flash

(three (3) times) the code associated with this alarm

condition.

Figure 4 Freeze rotection Sensor

BROWNOUT ROTECTION

The UPM controller will constantly monitor the power

supply, if the nominal voltage drops below 25% of its

value. (18 VAC approximately), the unit will enter

brownout protection mode. The compressor CC output

will be de-energized and the unit will enter the soft

lockout mode.

The controller will not monitor the power supply during

the first 500 milliseconds of compressor start up to avoid

noise and false alarms.

Once the UPM detects a brownout condition its fault LED

will flash five (5) times as error code indication.

Freeze

Protection

Sensor

1 2 3 4

ON

Lockout

Reset

Alarm

Test

6CA CONSOLE SERIES

UPM Dip Switch Configuration

4 LOCKOUT 4 2

3 RESET R Y

2 ALARM CONT PULSE

1 TEST YES NO

970-293 Revised 05-12

CONDENSATION OVERFLOW

The UPM controller continuously monitors the drain pan

for high condensate water level, and to do so it utilizes a

sensor and identifies an alarm condition when the

sensor’s impedance drops below 230KΩ +/- 15 % (ONLY

when condensate sensor option is present). Once the UPM

senses this resistance value it enters into a hard lockout

and reports the correspondent code via its status LED (4

flashes).

To exit the hard lockout water has to return to its normal

level the UPM has to be reset by removing the power from

the Y terminal (R if set on the DIP switch) the compressors

will be turned on after anti short cycle expires.

7

CA CONSOLE SERIES

970-293 Revised 05-12

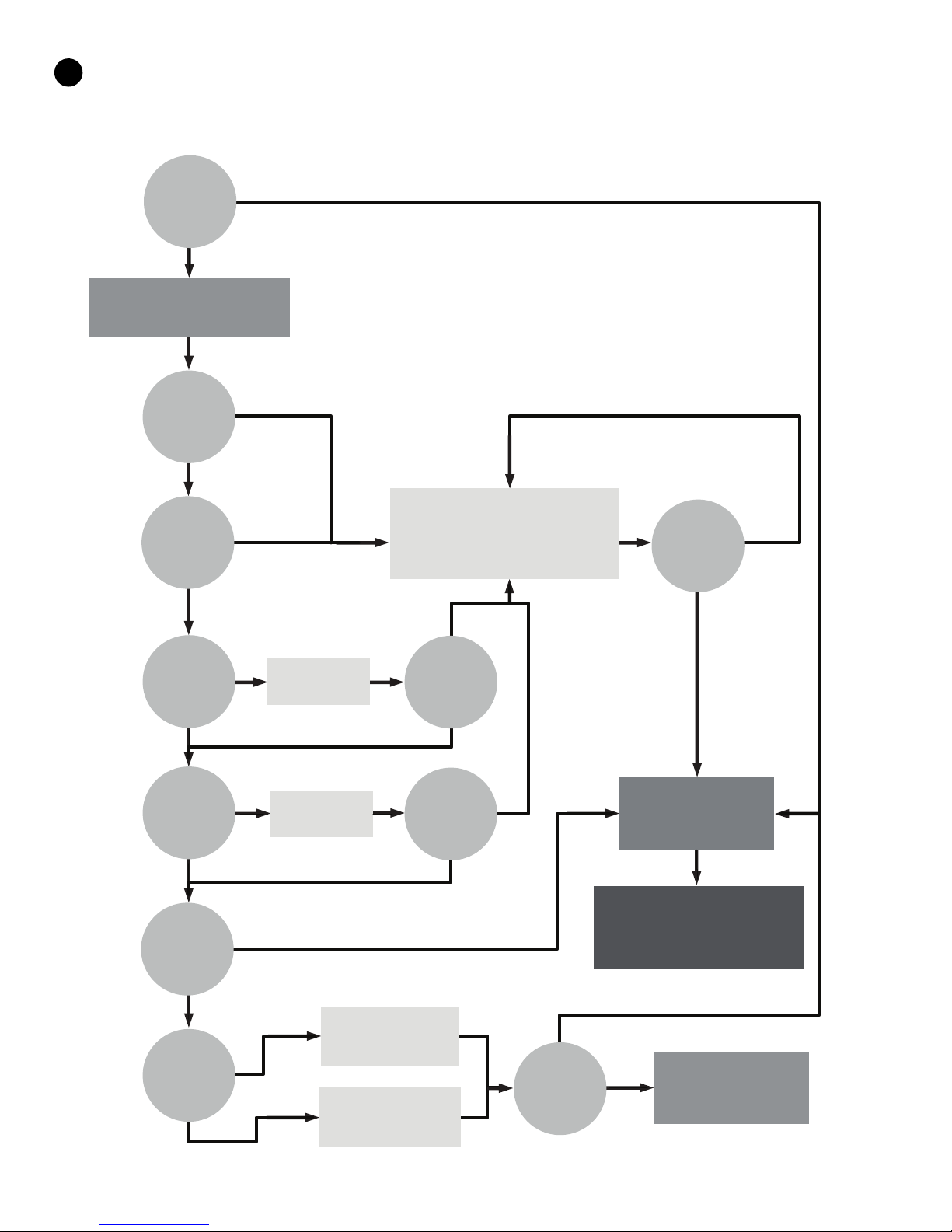

UPM Sequence of Operation (SOO) Flow Chart

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

Y1=1

V

>

1 8 V AC

HPC = 1

LPC = 1

FRZ

>

TEMP

LIM

CON

>

0

INITIAL

POWER UP T

>

ASC OR

RS SEC

TIME

>

30

SEC

TIME

>

120

SEC

COUNT = 2

Start Timer

Start Timer

CC Output = On

CC Output = Off

Blink Code On Status LED

Report Alarm Fault

Hard Lockout

ALR Output = On/Pulse

Blink Code On Status LED

Soft Lockout

Record Alarm

Start Counter (If Applicable)

Start

Anti Short Cycle

Start

Random Start Up

Lockout Can Be Set To

4 Via Dip Switch

Power/Switchs/Sensor

Status Check

8CA CONSOLE SERIES

970-293 Revised 05-12

9

CA CONSOLE SERIES

970-293 Revised 05-12

10 CA CONSOLE SERIES

970-293 Revised 05-12

11

CA CONSOLE SERIES

970-293 Revised 05-12

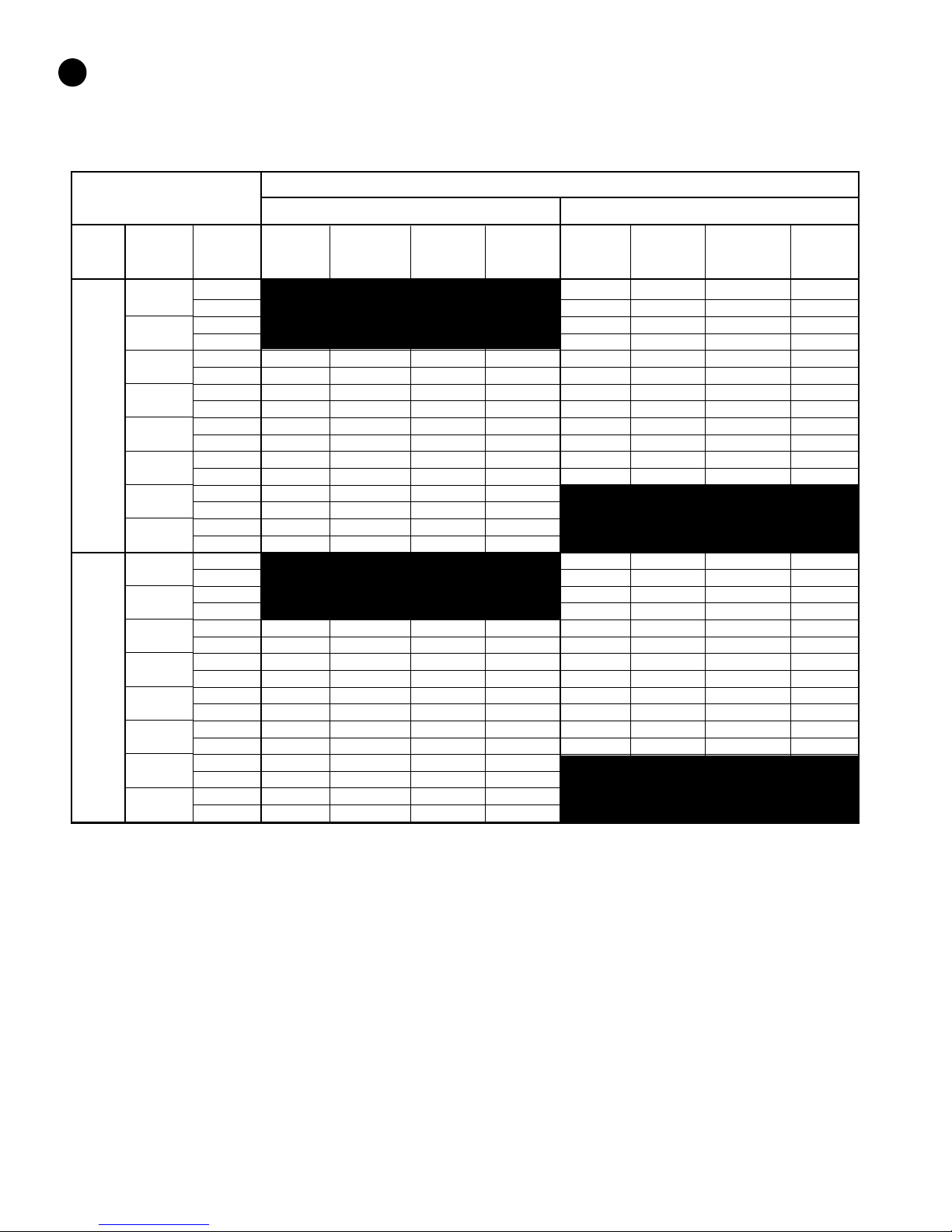

Operating Temperatures & Pressures Consoles

O ERATING DATA R-410A

COOLING HEATING

ENTERING FLUID SUCTION DISCHARGE FLUID AIR SUCTION DSICH FLUID AIR

MODEL FLUID FLOW PRESSURE PRESSURE TEMP TEMP PRESSURE PRESS., TEMP TEMP

TEMP, ˚F GPM PSIG PSIG RISE, ˚F DROP, ˚F PSIG PSIG DROP, ˚F RISE, ˚F

CA009

CA012

30˚

40˚

50˚

60˚

70˚

80˚

90˚

100˚

30˚

40˚

50˚

60˚

70˚

80˚

90˚

100˚

1.5 120-125 295-305 4.3-4.7 12.2-13.4

2 125-130 300-310 3.3-3.7 12.4-13.8

1.5 120-125 300-305 5.2-5.8 14.3-15.8

2 125-130 300-310 4.1-4.5 14.6-16.2

1.5 125-130 285-295 12.8-14.2 18.1-20.0 135-140 305-310 6.2-6.8 16.2-18.0

2 126-131 275-285 10.5-11.6 18.1-20.0 130-135 310-320 4.8-5.3 16.7-18.5

1.5 127-132 295-305 12.6-14.0 17.4-19.2 135-140 315-320 7.1-7.9 18.3-20.3

2 125-130 285-295 9.8-10.8 17.6-19.4 140-145 320-330 5.5-6.1 18.8-20.8

1.5 132-137 315-325 12.4-13.8 16.7-18.5 155-165 325-335 8.2-9.0 20.0-22.2

2 130-135 305-315 9.7-10.7 17.0-18.8 160-170 330-340 6.3-6.9 20.9-23.1

1.5 136-141 345-355 12.4-13.7 16.2-17.9 165-175 335-345 9.0-10.0 22.3-24.7

2 135-140 335-345 9.5-10.5 16.3-18.1 170-175 340-350 7.0-7.8 22.9-25.3

1.5 139-144 370-380 12.2-13.4 15.5-17.1

2 137-142 360-370 9.4-10.4 15.7-17.3

1.5 141-145 415-425 12.1-13.3 14.8-16.4

2 139-144 410-420 9.3-10.3 15.1-16.7

2 110-115 305-315 4.6-5.0 15.3-16.9

3 115-120 305-315 3.8-4.2 15.6-17.2

2 110-115 310-315 5.4-6.0 17.4-19.2

3 115-120 310-315 4.5-4.9 17.8-19.6

2 140-145 290-300 12.5-13.9 20.0-22.2 115-120 315-320 6.3-6.9 19.5-21.5

3 135-140 270-280 10.3-11.3 20.2-22.4 120-125 320-325 5.1-5.7 19.9-21.9

2 142-147 320-320 12.4-13.7 19.4-21.4 125-130 325-330 7.0-7.8 21.5-23.7

3 137-142 300-310 10.2-11.2 19.7-21.7 130-135 330-335 5.8-6.4 21.9-24.2

2 145-150 335-345 12.3-13.5 18.9-20.9 145-150 335-240 7.9-8.7 23.5-25.9

3 143-152 325-335 10.1-11.1 19.1-21.1 150-155 340-350 7.4-8.2 23.9-26.5

2 152-157 360-370 12.2-13.4 18.3-20.3 155-160 345-350 8.7-9.7 25.6-28.2

3 150-155 350-360 10.0-11.0 18.5-20.5 160-165 350-360 7.1-7.9 26.0-28.8

2 154-159 385-395 12.1-13.3 17.8-19.6

3 152-158 375-385 9.9-10.9 18.1-20.0

2 156-160 435-445 12.0-13.2 17.3-19.1

3 154-159 425-435 9.8-10.8 17.5-19.3

12 CA CONSOLE SERIES

970-293 Revised 05-12

Operating Temperatures & Pressures Consoles

This chart shows approximate temperatures and pressures for a unit in good repair.

The values shown are meant as a guide only and should not be used to estimate

system charge. This chart assumes rated air flow and 80º d.b./67º w.b. entering air

temperature in cooling, 70º d.b. entering air temperature in heating. Heating data at

entering fluid temperatures below 50º assumes the use of antifreeze.

FHP MANUFACTURING

601 N.W 65th Court • Ft. Lauderdale, FL 33309

Phone: (954) 776-5471 • Fax: (800) 776 5529

http://www.fhp-mfg.com

As a result of continuing research and development, specifications are subject to change without notice.

O ERATING DATA R-410A

COOLING HEATING

ENTERING FLUID SUCTION DISCHARGE FLUID AIR SUCTION DSICH FLUID AIR

MODEL FLUID FLOW PRESSURE PRESSURE TEMP TEMP PRESSURE PRESS., TEMP TEMP

TEMP, ˚F GPM PSIG PSIG RISE, ˚F DROP, ˚F PSIG PSIG DROP, ˚F RISE, ˚F

CA015

30˚

40˚

50˚

60˚

70˚

80˚

90˚

100˚

3 110-115 280-290 3.6-4.0 13.6-15.0

4 110-115 290-295 2.9-3.2 13.9-15.3

3 115-120 295-300 4.4-4.8 15.8-17.4

4 115-120 300-305 3.4-3.8 16.2-17.9

3 127-132 275-285 12.4-13.8 21.8-24.0 115-120 305-310 5.2-5.8 18.1-20.1

4 125-130 265-275 9.7-10.7 22.0-24.4 120-125 310-315 4.1-4.5 18.5-20.5

3 129-135 310-320 12.2-13.4 20.7-22.9 125-130 315-320 6.1-6.7 20.5-22.7

4 127-132 295-305 9.4-10.4 21.0-23.2 130-135 320-325 4.8-5.3 21.1-23.3

3 135-140 330-340 11.8-13.0 19.8-21.8 145-150 325-330 6.9-7.7 23.0-25.4

4 133-138 320-330 9.1-10.1 20.0-22.2 150-155 330-340 5.4-6.0 23.6-26.0

3 142-147 355-365 11.5-12.7 18.7-20.7 155-16- 335-340 7.8-8.6 25.3-27.9

4 140-145 345-365 8.9-9.9 19.0-21.0 160-165 345-350 6.0-6.6 25.9-28.7

3 144-149 380-390 11.1-12.3 17.7-19.5

4 143-148 370-380 8.6-9.6 18.0-19.8

3 147-152 430-440 10.8-12.0 16.7-18.5

4 145-150 420-430 8.4-9.2 16.9-18.7

13

CA CONSOLE SERIES

970-293 Revised 05-12

UNIT CHECK-OUT

SHEET

Customer Data

Customer Name ______________________________________________ Date _________________________________

Address _____________________________________________________

_____________________________________________________

Phone_______________________________________________________ Unit Number __________________________

Unit Nameplate Data

Unit Make _________________________________________

Model Number_____________________________________ Serial Number_________________________________

Refrigerant Charge (oz) ________

Compressor: RLA _____________ LRA ______________

Blower Motor: FLA (or NPA) ____________ HP_______________

Maximum Fuse Size (Amps) ___________

Minimum Circuit Ampacity (Amps) ______________

Operating Conditions

Cooling Mode Heating Mode

Entering / Leaving Air Temp _______________ /_______________ _______________ /_______________

Entering Air Measured at: _______________________________ _______________________________

Leaving Air Measured at: _______________________________ _______________________________

Entering / Leaving Fluid Temp _______________ /_______________ _______________ /_______________

Compressor Volts / Amps _______________ /_______________ _______________ /_______________

Blower Motor Volts / Amps _______________ /_______________ _______________ /_______________

Fluid Flow (gpm)* _______________________________ _______________________________

Fluid Side Pressure Drop* _______________________________ _______________________________

Suction / Discharge Pressure (psig)* _______________ /_______________ _______________ /_______________

Suction / Discharge Temp* _______________ /_______________ _______________ /_______________

Suction Superheat* _______________________________ _______________________________

Entering TXV / Cap Tube Temp* _______________________________ _______________________________

Liquid Subcooling* _______________________________ _______________________________

* Required for Troubleshooting ONLY

Auxiliary Heat

Unit Make _________________________________________

Model Number _____________________________________ Serial Number ________________________________

Max Fuse Size (Amps) _______________________________

Volts / Amps_____________________ /____________________

Entering Air Temperature ____________________________

Leaving Air Temperature _____________________________

CS-7.2-FO-15.Rev.0

14 CA CONSOLE SERIES

970-293 Revised 05-12

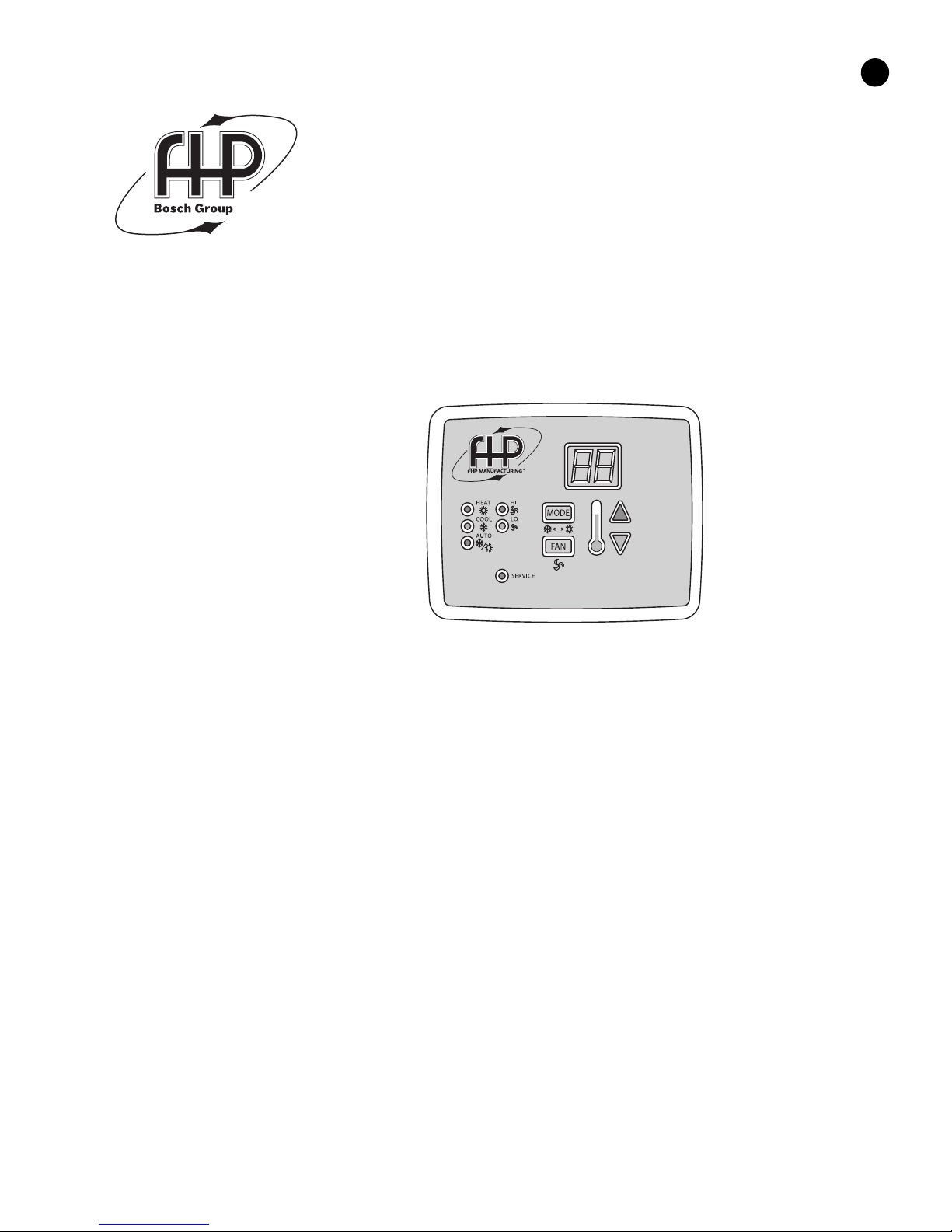

FHP introduces the latest in console solid state control technology. Designed to

enhance the unit operation with more flexibility, accurate control and

operating modes the CUC provides an increased level of comfort in the

conditioned space together with solid state reliability and ease of operation.

The same functions of the proven UPM module are incorporated into the CUC

for unit protection.

CUC controllers are standard on all FHP

series CA/CS console units except for

remote and master/slave options.

• Ta tile tou hpad for

temperature, fan and mode

adjustment.

• Digital display of temperature

in either degrees Fahrenheit or

Celsius.

• LED Display provides

indication for unit operating mode as well as fan speed and fault

indication for high or low pressure lockout.

• Adjustable Temperature Set point from 60° F through 80° F (15.5° C

through 26.7° C ).

• Adjustable Temperature Differential between 1° F and 6° F

(0.6° C and 3.3° C).

• Sele table options

•Manual/Automatic changeover

•Fan speed – High or Low

•Fan operation constant fan or cycling with compressor

• Additional features

•5 minute anti short cycling delay

•Random start

•90 second low pressure bypass timer prevents nuisance lockouts

during cold winter start up

•Intelligent reset allows the unit to automatically restart after 5

minutes if a fault is no longer active

CUC SOLID STATE

CONSOLE UNIT CONTROLLER

15

CA CONSOLE SERIES

970-293 Revised 05-12

601 N.W. 65th C urt, Ft. Lauderdale, FL 33309

Ph ne: 954-776-5471 | Fax: 954-776-5529

www.b schtaxcredit.c m | www.fhp-mfg.c m

Table of contents

Other FHP Heat Pump manuals

Popular Heat Pump manuals by other brands

Gree

Gree Vita GWC09ATCXB-D3DNA3A/I Operation manual

A.O. Smith

A.O. Smith AHPW-25 User's information manual

evoheat

evoheat CS Installation & operation manual

Bryant

Bryant 549J Series installation instructions

Waterstage

Waterstage WO G112LCT Series Installation and operating manual

Trane

Trane 2MCC05-C installation manual

Carrier

Carrier bryant 607E K Series installation instructions

CHAFFOTEAUX

CHAFFOTEAUX ARIANEXT COMPACT Installation and servicing instructions

Lennox

Lennox LHT/LDT024 installation instructions

Nibe

Nibe VVM 500 Installer manual

auer

auer HTi70 6 Installation and user manual

Daikin

Daikin Altherma 3 H HT F Series Operation manual