Page 10

505244M 10/09

While nitrogen is flowing, braze refrigerant line set

to the indoor and outdoor units. IMPORTANT: The

flow of nitrogen must have an escape path

other than through the joint to be brazed.

3. Use silver alloy brazing rods (5 or 6 percent minimum

silver alloy for copper−to−copper brazing or 45 percent

silver alloy for copper−to−brass or copper−to−steel

brazing) which are rated for use with HFC−410A

refrigerant.

4. Wrap a wet cloth around the valve body and the copper

tube stub to protect it from heat damage during

brazing. Wrap another wet cloth underneath the valve

body to protect the base paint.

NOTE − The tube end must stay bottomed in the fitting

during final assembly to ensure proper seating,

sealing and rigidity.

5. Install a field−provided check expansion valve

(approved for use with HFC−410A refrigerant) in the

liquid line at the indoor coil.

Flushing Existing Line Set and Indoor

Coil

IMPORTANT

If this unit is being matched with an approved line

set or indoor coil which was previously charged

with HCFC−22 refrigerant, or if it is being matched

with a coil which was manufactured before

January of 1999, the coil and line set must be

flushed prior to installation. Take care to empty all

existing traps.

Polyol ester (POE) oils are used in Lennox units

charged with HFC−410A refrigerant. Residual

mineral oil can act as an insulator, preventing

proper heat transfer. It can also clog the check

expansion valve, reducing system performance

and capacity.

Failure to properly flush the system per the

instructions below will void the warranty.

WARNING

Danger of fire. Bleeding the

refrigerant charge from only the high

side may result in the low side shell

and suction tubing being

pressurized. Application of a brazing

torch while pressurized may result in

ignition of the refrigerant and oil

mixture − check the high and low

pressures before unbrazing.

CAUTION

This procedure should not be performed on

systems which contain contaminants (Example:

compressor burn out).

IMPORTANT

The line set and indoor coil must be flushed with

at least the same amount of clean refrigerant that

previously charged the system. Check the charge

in the flushing cylinder before proceeding.

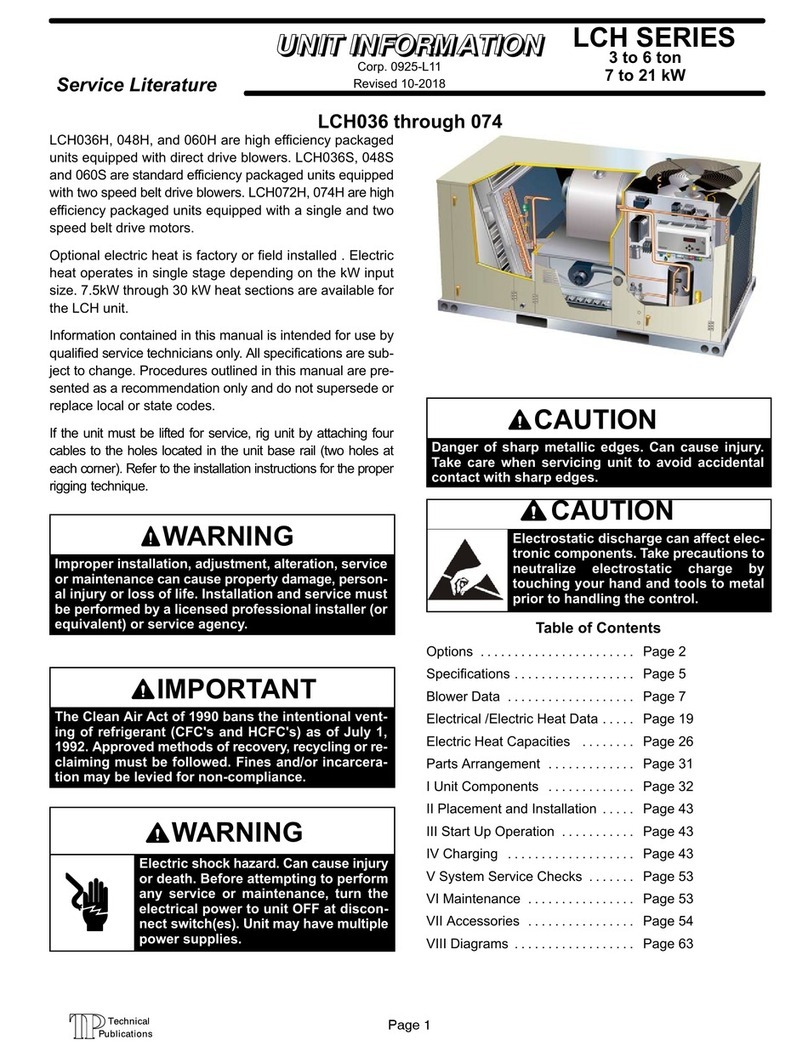

EQUIPMENT REQUIRED FOR FLUSHING LINE SET

The following equipment is required to flush the existing

line set and indoor coil:

two clean HCFC−22 recovery cylinders

oilless recovery machine with a pump down feature

gauge set for HCFC−22 refrigerant

gauge set for HFC−410A refrigerant (see Manifold

Gauge Set section on page 12).

FLUSHING PROCEDURE

1. Remove existing HCFC−22 refrigerant using the

following, applicable procedure as illustrated in figure

18:

If the existing outdoor unit is not equipped with

shut−off valves, or if the unit is not operational

AND you plan to use the existing HCFC−22

refrigerant to flush the system −

Disconnect all power to the existing outdoor unit.

Connect to the existing unit, a clean recovery

cylinder and the recovery machine according to

the instructions provided with the recovery

machine.

Remove all HCFC−22 refrigerant from the existing

system. Check gauges after shutdown to confirm

that the entire system is completely void of

refrigerant.

Disconnect the liquid and vapor lines from the

existing outdoor unit.

If the existing outdoor unit is equipped with

manual shut−off valves AND you plan to use NEW

HCFC−22 refrigerant to flush the system −

Start the existing HCFC−22 system in the cooling

mode and close the liquid line valve.

Pump all of the existing HCFC−22 refrigerant back

into the outdoor unit. (It may be necessary to

bypass the low pressure switches to ensure

complete refrigerant evacuation.)

When the low side system pressures reach 0 psig,

close the vapor line valve.

Disconnect all power to the existing outdoor unit.

Check gauges after shutdown to confirm that the

valves are not allowing refrigerant to flow back into

the low side of the system.

Disconnect the liquid and vapor lines from the

existing outdoor unit.

2. Remove the existing outdoor unit. Set the new

HFC−410A unit and follow the Brazing Connection

Procedure provided on page 9 to make line set

connections. DO NOT install HFC−410A

check/expansion valve at this time.

3. Make low voltage and line voltage connections to the

new outdoor unit. DO NOT turn on power to the unit

or open the outdoor unit service valves at this

time.