Fiamm SODIUM SoNick 48TL160H Manual

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.1

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.2

Index

1 SAFETY.......................................................................................................................................4

1.1 Purpose................................................................................................................................4

1.2 Safety Precautions..............................................................................................................4

2 GENERAL INFORMATION .........................................................................................................4

2.1 Introduction .........................................................................................................................4

2.2 Unpacking And Inspections................................................................................................4

2.3 Handling...............................................................................................................................5

2.4 Storage.................................................................................................................................5

2.5 Battery Return and Disposal...............................................................................................5

2.6 Packaging ............................................................................................................................5

2.7 Transportation.....................................................................................................................6

3 BATTERY INSTALLATION.........................................................................................................7

3.1 Tools and Hardware Required............................................................................................7

3.2 Battery Layout and Mounting Orientation .........................................................................7

3.3 Battery Front Panel .............................................................................................................8

3.4 Power Cable Connection ....................................................................................................9

3.4.1 Individual connection.......................................................................................................9

3.4.2 Parallel Connection........................................................................................................10

3.5 Data Cable Connection .....................................................................................................11

3.5.1 Com port pin-out ............................................................................................................11

3.5.3 Alarm Dry contact configuration...................................................................................11

3.5.4 Single battery installation..............................................................................................12

3.5.5 Multiple batteries installation ........................................................................................12

3.6 Battery activation ..............................................................................................................13

4 BATTERY IN OPERATION .......................................................................................................14

4.1 Battery Warm-Up...............................................................................................................14

4.2 Battery Charging ...............................................................................................................14

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.3

4.3 Floating..............................................................................................................................14

4.4 Discharging and Rated Capacity......................................................................................15

4.5 Battery Cool Down ............................................................................................................15

4.6 Battery Internal Resistance ..............................................................................................15

4.7 Maintenance Free..............................................................................................................15

5 TECHNICAL INFORMATION....................................................................................................15

5.1 FIAMM SoNick Battery Description..................................................................................15

5.1.2 BMS functions ................................................................................................................16

5.2 Battery Specification.........................................................................................................16

5.3 Battery Labels....................................................................................................................17

5.3.1 Front label.......................................................................................................................17

5.3.2 Top label..........................................................................................................................17

5.3.2 Side BMS label................................................................................................................18

5.4 Battery Alarms...................................................................................................................18

5.4.1 Warnings/alarms list.......................................................................................................19

5.5 Service Life Definition.......................................................................................................20

5.6 Extended Outages.............................................................................................................20

5.7 Light Emitting Diodes (LED’s) explanation......................................................................20

5.8 Display ...............................................................................................................................21

5.9 Safe Technology................................................................................................................21

5.10 Battery Protection ...........................................................................................................21

5.10.1 Electrical Protection.....................................................................................................21

5.10.2 Thermal Protection.......................................................................................................22

5.10.3 Mechanical Protection..................................................................................................22

5.10.4 Reliability ......................................................................................................................22

5.11 Technical Assistance......................................................................................................22

Appendix .....................................................................................................................................22

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.4

1 SAFETY

1.1 Purpose

This manual provides information required to install and operate the FIAMM SoNick 48TL160H

battery.

Anyone involved in handling, installing or using the FIAMM SoNick 48TL160H battery must read

and understand this manual.

1.2 Safety Precautions

To prevent damages to the batteries and personal injuries, following safety instructions need to be

followed all the times:

Do not install the battery if you notice physical damage

Do not place the battery on its power terminals, with the front plastic cover facing down or

upside down

Do not pack the battery when it is hot

Do not expose the battery to temperatures above 90°C (194°F) or below -40°C ( 40°F)

Do not allow metal objects to rest on the battery or to fall across the terminals

Remove rings or metal wristbands when working with the battery

Use insulated tools to install the battery

Use all the handles when handling the battery

Unlike traditional batteries, this Sodium Nickel battery can be charged or discharged only

when the internal temperature reaches the operative value. Whenever the internal

temperature is below, the battery acts as a passive device.

Before use, be sure to fully understand the battery functionality described in this manual.

2 GENERAL INFORMATION

2.1 Introduction

The 48TL160H is a 48 Volt –160Ah complete battery system designed for stationary applications.

This battery, assembled with four strings of Sodium-Nickel cells in a 20 cell series configuration, is

provided with internal electric heaters to achieve and maintain the internal working temperature of

265°C. The thermal insulation of the battery is such that, with an internal temperature of 265°C, the

surface temperature of the enclosure is just a few degrees above the environment. The battery

enclosure has a good thermal insulation thanks to the

vacuum between the inner and the external box.

The battery is provided with an electronic controller (BMS) which manages all the battery functions

and ensures a reliable and safe operation.

2.2 Unpacking And Inspections

FIAMM SoNick carefully tests and inspects the battery before shipment.

Upon receiving a shipment of batteries, open the wooden crate box and check the battery and

hardware against the packing list.

Report any damage immediately to the carrier if the shipment shows signs of damage in transit.

Also notify your FIAMM SoNick customer service representative.

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.5

2.3 Handling

The use of non-conductive tools or tools rendered non-conductive by means of an insulating

material is highly recommended.

High energy batteries should always be handled carefully to avoid the possibility of creating a short

circuit. In some circumstances, when in operation, the battery surface may be hot.

Battery handles are for hand carrying only, do not sling from the handles. Use an appropriate

battery lifting harness for hoisting the battery. The battery handles are to be used to remove the

battery from its original packaging and to securely place the battery in its operating location.

Always use all handles when handling the battery.

Never push or pull the battery by applying force to the Battery Management System.

Personnel should inspect the nearby environment where batteries will be handled to identify and

eliminate all potential sources of electrical and physical damage to the batteries. Avoid conditions

that could result in short-circuits, overheating, puncture or crush.

Figure 1

2.4 Storage

The suitable environment for battery storage in general is in a cool, dry, and well-ventilated place.

Sodium Nickel batteries should be stored in an identified area of the warehouse equipped with

Class ''D'' fire extinguishers. The battery can be stored for any length of time in the cold state

without changing its characteristics or state of charge.

The battery has an extremely high resistance in the cold state and even a very low current can

damage the battery when cold. Do not try to disassemble the battery management system (BMS)

and apply any load or perform any measurement using the internal terminals of the battery,

especially when it is in cold state.

The storage temperature should be between –40°C and +60°C.

2.5 Battery Return and Disposal

A Sodium Nickel battery must be transported cold and if possible discharged.

Do not burn or dispose of the battery. End of life or defective batteries are to be returned to FIAMM

SoNick, where recycling and/or disposal of the different parts will be performed.

Notify FIAMM SoNick customer service prior to returning the battery.

2.6 Packaging

The 48TL160H battery is shipped cold and completely discharged in a wooden crate fixed with

straps to avoid any risk of uncontrolled movement or drops and surrounded by a protective foam

cushion (fig.2, dimensions in mm).

In case of battery return, battery should be packed in the original wooden box, only when turned off

and cold. Battery with a heavily damaged external case should be wrapped with polyethylene

sheets before of the packing, to avoid the risk of release of material or odors.

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.6

The package should include the relevant safety information for the transport: please contact

FIAMM SoNick for the details.

Figure 2

2.7 Transportation

Sodium Nickel batteries are classified as dangerous goods (hazardous materials) for transportation

purposes. Consequently, anyone who is engaged in shipping this product must comply with all the

rules and regulations, covering the shipping of dangerous goods

UN number:

3292 “Batteries or cells containing sodium”

Class:

4.3 “Water reactive substances” In contact

with water produces flammable gas

Packing group:

Il Materials of medium danger

Packing instructions:

433 for air shipment

P408 for road shipment

IMDG for sea shipment

Kemler nr:

not identified

ERG:

4W

Particular caution:

Protect from humidity and water

Handle with care

Table A

Transport classification conforming to the following specific regulations:

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.7

For road or rail transport

ADR/RID (SDR)

For air transport

lATA

For sea transport

IMDG

Table B

Use ADR vehicles only if the gross weight for each transport unit is > 333 kg.

During air transport: use only cargo flight

Conforming to the regulations the batteries are transported:

At ambient temperature with the sodium at the solid state

labeled and packed conforming to international rules (ADR, IATA, IMDG)

Not charged (state of charge 0%).

3 BATTERY INSTALLATION

3.1 Tools and Hardware Required

Insulated 13mm socket and a torque wrench 5-10Nm (3 -7Ft/Lbs or 10 - 88 In/Lbs)

Combination wrench set, screwdrivers

Multi-meter

3.2 Battery Layout and Mounting Orientation

The FIAMM SoNick 48TL160H battery when active contains some materials in a liquid form. Even

though the battery is fully sealed, the maximum permanent inclination when installed is 30

degrees.

During handling when the battery is cold (all internal materials are in a solid state) a temporary

placement, with angles greater than 30° are allowed.

In any case, never place the battery on its power terminals or upside down or with the front plastic

cover facing down.

Provide adequate shelf loading capacity, ensure that there is sufficient aisle space and avoid short-

circuits between the battery terminals and the shelf's metal parts.

Figure 3A Figure 3B

The battery must be properly locked to the shelf, ensuring complete mechanical stability.

Fixing points are indicated in the following picture:

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.8

Figure 4

Point

Item

Suggested operation

A

Lateral handles

Fasten to the structure by means of ties

Table C

Never drill, weld or modify battery surface to lock it to structure

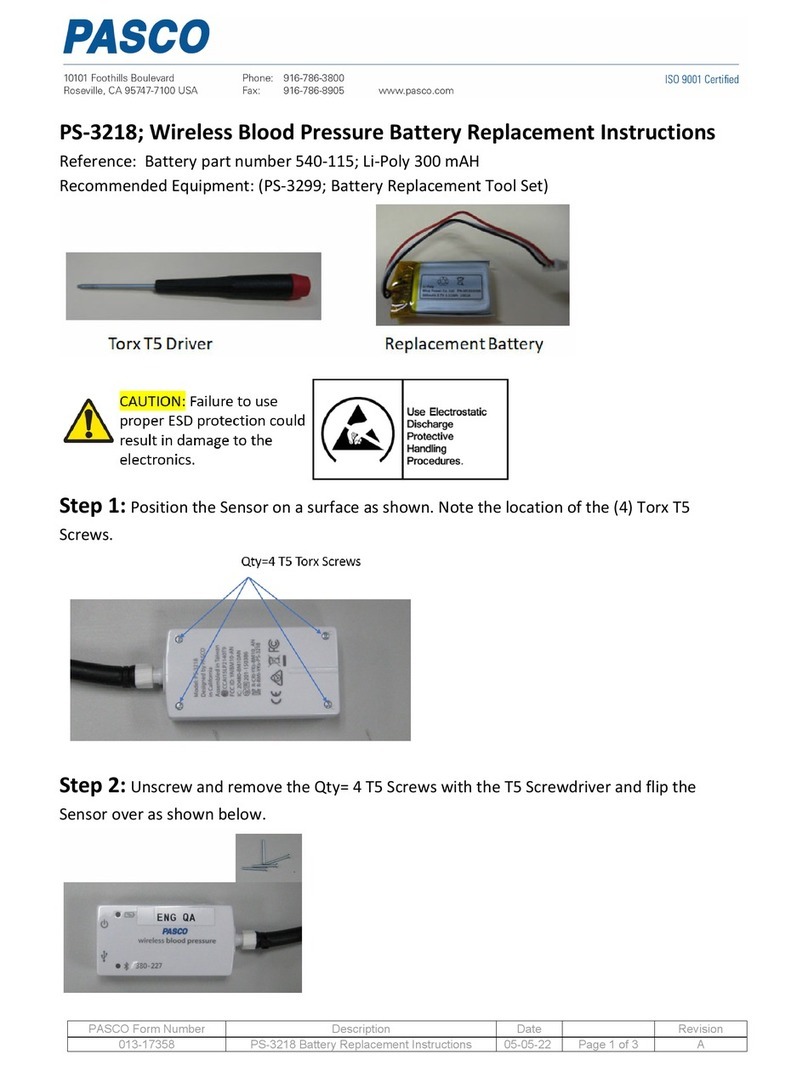

3.3 Battery Front Panel

The battery power terminals and interface ports are located in the front panel of the battery as

indicated in the fig.5. Some connection (n° 2,3,4,6,7,8 of the fig.5) are protected by six plastic

screw plugs. All the connections of the 48TL160H battery are described in the table D.

The IP rating of the battery is guarantee only if all the plastic plugs in the front panel are

properly screwed in. If the higher IP rating is required while one or more cables are

permanently connected to the battery, the appropriate PG11 cable glands must be used.

Figure 5

Item

Description

Type

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.9

1

Negative battery terminal

M8,female

2

Power switch

-

3

USB port

USB type B

4

Not used

-

5

Positive battery terminal

M8, female

6

Com port output

(RS485/CanBus)

RJ-45

7

Com port input

(RS485/CanBus)

RJ-45

8

Alarm configuration jumper

-

Table D

3.4 Power Cable Connection

Do not connect in series two or more batteries. Parallel connection is allowed.

Each 48TL160H battery is a 48 Vdc battery and is to be considered as a 48 Vdc battery

system.

If there is a switch in the battery line, please turn it off before connecting the power

cables to the battery. Otherwise please note that sparks may occur. In any case the

battery and the BMS are not damaged.

3.4.1 Individual connection

1) Remove the terminal insulation covers by pulling them as in the figure n°6 below

Figure 6

2) Ensure that the battery switch is in the OFF position (Fig.7)

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.10

Figure 7

3) Connect the negative DC power supply terminal to the negative terminal of the battery (1,

fig.5).

4) Connect the positive DC power supply terminal to the positive terminal of the battery (5,

fig.5).

5) Power terminal bolts should be torqued to 7-8 Nm (5-6 Ft/Lbs,60-70 In/Lbs). Install the

terminal insulator cover on the terminal bolts to protect the battery terminals from accidental

contact/short circuit.

6) If a Ground connection is necessary, a bolt on the side of the battery can be used, as

indicated in the picture 8 below.

7) If no data connection is being used, secure all the protective dust caps provided with the

battery on each data port.

Figure 8

3.4.2 Parallel Connection

48TL160H batteries can be connected in parallel to the same rectifier. There is no limit in

the number of the batteries that can be paralleled

1) Before connecting any cables, match proper polarity (only connect positive to positive

and negative to negative).

2) Connect the positive terminal of each battery together or to the same DC bus bar

3) Connect the negative terminal of each battery together or to the same DC bus bar

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.11

4) Power terminal bolts should be torqued to 7-8 Nm (5-6 Ft-Lbs,60-70 In-Lbs). Install the

terminal insulator cover on the terminal bolts to protect the battery terminals from

accidental contact/short circuit.

5) For more than one paralleled string of batteries, repeat steps 1 to 4.

6) If a Ground connection is necessary, a bolt on the side of the batteries can be used, as

indicated in figure 8 above.

7) If no data connection is being used, secure all the protective dust caps provided with

the battery on each data port.

3.5 Data Cable Connection

3.5.1 Com port pin-out

The following tables shows the pinout of the output com port (ref. 6, fig.5)

PIN

RS485

CanBus

1

ALARM dry contact, NC

2

ALARM dry contact, C

3

ALARM dry contact, NO

4

Remote ON/OFF

5

Remote ON/OFF

6

GND_485

GND_CAN

7

RS485 D+

CAN_L

8

RS485 D-

CAN_H

Table E

3.5.2 Remote power on/off

Battery can be turned on and off applying or not a DC voltage (12-60V) between the pins n°

4 and 5 of the com port.

Remote battery powering is enabled only when the battery switch is the OFF

position. When the battery switch is in the ON position the battery is forced on.

Battery switch

DC Voltage between pins 4&5

Battery status

OFF

yes

Powered

no

Not Powered

ON

yes

Powered

no

Powered

Table F

3.5.3 Alarm Dry contact configuration

When the battery issues an alarm, a dry contact is activated. Dry contact terminals are

located in the (output) com port as indicated in the table E.

Dry contact is active only when the jumper located under the plastic plug (ref.8

fig.5) is in the position 2, as indicated below.

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.12

Fig.9

3.5.4 Single battery installation

In case of a single battery installation a data cable could be permanently connected to the

output port in order to access the communication bus, the alarm dry contact and the remote

powering pins

Fig 10

3.5.5 Multiple batteries installation

In case of multiple battery installation, a daisy chain configuration of the data cable is

possible. Output port of one battery should be connected with the input port of the following

battery, as showed in the figure 11. With this configuration all the battery of the chain are

connected to the same communication bus (RS485 or CanBus) and each single battery

have to be named with the software configuration.

Maximum number of batteries that can be connected in the same data chain is 64

with the RS485 or 127 when CanOpen protocol is used.

Fig. 11

RS485

CANBUS

Alarm

dry

contact

Remote

power

on/off

RS485/

CANBUS

Common

alarm dry

contact

Common

remote

power

on/off

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.13

With this configuration the Alarm dry contacts are connected together in order to have a

common signal. Two options are available depending on the jumper configuration, as

indicated in the table G (ref. fig.9 and fig.11)

option

configuration

Output pins on battery

1

Jumper setting

1

Series of normally

closed contacts

Output port, pins 1 and

2

Batteries 1..N-1 : 1

Battery N : 2

2

Parallel of

normally opened

contacts

Output port, pins 2 and

3

Batteries 1..N : 2

Table G

3.6 Battery activation

1) Set the DC power supply at a voltage between 53Vdc and 59Vdc. No current limitation is

needed, however, with the factory setting, a minimum current supply of 32 Amps per module from

the rectifier is necessary to ensure the shortest charging time.

2) Turn on the DC power supply

3) Turn the battery switch (Fig.7) to the ON position. The display should indicate “INIT” and the

green led (1, Fig.12) on the front panel should start blinking, indicating that the BMS is powered

and the battery is not yet connected to the DC Bus (the internal power switch is still open).

Figure 12

4) If the battery internal temperature is below 265°C (518°F) the warm up phase is started, (see

section 4.1 of this manual) till the target temperature is achieved. At this point the power switch is

closed, connecting the battery to the DC power supply. The green and blue led (1-3, Fig.12) on the

front panel stops blinking and remains solid.

5) Now the battery is electrochemically operative, and if it is not in the full state of charge, the built-

in battery charger turns on and the charging phase starts. (See section 4.2 of this manual).

6) A discharge is always possible, even if the battery is in charge mode (see section 4.2 of this

manual)

When an SMC battery is turned off, it’s always necessary to connect it to a powered

DC bus to turn it on again, for any battery SOC and internal temperature condition.

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.14

4 BATTERY IN OPERATION

4.1 Battery Warm-Up

The Fiamm SoNick 48TL160H battery needs to be warm before it starts to deliver energy since it

operates between 265° and 350°C (509-662°F).

The BMS performs the warm-up process automatically as soon as it is powered (by the power

switch or by the external 48V EPO Emergency Power Off circuit). When the battery is in this state

the led indication is both green and blue leds blinking while the 7 Segment display of the battery

continuously indicates the internal temperature.

Starting from room temperature, this process takes 13 hours. A graph of the process is included in

the appendix I section. Power consumption during this process is indicated in the table H.

Elapsed Time (h)

Temperature (°C)

Power consumption (W)

0

25

330

7

160

330

13

260

330

>14

265

50

Table H

4.2 Battery Charging

The BMS of the 48TL160H battery is equipped with an integrated charge regulator, basically a

DCDC step-down (Buck) converter. The battery accepts any voltage between 53 and 59V, and

regulates the charging current and the charging voltage to the optimal levels. Recharge current is

limited by the BMS to 32A therefore there is no need to limit the current at the rectifier level. To

charge the battery, a simple DC power supply can be used. In any case the BMS is fully

compatible with any typical rectifier used in the market.

If the BMS detects that the SOC of the battery is below 100%, the charge phase is automatically

started. This is indicated by the blue LED which will turn solid on while the display of the battery

alternatively shows all the charging parameters (voltages, current)

Battery recharge time depends on the current availability and the initial SOC. If the full current is

available, a complete charge takes approximately 12hrs. More charging information is included in

the appendix II section.

If the available current is below 32A, during the first part of the charge process, the DC

Bus voltage could decrease below the minimum value. A warning could be issued by the

BMS . Besides the factory setting of 32A, lower current setting are available on request.

4.3 Floating

When a fully charged battery is connected to the DC bus (with only green led solid on) the internal

charge regulators are switched off. In this condition the Battery “float” current has 2

main “components”.

The first one is due to the power consumption of the electronics controller and the second is due to

the power consumption used to compensate for the heat losses.

The first component of the float current is constant over the battery status while the second

depends on battery working conditions. (i.e. ambient temperature).

The average float power consumption at 20°C is 50W, more detailed information is available in the

appendix III section of this manual.

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.15

4.4 Discharging and Rated Capacity

A discharge is always possible in case the battery is in float or charge state, when the green LED

is on solid. When the battery is performing a warm-up or is an alarm condition a discharge is not

possible (green LED blinking).

In case the battery goes into discharge, the yellow LED turns on solid and, when the state of

charge of the battery is under 20% of its nominal capacity value this LED turns to a blinking

indication.

The rated capacity of The Fiamm SoNick 48TL160H battery is 160 Ah. At higher rates the capacity

is lower because of the higher internal resistance losses; at lower rates the useful capacity is lower

due to the fact that some power is needed to maintain the battery at the internally working

temperature and this power is drawn from the battery itself. The 48TL160H discharge performance

is not significantly affected by temperature variations, especially compared with other battery

technologies. Even if the outside ambient temperature varies greatly, its internal temperature will

remain within the operative range and then the capacity and life are not affected.

Detailed information is available in the appendix IV section of this manual.

4.5 Battery Cool Down

The 48TL160H battery is kept at its operating temperature with three internal heaters, controlled by

the BMS and it is insulated with special insulation material to limit both the thermal losses and the

temperature gradients inside the battery. If the battery is operative (ON-LINE), the thermal

management of the BMS keeps the internal temperature at a minimum of 265°C.

As soon as the battery is turned off (by the power switch) the BMS is powered off and so the

heating elements: the internal temperature starts to decrease with a typical behavior (see appendix

V section for details).

If the battery is removed from the DC bus with its power switch in the on position, the battery starts

to use its own energy to keep the internal temperature. After a number of hours, depending on the

SOC, the battery turns off (when its SOC=0%) and the temperature starts to decrease.

4.6 Battery Internal Resistance

The internal battery resistance varies depending on the different states of charge;

Average value is 44mOhm, see appendix VI section for details.

4.7 Maintenance Free

The FIAMM SoNick Sodium Nickel Metal Chloride battery does not require any maintenance.

5 TECHNICAL INFORMATION

5.1 FIAMM SoNick Battery Description

The battery’s primary function is to store electrical energy and to supply it to an external load when

needed. The battery management system also provides secondary functions that are essential to

achieve the required service life duration.

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.16

5.1.2 BMS functions

Main functions of the integrated Battery Management System (BMS) are:

Battery Thermal Management: battery needs to be warm before it starts receive or deliver

energy. The thermal management of the BMS performs the warm-up process automatically

as soon as it is powered.

Battery Charge Process: the BMS is equipped with a charge controller which is able to

regulate the charging parameters (voltage and current) in order to obtain the best charging

performance.

Battery Power/Energy Output Checks: the BMS calculate the battery SOC to provide a

reliable and safe operation and to avoid overcharge or over discharge.

Battery Operating Conditions Checks: the BMS continuously measures all the battery

parameters such as voltages, currents, temperatures, insulation levels providing a

continuous monitoring of the operating conditions.

Redundant Control: the controller is equipped with a safety redundant microprocessor

(Watchdog) for safe operations.

Battery communication: the BMS has various communication capability using different

communication ports: USB, RS485, optional CAN Bus or Ethernet.

5.2 Battery Specification

Characteristics

Values

Nominal Voltage

48 Vdc

Operating Voltage Range

42 to 60 Vdc

Nominal Capacity

160 Ah at C4 to 42V

Nominal Energy

7600 Wh at C4 to 42V

Continuous Discharge Current

65A

DC Bus Voltage Range

53 –59 Vdc

Internal Low Voltage

Disconnect

40 Vdc

Power Fuse Rating

200A

Communication Port

RS 485 / USB / Ethernet / CAN-bus

Alarm Dry Contact

230Vac 2A

Length

496 mm

Width

578 mm

Height

325 mm

Weight

90 kg

Continuous Operating

Ambient Temperature

-20 to +60°C (-4 to 140°F)

Terminal Bolt Torque

7-8 Nm, 5-6 Ft-Lbs, 60-70 In-Lbs

Terminal Bolt Size

M8

Table I

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.17

5.3 Battery Labels

The FIAMM SoNick 48TL160H battery has three visible labels located as in the picture 13 below:

Fig.13

5.3.1 Front label

The label in Fig.14 contains battery technical information and the LED explanation legend

Fig.14

5.3.2 Top label

The label in Fig.15 contains battery technical information, the production date and the

battery serial number

Fig.15

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.18

5.3.2 Side BMS label

The label in Fig.16 contains the BMS serial number

Fig.16

Keep the battery in the upright position. Do not connect in series two or more

batteries. Parallel connection is allowed.

Hazardous voltage risk of electric shock. Authorized personnel only.

The battery surface may be hot.

Observe operating instruction and display it visible in the vicinity of the battery. Work

on batteries only after instruction by qualified staff.

Wear eyes protection and protective clothing when working with batteries. Observe

accident prevention regulations.

5.4 Battery Alarms

Battery management system issues warnings or alarms depending on the battery working

conditions or to the presence of internal faults. Depending on the criticality of the situation, the front

Red LED becomes blinking (warning) or solid on (Alarm). In case of alarm situation the display

shows the alarm code, as indicated in the table F below, the main contactor is open (Green LED

blinking) and the alarm dry contact is closed

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.19

5.4.1 Warnings/alarms list (fw vers.: mcu_app 0.2.xxx , mcu_app 0.3.xxx)

no.

String

Function

Alarm

Family

Severity

Delay

Description

0

Tam

Tamb_Min

TEMP

Recoverable Alarm

NULL

Low ambient temperature alarm

1

TaM1

Tamb_Max_1

TEMP

Warning

NULL

High ambient temperature warning

2

TaM2

Tamb_Max_2

TEMP

Recoverable Alarm

LONG

High ambient temperature alarm

3

Tbm

Tbatt_Min

TEMP

Recoverable Alarm

SHORT

Low battery internal temperature

alarm

4

TbM1

Tbatt_Max_1

TEMP

Warning

LONG

High battery internal temperature

warning

5

TbM2

Tbatt_Max_2

TEMP

Recoverable Alarm

SHORT

High battery internal temperature

alarm

6

VBm1

Vbus_Min_1

V_BUS

Warning

NULL

Bus voltage < 40V

7

VBm2

Vbus_Min_2

V_BUS

Recoverable Alarm

LONG

Bus voltage < 39V

8

VBM1

Vbus_Max_1

V_BUS

Warning

NULL

Bus voltage > 60V

9

VBM2

Vbus_Max_2

V_BUS

Recoverable Alarm

LONG

Bus voltage > 65V

10

IDM1

Ibatt_Dch_Max_1

DCH

Warning

NULL

High discharge current warning

11

IDM2

Ibatt_Dch_Max_2

DCH

Recoverable Alarm

NULL

High discharge current alarm

13

MSWE

Main_Sw_Error

HW

Unrecoverable Alarm

SHORT

Main switch error

14

FUSE

Fuse_Blown

HW

Unrecoverable Alarm

SHORT

Fuse blown

15

HTRE

Heaters_Error

HW

Recoverable Alarm

LONG

Heaters failure

16

TCPE

Thermocouple_Error

HW

Unrecoverable Alarm

LONG

Thermocouple failure

17

STRE

String_Voltage_Measure_Error

HW

Recoverable Alarm

LONG

Voltage measurement circuit failure

18

CM E

String_Current_Measure_Error

HW

Recoverable Alarm

LONG

Current measurement circuit failure

19

HWFL

Hw_Failure

HW

Unrecoverable Alarm

NULL

BMS hardware failure

20

HWEM

HW_Emergency

HW

Recoverable Alarm

NULL

Hardware protection system

activated

21

ThM

Ths_Max

TEMP

Recoverable Alarm

LONG

High heatsink temperature alarm

22

vsm1

Vstr_min_1

DISCH

Recoverable Alarm

SHORT

Battery String voltage < 39V

23

vsm2

Vstr_min_2

DISCH

Unrecoverable Alarm

NULL

Battery String voltage < 38V

24

vsM1

Vstr_MAX_1

V_STR

Warning

SHORT

Battery String voltage > 53.5V

25

vsM2

Vstr_MAX_2

V_STR

Recoverable Alarm

SHORT

Battery String voltage > 53.6V

26

iCM1

Istr_Ch_Max_1

CHRG

Warning

LONG

High string charge current warning

27

iCM2

Istr_Ch_Max_2

CHRG

Unrecoverable Alarm

LONG

High string charge current alarm

28

iDM1

Istr_Dch_Max_1

DISCH

Warning

NULL

High string discharge current

warning

29

iDM2

Istr_Dch_Max_2

DISCH

Recoverable Alarm

NULL

High string discharge current alarm

30

MID1

MidString_Error_1

V_STR

Warning

LONG

String voltages unbalance warning

31

MID2

MidString_Error_2

V_STR

Recoverable Alarm

LONG

String voltages unbalance alarm

32

BLPW

Bus_Power_Too_Low

CHRG

Warning

SHORT

Dc bus power too low for charging

33

CCBF

CCB_HW_Error

HW

Unrecoverable Alarm

LONG

Charge regulator failure

35

Ah_W

Ah_String_Empty_1

DISCH

Warning

SHORT

String capacity < 12.5%

40

TCdi

ThermoCoupleDiff

TEMP

Warning

LONG

Thermocouples mismatch

43

HTFS

Heaters_Fuse_Blown

INIT

Unrecoverable Alarm

SHORT

Heaters Fuse Blown

SHORT Delay

Default value is 10 seconds

LONG Delay

Default value is 120 seconds

NULL Delay

No delay

Table L

FIAMM SoNick I&O - 48TL160H rev.0–July 2013

pag.20

5.5 Service Life Definition

The service life of the FIAMM SoNick 48TL160H battery is the period of useful service under the

conditions defined in the battery specification expressed as the period elapsed between the start of

life and the time where the ampere-hour maximum capacity has fallen to 80% of the rated capacity.

Even if the battery goes below 80%, its rated capacity will not drop abruptly and suddenly like other

battery technologies.

5.6 Extended Outages

Extended outages don’t have any consequences on the battery health. In case of a prolonged

discharge, the battery disconnects itself from the load when its energy is expended and, if the main

DC supply doesn’t come back, the internal temperature will start to decrease. When cold the

battery is completely inactive and can stand in such condition for a period of time which is virtually

infinite. As soon as the mains return the battery starts the warm up procedure (if needed).

5.7 Light Emitting Diodes (LED’s) explanation

LED COLOUR

INDICATION

NOTE / ACTION

SOLID GREEN

Battery ready to operate,

connected to the DC bus

The battery is fully charged

State of Charge (SOC) =100%

BLINKING GREEN

BLINKING BLUE

Battery is warming up,

not connected to the DC bus

Temperature is below

operational. Charging or

discharging is not allowed

SOLID GREEN

SOLID BLUE

Battery under charge,

connected to the DC bus

Battery SOC is < 100%

Discharging is allowed

SOLID GREEN

SOLID YELLOW

Battery is discharging

Battery SOC is > 20%

SOLID GREEN

BLINKING YELLOW

Battery is discharging

Battery SOC is < 20%

SOLID GREEN

BLINKING RED

A warning occurred during

the float (idle) condition

Check float (idle)

conditions/parameters

SOLID GREEN

SOLID BLUE

BLINKING RED

A warning occurred while

the battery was charging

Check charge

conditions/parameters

SOLID GREEN

SOLID YELLOW

BLINKING RED

A warning occurred while

the battery was discharging

Check discharge

conditions/parameters

BLINKING GREEN

SOLID RED

Alarm status –the battery

is not connected to the DC bus

The battery was disconnected

because of a major issue.

Charging or discharging

is not allowed

NO LED ON

the BMS is not powered-up

Check if battery switch is OFF

If not, check if DC bus is up

otherwise, the BMS has to be

serviced/repaired

Table M

Table of contents

Other Fiamm Camera Accessories manuals

Popular Camera Accessories manuals by other brands

Teknoware

Teknoware TKT65 B Series Installation and maintenance instructions

Sony

Sony Exmor HXCU-D70 operating instructions

MRMC

MRMC MRMC-1166-02 quick start guide

FujiFilm

FujiFilm WP-FZX100 owner's manual

Teknoware

Teknoware TKT68C Installation and maintenance instructions

Aibird

Aibird uoplay 2 user guide