Fiamm FLX Manual

FIAMM Industrial Batteries December 2012

FIAMM AGM Valve Regulated Recombination Batteries: FLX Series- Engineering Manual

This document and any confidential information it contains shall be distributed, routed or made available solely with written permission of

FIAMM. FIAMM reserves the right to change or revise without notice any information or detail given in this manual Page

1

TABLE OF CONTENTS PAGE

1 OPERATING CHARACTERISTICS 2

2 INSTALLATION 4

3 CHARGING 6

4 STORAGE AND REFRESH CHARGING 8

5 MAINTENANCE AND TESTING 9

6 SAFETY 10

7 APPLICABLE STANDARDS 10

8 RECORDS DATA 10

FIAMM Industrial Batteries

FIAMM AGM Valve Regulated Recom

This document and any confidential

informa

FIAMM. FIAMM reserves the right to change

1 OPERATING

C

Capacity

and final discharge vo

Battery

capacity is rated in Ampe

discharging rate of 20 h

ours to 1.

FIAMM FLX Series batteries

can

vice versa.

Internal resistance and short ci

The internal resistance and sho

plate thickness, number of plates

charge and other variables.

Product ratings

are determined

described in IEC or BS standards

Voltage

The voltage of lead acid cells is

electrode materials (PbO

2

and Pb

on the electrolyte concentration in

Power

Design life

ombination Batteries: FLX Series

- Engineering Manual

ation it contains shall be distributed, routed or made available sole

ge or revise without notice any information or detail given in this m

CHARACTERISTICS

voltage

peres per hours (Ah). Nominal capacity is usually

1.75 volt per cell at 77°F

for different applications.

an be discharged to

a lower voltage using hi

ghe

circuit current

ort circuit current of a battery are functions of its

tes, separator material,

electrolyte specific gravity,

ed

through performance test

ing done in accor

ds.

is

related to the electrochemical potential differenc

Pb) in the presence of electrolyte (sulphuric acid).

in contact with these elec

trodes and the state

of c

FIG.1 – POWER

December 2012

lely with written permission of

manual

Page

2

ly declared according to

er discharge current or

its construction design,

ty, temperature, state of

ordance

with methods

nce between the active

). Its value

is dependent

charge

of the battery.

FIAMM Industrial Batteries December 2012

FIAMM AGM Valve Regulated Recombination Batteries: FLX Series- Engineering Manual

This document and any confidential information it contains shall be distributed, routed or made available solely with written permission of

FIAMM. FIAMM reserves the right to change or revise without notice any information or detail given in this manual Page

3

According to international standards a battery is considered at the end of its service life when the

battery delivers less than 80% of its rated capacity. FIAMM FLX batteries have a design life of up to 10

years. Confirmation of service life comes not only from consistent feed-back from field applications, but

also from extensive accelerated thermal testing.

Operation at temperatures higher than 77° F reduces the performance life expectancy of a battery.

Service life of the battery is also affected by the float voltage chosen for battery charging, as showed in

figure 2.

FIG.2 – EXPECTED SERVICE LIFE VS FLOAT VOLTAGE RANGE

Capacity in relation to the temperature

The capacity available from a battery, at any particular discharge rate, changes according to the

working temperature.

Capacity in relation to the discharge rate

The capacity available from a battery depends also on the rate of discharge. For FIAMM FLX batteries

at 77°F please refer to table 1.

Table 1 – AVERAGE CAPACITY VS DISCHARGING RATIO

DISCHARGE RATE

(hours)

END

VOLTAGE

CAPACITY

(% of C20 Ah)

FLX

20 1.75 100

10 1.80 90

5 1.80 85

3 1.80 77

1 1.75 63

FIAMM Industrial Batteries December 2012

FIAMM AGM Valve Regulated Recombination Batteries: FLX Series- Engineering Manual

This document and any confidential information it contains shall be distributed, routed or made available solely with written permission of

FIAMM. FIAMM reserves the right to change or revise without notice any information or detail given in this manual Page

4

Self discharge

The state of charge of lead acid batteries slowly decreases while on open circuit due to self discharge.

In FIAMM FLX batteries, the rate of self discharge is approximately 2% per month at 77°F (+/- 5° F). In

case of extended storage it is necessary to refresh the batteries every 6 months to avoid a permanent

loss of capacity.

Cycling

FIAMM FLX batteries have been tested successfully according to the latest cycle life test procedure

standards specified for VRLA batteries (IEC and BS).

Gassing

Having a very high recombination efficiency (>99%), for batteries operated at 77° F and under normal

operating conditions, gas release is negligible. Laboratory test measurements show the following

gassing rates under normal operating conditions (2.27 Vpc, 77°F):

•1

st

week of service 80cc/Ah/day

•2

nd

week of service 10cc/Ah/day

•After stabilization (2 months) 2cc/Ah/day

Battery rooms or cabinets should have natural ventilation and should not be fully sealed.

Operation of batteries in parallel

When the required capacity exceeds the capacity of a single string of batteries, it is common practice to

connect strings in parallel. It is important to pay attention to the following guidelines:

•In each string only batteries of the same type, model, age and quantity should be used;

•A symmetrical layout of the batteries should be designed (i.e. length and type of connector)

to minimize possible resistance variations;

•Number of strings in parallel should be reasonable in terms of layout and application. If

strings are properly cabled, with equal voltage losses for each string, multiple strings can be

connected in parallel, safely to reach required total capacity.

2 INSTALLATION

Unpacking and inspection

Upon receiving a shipment of batteries it is important to check it carefully against related packing list.

Even though each consignment is certified and inspected by FIAMM before shipping, missing parts or

damages could be caused by mishandling during transportation. Any damage or any specific problem

found must be reported immediately by the consignee to the carrier and to the manufacturer for further

insurance or legal actions.

FIAMM FLX batteries are shipped fully charged with terminal posts insulated to avoid any possible short

circuit.

Batteries delivered in cabinets

For safety reasons, it is not advisable to pre-assemble batteries strings into cabinets before shipping

equipment to the site. However, if this is necessary, it is strongly recommended to protect the battery

system from mechanical stress and vibrations occurring during transportation. Batteries should be

properly fastened to the relevant cabinet shelves by means of plastic band and/or other adequate

methods. Furthermore the cabinets should be protected using shock-absorbing packaging material.

Special precautions must be taken to avoid accidental short circuits.

Handling requirements

Batteries are heavy so they require proper care in handling. Always lift each cell/block from underneath

or by the lifting handles. Never apply force to, or drop anything on, the terminal posts.

Room requirements

Batteries should be installed in a clean, cool, dry room on insulated racks or in a cabinet. Care must be

taken in providing adequate floor loading capability and sufficient aisle space for servicing. Good

lighting is also important to carry out visual inspections. Access to the battery room must be restricted to

qualified personnel only.

FIAMM Industrial Batteries December 2012

FIAMM AGM Valve Regulated Recombination Batteries: FLX Series- Engineering Manual

This document and any confidential information it contains shall be distributed, routed or made available solely with written permission of

FIAMM. FIAMM reserves the right to change or revise without notice any information or detail given in this manual Page

5

Ventilation in battery room

Under normal operating conditions, the gassing rate of FIAMM FLX Series batteries is extremely low.

However, the battery room should have sufficient ventilation to avoid temperature rise in the event of

unexpected circumstances such as overcharge due to a charger malfunction. As accelerated

recombination reaction generates heat, it is important that there allowances in ventilation to dissipated

excess heat through ventilation or air conditioning.

Temperature control in battery room

Battery life and performance are optimal at a temperature of 77° F. Operation at lower temperature will

reduce available capacity (for the period of time that the battery remains at low temperature). Higher

operating temperatures affect battery performances and will shorten the battery service life. Air

circulation within the battery room must be sufficient to avoid hot or cold spots. The total temperature

spread between the hottest and the coldest cell of the same string should be maintained inside a

window of +/- 5°F.

Racks

Battery racks should be grounded and made of acid resistant and insulated material. For safety reasons

they should be installed as level as possible. The depth and the height of the racks, along with servicing

headroom, should allow both adequate ventilation and a satisfactory servicing.

Cabinets

Good ventilation is extremely important for battery cabinets. Ventilation openings should be both at the

bottom of the cabinet, and as close as possible to the top, to prevent any hydrogen accumulation in an

abusive situation. Cabinets should be placed/fastened steadily to the floor.

Installation procedure

For a proper installation clean the blocks with a soft dry antistatic cloth or soft water-moistened cloth.

Place each cell/block at their correct position according to the electrical layout. Start with the lowest

shelf to ensure stability. Inter-tier and inter-row connections should be applied only once all blocks have

been connected properly. For proper ventilation and airflow maintain a distance of .25” or greater

between all battery blocks.

Interblock connecting procedure

It is extremely important to ensure proper surface contact between battery terminal posts and cables

(recommended) or solid connectors used to complete each string. Each connecting surface must be

clean and without oxidation. If required use very fine grit abrasive paper to remove any dirt on each

surface. Do not use wire brushes or similar tools that may damage the plating film around terminals’ and

connectors’ copper. Then apply a light coating of No-Ox grease to the terminals and connectors prior to

installation of the connection hardware.

Terminal torque settings

To ensure a proper electrical connection between the flat surface of each terminal and the connector a

calibrated torque wrench must be used. Torque the electrical connections to the settings in Table 2.

Table 2 – TORQUE SETTING VALUES

Battery Terminal Type Torque (in-lbs)

Final checking of connections

To perform a final check of the connections it is advisable to measure the overall battery voltage and

make sure that this value is equal to the open circuit voltage of an individual block multiplied by the

number of blocks.

Paste a sticker with a progressive number to each block, making sure that the surfaces are dry and

clean. It is a good practice to number the blocks beginning with #1 at the positive end of each string.

FIAMM Industrial Batteries December 2012

FIAMM AGM Valve Regulated Recombination Batteries: FLX Series- Engineering Manual

This document and any confidential information it contains shall be distributed, routed or made available solely with written permission of

FIAMM. FIAMM reserves the right to change or revise without notice any information or detail given in this manual Page

6

Connection of the battery to the rectifier/load

The end positive terminal of each string of batteries should be connected to the positive terminal of the

charger, and the battery negative to the charger negative. Same procedure needs to be used for load

connections. A proper selection in cables and connectors should be used to avoid excessive voltage

drop, as well as overheating in case of high rate discharge. If a large section of cables are used their

weight should not stress cell/block terminals. A good method to use is to affix cables on the rack or the

nearby wall.

3 CHARGING

Introduction

After installation, in order to ensure the best protection against power failures, it is necessary that

batteries are kept in the following conditions:

•float charged throughout their standby period;

•fully recharged soon after a discharge.

Recharging process can be performed in several ways, depending on the site and equipment

conditions, but there are two main methods:

•float voltage recharge

•boost charge

The IU recharge method, also known as the modified constant voltage recharge, has been used for

many years and in a variety of applications. This method combines the need to have the battery quickly

recharged while ensuring maximum battery life. With this method, recharge starts at a constant current

rate. The voltage increases up to a pre-set value. The pre-set voltage is maintained and the current

then decreases to a minimum defined value. Finally, the recharge is completed at a final constant

voltage value equal to or less than that defined for float charge with the current decreasing to the value

used in float.

•

For UPS systems that do not utilize a constant float voltage charging profile or use an

Advanced Battery Management charging profile please set the charging parameters per

table 3.

Table 3 – ALTERNATE CHARGING PROFILE SETTINGS

FLX MODEL CURRE T LIMIT VOLTAGE

Recommended procedure for initial charging

For a safe installation of FIAMM FLX batteries only constant voltage chargers should be used.

The best charging method operates with a preset constant voltage value supplying an automatically

limited charging current. It is called constant voltage charging with current limit and automatic

crossover.

An initial charge of 2.35 to 2.40 volts per cell for at least 24 hours (at 77° F) is suggested during

commissioning or before a capacity test in order to be sure that the battery is in fully charged condition.

FIAMM Industrial Batteries December 2012

FIAMM AGM Valve Regulated Recombination Batteries: FLX Series- Engineering Manual

This document and any confidential information it contains shall be distributed, routed or made available solely with written permission of

FIAMM. FIAMM reserves the right to change or revise without notice any information or detail given in this manual Page

7

Float operation for standby use

For standby applications the recommended float voltage window is between 2.25 to 2.30 volts per cell

depending on the model and on site temperature, as showed in table 4 (charger’s float voltage

tolerance is within ±0.005 volt per cell).

Table 4 – FLOAT VOLTAGE VS SITE TEMPERATURE

Site Temperature

(°

°°

°F)

Float voltage per cell

FLX

60 2.29

64 2.285

68 2.28

72 2.275

75 2.27

77 2.27

79 2.265

82 2.26

86 2.255

90 2.25

93 2.245

97 2.24

100 2.235

104 2.23

Residual current

Whenever battery chargers are working properly (and in accordance with manufacturer instructions) it is

normal to have a residual float current in fully charged batteries. Residual float currents will slowly

increase during a batteries life and according to cycle frequency. Although the charger is set on a fixed

average voltage, it is normal to record a spread in voltage between each block inside a string. Voltage

variation within ±250mV/battery is considered as a normal value particularly in the first 12 months from

initial installation.

Recharge following discharge for standby use and boost charge

At the first installation, or soon after a discharge, the recommended recharge method is to use a

constant voltage equal to the float charge voltage with a maximum charge current of 25% of nominal

capacity.

To reduce the recharge time, the IU recharge method can be used with a higher voltage of 2.35-2.40

V/cell at 77° F for 24 hours and a current limit of 0.25 C

10

. This process, also called boost charging,

should be applied only when batteries are not in a fully charged condition and need to be recovered in a

short period of time.

The battery should be placed back on float as soon as possible, ideally as soon as the charge current

has dropped below 20 mA/Ah (or lower if the application has frequent power failures).

Boost charge should be used only when necessary. Frequent equalize charging can result in more

water consumption, which will lead to reduced capacity and shortened battery life.

Float voltage and recharge procedures for frequent discharge applications

Whenever FIAMM FLX batteries are used in applications with frequent power failures (such as several

discharges a month) float voltage should be set at a higher range compared with a standby applications

range (i.e. from 2.27 to 2.30 volt per cell at 68-77°F). The recommended float voltage values necessary

to maximize the battery life at different temperatures are shown in table 4. The most important target in

this type of environment is to have the batteries recovering promptly after a discharge

FIAMM Industrial Batteries December 2012

FIAMM AGM Valve Regulated Recombination Batteries: FLX Series- Engineering Manual

This document and any confidential information it contains shall be distributed, routed or made available solely with written permission of

FIAMM. FIAMM reserves the right to change or revise without notice any information or detail given in this manual Page

8

To reduce the recharge time, the IU recharge method can be used with a maximum voltage of 2.30

V/cell at 68-77° F for 24 hours. Current should not be over 25% of nominal capacity, especially in sites

where temperature may exceeds 86° F to avoid thermal runaway, overheating or overcharging of the

batteries.

For very deep cyclic applications recharge voltage should not be higher than 2.30 V/cell for 16 to 24 hrs

after every discharge.

Temperature compensation of the float voltage .

To optimize FIAMM FLX battery life and performance over the normal operating temperature range, the

float voltage should be adjusted in accordance with table 4.

In environments where temperature fluctuations are very limited, float voltage can be adjusted manually

as needed. For most sites without a climate control systems it is advisable to have batteries connected

to a charger with a built-in temperature compensation circuit.

Temperature sensor needs to be positioned on or over the batteries and not in the charger.

Ripple

Excessive ripple currents can cause battery overheating, which will lead to shorter life expectancy and

reduced product performance. It is recommended that voltage regulation across the system (including

the load, but with battery disconnected), under steady state conditions, should be better than ±1%

through 5% to 100% load. Transient and other ripple type excursions can be accommodated provided

that, with the battery disconnected but the load connected, the system peak to peak voltage, including

the regulation limits, falls within ±2.5% of the recommended float voltage of the battery. Under no

circumstances should the current flowing through the battery, when it is operating under float conditions,

reverse into the discharge mode.

4 STORAGE AND REFRESH CHARGING

Storage

Batteries are delivered filled and charged ready for installation. If they cannot be installed immediately,

batteries need to be kept in fresh, clean dry rooms.

Refreshing charge procedure

During storage batteries will lose part of their capacity due to self-discharge (2% per month at 77°F). A

freshening charge is recommended at least every 6 months (at 77°F storage temperature).

Batteries should be refreshed, even if kept in storage at 77° F, when the cell voltage drops below the

values listed in table 5. A freshening charge could be carried out by charging at 2.4 V/cell for about 24

hours at 77°F (boost). If the charging system can not meet the above requirement (lower than 2.4 Vpc,

it is necessary to extend the charging time 24 hrs for every 0.03V/cell lower than 2.30V/cell, for

example, 120 hours at 2.28 V/cell).

Table 5 – OPEN CIRCUIT VOLTAGE VALUES REQUIRING A RECHARGE (WHEN STORAGE AT 77°F)

RANGE

OPEN CIRCUIT VOLTAGE (PER CELL)

FL

X

2 months 2.120

4 months 2.105

6 months 2.095

FIAMM Industrial Batteries December 2012

FIAMM AGM Valve Regulated Recombination Batteries: FLX Series- Engineering Manual

This document and any confidential information it contains shall be distributed, routed or made available solely with written permission of

FIAMM. FIAMM reserves the right to change or revise without notice any information or detail given in this manual Page

9

5 MAINTENANCE AND TESTING

FIAMM FLX Series batteries are maintenance-free with respect to the water additions, but it is important

to carry out few standard maintenance procedures to ensure the longevity and the reliability of the

battery.

Visual inspection

FLX Series batteries should undergo a thorough visual inspection on a periodic basis to verify the

following parameters:

-Cleanliness of the battery and surrounding area;

-Signs of corrosion at the terminals, connections, or support structure (rack or cabinet);

-Block integrity (cracks, or excessive jar/cover distortion, or signs of electrolyte leaks or

seepage);

-Tightness of the terminal and intercell connections.

If any block shows physical damage it is recommended to immediately check the block float voltage

and/or temperature.

Cleaning

When necessary, batteries could be cleaned using a soft dry cloth or water-moistened soft cloth paying

attention not to cause any ground faults.

No detergent or solvent-based cleaning agents or abrasive cleaners should be used as they may cause

permanent damage to the battery plastic container and lid.

Voltage checks

All voltage measurements should be made when the entire battery has stabilized on float, at least 7

days after battery installation or after a discharge cycle.

Measure and record individual block voltages on float once a year. It is normal to have a spread of block

voltages up to ±250 mV/battery, particularly in the first year of operation. No corrective action is

required in this case.

Maintaining a correct battery charging voltage is extremely important for the reliability and life of the

battery. It is advisable to carry out periodic checks of the overall float voltage to verify any possible

defect of the charger or connections.

Capacity/Power Test

It is very important to verify connections and potential voltage drops as high power discharge can be

dangerous if connections are improper or not in good condition.

Before any discharge testing, batteries should be properly prepared with a boost charge to ensure they

are in a fully charged condition. In order to take temperature readings of a battery, one pilot cell or block

should be chosen. The surface temperature of the container wall center of each pilot block should be

measured immediately prior to the discharge test. The individual readings should be between 59°F and

86° F. The temperature of the selected block should be considered as representative of the average

temperature of the battery. It is desirable that the average basal surface temperature and the ambient

temperature fall as near to the reference temperature of 77°F as possible.

In case of batteries having a capacity lower than 80% of the nominal rating it is advisable to replace

them within 12 months.

FIAMM Industrial Batteries December 2012

FIAMM AGM Valve Regulated Recombination Batteries: FLX Series- Engineering Manual

This document and any confidential information it contains shall be distributed, routed or made available solely with written permission of

FIAMM. FIAMM reserves the right to change or revise without notice any information or detail given in this manual Page

10

6 SAFETY

Under normal operating conditions FLX Series batteries are considered 'office compatible'. However,

under abusive conditions, such as charger malfunction or physical damage, there is potential danger of

corrosion or fire. Therefore it is strongly recommended to carefully read the instructions contained in this

manual to avoid any critical situation. In any case local safety regulations for electrical equipment sites

must be regarded as a basic requirement.

Protective material list

Make sure that the following equipment is available to personnel working with batteries:

-Engineering/installation manual;

-Insulated spanners and tools;

-Fire extinguishers;

-Proper protective clothing.

Safety Precautions

Batteries are no more dangerous than any other electrical equipment when handled properly.

So for safety reasons it is necessary to follow few important precautions below reported:

-Do not allow metal objects to rest on the battery or fall across the terminal posts;

-Never wear rings or metal wristbands when working on batteries;

-Do not try to remove the battery cap to add water or acid into the cell(s);

-Do not touch non-insulated terminals or connectors as there is a risk of electric shock;

-Do not allow naked flames, hot objects or sparks near the battery;

-Do not smoke near the battery or in the battery room.

The electrolyte (diluted sulphuric acid) is extremely corrosive. Any contact with eyes can cause severe

and permanent damage. Contact with skin could result in severe burns. In case of severe physical

contact with electrolyte wash the affected area with running water immediately and go to the closest

hospital to seek medical attention.

Decommissioning of the batteries

Most components of a lead acid battery are recyclable. Lead acid batteries must be disposed according

to local regulations. It is strongly recommended that, at the end of their service life, batteries are

delivered to a certified lead smelter for proper recycling.

7 APPLICABLE STANDARDS

FIAMM FLX batteries comply with International Standards. Furthermore, FIAMM valve regulated

recombinant batteries are approved by most major Telecom Operators, UPS and Power Equipment

manufacturers.

8 RECORDS DATA

Complete written records of the installation, maintenance and testing of the product is important to

ensure a proper understanding of the operational history of the batteries.

Records are necessary for the manufacturer/user to understand when corrective actions should be

taken. Data required for a proper engineering review are

•Production date of batteries,

•Installation date,

•Historical average temperature of the site,

•Float voltage,

•Discharge frequency,

•Load applied during each discharge.

BATTERY MAINTENANCE REPORT

Installation Date:……………………………… Battery Location:………………………………………………

Battery/Cell Type:.…………………………….. Pilot Block No.:………………………………………………..

Other::………………………………………………………………………………….……………………………………..

MONTHLY READINGS

INDIVIDUAL CELL/BLOCK READINGS

Date String

voltage (V)

Pilot cell/block Date:

Volts Temperature (F)

Time:

String voltage (V):

Charge current (A):

Block No. Volt

Block No. Volt

1 31

2 32

String Discharged:

Date : …………… Duration :………..

Date : …………… Duration :………..

String Equalized:

Date : …………… Duration :………..

Date : …………… Duration :………..

Remarks:

3 33

4 34

5 35

6 36

7 37

8 38

9 39

10 40

11 41

12 42

13 43

14 44

15 45

16 46

17 47

18 48

19 49

20 50

21 51

22 52

23 53

24 54

25 55

26 56

27 57

28 58

29 59

30 60

Blocks temperature: #01………., #12…………,#24…………

Blocks temperature: #36………., #48…………,#60…………

Readings taken by:

Table of contents

Other Fiamm Camera Accessories manuals

Popular Camera Accessories manuals by other brands

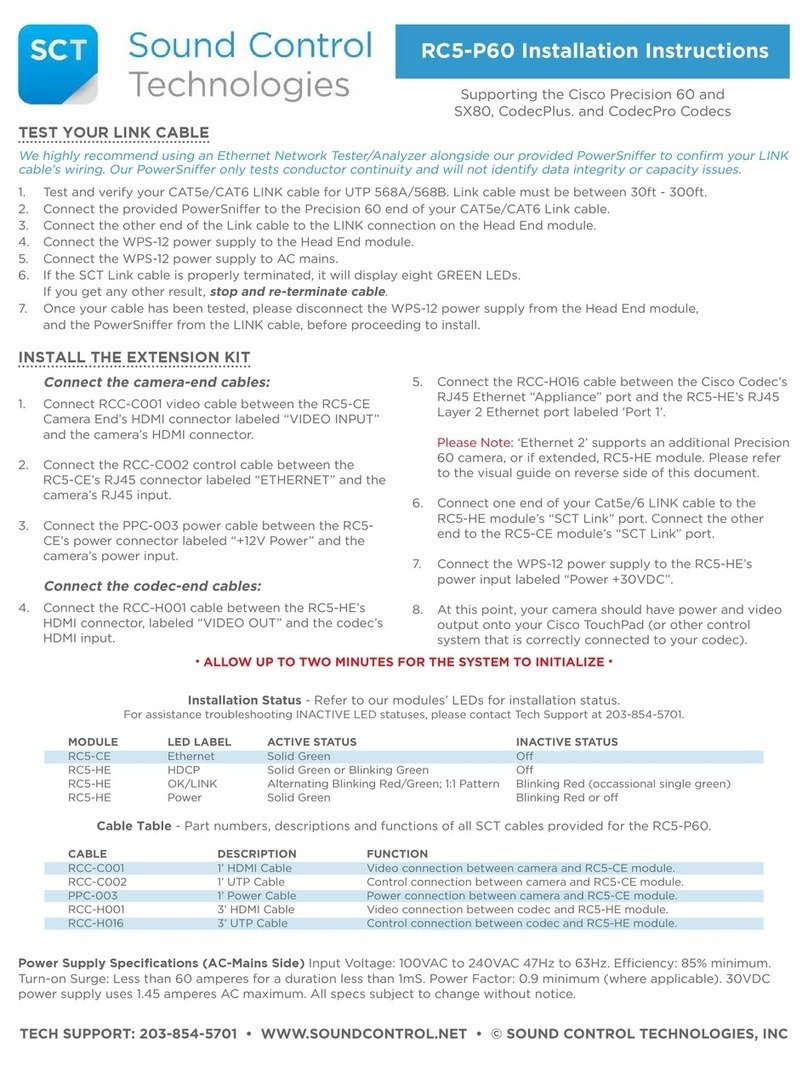

SCT

SCT RC5-P60 installation instructions

Bosch

Bosch MIC-67SUNSHLD Quick installation guide

Puredrive

Puredrive PureStorage II user manual

Chesapeake & Midlantic

Chesapeake & Midlantic BMT-70A10 installation manual

Iqinvision

Iqinvision X2 installation instructions

Vello

Vello FreeWave Fusion Basic user manual