NUOVA PANDA

Electrical system

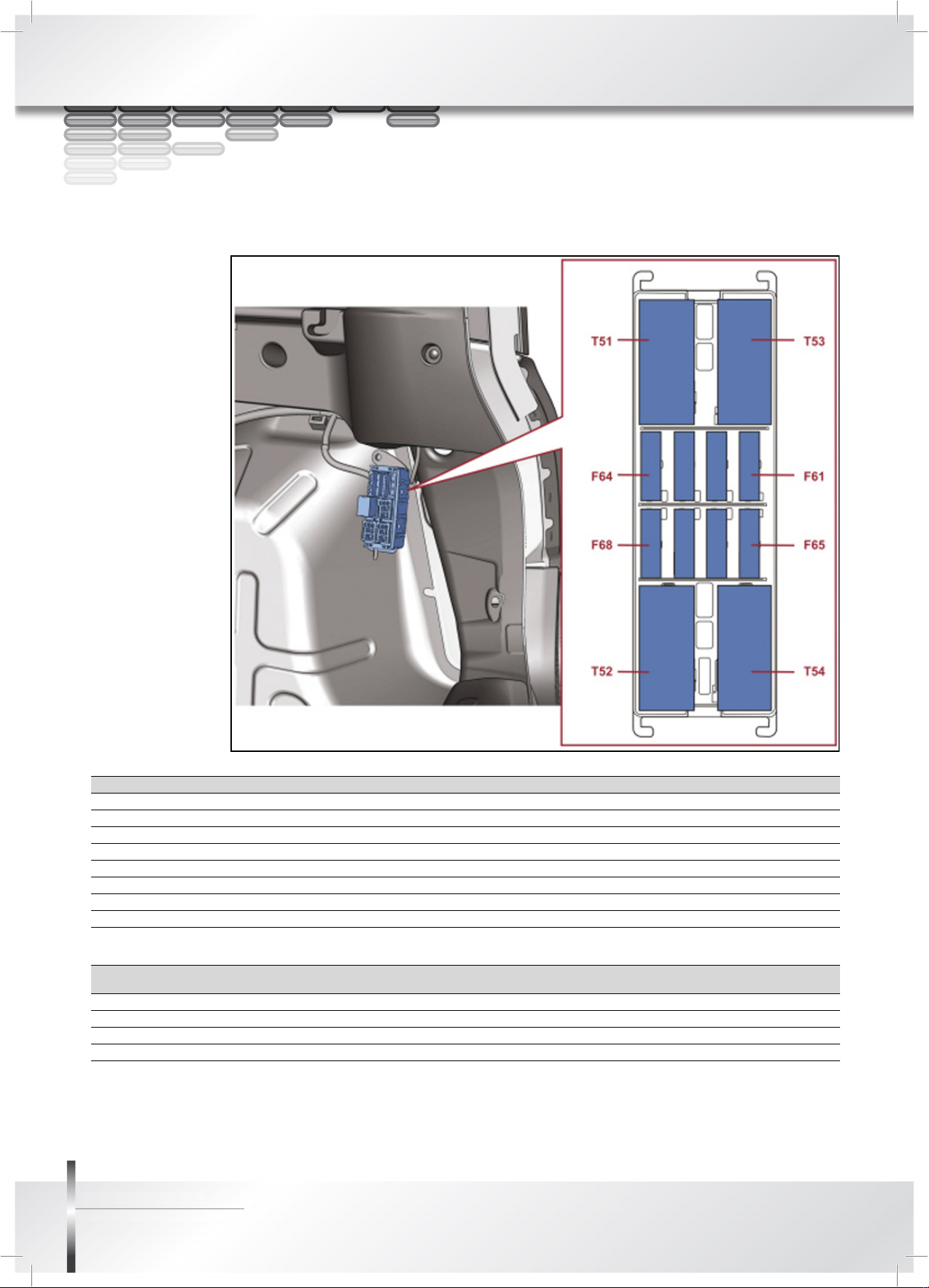

Relay switch T20 for LPG supply / Methane system supply and regulation (CNG version) F23 7,5

Braking System Node and Electric Steering Node F24 7,5

Heated blow-by resistance (TwinAir 85 HP and 1.3 MJet versions) F30 5

Robotised gearbox electric pump F81 30

Heater plug control unit (1.3 MJet version) F81 50

Electric roof motor F82 20

Braking System Node F83 20

Robotised Gearbox Node F84 10

Differential unlocking control unit (4×4 version) / Methane injectors (CNG version) F84 7,5

Reversing light switch (for versions with manual gearbox only) F87 5

Mirror demisting F88 7,5

Heated rear window F89 30

Battery charge status sensor for Start&Stop system (IBS) F90 5

Heated seats Fxx 15

User Relay

switch

Ampere

Main beam headlights T02 20 (micro)

Acoustic warning T03 20 (micro)

Air conditioning compressor T05 20 (micro)

One-speed engine cooling fan T06 30 (micro)

Engine cooling fan (low speed) T06 30 (micro)

Engine cooling fan (high speed) T07 50 (maxi)

Passenger compartment air fan T08 30 (micro)

Engine management system (main relay) T09 30 (micro)

Relay switch 1 for start-up management with Start&Stop system from Body Computer node / Methane injector supply relay

switch (CNG version) T10 30 (micro)

Current socket/cigar lighter T14 30 (micro)

Heated rear window/window defrosting T17 30 (micro)

Fog lights T19 20 (micro)

Relay switch 2 for starting management with Start&Stop system from Engine Control Node T20 30 (micro)

Relay switch for LPG supply / Methane system supply and regulation relay switch (CNG version) T20 20 (micro)

Fuel pump T31 30 (micro)

Heated blow-by T89 20 (micro)

Heated diesel filter (1.3 MJet version) T90 30 (micro)

User Fuse Ampere