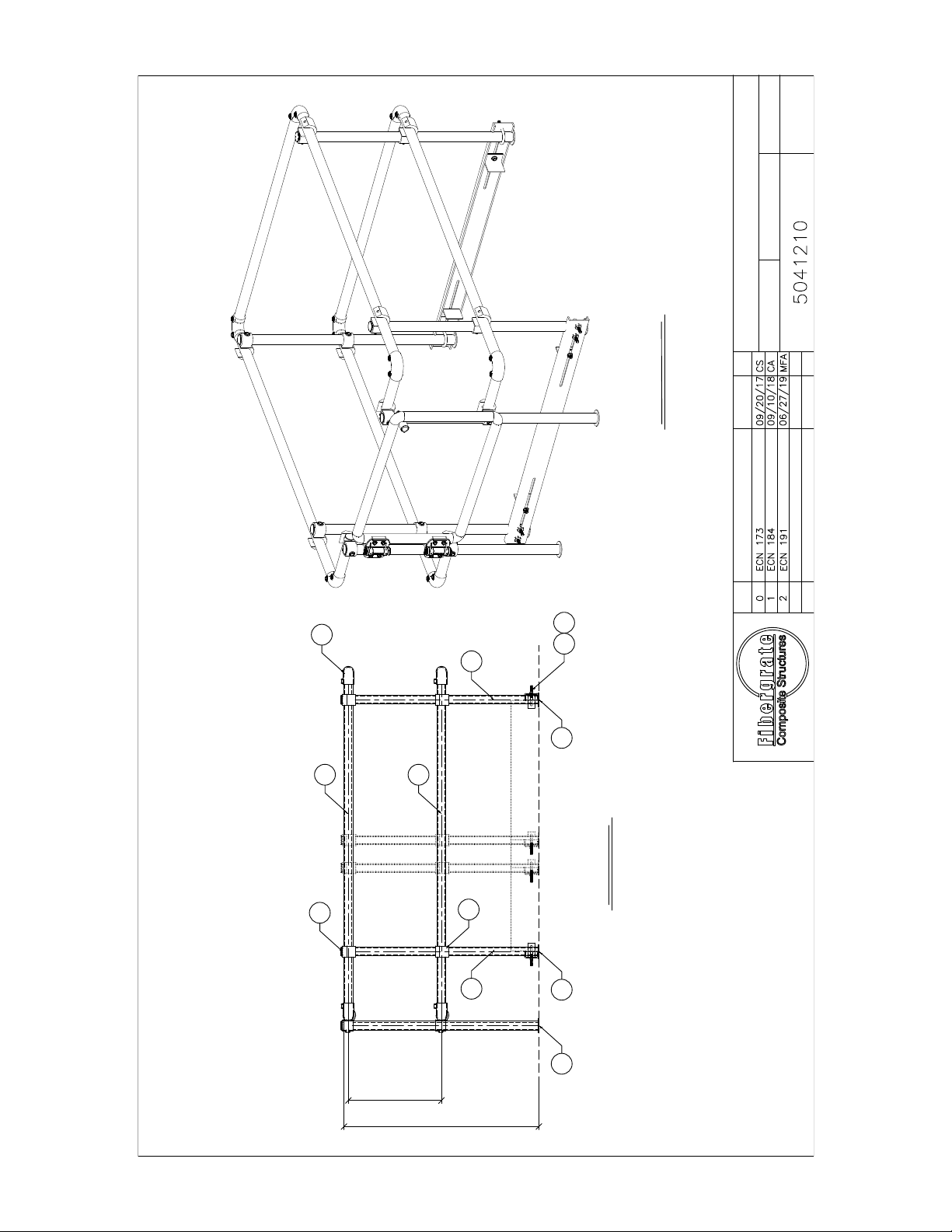

Fibergate 5041210 DynaRound RG Hatch Guard Yellow User manual

www.bergrate.com | 800-527-4043 1

DynaRound™ Hatch Guard System Installation Instructions

ASSEMBLY INSTRUCTIONS:

1. Inspect and inventory all components of the Dynaround RG Hatch Guard and compare to the bill of materials listed on the rst

page of the drawings to verify that all materials are available for installation. Contact Fibergrate at 1-800-427-4043 to report

missing material and obtain replacements.

2. Read these instructions and study the drawings thoroughly before attempting to install the DynaRound RG Hatch Guard. Be

sure you are referring to the correct drawings for the Hatch Guard being installed.

3. Inspect the hatch and surrounding roof area where the DynaRound RG Hatch Guard is to be installed. Remove any debris or

obstructions in the installation area and verify all eld dimensions and conditions prior to assembling and installing the Hatch

Guard.

4. It is recommended to assemble the Hatch Guard adjacent to the hatch, then lift it over the hatch and clamp the Hatch Guard

in place. Prepare a suitable assembly area adjacent to the hatch and protect the roof in that area following the roong

manufacturer’s recommendations

5. While the components of the DynaRound RG Hatch Guard which contact the roof are designed not to damage roong

materials, it is recommended that the roof manufacturers recommendations be followed for protecting the roong material

from abrasion damage at any location where the Hatch Guard contacts the roof.

IMPORTANT

Read these instructions completely before attempting to install the DynaRound Hatch Guard. It is important to understand

the installation procedure thoroughly prior to beginning work. It is the installer’s responsibility to carefully follow fabrication

and installation plans and instructions to ensure design performance characteristics of the DynaRound Hatch Guard. The

installer could be liable for claims that result from improper installation.

The DynaRound Hatch Guard System is designed to protect all rooftop hatch entry and exit points. This non-penetrating

system is easily installed and can be used both temporarily and preeminently depending on need. The FRP railings and

galvanized ttings ensure a long service life.

NOTE: Cuts and drilled holes must be sealed to maintain corrosion protection.

o5/16-inch Hex (Allen) Wrench

o5/16-inch Hex Drive Socket (to t torque wrench)

oTorque wrench 5 – 50 lb-ft range (6.8 –67.6 N-m)

oSocket Set with extensions – SAE (inches)

oOpen End Wrench Set – SAE (inches)

oMarker or Pencil

o25-foot tape measure

oBlue (removable) thread locking compound

TOOLS REQUIRED

Estimated Installation Time: 2 Man Crew, 60 - 90 Minutes

INSTALLATION INSTRUCTIONS ARE FOR:

oPN 5041210 DynaRound RG Hatch Guard Yellow – Fits Hatches 30-36 inches x 30-54 inches

oPN 5041310 DynaRound RG Hatch Guard Yellow – Fits Hatches 30-36 inches x 96-114 inches

oPN 5041410 DynaRound RG Hatch Guard Yellow – Fits Hatches 42-48 inches x 42-60 inches

oPN 5041212 DynaRound RG Hatch Guard Lt. Gray – Fits Hatches 30-36 inches x 30-54 inches

oPN 5041312 DynaRound RG Hatch Guard Lt. Gray – Fits Hatches 30-36 inches x 96-114 inches

oPN 5041412 DynaRound RG Hatch Guard Lt. Gray – Fits Hatches 42-48 inches x 42-60 inches

Drawings for each part number of yellow Hatch Guard are included at the end of these installation instructions. The drawings

for the Lt. Gray Hatch Guards are identical except for color.

Installation Instructions

6. Attach two Item (7) Hatch Guard 3.25”(82 mm) Angle into the long slots in each Hatch Guard 55”(1397 mm) Channel or Hatch

Guard 67”(1702 mm) Channel (depending on Hatch Guard being installed) using 3/8”diameter nuts, bolts, and washer, Items

(9) – (11). The washer is only required on the channel side of the connection. Install item (7) on the ange side of the channels

as shown in the plan view. Build two sub-assemblies. Do not torque the bolts at this time, allowing the Angle Bracket to slide

freely in the slot in the Hatch Channel.

7. Assemble two Item (15) Posts to each Item (6) Hatch Channel. Attach the Posts in the semi-circular cut-outs in the ends of the

Hatch Channels using one each Item (8) 3/8” x 4” U-Bolts with 3/8” nuts and washers. Install each U-bolt using two at washers

and the 3/8” nuts supplied with each U-bolt. Torque the bolts to 40 lb-ft (54.1 N-m), then install a second nut on each side of the

U-bolt to act as a lock nut. Then Install Item (15) Post with the plug end up and the open, bottom end ush with the bottom of

Item (6) Hatch Channel. Cap the bottom of each post with one each Item (4) Caplugs Flanged Plug.

8. Install two Item (1) Open Cross Over to each post as shown in the section on the right side of page 3 of 4 of the drawings. The

upper Open Cross Over should be ush with the top of the post. The lower Open Cross Over should be installed 20-1/16”(510

mm) below the top of the post. Torque the set screws only as needed to hold the Open Cross Overs in place. They may require

adjusting later in the assembly process.

9. Mark each of the four longest sections of 1.9” (48 mm) Diameter Round Tube (Item (13) for PN 5041210, Item (16) for PN

5041310, and Item (19) for PN 5041410) at 6”(152 mm) from one end.

10. Stand up the two post/channel assemblies oriented as they will be in the nal assembly (anges of the Item (6) or (21) Channel

facing toward each other). Locate them approximately the maximum distance apart as shown in the drawings. Place the four

long sections of 1.9” (48 mm) Diameter Round Tube into the Open Cross Overs and align the rails so that the center of the post

opposite the gate is aligned with the marks made in Step 9. After checking that the post channel assemblies are plumb and

properly aligned, torque the set screws in the Open Cross Overs only as needed to hold the 1.9”(48 mm) Diameter Round Tube

in place.

11. Install the two 1.9” (48 mm) Diameter Round Tube Rails (Item (14) for PN 5041210, Item (14) for PN 5041310, and Item (20) for PN

5041410) on the side of the Hatch Guard opposite the gate using four each of Item (2) Two Way Elbow. Torque the set screws in

the Two-Way Elbows only as needed to hold the 1.9” (48 mm) Diameter Round Tube in place.

12. Assemble Item (17) Post w/Gate Support by adding two each Item (1) Open Cross Over as shown in the section on the left of

page 3 of the drawings and the isometric on page 2. The upper Open Cross Over should be ush with the top of the post. The

lower Open Cross Over should be installed 20-1/16” (510 mm) below the top of the post. Cap the bottom of the post with one

each Item (4) Yellow Flanged Plug.

13. Assemble item (5) Hatch Post w/Gate by adding two each Item (1) Open Cross Over following the same directions as in Step 12.

Cap the bottom of the post with one each Item (4) Yellow Flanged Plug.

14. Following the layout shown in the section on the left side of page 3 of the drawings, connect the assembled Item (5) Hatch Post

w/Gate and Item (17) Post w/Gate Support to the ends of the rails installed in Step (9) using Items (2) Two Way Elbows and the

four short sections of 1.9” (48 mm) Diameter Round Tube (Item (12) for PNs 5041210 and 5041310, Item (18) for PN 5041410).

When viewed from the outside of the Hatch Guard, Item (5) is installed on the left side and Item (17) is installed on the right

side. The Gate Support on Item (17) will point outward from the hatch guard as shown in the isometric view on page 2 of the

drawings. Torque all set screws only as needed to hold the assembly in place. Be sure that the posts are located on the outside

of the roof guard as shown in the plan on page 1 of the drawings. Item (5) should be installed such that the end of the gate is

resting against Item (17) Post w/Gate Support.

15. Using a minimum of two people with one on each long side of the Hatch Guard, lift the assembled Hatch Guard over the hatch

and position the hatch so that it falls between the post/channel assemblies. Orient the Hatch Guard so that the self-closing gate

faces the open side of the hatch.

16. Push the assembled Hatch Guard so that the post/channel assembly that is opposite the self-closing gate bears against the

hatch body. Insure that the Hatch Guard is centered on the hatch body. Slide the two Item (7) 3.25” (82 mm) Angle Brackets

until they just contact the hatch body. Apply blue thread locking compound to the bolt threads and torque the bolts to 40 lb-ft

(54.1 N-m).

17. Loosen the set screws in the Open Cross Overs on the post/channel assembly adjacent to the self-closing gate and slide the

post channel assembly until it bears against the hatch body. Re-torque the set screws in the Open Cross Overs to hold the post/

channel assembly in place. Slide the two Item (7) 3.25” (82 mm) Angle Brackets until they just contact the hatch body. Apply

blue thread locking compound to the bolt threads and torque the bolts to 40 lb-ft (54.1 N-m).

18. Verify that the tops of all rails, including the self-closing gate, are at least 42”(1067 mm) above the roof surface and adjust if

needed. After this is veried, all set screws in the (1) Open Cross Overs and (2) Two Way Elbows should have thread locking

compound applied to them and be torqued to 7.5 lb-ft (10.1 N-m)

19. Check the swing of the self-closing gate to verify that it swings freely without binding. Adjust the tension on the hinges

following the instructions provided by Tru-Close and included with the Hatch Guard. Apply equal tension to each hinge. Dial in

only enough tension so that the gate reliably returns to the closed position when opened. Excessive tension may cause damage

to the hinges or gate. Verify that Item (1) Open Cross Over installed upside down in Step (12) to Item (15) has no more than ½”

(13 mm) clearance to the lower surface of the top rail of the self-closing gate.

20. The installed system should be inspected annually by a qualied inspector. The inspection should include checking the set

screws for correct torque, checking for corrosion of the metallic ttings, inspecting the 1.9”(48 mm) diameter FRP tubes for

signs of damage, and checking the self-closing gate for correct operation. Any corrective actions required by this inspector

must be implemented immediately or the Hatch Guard should be clearly tagged as unsafe for use. Written logs should be kept

of every inspection and any corrective actions documented.

NUMBER

PARTITEM QTY

REQ'D

NO.

4

DESCRIPTION

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF1

06/27/19

REV BYDATEDESCRIPTION

5041130

PN 5041210 (ASSEMBLY)-YL

DynaRound RG Hatch Guard

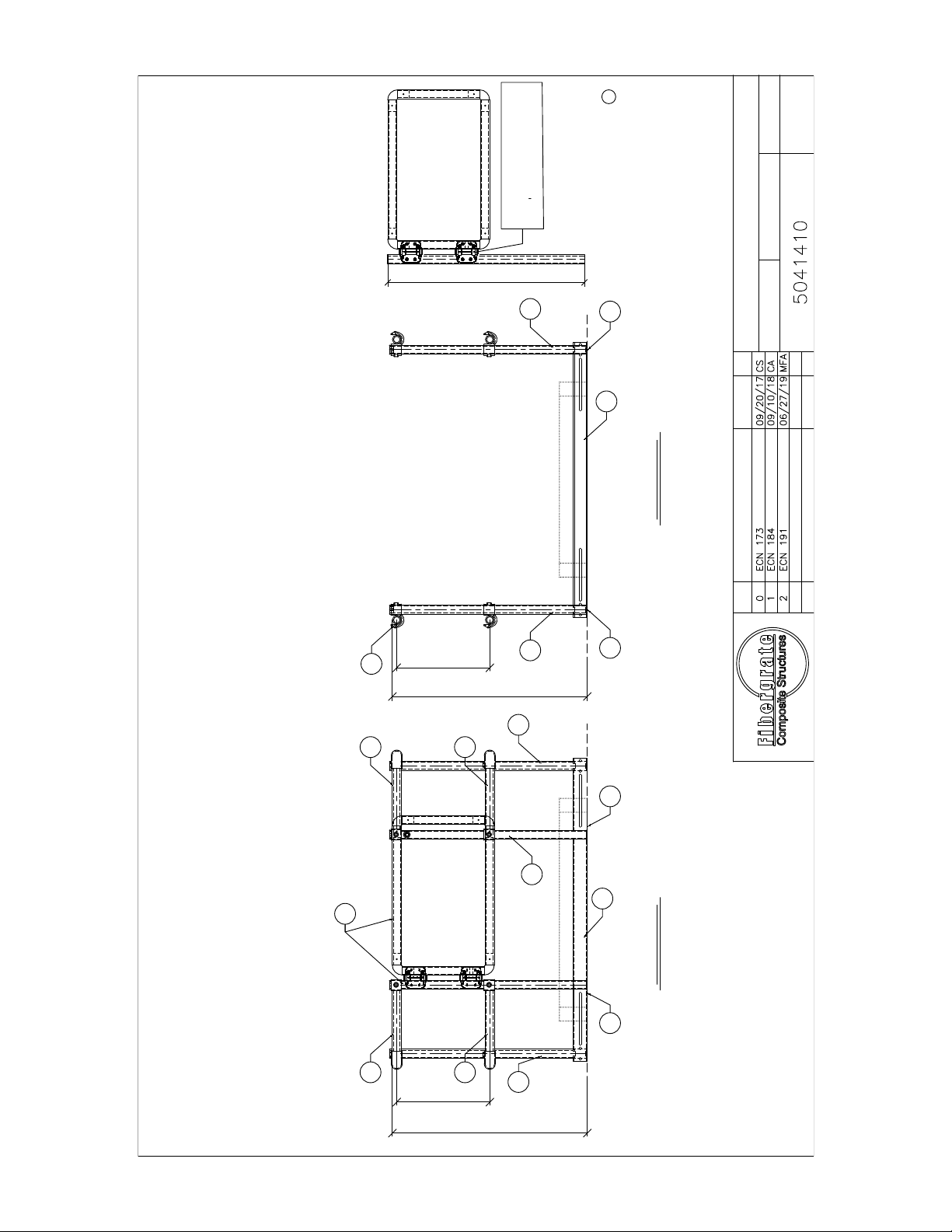

PLAN VIEW

WEIGHT = 152 lb

(69 kg)

2

4

12 Open Cross Over793201

8 Two Way Elbow793125

2Hatch Guard 55" Channel5041113

6 Caplugs Yellow Flanged Plug WWX-17793113

1

4McMaster 3/8"Ø x 4" U-Bolt W/ Nuts Zinc Plated PN 8875T858793114

8 End Cap - UV Coated7926150

4

Hatch Side Rail 74" YL

5041140 Hatch End Rail 52-1/2" YL

5041150 Hatch Post 42-3/8" YL

5041120 Hatch Gate Rail 11-1/4" YL

4

76 3/8"

[1941 mm]

74"

[1880 mm]

54 1/4"

[1378 mm] FOR 36x54 HATCH

6"

[152

mm]

36 1/4"

[921 mm]FOR 30x36 HATCH

30"

[762 mm]

12 3/16"

[310 mm]

52 1/2"

[1333 mm]

57 7/8"

[1471 mm]

A

A

B

B

Material Requirements for 5041210

4 3/8" Ø Nut78420010

12

7

8

3

4

5

2

6

15

1

13

14

12 3/8" Ø Washer78520011

49

12

6

9

10 11

7

12

13

14

3

30 1/4"

[768 mm]FOR 30x30 HATCH

30-36 x 30-54

50

5

Hatch Guard 3.25" Angle5041115

Hatch Post 42-3/8" w/Gate YL5041150.1

3/8" Ø x 1 1/4" Lg. Bolt754530

1 883304 Dynarail-Hatch Guard Installation Instructions16

Yellow

Hatch Post 42-3/8" w/Gate Support YL

1 5041150.217

17

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF2

06/27/19

REV BYDATEDESCRIPTION

ELEVATION

3

48 11

13

13

42"

[1067 mm]

20 1/16"

[510 mm]

4 4

2

1

15 15

ISOMETRIC VIEW

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF3

06/27/19

REV BYDATEDESCRIPTION

SECTION A-A SECTION B-B

15

12

15

12

1212

66

42"

[1067 mm]

20 1/16"

[510 mm]

20 1/16"

[510 mm]

42"

[1067 mm]

4 4 44

15 15

2

1

4 4

5

42 3/8"

[1076 mm]

Hatch Post 42 3/8" w/Gate YL 5

5041150.1

SHIP TRU-CLOSE HINGE

INSTRUCTIONS LOOSE WITH HATCH

GUARD. DO NOT TENSION HINGES

AFTER ATTACHING GATE TO POST.

17

1.9"Ø ROUND TUBE 12

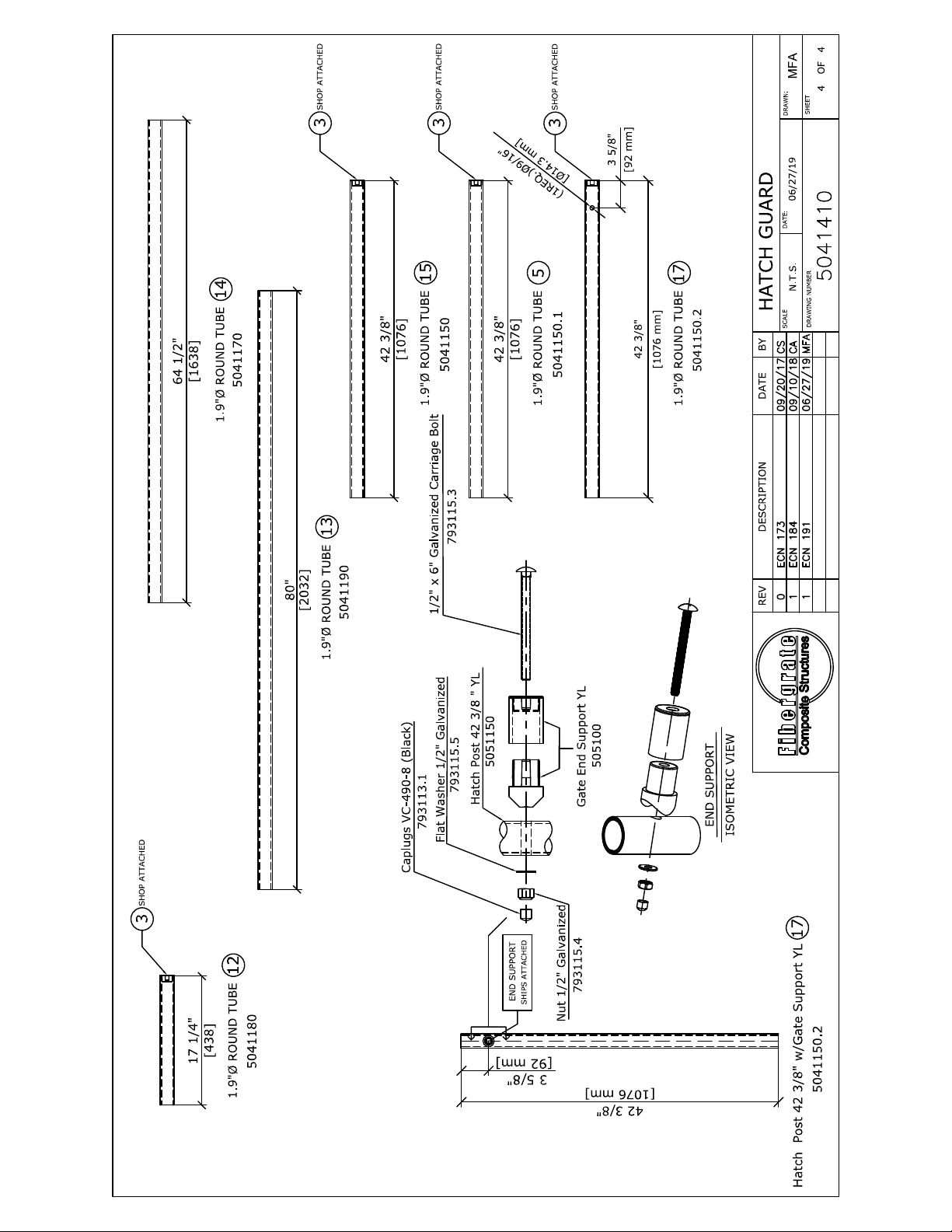

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF4

06/27/19

REV BYDATEDESCRIPTION

11 1/4"

[285 mm]

1.9"Ø ROUND TUBE 13

74"

[1880 mm]

1.9"Ø ROUND TUBE 14

52 1/2"

[1333 mm]

1.9"Ø ROUND TUBE 15

42 3/8"

[1076 mm]

SHOP ATTACHED

3

SHOP ATTACHED

3

5041120 5041130

5041140

5041150

1.9"Ø ROUND TUBE 5

42 3/8"

[1076 mm]

SHOP ATTACHED

3

5041150.1

42 3/8"

[1076 mm]

3 5/8"

[92 mm]

Hatch Post 42 3/8" w/Gate Support YL 17

5041150.2

1.9"Ø ROUND TUBE 17

42 3/8"

[1076 mm]

SHOP ATTACHED

3

5041150.2

3 5/8"

[92 mm]

END SUPPORT

(1REQ.)Ø9/16"

[Ø14.3 mm]

SHIPS ATTACHED

Hatch Post 42 3/8 " YL

5051150

Gate End Support YL

505100

Flat Washer 1/2" Galvanized

793115.5

Nut 1/2" Galvanized

793115.4

Caplugs VC-490-8 (Black)

793113.1 1/2" x 6" Galvanized Carriage Bolt

793115.3

END SUPPORT

ISOMETRIC VIEW

NUMBER

PARTITEM QTY

REQ'D

NO. DESCRIPTION

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF1

06/27/19

REV BYDATEDESCRIPTION

PN 5041310 (ASSEMBLY)-YL

DynaRound RG Hatch Guard - 30-36 x 96-114

PLAN VIEW

WEIGHT = 176 LBS

(80 Kg)

4

2

12 Open Cross Over793201

8 Two Way Elbow793125

2

6 Caplugs Yellow Flanged Plug WWX-17793113

1

4

McMaster 3/8"Ø x 4" U-Bolt W/ Nuts Zinc Plated PN 8875T858

793114

8End Cap - UV Coated7926150

4

5041160 Hatch Side Rail 134" YL

5041140 Hatch End Rail 52-1/2" YL

5041120 Hatch Gate Rail 11-1/4" YL

4

Material Requirements for 5041310

4 3/8" Ø Nut10

12

7

8

3

4

5

2

6

14

1

13

12 3/8" Ø Washer11

49

136 3/8"

[3465 mm]

134"

[3404 mm]

114 1/4"

[2902 mm] FOR 36x114 HATCH

6"

[152

mm]

96 1/4"

[2445 mm] FOR 30x96 HATCH

30"

[762 mm]

12 3/16"

[310 mm]

52 1/2"

[1333 mm]

57 7/8"

[1471 mm]

C

C

D

D

12

6

9

10 11

7

12

13

14

4 5041150 Hatch Post 42-3/8" YL15

784200

785200

3

16 1 Dynarall-Hatch Guard Installation Instructions883304

3/8" Ø x 1 1/4" Lg. Bolt754530

Hatch Guard 55" Channel5041113

Hatch Guard 3.25" Angle5041115

Hatch Post 42-3/8" w/ Gate YL5041150.1

5

Yellow

Hatch Post 42-3/8" w/Gate Support YL

15041150.2

17

17

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF2

06/27/19

REV BYDATEDESCRIPTION

ELEVATION

3

48 11

13

13

42"

[1067 mm]

20 1/16"

[510 mm]

4 4

2

1

15 15

ISOMETRIC VIEW

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF3

06/27/19

REV BYDATEDESCRIPTION

SECTION C-C SECTION D-D

15

12

15

12

1212

66

42"

[1067 mm]

20 1/16"

[510 mm]

20 1/16"

[510 mm]

42"

[1067 mm]

4 4 44

15 15

1

4 4

5

42 3/8"

[1076 mm]

17

Hatch Post 42 3/8" w/Gate YL 5

5041150.1

SHIP TRU-CLOSE HINGE

INSTRUCTIONS LOOSE WITH HATCH

GUARD. DO NOT TENSION HINGES

AFTER ATTACHING GATE TO POST.

1.9"Ø ROUND TUBE 12

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF4

06/27/19

REV BYDATEDESCRIPTION

11 1/4"

[285]

1.9"Ø ROUND TUBE 13

134"

[3404]

1.9"Ø ROUND TUBE 14

52 1/2"

[1333]

1.9"Ø ROUND TUBE 15

42 3/8"

[1076]

SHOP ATTACHED

3

SHOP ATTACHED

3

5041150.1

1.9"Ø ROUND TUBE 5

42 3/8"

[1076]

SHOP ATTACHED

3

5041150

5041160

5041120 5041140

42 3/8"

[1076 mm]

3 5/8"

[92 mm]

Hatch Post 42 3/8" w/Gate Support YL 17

5041150.2

1.9"Ø ROUND TUBE 17

42 3/8"

[1076 mm]

SHOP ATTACHED

3

5041150.2

3 5/8"

[92 mm]

(1REQ.)Ø9/16"

[Ø14.3 mm]

END SUPPORT

SHIPS ATTACHED

Hatch Post 42 3/8 " YL

5051150

Gate End Support YL

505100

Flat Washer 1/2" Galvanized

793115.5

Nut 1/2" Galvanized

Caplugs VC-490-8 (Black)

793113.1 1/2" x 6" Galvanized Carriage Bolt

793115.3

END SUPPORT

ISOMETRIC VIEW

793115.4

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF1

06/27/19

REV BYDATEDESCRIPTION

PN 5041410 (ASSEMBLY)-YL

DynaRound RG Hatch Guard - 42-48 x 42-60

WEIGHT = 163 LBS

(74 Kg)

PLAN VIEW

82 3/8"

[2093 mm]

80"

[2032 mm]

60 1/4"

[1530 mm] FOR 48x60 HATCH

6"

[152

mm]

42 1/4"

[1073 mm] FOR 42x42 HATCH

30"

[762 mm]

18 3/16"

[462 mm]

64 1/2"

[1638 mm]

69 7/8"

[1775 mm]

E

E

F

F

12

9

10 11

7

12

13

14

3

6

65 1/4"

[1657 mm]

NUMBER

PARTITEM QTY

REQ'D

NO.

2

DESCRIPTION

5041170

4

12 Open Cross Over793201

8 Two Way Elbow793125

6 Caplugs Yellow Flanged Plug WWX-17793113

1 Hatch Post 42-3/8" w/Gate YL5041150.1

4

McMaster 3/8"Ø x 4" U-Bolt W/ Nuts Zinc Plated PN 8875T858

793114

8 End Cap - UV Coated7926150

4

Hatch End Rail 64-1/2" YL

5041150 Hatch Post 42-3/8" YL

5041190 Hatch Side Rail 80" YL

4 Hatch Guard 3.25" Angle5041115

Material Requirements for 5041410

4 3/8" Ø Nut10

13

7

8

3

4

5

2

1

14

15

12 3/8" Ø Washer11

4 3/8" Ø x 1 1/4" Lg. Bolt9

4 5041180 Hatch Gate Rail 17-1/4" YL12

784200

785200

754530

6

16

2 Hatch Guard 67" Channel5041114

1 Dynarail-Hatch Guard Installation Instructions883304

5 Yellow

Hatch Post 42-3/8" w/Gate Support YL

1 5041150.217

17

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF2

06/27/19

REV BYDATEDESCRIPTION

ELEVATION

3

48 11

13

13

42"

[1067 mm]

20 1/16"

[510 mm]

4 4

2

1

15 15

ISOMETRIC VIEW

DATE:

HATCH GUARD

N.T.S.

SCALE

DRAWING NUMBER

4

MFA

SHEET

DRAWN:

OF3

06/27/19

REV BYDATEDESCRIPTION

SECTION E-E SECTION F-F

15 15

12

12

42"

[1067 mm]

20 1/16"

[510 mm]

20 1/16"

[510 mm]

42"

[1067 mm]

4

15

12

12

4

15

66

1

4 4

5

42 3/8"

[1076 mm]

17

Hatch Post 42 3/8" w/Gate YL 5

5041150.1

SHIP TRU-CLOSE HINGE

INSTRUCTIONS LOOSE WITH HATCH

GUARD. DO NOT TENSION HINGES

AFTER ATTACHING GATE TO POST.

This manual suits for next models

5

Table of contents