FibroPool FH135 Guide

V.23.02 FIBROPOOL USA

1. WARNING

TO DO:

●Please install the unit in compliance with local CODES regulations and standards;

●Please use a solid base, such as 2 pieces of 16” x 16” x 4” concrete blocks or an equipment

base of 16” x 32 inches minimum size

●Confirm power voltage and frequency; 110-125 volts, 60 Hz 20 Amps

●If the heater is within 50 feet of the breaker box, use 12 AWG gauge wire (12-2+ Ground) and

20 Amp breaker on a GFCI protected outlet

●If the heater is 50-150 feet from the breaker box, use 10 AWG wire (10-2+Ground) and 20

Amps GFCI breaker

●The heater must be BONDED to a ground rod, using #8 AWG bare copper wire

●An external timer can be used, be sure it I an outdoor Appliance type, minimum 15 amps

Inductive

●1 1/2” schedule 40 PVC OR 1 ½” or 1 ¼” corrugated filter connection hoses OR 1 5” Intex

hoses must be used to connect plumbing

●WATER AND ELECTRICITY DON’T MIX PLEASE USE ALL PRECAUTIONS

●This heater is made of mostly metal alloys and may have sharp edges Please use gloves

while handling it

●Keep a minimum of 6 feet distance between the heater and the pool wall

●Fibropool FH135 is weatherproof and designed to be outdoors, but is not splash-proof Choose

a location away from splashing from the pool

NOT TO DO:

●Do NOT install this heater where there may be flammable gas

●Do NOT install this heater in an enclosed room Without adequate air supply, performance will

be severely limited If the unit is installed in a closed area or limited space, please consider the

size of room and ventilation to prevent suffocation caused by refrigerant leakage

●Do NOT try to lift the unit by yourself The FH135 weighs about 100 lbs It is a 2 person

handling size and weight

●Do NOT install below eaves of the roof, where water pours onto it

●DO NOT SHORTCUT ANY SAFETY PROCEDURES

V.23.02 FIBROPOOL USA

System Specifications

1. Specifications

Model FH135

82'F Air 82'F Water 82% RH

Max Heating capacity (Btu/h) 34,700

Max Power input (Btu/h) 7200

COP 5 56

60'F Air 75'F Water 65%RH

Heating capacity (Btu/h) 33440

Power input (Btu/h) 8360

COP 4 01

Power supply 110-125V/60Hz

Max power input (Btu/h) 7200

Max current (A) 15 7

Setting temperature range (Heating) 60°F~99°F

Setting temperature range (Cooling) 50°F~82°F

Running (Air) temperature range 45°F~115°F

Refrigerant type/quantity (Oz) R410A/ 16 Ozs

Air side heat exchanger Hydrophilic fin exchanger

Water side heat exchanger Titanium tube heat exchanger

Water flow (gpm) 33 GPM

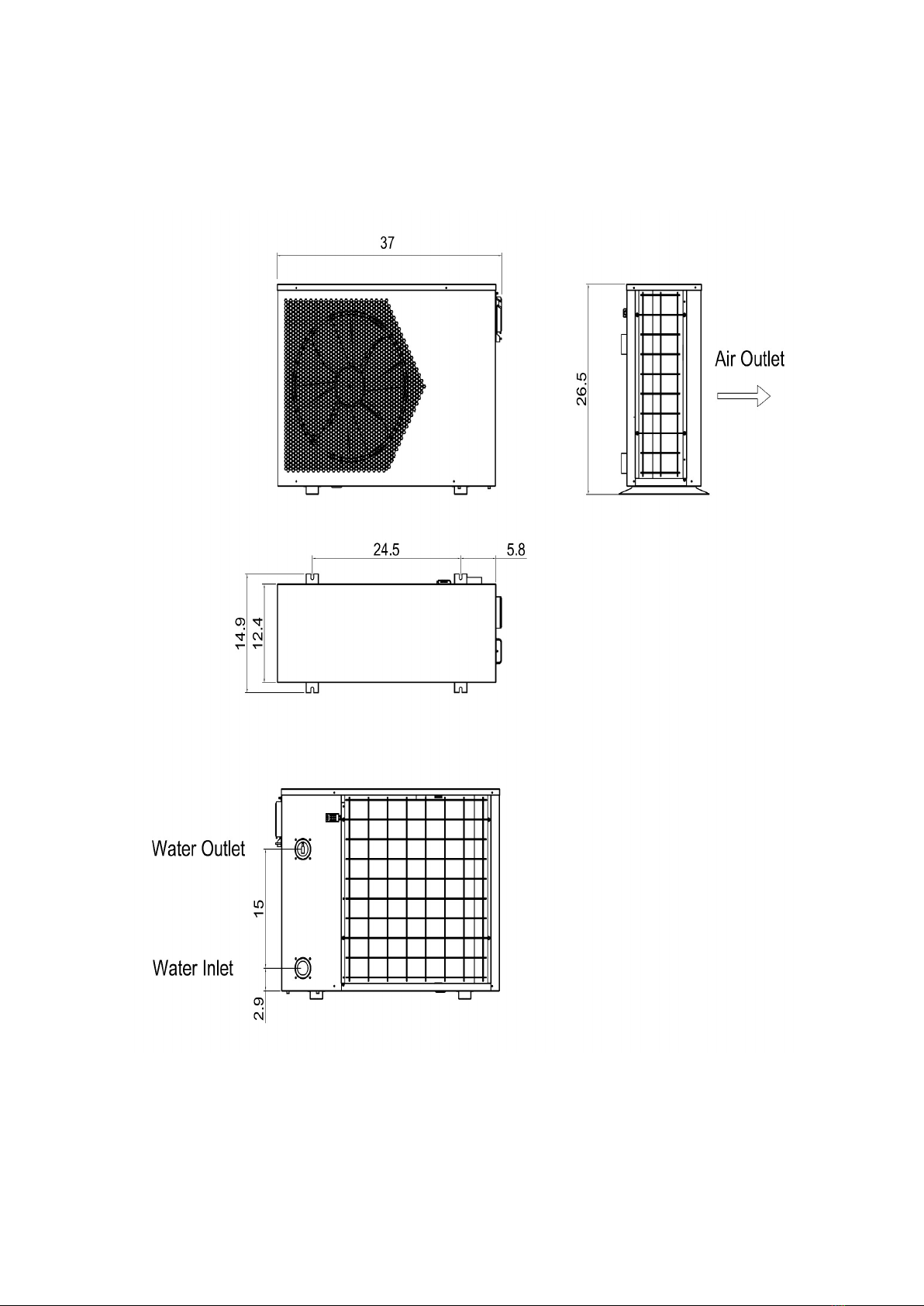

Net dimension LxWxH (inch) 37 x 14 x 25

Packing dimension LxWxH (inch) 41 x 17 x 33

Net weight (lbs) 78 lbs

Packing weight (lbs)98

Noise level dB(A) 47

Water proof level IPX4

Water pipe connection PVC Sch 40 1-1/2”

Inlet/Outlet

The technical specification of our heat pumps is provided for informational purpose only We

reserve the right to make change without notice in advance

Performance varies greatly depending on the weather conditions

1 Ratings based on US Dept Of Energy guidelines, 82-82-82 / 80-80-80/ 78-78-78

2 US Dept Of Energy recommends pool water temperatures 78, 80, or 82 Degrees

3 FH 135 is engineered and optimized based on US Dept Energy recommendations

4 We do not calibrate or size the heaters above 82'F pool water temperatures

5 55 dB noise at 10 feet, complies with Directives EN ISO 3741 and EN ISO 354

V.23.02 FIBROPOOL USA

1. Unit Dimensions

Model: FH 135

Dimensions are in Inches

V.23.02 FIBROPOOL USA

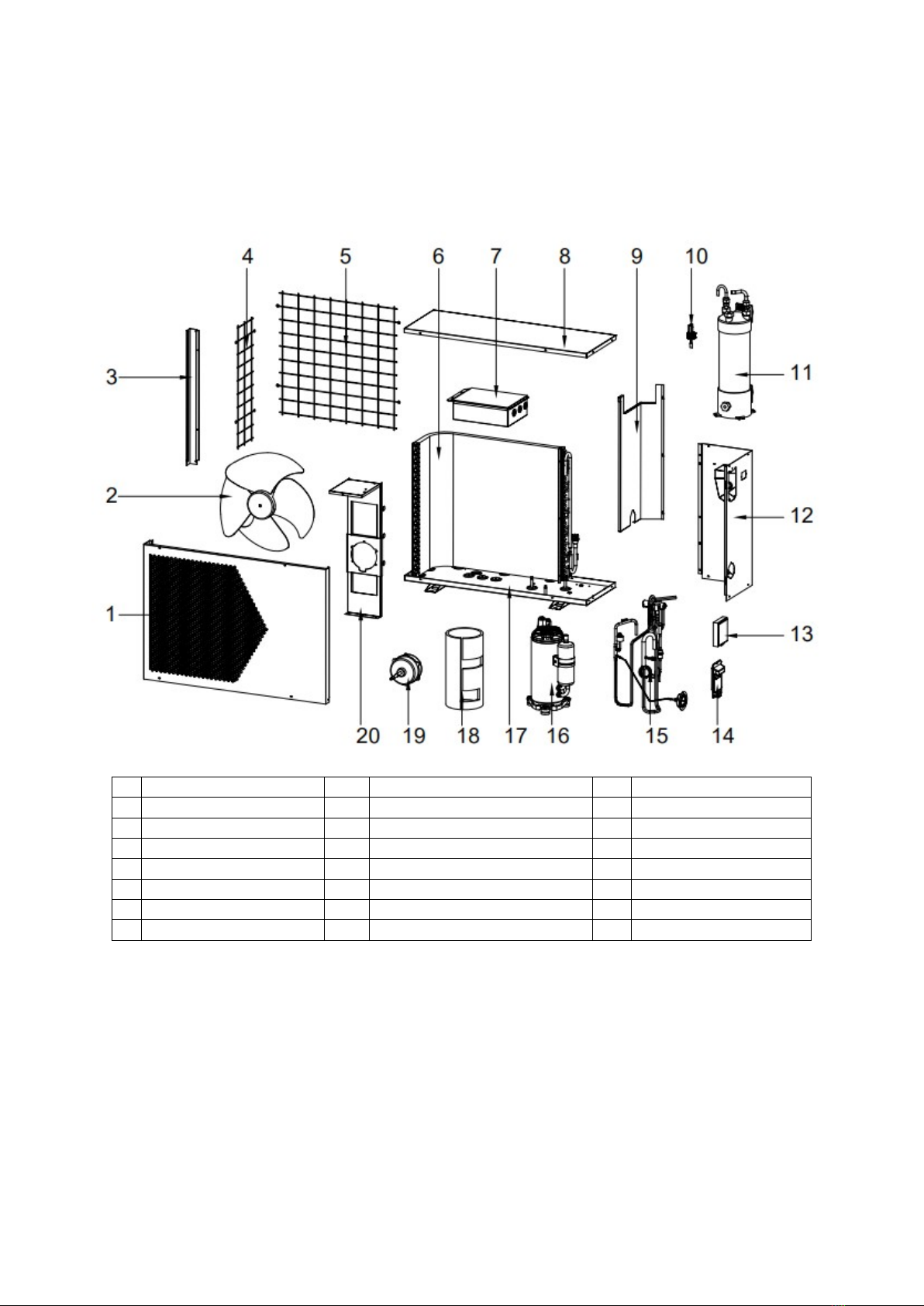

1. Exploded View

1 Grill Panel 9 Baffle plate 17 Base Frame

2 Fan 10 Water flow switch

3 Corner Bracket 11 Titanium heat exchanger 19 Fan Motor

4 Protective grill 12 Corner panel 20 Fan Bracket

5 Protection grill 13 Flip Cover

6 Evaporator coil 14 Terminal Cover

7 Electrical box 15 Cooper manifold

8 Top panel 16 Compressor

V.23.02 FIBROPOOL USA

Installation Instructions

WARNING: Installation must be performed by a qualified person

This section is provided for information purposes only and may vary depending on your

location, regulations, and available space for installation

1. Pre-Requirements

Required equipment for installation of heat pump:

Suitable power outlet, 110-125 volts, GFCI protected outlet

PVC pipe and fittings OR Corrugated filter connection hoses and necessary adapters, Pipe

cleaner/ primer, Medium Bodied Glue

Electrical tools, and a multi-meter

An equipment pad, 16” x 32” x 4” thick or 2 pieces of concrete blocks, 16 x 16 x 4 inches each

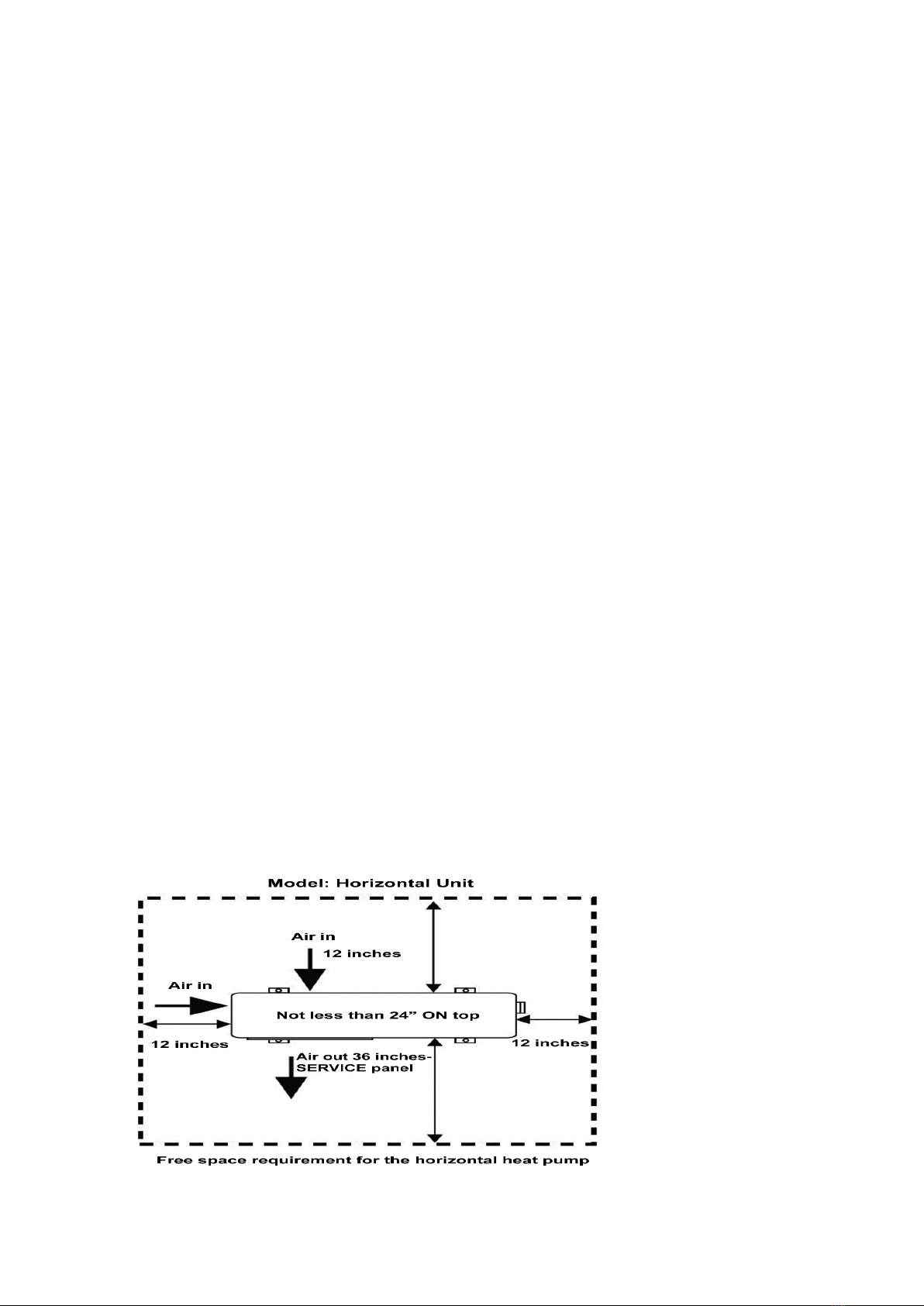

2. Location

Please consider the following when choosing a location for the heat pump:

1 Make sure the heater is not directly below roof drains, such as a gutter drain, or eaves

2 Be sure that the heater does not submerge in water in heavy rain

3 Be sure to install the drain adapters into the heater and attach the hose to direct the

condensation water Heater will produce gallons of water from condensation daily

4 Confirm the unit is in well-ventilated conditions and that the fan discharge grill vent is not

blocked (fan blows outwards )

5 Keep at least 12 inches of clearance on the two short sides and the long radiator side

6 Keep at least 3 feet of clearance on the fan side of the heater

7 Keep the unit as far as possible out of the reach of children and within 25 feet of the pool

V.23.02 FIBROPOOL USA

DRAIN ADAPTERS

Please install the drain adapters beneath the heater prior to installation You can attach 5/8” hose

to the adapters to direct the condensation water

PLUMBING

·On a typical installation on a pool with a small pump, such as ½, ¾ hp pump with 1 1/2”

PVC or flexible hoses, only the plumbing IN from the BOTTOM and OUT from the TOP pipe

connection is necessary

·For stronger systems (those with 1 5 HP and larger pumps and 2 inch plumbing systems) a

bypass system should be installed

·** A BYPASS SYSTEM IS NOT NECESSARY FOR ABOVE GROUND POOLS****

·If the heat pump is connected to a filtration circuit with a by-pass valve: We suggest to open

the bypass 50% then adjust down to achieve the lowest flow rate into the heater without

triggering error messages (EE-3, PL, EE1) This will give enough water to the heater without

restricting the flow The IN and OUT difference should be 1-5° Fahrenheit If the difference

is too great, increase the water flow through the heater for optimal heating

·The old system BYPASS path usually consists of 3 valves The New FIBROPOOL BYPASS

VALVE is just 1 valve This makes it possible to adjust water flow passing through the heat

pump

V.23.02 FIBROPOOL USA

1. Installation of a Single Heater

2. Parallel Installation for 2 Units

Throttled bypass valve, 50% open

V.23.02 FIBROPOOL USA

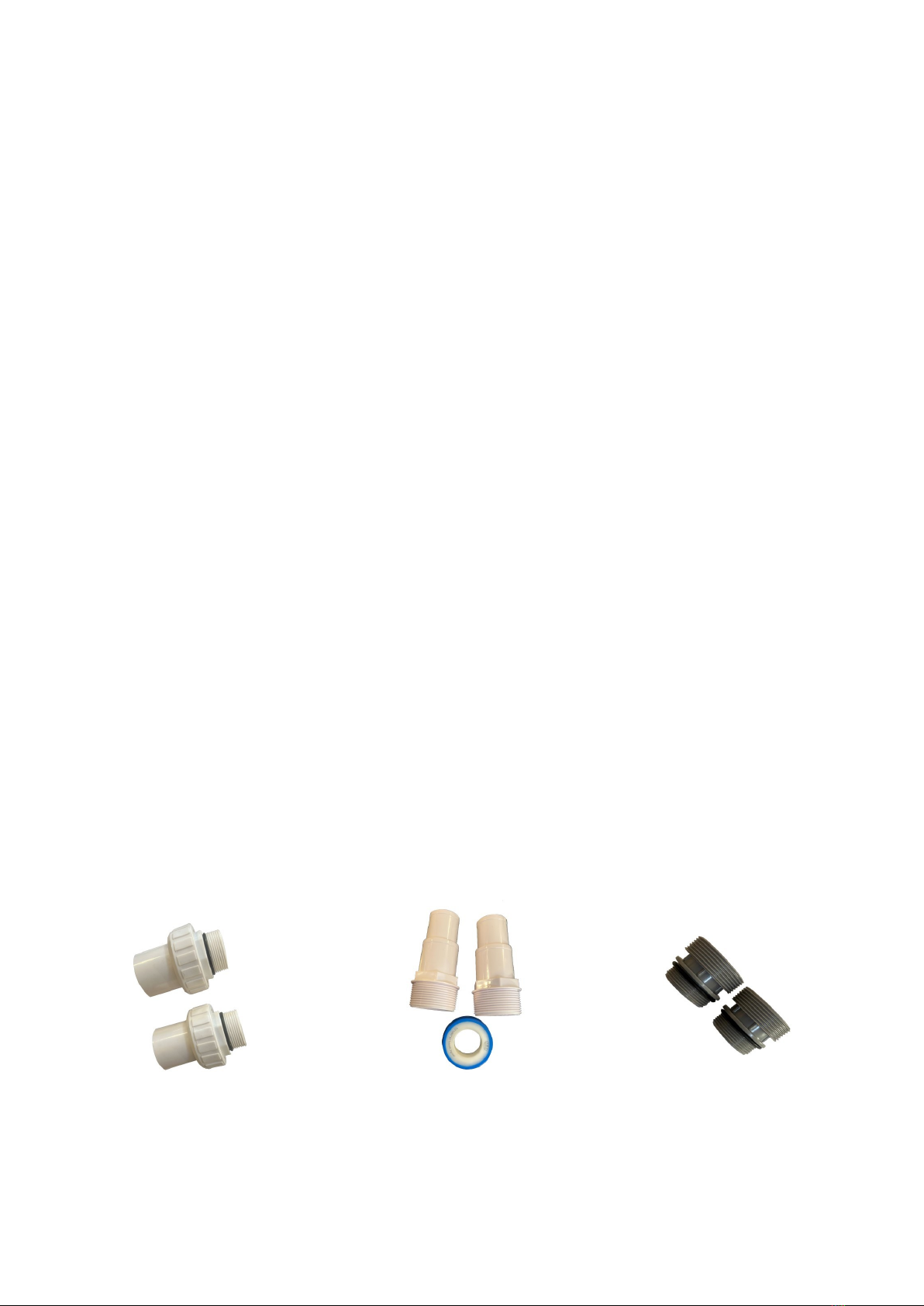

PIPE C NNECTI NS

1. FH 135 Features 1 1/2” SAE machine threads They are NOT the typical pipe threads You

can use the included unionized fittings with o-rings WITHOUT thread tape, or you can use

the conical hose adapters WITH thread tape

2. All fittings and pipes used must be 1 1/2” Sch 40 (Schedule 40) PVC pipe If using

corrugated flexible filter hoses, try to use the 1 ½” diameter hoses

3. Tighten all fittings by hand only If using the threaded hose adapters with thread tape, give

a ¼ turn with pliers after hand tight Excessive tightening will crack fittings

4. A minimum of 6 inches of straight pipe must be used before any elbows/fittings etc

5. Please support the pipes in the air, as gravity will eventually bend and break the fittings

6. If using flexible hoses, be sure to tighten the clamps well

7. Be sure to check your fittings and glue them properly, using pipe cleaner and a good grade

Medium bodied glue

8. Heaters have heat exchanger coils, therefore they increase back pressure

9. If your pool pump is larger than 1 horsepower, you should use a bypass valve This will help

water flow of your system to continue as original plumbing You simply need a 3 way valve,

and a Tee Refer to diagrams for the bypass set up

10. If you have 2 inch plumbing, use our 2 inch bypass valve and a 2 inch TEE, then use

reducers to 1 1/2” pipe to connect to the heater This way you will not compromise the water

flow

11. Be sure that WATER IN pipe is connected to the BOTTOM, and WATER OUT pipe is on

TOP Reversal will result in flow error code PL

Hard PVC Adapters Corrugated Filter Hose Adapters Intex Integrated hose

adapters

V.23.02 FIBROPOOL USA

ELECTRICAL C NNECTI NS

Power Supply Wires Size

Model Power Supply Wires

Power Supply Breaker Size Plug rating

FH 135 110-125V/60Hz 20 Amps 20 Amps

➢Step 1: Remove the 8 screws that are holding down the top lid of the heater ( yellow

stickers pointing to them). All adapters etc are inside the heater contained in a bag.

➢Step 2: Remove the bag and reinstall the lids 8 screws hand tight.

➢Step 3: Plug in the power cord of the heater and reset the GFCI by pushing the TEST

and RESET buttons.

➢FH 135 requires equipotential bonding. Please connect an #8 AWG bare copper wire to a

ground rod. This is required for safety and corrosion prevention of the heater’s metal

chassis.

V.23.02 FIBROPOOL USA

Running Test

Inspection Before Running Test

1. Check electrical connectors terminal screws. Be sure all are tight

2. Check voltage at the power supply 110-125 volts range must be observed on the outlet

3. Check Bonding wire's tightness and attachment to the ground rod.

4. Check plumbing connections make sure all glued tight and IN from BOTTOM OUT from

TOP

Turn on the pump………………….

………………………..Wait about 1 minute for all the air to purge from the system

Turn on the heater

Push the ON/OFF button on the heater Making sure the SUNSHINE sign is on top……………...

……………….ALLOW ABOUT 5 MINUTES FOR THE FAN TO START BLOWING COLD AIR AND

CONDENSATION TO START DRIPPING.

These indicate the heater is running. Another indication of the heater operating properly is the

pressure gauge on its side will climb up.

If all is well leave your heater running. Your heater will only be on while your pump is ON

In and out temperatures maybe very close or even the same but this depends on many

factors including a strong pump pushing the water too fast to register.

The primary indicators of heating are cold air and condensation.

The Pressure gauge is oil filled with an air bubble. Do not mistake it for an oil or water leak.

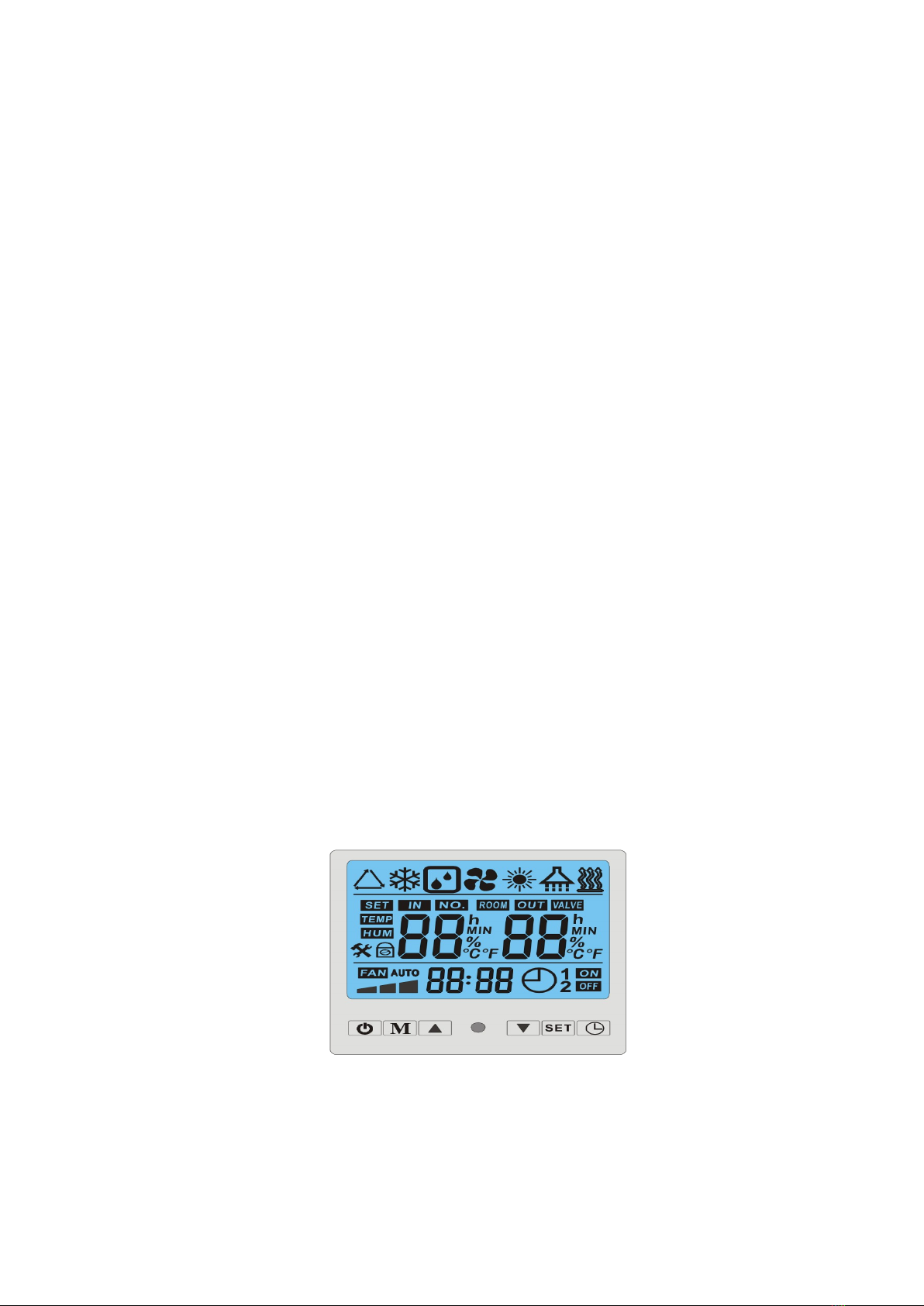

1. Control Function Description

➢“ON/OFF” key:Turn ON/OFF the heat pump

➢“MODE” key:Press MODE key to select, while the heater is RUNNING

AUTO mode – Triangle Sign

COOLING mode – Snowflake sign

V.23.02 FIBROPOOL USA

HEATING mode – Sunshine Sign

➢CLOCK key:Time setting (NOT AVAILABLE ON MOST MODELS)

Press this key, then SET Use the up and down arrows to set the current time Use M button to

swap between hour/ minute settings There is NO TIMER This is only to set the time You DON'T

have to set the time, it does not affect the operation of the heater at all

➢UP AND DOWN “”and“”key:

Press “”and“”key to increase or decrease the values

ADJUSTING THE TEMPERATURE: MAKE SURE THE HEATER IS ON THEN USE THE UP

AND DOWN ARROWS TO ADJUST THE TEMPERATURE. (temp must be set individually for

heating cooling and auto modes)

➢“SET” key:

Press this key to enter the fault query state, and then press this key to query other fault

displays in the current state

Press and hold SET key to enter parameter state, then press “MODE” key to enter the setting

You can set the parameters by pressing “”“” key, press “SET” key to set other parameters

Exit the parameter setting state automatically if there is no operation within 5 seconds

On occasion, you may see a square with Rain drops in it This means the heaters coils are too cold

and its in defrost mode Do not be alarmed, as it is a normal function in colder air temperatures

FOR A HOMEOWNER ONLY THE HEATING AND COOLING TEMPERATURES NEED TO BE

ADJUSTED. SIMPLY PRESS MODE TO GO TO HEATING AND USE THE UP AND DOWN

ARROWS TO ADJUST. ADJUSTING OTHER SETTINGS CAN AFFECT THE PERFORMANCE

AND OPERATION OF THE HEATER. WE DO NOT RECOMMEND THAT HOMEOWNERS

CHANGE ANY OTHER OPERATIONAL SETTINGS.

V.23.02 FIBROPOOL USA

SYSTEM PARAMETERS

No Parameter Name Range Default Remark

()()

()()

!"

#℃$%!&#% ℉$ ℃$'!( ℉

$)!"

#$ $#$'!( ℃ ℉ ℃$ ℉

( *+ $#, (

% -. #$ / #$%0#$0℃ ℃ # 1$0℃

1$

& ."! #$ $%!& ℃ ℉ %℃%, ℉

' 3 # 2

2 - ,# ,(#(2 ℃ ℉ ℃

$ ℉

, 3 %/( ℃''#( ℉( ,,℃ ℉ 4

5+ (6)(7)

58*+

! $#47 %

6#9+ (:;)1(<*) 7

$ = +(+

*+)(*+)

( :+**

>*

>*

>4

% ?*

>*

>*

>4

& 5@*

>A*

>-*

>4

' <+* ><

>.

2 <** >*

>4 #

, <<B #, $6

+6=;<C:< #2/%℃℃((℉)

3*<<B

&#%℃,%℃℉

<<B++ /(% ( .D

$ +<<B &/% & .D

( <<B+ 1

% <<B+ /(% $ .D

& 4 #,/,,℃&#℉

' A! #,/,,℃&#℉

2 -!*+ #,/,,℃&#℉

, <3*+! /%℃#%'℉

$ ! #,/,,℃&#℉

$ 6 #,/,,℃&#℉

$ -+ #,/,,℃&#℉

$$ <<B+ /(2 .D

WE DO NOT RECOMMEND CHANGING FACTORY SETTINGS. THERE IS NO FACTORY

SETTINGS- RESET BUTTON. THE ONLY OPTION IS TO REPROGRAM THESE FUNCTIONS

INDIVIDUALLY OR REPLACE THE MOTHERBOARD. IN MOST CASES THE ERROR/

PROBLEM WILL GO AWAY BY RESTARTING THE SYSTEM. TURN OFF THE BREAKER FOR

45 SECONDS AND TURN IT BACK ON. THIS WILL ERASE THE SENSORS' MEMORY.

V.23.02 FIBROPOOL USA

BELOW ARE COMMON QUESTIONS ASKED

To resolve a problem, we nee to i entify whether it is a mechanical problem, or performance.

POOL NOT HEATING:

•In and out difference too small: Either the air humidity is too low, or the pool pump is

pushing too hard Difference 0-4 degrees accepted Higher humidity (80% or higher)

equates to higher difference

•Initial heating takes time Allow a few days for the water to heat up, leaving the pool pump

and heater on 24-7 Covering the pool can dramatically speed up heating

•Heater is not working: There are 3 basic indicators of the heater’s operation: 1- heater

blowing cold air 2- compressor pressure goes up by about 0 5 MPa 3- heater dripping water

from the condensation lines after 10-15 minutes If any of these conditions are observed,

the heater is working

•Heater is not leaking water from the bottom: Heat pumps will create quite a bit

condensation, which will drain from the bottom of the heater

•The air is too dry: Pool heat pumps are optimized for 80% humidity If the humidity is

significantly lower, we recommend installing a set of micron misters A set can be purchased

for about 20-30 dollars from hardware stores These sets typically screw into a garden hose

and spray mist Place the heads near the coils in order to increase the available moisture for

the system, boosting performance

•Pool pump's timer setting is too short: Pool heaters are fed by the pool pump’s

circulation A shorter pump timer will result in a shorter heating period Please adjust the

timer settings on your pump or remove the timer when heating

•The fan is not coming on the pressure is not going up on the pressure gauge: When

the thermostat calls for heat, the fan will come on within 4 minutes, and within 45 seconds,

the compressor will kick in If this doesn’t happen, and the pool water temperature is much

lower than the desired temperature, there is a mechanical issue of an error message on the

screen Be sure that there is no error messages on the screen This may require a phone

call to us at Fibropool Co 1 228 313 7874

•Pool is too big for the heater or for your climate zone: There is not much can be done,

except adding a second heater into the system

•Air is too cold: Heat pumps absorb heat from the air If the air too cold-below 60°F-

performance will be extremely weak This is often a sign that the swimming season in your

area is over

HEATER IS GIVING WATER FLOW ERROR (PL)

•Pool pump is OFF

•Pool pump is very weak

•Pool filter is dirty

•Plumbing is connected backwards, cold water is connected to top

•Bypass valve is set incorrectly, and water is not being allowed through the heater.

•Flow switch is malfunctioning.

HEATER IS VIBRATING/ SHAKING HEAVILY

•Loose or broken Fan blade

NO DISPLAY

•igital display is damaged. This happens most frequently if the protective cover is broken or missing,

making the controller NOT weather proof.

•The incoming power is not 220 volts. Reading between L1 and L2 should be between 208-240 volts.

•Motherboard's fuse is blown.

V.23.02 FIBROPOOL USA

ERROR CODES

V.23.02 FIBROPOOL USA

ERROR CODE DESCRIPTION POSSIBLE CAUSES ACTION

PL

Water f low sw itch failure

PC

PC

P1 Coil temp sensor f ailure Softw are Crash/ Sensor failure

P2 Softw are Crash/ Sensor failure

P3 Inlet w ater temp sensor failure

P4 Outlet w ater temp sensor f ailure

P6

P7 Ambient temp sensor f ailure Softw are Crash/ Sensor failure

P8

P9

Low Freon pressure

E2

E3

E4 High Freon pressure

E8

Communication failure

Insuf ficient Water Flow /

Plumbing Connected backw ards/

Flow sw itch Failure /

Motherboard Failure

*Make Sure the w ater is

circulating back to Pool

*Check the plumbing lines, make

sure the w ater IN from the filter

is connected to the bottom port

Level 1 anti-freeze protection in

Winter

The A ir temperatures too low

and unit is on standby

*Wait f or outside air

temperatures to increase

Level 2 anti-freeze protection in

Winter

The A ir temperatures too low

and unit is on standby

*Wait f or outside air

temperatures to increase

+Turn the heater of f at the

breaker for 45 seconds and

restart *Replace the Sensor

Compressor exhaust gas temp

sensor failure

*Turn the heater of f at the breaker

for 45 seconds and restart

*Replace the Sensor

Softw are Crash/ Sensor failure/

Open circuit

*Turn the heater of f at the

breaker for 45 seconds and

restart *Check the w ire and

connection * Replace the

sensor * Replace the

Motherboard

Softw are Crash/ Sensor failure/

Open circuit

*Turn the heater of f at the

breaker for 45 seconds and

restart * Check the w ire and

connection *Replace the sensor

*Replace the Motherboard

Excessive Temperature Diff erence

for IN and OUT sensors

Low w ater f low /Motherboard

failure

*Check w ater circulation *Check

w ater temperature * Replace

motherboard

*Turn the heater of f at the

breaker for 45 seconds and

restart *Replace the Sensor

Excessively LOW outlet w ater

temp in cooling mode

Low w ater f low rate/ Water inlet

w ater temp too low /

Motherboard f ailure

*Turn the heater of f at the

breaker for 45 seconds and

restart *Check the w ater flow

through the heate r *Adjust the

set temp to a higher level

*Replace motherboard

Low ref rigerant /

Capillary block / Pressure sw itch

connections / The pressure

sw itch f ailure /

Motherboard Failure

*Add Ref rigerant *Replace the

capillary

*Repair the sw itch w ires

*Replace the pressure sw itch

*Replace the Motherboard

Excessive Temperature Diff erence

for IN and OUT sensors

Low w ater flow /

inlet w ater temp is too low /

Motherboard f ailure

*Check w ater circulation

* Check w ater temperature

*Replace motherboard

Excessively high compressor

tempertures

*Low w ater f low rate

*Low refrigerant

* Water temp is set too high

*Pressure sw itch Wiring Failure

*The pressure sw itch failure

*Motherboard f ailure

*Check pool's w ater circulation

* If using a bypass valve,

increase the flow to the heater

* Drain and recharge the refri

*Reduce desired temp setting

* Check the w iring of the sw itch

* Replace the pressure sw itch

* Replace the Motherboard

*Low w ater f low rate

*Overcharged ref rigerant

* Water temp is set too high

*Pressure sw itch Wiring Failure

*The pressure sw itch failure

*Motherboard Failure

*Check pool's w ater circulati *

*If using a bypass valve,

increase the flow to the heater

*Drain and recharge the

refrigerant

*Reduce desired temp setting

* Check the w iring of the sw itch

* Replace the pressure sw itch

* Replace the Motherboard

*Digital controller Failure

*Communication line is

disconnected, damaged or

unplugged f rom the motherboard

*Motherboard Failure

*Replace the Digital Controller

*Repair/ reinstall/ plug the w ire

*Replace the Motherboard

MAINTENANCE

•For best performance, we recommend setting the temperature and allowing your heater to

run as much as possible Electronic circuits should stay dry and warm with electricity

• Clean your pool's filtration system regularly to avoid damage to the unit due to a dirty or

clogged filter

• Winterize properly by making sure no water remains in the heater’s tank If possible,

bring the unit inside during winter to minimize risks

• After the unit is winterized, it is ideal to cover the unit with the special winter heat pump

cover

• Please keep the coils clean, by using “Foaming air conditioner coil cleaner”, available at

hardware stores

•Winterization: If the unit is not running during winter months, please disconnect

power supply and pipes, and let out drain water from unit by tilting the heater toward the

water inlet side by 45 degrees A shop vac can also be used for this

•Winterization: if you want to move the unit indoors, just disconnect everything and

take it into your garage

V.23.02 FIBROPOOL USA

V.23.02 FIBROPOOL USA

FIBROPOOL HEAT PUMP LIMITED FACTORY WARRANTY

This warranty certificate applies only to FibroPool brand electric heat pumps Fibropool Co LLC

warrants this Pool/ Spa Heat Pump, to the original owner, to be free of material and workmanship

defects for a limited TEN(10) year term Heat pumps utilizing Fibropool Titanium Heat Exchangers

carry a lifetime warranty on the titanium coil tubing

Specific warranty terms are listed below This warranty will begin on the day of purchase, verified

by the homeowner's proof of purchase documents

The full warranty term includes parts and labor charge to remove, repair or replace defective

components or failure due to workmanship

CLAMS FOR WARRANTY REIMBURSEMENT MUST HAVE PRIOR AUTHORIZATION BY FIBROPOOL

and be performed by a qualified person This warranty does not cover transportation charges for equipment or

component parts to and from the factory

PROOF OF PURCHASE REQUIRED FOR WARRANTY COVERAGE

This warranty is applicable only if the unit's installation and operation is expressly and completely followed in

accordance with the purchase model's Owner / Installation manual

These documents are furnished with each unit and are available by contacting Fibropool Co LLC

The liability of Fibropool Co LLC shall not exceed the repair or the replacement of defective parts under the

including refrigerant or transportation to or from the Fibropool Service Center

Fibropool Co LLC Is not liable for any damages of any sort whatsoever, including incidental and consequential

This warranty does not include damage to any internal piping or components due to freezing conditions,

negligence and abuse, installations in corrosive environments or atmospheres, nor acts of God

There are no implied warranties of merchant ability of fitness for a particular purpose that apply to this product

To obtain warranty authorization, please contact: Fibropool Co LLC , PO Box 2425, Bay Saint Louis, MS 39521 USA

Above mentioned warranties apply only to the original purchase Warranty is non-transferable

Fibropool will have the option to repair or replace the item if found to be defective after inspection

Purchaser is responsible for shipping cost to and from the nearest warranty / repair center

FIBROPOOL WILL NOT BE HELD RESPONSIBLE FOR ANY CONSEQUENTIAL, INCIDENTAL OR CONTINGENT DAMAGE

Some states do not allow exclusion of incidental and consequential damages and on how long implied warranty lasts; so above

conditions and limitations may not apply to you

This warranty grants you specific rights which may vary from state to state

Toll free: 1-228 313 7874 Fax:+1-201 328 3300 Email: support@Fibropool com V23.02

V.23.02 FIBROPOOL USA

PRORATED WARRANTY COVERAGE IS AS

FOLLOWS:

0-1 YEAR: 100%

1-2 YEARS: 90%

2-5 YEARS: 50%

5-10 YEARS: 25%

Lifetime parts warranty on titanium tubing heat exchange (plastic tank is excluded)

1 Year Labor on the entire unit

1 Year full on compressor, cabinet, motherboard and digital display

2-10 years prorated warranty on the compressor, cabinet

1 Year full warranty on all other parts

Table of contents

Other FibroPool Heat Pump manuals

Popular Heat Pump manuals by other brands

Baxi

Baxi Platinum BC iPlus V200 Smart 4.5 Installation, user and service manual

York

York YCUL0045E Installation operation & maintenance

Carrier

Carrier AQUAZONE 50VQP084-300 Installation and service instructions

BritTherm

BritTherm UPSA Domestic Installation & operating instructions

LG

LG LRNN TE Series installation manual

LG

LG Hydro Kit IWT owner's manual

Carrier

Carrier AQUAZONE 50RLP installation instructions

Trane

Trane TWA Series Installation & operation manual

Nortek

Nortek T4BE-018 Series installation instructions

Panasonic

Panasonic S-26PK1U6 quick guide

Dimplex

Dimplex S1 7KS Installation and operating instructions

Dimplex

Dimplex SI 22TU Installation and operating instructions