EN

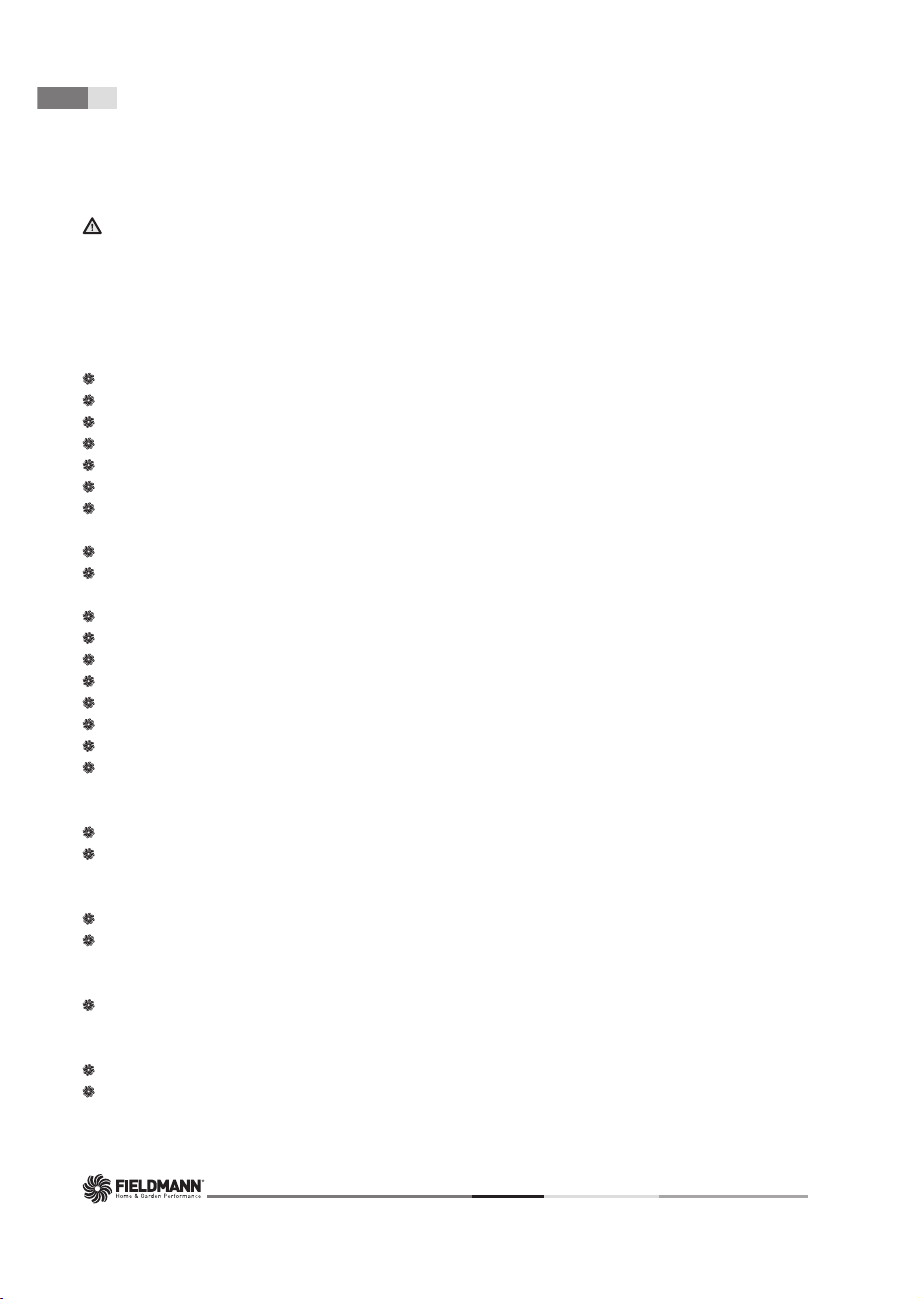

INVERTER WELDING MACHINE USER’S MANUAL

7

General safety instructions

Always stand fi rmly and keep your balance. Work only in places that you can reach safely.

Never overestimate your own strength. Do not use power tools if you are tired.

Dress appropriately. Use working clothes. Do not wear loose clothing or jewellery. Make sure that your hair,

clothing, gloves or other body parts do not come overly close to rotating or heated parts of the power tool.

Connect the equipment to the dust exhaust. If the tool offers the possibility to connect equipment for

capturing dust or dust suction, make sure that it is properly connected and used. Using this equipment can

reduce danger resulting from dust.

Firmly fasten the workpiece. Use a carpenter’s clamp or vice to secure the piece you will be cutting.

Do not use power tools if you are under the infl uence of alcohol, drugs, medication or other narcotics or

addictive substances.

This equipment is not intended to be used by persons with limited physical, sensory or mental abilities

(including children) or persons with insuffi cient experience and knowledge, unless they are supervised or

received instructions to use the equipment from a person responsible for his/her safety. Children must be

supervised in order to ensure that they are not playing with the equipment.

Using power tools and their maintenance

Always disconnect the power tool from the electric grid if there is any problem during work, before every

cleaning or maintenance, during every shift and after fi nishing work! Never work with power tools if they are

damaged in any way. If the tool starts emitting abnormal noises or odours, immediately stop working.

Do not overload power tools. The power tool will function better and more safely if it operates at speeds for

which it was designed. Use correct tools that are designated for the given activity. The correct tool works

better and more safely.

Do not use power tools that cannot be turned on safely and cannot be turned on and off with a control

switch. Using this type of tool is dangerous. Faulty switches must be repaired at a certifi ed service centre.

Disconnect the tool from the power supply before you start setting, changing accessories or maintenance.

This measure will prevent the risk of accidental start-up.

Store unused power tools so that they are out of the reach of children and unauthorized persons. Power

tools in the hands of inexperienced users can be dangerous. Store power tools in a dry and safe place. Keep

power tools in good condition. Regularly check the setting of moving parts and their movability. Check if the

protective cover or other parts that can limit the safe functioning of the power tool are not damaged. If the

tool is damaged, ensure its proper repair before the next use. Many injuries are caused by poorly maintained

power tools.

Keep cutting tools sharp and clean. Properly maintained and sharpened tools make work easier, limit the risk

of injury and work with them is much more easily controlled. Using other accessories than those listed in the

instruction manual can cause damage to the tool and can cause injury.

Use power tools, accessories, work tools, etc. in accordance with these instructions and in a way that is

described for the specifi c power tool and with regard to the given working conditions and the type of job.

Using tools for other purposes than those intended can lead to dangerous situations.

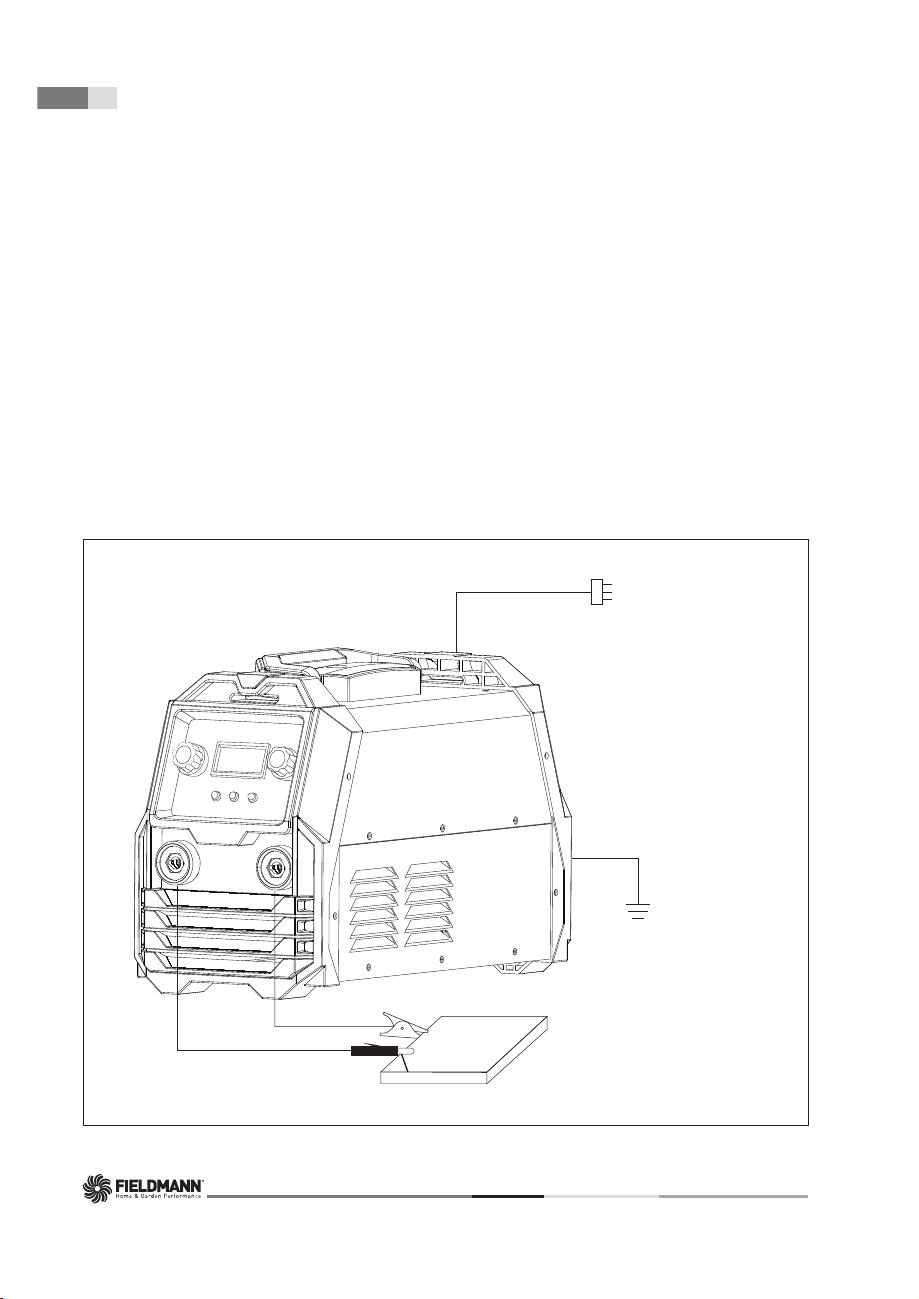

Electrical safety

The power tool’s power plug must correspond to the power outlet. Never alter the plug in any way. If the

tool’s plug has a safety peg, never use an adapter of any kind. Undamaged plugs and corresponding outlets

prevent the risk of injury by electric current. If the power cord is damaged, it must be replaced by a new

power cord that can be obtained from an authorized service centre or the importer.