98

Specifications

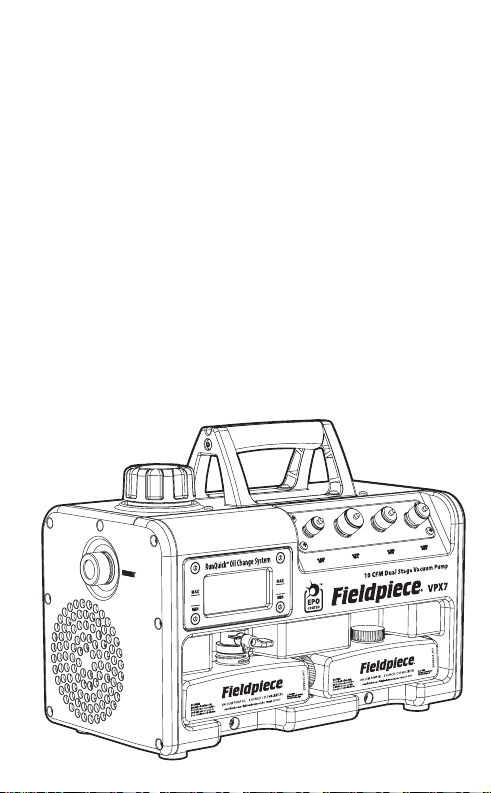

Flow Rate: 10CFM (VPX7), 8CFM (VP87), 6CFM (VP67)

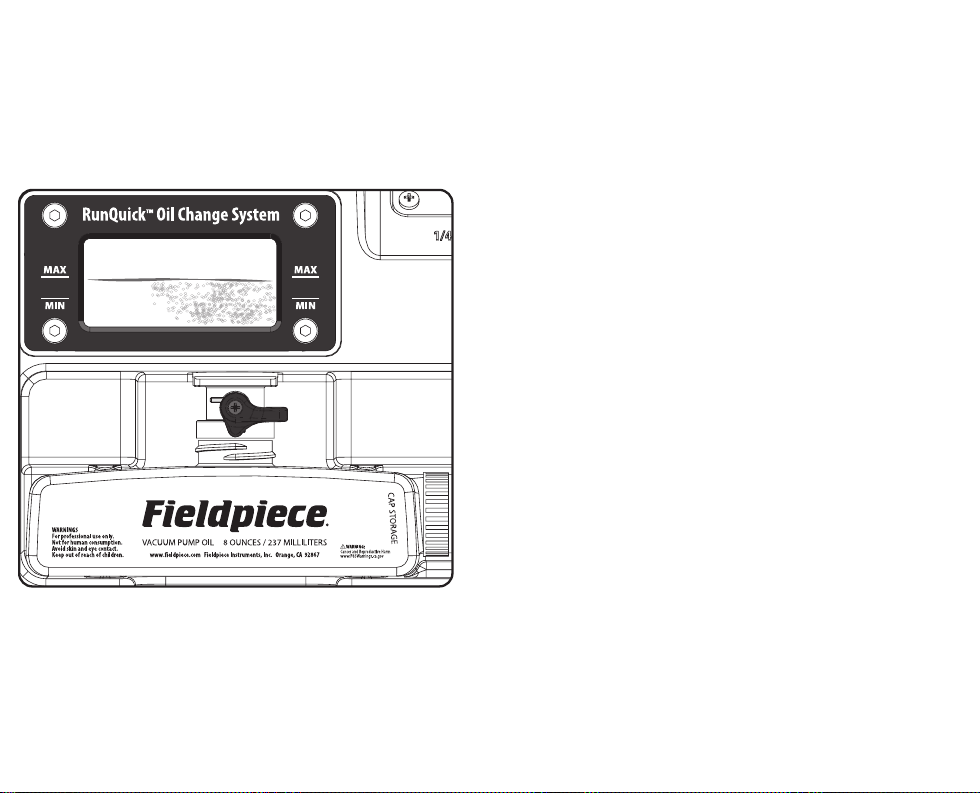

Oil Capacity: 8oz (237mL)

Oil Compatibility: Fieldpiece Vacuum Pump Oil

(Highly refined and optimized for proper sealing and lubrication)

Fieldpiece part numbers: OIL8X3, OIL32, OIL128

Oil Backlight: Blue LED

Oil Drain: Ball valve

Port Sizes: (1) 1/4”, (2) 3/8”, (1) 1/2”

Compressor: Rotary vane, two stage

Motor: 3/4 HP Brushless DC (VPX7/VP87), 1/2 HP AC (VP67)

RPM: 2500 (VPX7/VP87), 3440 (VP67 @ 60 Hz), 2866 (VP67 @ 50 Hz)

Power Source:

120/230 VAC selectable @ 50/60 Hz 1 phase

(VP67UK, VP67EU, VP67AU),

230 VAC @ 50/60 Hz 1 phase

(VPX7EU, VPX7AU, VPX7UK230, VP87EU, VP87AU, VP87UK230)

Nominal Current Draw:

2 AAC (VPX7EU, VPX7AU, VPX7UK230, VP87EU, VP87AU,

VP87UK230, VP67 @ 230V), 5 AAC (VP67 @120V)

Nominal Power:

560 W (VPX7EU, VPX7AU, VPX7UK230, VP87EU, VP87AU,

VP87UK230), 400 W (VP67)

Ultimate Vacuum at Input Ports: 15 microns

Dimensions: 7.9 inch x 11.7 inch x 16.0 inch

(201 mm x 296 mm x 406 mm)

Weight Empty: 24 lb / 10.9 kg (VPX7), 27 lb / 12.3 kg (VP87),

29 lb / 13.2 kg (VP67)

Operating Environment:

30°F to 122°F (-1.1°C to 50°C) (VPX7/VP87),

30°F to 104°F (-1.1°C to 40°C) (VP67)

Hazardous Location: Class I, Division 2, Group D, T4

US Patent: www.fieldpiece.com/patents

Safety Information

General

1. This machine is only intended for use by qualified personnel

trained in servicing and installation of A/C/Refrigeration

equipment.

2. Read and understand this operator’s manual in its entirety before

using to prevent injury or damage to you or equipment.

3. Always dispose of oil according to local jurisdiction.

Environmental

1. Use only within operating environment specification.

2. Ensure fan opening is clear of debris.

3. Explosion and fire risks:

Do not use near sewer lines.

Do not use in poorly ventilated enclosed areas.

Do not use near gasoline, acetylene, or other flammable gases.

Do not use to pump hydrocarbons.

Do not use near flames or sparks.

Assume all components are pressurized.

Personal Protection

1. Frostbite danger. Be careful using hoses.

2. Use personal protective equipment:

Wear safety goggles.

Wear earplugs if using for long durations.

Wear protective gloves.

3. Oil from the vacuum pump can be hot.

Use caution while handling.

4. Do not use in poorly ventilated enclosed areas.