FieldServer ProtoCessor FPC-FD2 User guide

Kernel Version:

5.22

Document Revision:

4

ProtoCessor/ProtoCarrier Start-Up Guide

APPLICABILITY & EFFECTIVITY

Explains the operation and installation of the following hardware:

ProtoCessor: FPC-FD2; FPC-F03; FPC-F04

ProtoCarrier: FPC-C01; FPC-CD2

The instructions are effective for the above as of December2012

ProtoCessor/ProtoCarrier Start-Up Guide Table of Contents

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

TABLE OF CONTENTS

1Introduction ................................................................................................................................................... 4

1.1 BTL Mark –BACnet Testing Laboratory........................................................................................................4

2ProtoCessor FFP (Full Function ProtoCessor).................................................................................................. 5

2.1 FFP-485 ProtoCessor (FPC-FD2) (Replaces FPC-FO2) ...................................................................................5

2.2 FFP-ETH ProtoCessor (FPC-F03) ...................................................................................................................5

2.3 FFP-LON ProtoCessor (FPC-F04)...................................................................................................................5

2.4 Powering up the ProtoCessor. .....................................................................................................................6

3Using the ProtoCarrier solution...................................................................................................................... 7

3.1 ProtoCarrier 232 (FPC-C01)..........................................................................................................................7

3.1.1 Board Layout............................................................................................................................................7

3.2 ProtoCarrier 485 (FPC-CD2) .........................................................................................................................8

3.2.1 Board Layout............................................................................................................................................8

4DIP Switch Configuration ............................................................................................................................... 9

4.1.1 Using A0 –A7 to set Node ID ...................................................................................................................9

4.1.2 Using B0 –B3 to set Baud Rate..............................................................................................................10

4.1.3 Using S0 –S3 to select and load Configuration Files .............................................................................10

5Connecting the ProtoCessor to the ProtoCarrier Boards .............................................................................. 11

5.1 Connection using RS-232 ProtoCarrier (FPC–C01) .....................................................................................11

5.1.1 Power Pin assignments: .........................................................................................................................11

5.1.2 Voltage Selection ...................................................................................................................................11

5.1.3 Summary of SolderLinks.........................................................................................................................11

5.2 Connection using RS-485 ProtoCarrier (FPC-CD2)......................................................................................12

5.2.1 Connection to FPC-FD2 ..........................................................................................................................12

5.2.2 Connection to FPC-F04 ...........................................................................................................................12

5.2.3 6-pin Phoenix Connector Pin Assignments .............................................................................................12

5.2.4 Voltage Selection ...................................................................................................................................13

6Software Interface Connection to the ProtoCessor/ProtoCarrier ................................................................. 14

6.1 Connect the PC to the ProtoCessor/ProtoCarrier via the Ethernet port....................................................14

6.2 Use the Web GUI to Connect to the ProtoCessor/ProtoCarrier ................................................................15

6.3 Set IP Address for BACnet/IP......................................................................................................................15

7Configuring the ProtoCessor ........................................................................................................................ 17

7.1 Retrieve the Sample Configuration File .....................................................................................................17

7.2 Change the Configuration File to Meet the Application ............................................................................17

7.3 Load the Updated Configuration file..........................................................................................................18

7.4 Test and Commission the ProtoCessor ......................................................................................................19

8LED Interpretation........................................................................................................................................ 20

8.1 Power up process of ProtoCessors’ LED’s ..................................................................................................20

8.1.1 FPC-FD2..................................................................................................................................................20

8.1.2 FPC- F04 .................................................................................................................................................21

8.1.3 FFP-F03 ..................................................................................................................................................22

8.2 Troubleshooting Tips..................................................................................................................................22

8.3 ProtoCarrier 232 (FPC-C01)........................................................................................................................22

8.3.1 RS-232 Signal LEDs .................................................................................................................................22

ProtoCessor/ProtoCarrier Start-Up Guide Table of Contents

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

8.4 ProtoCarrier 485 (FPC-CD2) .......................................................................................................................23

8.4.1 RS-485 Signal LEDs .................................................................................................................................23

Appendix A. Useful Features................................................................................................................................ 24

Appendix A.1. Enhanced Network Security .............................................................................................................24

Appendix B. Reference ........................................................................................................................................ 25

Appendix B.1. ProtoCessor FFP Specifications ........................................................................................................25

Appendix B.2. ProtoCarrier Specifications...............................................................................................................25

Appendix B.3. Mounting Drawings ..........................................................................................................................26

Appendix B.3.1. FPC-FD2 on FPC-CD2...............................................................................................................26

Appendix B.3.2. FPC-F03 on FPC-CD2 ...............................................................................................................26

Appendix B.3.3. FPC-F04 on FPC-CD2 ...............................................................................................................27

Appendix B.4. Address DIP Switch Settings .............................................................................................................27

Appendix C. Limited 2 year Warranty .................................................................................................................. 34

ProtoCessor/ProtoCarrier Start-Up Guide Page 4 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

1INTRODUCTION

This document describes the installation and operation of the ProtoCessor FPC-FD2; FPC-F03 and FPC-F04 protocol

gateway solutions and the FPC-C01 and FPC-CD2 ProtoCarrier boards.

ProtoCarrier boards can be powered from a fixed 5V DC supply or a 9V - 30V AC/DC. The input voltage is rectified

and regulated to meet the requirements of the ProtoCessor devices.

The ProtoCarrier-232 FPC-C01 board provides a serial port interface to the TTL socket serial port provided on the

ProtoCessor. The board allows easy connection to the serial ports using a DB-9 connector, connected as a DTE

(Data Terminal Equipment) so that it may be connected to DCE (Data Communication Equipment) device e.g. a

modem. Full serial status indication is provided with LED’s.

The ProtoCarrier-485 FPC-CD2 board provides an RS-485 interface to the TTL socket serial port provided on the

ProtoCessor. The board uses a screw terminal connection.

1.1 BTL Mark –BACnet Testing Laboratory

The BTL mark is a symbol that indicates to a consumer that a product has passed a

series of rigorous tests conducted by an independent laboratory which verifies that the

product correctly implements the BACnet features claimed in the listing. The mark is a

symbol of a high-quality BACnet product. For more information about the BACnet

Testing Laboratory go to: http://www.bacnetinternational.net/btl/.

The ProtoCessor FFP-485 (FPC-FD2) and the ProtoCarrier-485 (FPC-CD2) board are BTL certified and carry the BTL

certification Logo

When selling the modules separately to OEM customers, we use the same ProtoCessor and BTL certified code that

is used in the ProtoCarrier. BTL has provided a procedure for OEM’s using the ProtoCessor FFP-485 to easily

submit their product for BTL certification (with minimal testing).

ProtoCessor/ProtoCarrier Start-Up Guide Page 5 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

2PROTOCESSOR FFP (FULL FUNCTION PROTOCESSOR)

These modules are designed on the OEM’s controller by implementing a ProtoCessor serial TTL socket (5 VDC). See

voltage ranges in Appendix B.1

2.1 FFP-485 ProtoCessor (FPC-FD2) (Replaces FPC-FO2)

2.2 FFP-ETH ProtoCessor (FPC-F03)

2.3 FFP-LON ProtoCessor (FPC-F04)

RS-485 Phoenix

connector for

Field serial

protocol support

Ethernet port for

Diagnostics and

Host or Field

protocol support

Dip Switches

(See 4)

End of line

termination switch

Soft Reset button

Ethernet port for

Diagnostics and

Host or Field

protocol support

ProtoCessor TTL

Socket - Supporting

RX and TX signals –

5VDC (Underneath)

ProtoCessor TTL

Socket - Supporting RX

and TX signals –5VDC

(Underneath)

Rx, Tx LED’s

LED’s

LonWorks-FTT-

10 port (2-wire)

for Field

LonWorks

protocol support

Ethernet port for

Diagnostics and

Host or Field

protocol support

ProtoCessor TTL

Socket - Supporting

RX and TX signals –

5VDC (Underneath)

Rx, Tx LED’s

Soft Reset button

LonWorks

Commissioning pin

ProtoCessor/ProtoCarrier Start-Up Guide Page 6 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

2.4 Powering up the ProtoCessor.

1. Set the DIP switches (FPC-FD2). See Section 4

2. Connect up the Field and Host cables.

3. Connect the power.

4. If the Field protocol is an Ethernet protocol, refer to Section 6 for information on Software interface

connections.

ProtoCessor/ProtoCarrier Start-Up Guide Page 7 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

3USING THE PROTOCARRIER SOLUTION

The ProtoCarrier solution is recommended in cases where it is not possible to include a ProtoCessor socket on the

OEM board. A ProtoCarrier RS-485 or RS-232 card can be attached to the OEM’s existing hardware (Width=2.2 in.

Length=4.2 in.). The ProtoCarrier includes a serial port to connect to the OEM’s Host or Field port. The

ProtoCessor socket on the ProtoCarrier can accept any ProtoCessor.

ProtoCarrier can connect to the OEM’s RS-232 or RS-485 or Ethernet port and translate to any Serial,

Ethernet or LonWorks protocols.

Supports 5VDC or 9-30VAC/VDC.

3.1 ProtoCarrier 232 (FPC-C01)

The ProtoCarrier-232 FPC-C01 board is a carrier board for ProtoCessor devices providing a serial port interface to

the TTL socket serial port provided on the ProtoCessor. The board allows easy connection to the serial ports using

a DB-9 connector, connected as a DTE (Data Terminal Equipment) so that it may be connected to DCE (Data

Communication Equipment) device e.g. OEM’s Serial RS-232 device. Full serial status indication is provided with

LED’s.

The board can be powered from a fixed 5V DC supply or a 9V - 30V AC/DC. The input voltage is rectified and

regulated to meet the requirements of the ProtoCessor devices.

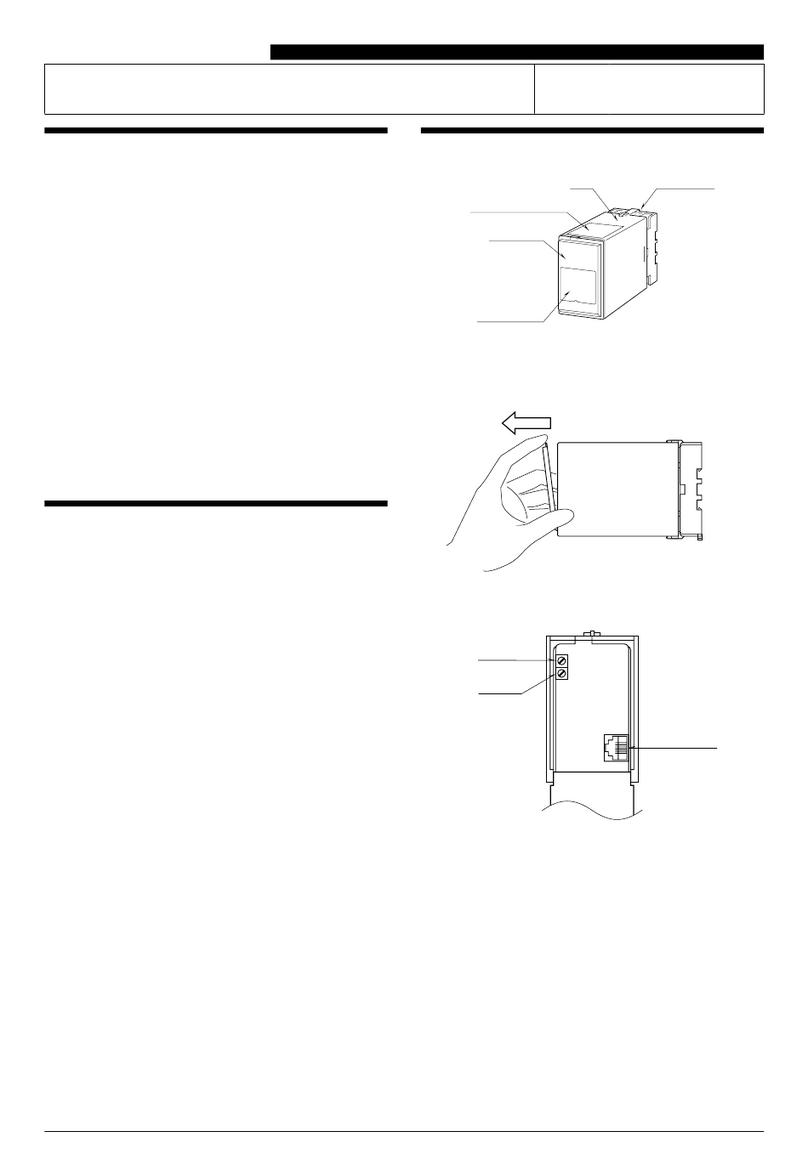

3.1.1 Board Layout

The important ports and devices on the ProtoCarrier-232 FPC-C01 board are indicated below.

DB9 Serial port

Signal LED’s (See

8.3.1)

Power +/- and FG

5VDC, 9-30 VAC or

VDC.

ProtoCessor TTL Socket

accepts any ProtoCessor

Module

Voltage selection

5VDC, 9-30 VAC or

VDC (See5.1.2)

Power LED.

ProtoCessor/ProtoCarrier Start-Up Guide Page 8 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

3.2 ProtoCarrier 485 (FPC-CD2)

The ProtoCarrier-485 board is a carrier board for ProtoCessor devices providing a RS-485 interface to the TTL

socket serial port provided on the ProtoCessor. The board can be powered from a fixed 5V DC supply or a 9V - 30V

AC/DC. The input voltage is rectified and regulated to meet the requirements of the ProtoCessor devices.

3.2.1 Board Layout

The following diagram shows the layout of the ProtoCarrier-485 board indicating the most important ports and

devices.

RS-485 Port

Signal LED’s

(See 8.4.1)

Connector

(labeled at

base).

Power +/- and

FG 5VDC

Voltage

Selector

(See 5.2.4)

Power

LED (See

8.4.1)

ProtoCessor TTL

Socket accepts any

ProtoCessor Module

Pin

1

Pin 10

Pin 20

Pin 11

Dip Switches

(See 4)

ProtoCessor/ProtoCarrier Start-Up Guide Page 9 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

4DIP SWITCH CONFIGURATION

The DIP switches on the FPC-FD2 and FPC-CD2 allow users to set the Baud Rate, Node-ID, and MAC address on the

Field RS-485 protocol as well as to automatically download configuration files for certain protocols. They can be

enabled on request before the unit ships from the FieldServer’s factory or in the field by editing the configuration

file. (Refer to the ProtoCessor Configuration Manual).

If the FPC-FD2 is used with the FPC-CD2, the DIP switches on the FPC-CD2 must be used. The switches

on the FPC-FD2 are disabled.

The DIP switch settings are the same for FPC-FD2 and FPC-CD2

Physical DIP

Switch

Settings

ProtoCessor

FFP-485

Equals

ProtoCarrier

Bank A

A1

=

A0

A2

=

A1

A3

=

A2

A4

=

A3

A5

=

A4

A6

=

A5

A7

=

A6

A8

=

A7

Bank B

B1

=

B0

B2

=

B1

B3

=

B2

B4

=

B3

S0

S1

S2

S3

4.1.1 Using A0 –A7 to set Node ID

DIP switches A0 –A7 can be used to set the Node ID or MAC Address (or both) DIP switch settings for the full range

of addresses are tabled in Appendix B.4

A7

A6

A5

A4

A3

A2

A1

A0

Address

Off

Off

Off

Off

Off

Off

Off

On

1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

On

Off

Off

Off

Off

Off

Off

Off

128

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

On

On

On

On

On

On

On

On

255

ProtoCessor/ProtoCarrier Start-Up Guide Page 10 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

4.1.2 Using B0 –B3 to set Baud Rate

For setting serial field protocol baud rate, the DIP switches B0 –B3 can be set for the following speeds.

Baud

B3

B2

B1

B0

Auto1

Off

Off

Off

Off

110

Off

Off

Off

On

300

Off

Off

On

Off

600

Off

Off

On

On

1200

Off

On

Off

Off

2400

Off

On

Off

On

4800

Off

On

On

Off

9600

Off

On

On

On

19200

On

Off

Off

Off

20833

On

Off

Off

On

28800

On

Off

On

Off

38400

On

Off

On

On

57600

On

On

Off

Off

76800

On

On

Off

On

115200

On

On

On

Off

4.1.3 Using S0 –S3 to select and load Configuration Files

The S bank of DIP switches, S0 - S3 can be used to select and load a particular configuration file from 6-7

Configuration files that can be stored on the ProtoCessor

The DIP switch settings can be viewed by uploading the configuration file using the RUI Utility. (Refer to Section

6.1.)

1

Auto-baud is only supported for BACnet MSTP

ProtoCessor/ProtoCarrier Start-Up Guide Page 11 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

5CONNECTING THE PROTOCESSOR TO THE PROTOCARRIER BOARDS

5.1 Connection using RS-232 ProtoCarrier (FPC–C01)

If connecting a FFP-FD2, configure DIP Switches as described in Section 4

Plug the ProtoCessor into the ProtoCessor socket on the ProtoCarrier board as depicted below.

The DB9 connector on the RS-232 board connects to the serial port on a third party device.

Conect power and select Voltage as described in Sections 5.1.1 to 5.1.3.

5.1.1 Power Pin assignments:

Pin No

Pin Assignment

Pin 1

V +

Pin 2

V -

Pin 3

FRAME GND

5.1.2 Voltage Selection

By default the Voltage is set for 9V –30V AC/DC input. To use a fixed 5V DC input the SolderLink P1 needs to be

cut and SolderLinks P2 and P3 need to be connected.

5.1.3 Summary of SolderLinks

Link

Function

9V –30V AC/DC input

Select

Deselect

P1

These links are used to select power input. For 9V –30V AC/DC input

(default) P1 is selected and P2, P3 deselected.

For 5V DC supply, P1 must be deselected and P2, P3 selected.

Solder across

the link.

Clear solder

from link.

P2

P3

Power +/- and FG

5VDC, 9-30 VAC or

VDC.

DB9 Serial port

RS-485 Phoenix

connector for Field

serial protocol

support

To use fixed 5V DC input, cut

solderlink P1 and connect

solderlink P2 & P3.

ProtoCessor/ProtoCarrier Start-Up Guide Page 12 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

5.2 Connection using RS-485 ProtoCarrier (FPC-CD2)

If DIP Switches are enabled, configure as described in Section 4. DIP Switches are disabled by default and

can be enabled via the Configuration file. (Refer to ProtoCessor Configuration Manual). Note that if DIP

Switches on the FPC-CD2 are enabled, the DIP Switches on the FPC-FD2 are disabled.

Plug the ProtoCessor into the ProtoCessor socket on the ProtoCarrier board as depicted below.

The ProtoCarrier-485’s 6 pin green connector, connects to Power and to the serial RS-485 port on a third

party device. The pinouts for the 6 connector are located at the base of the 6 pin connector.

Select Voltage as described in Section 5.2.4

5.2.1 Connection to FPC-FD2

5.2.2 Connection to FPC-F04

5.2.3 6-pin Phoenix Connector Pin Assignments

Pin No

Pin Assignment

Pin 1

RS-485 +

Pin 2

RS-485 –

Pin 3

RS-485 GND

Pin 4

V +

Pin 5

V -

Pin 6

FRAME GND

Power +/- and FG

5VDC, 9-30 VAC or

VDC.

RS-485 Port

LonWorks-FTT-10

port (2-wire) for

Field LonWorks

protocol support

RS-485 DB9 port

for Field serial

protocol support

Power +/- and FG

5VDC, 9-30 VAC or

VDC.

RS-485 Port

ProtoCessor/ProtoCarrier Start-Up Guide Page 13 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

5.2.4 Voltage Selection

Voltage selection is done using a jumper on Headers JP3 and JP4

For 9V-30V AC or DC input the

Jumpers on JP3 and JP4 should

be in the position shown in blue

For a fixed 5V DC input the

Jumpers on JP3 and JP4 should

be in the position shown in

orange

A power LED is included to

display whether the board is

using 5V power or not

ProtoCessor/ProtoCarrier Start-Up Guide Page 14 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

6SOFTWARE INTERFACE CONNECTION TO THE PROTOCESSOR/PROTOCARRIER

6.1 Connect the PC to the ProtoCessor/ProtoCarrier via the Ethernet port

Figure 1: Ethernet port location of ProtoCessor

Connect a standard CAT5 Ethernet cable (straight through or cross) between the PC and

ProtoCessor/ProtoCarrier

The Default IP Address of the ProtoCessor is 192.168.1.24, Subnet Mask is 255.255.255.0. If the PC and

the ProtoCessor/ProtoCarrier are on different IP Networks, assign a static IP Address to the PC on the

192.168.1.xxx network

Go to > >

Right-click on Local Area Connection > Properties

Highlight >

Select: Use the following IP address

Click twice

Ethernet Port

ProtoCessor/ProtoCarrier Start-Up Guide Page 15 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

6.2 Use the Web GUI to Connect to the ProtoCessor/ProtoCarrier

Open PC web browser enter the default IP address of the ProtoCessor/ProtoCarrier 192.168.1.24

determine if the ProtoCessor/ProtoCarrier is up and communicating.

Figure 2: FST Web GUI screen

6.3 Set IP Address for BACnet/IP

From the GUI main home page, click on setup and then Network Settings to enter the Edit IP Address

Settings menu.

Modify the IP address (N1 IP address field) of the ProtoCessor/ProtoCarrier Ethernet port.

If necessary, change the Netmask (N1 Netmask field).

Type in a new Subnet Mask

If necessary, change the IP Gateway (Default Gateway field)

Type in a new IP Gateway

Note: If the ProtoCessor/ProtoCarrier is connected to a router, the IP Gateway of the

ProtoCessor/ProtoCarrier should be set to the IP address of the router that it is connected to

Reset ProtoCessor/ProtoCarrier

Unplug Ethernet cable from PC and connect it to the network hub or router

ProtoCessor/ProtoCarrier Start-Up Guide Page 16 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

ProtoCessor/ProtoCarrier Start-Up Guide Page 17 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

7CONFIGURING THE PROTOCESSOR

7.1 Retrieve the Sample Configuration File

The configuration of the ProtoCessor is provided to the ProtoCessor’s operating system via a comma-delimited file

called “CONFIG.CSV”.

If a custom configuration was ordered, the ProtoCessor will be programmed with the relevant device registers in

the Config.csv file for the first time start-up. If not, the product is shipped with a sample config.csv that shows an

example of the drivers ordered.

In the main menu of the FS-GUI screen, go to Setup, File Transfer, Retrieve.

Click on config.csv, and open or save the file

7.2 Change the Configuration File to Meet the Application

Refer to the ProtoCessor Configuration Manual in conjunction with the Driver supplements for information on

configuring the ProtoCessor.

ProtoCessor/ProtoCarrier Start-Up Guide Page 18 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

7.3 Load the Updated Configuration file

In the main menu of the FS-GUI screen, go to Setup, File Transfer, Update

Browse and select the .csv file, open, then click Submit

Once download is complete, click the System Restart Button (or simply cycle power to the ProtoCessor) to

put the new file into operation. Note that it is possible to do multiple downloads to the ProtoCessor

before resetting it.

ProtoCessor/ProtoCarrier Start-Up Guide Page 19 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

7.4 Test and Commission the ProtoCessor

Connect the ProtoCessor to the third party device(s), and test the application.

From the main menu of FS-GUI click on View, Connections to see the number of messages on each

protocol.

For troubleshooting assistance refer to any of the troubleshooting Appendices in the related Driver

Supplements and Configuration Manual. FieldServer Technologies also offers a Technical support

page on the FieldServer website at www.FieldServer.com, which contains a significant number of

resources and documentation that may be of assistance.

ProtoCessor/ProtoCarrier Start-Up Guide Page 20 of 34

ProtoCessor 1991 Tarob Court Milpitas, California, 95035 USA Web: www.protocessor.com

Tel: (408) 964 4444 Fax: 408-262-2269 Toll Free: (888) 509 1970 x141 email: support@protocessor.com

8LED INTERPRETATION

8.1 Power up process of Pro toCessors’ LED’s

8.1.1 FPC-FD2

Light

Description

PWR

This is the power light and should show steady green at all times when the FPC-FD2 is powered.

SYS ERR

The SYS ERR LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. A steady red

light will indicate there is a system error on the ProtoCessor. If this occurs, immediately report the related

“system error” shown in the error screen of the RUI interface to FieldServer Technologies for evaluation.

COMM

ERR

COMM ERR LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. A steady red

light will indicate the communications problem if there is a configured node connected to the ProtoCessor

that is offline. To establish the cause of the error, go to the error screen of the RUI interface.

Config

ERR

Config ERR LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. A steady amber

light will indicate a configuration error exists in the active configuration. See the Error Screen in the

Remote User Interface for a description of the configuration error.

Node

Offline

Node Offline LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. If the Node

Offline LED stays on solid, a node offline condition has occurred.

Unused

15 seconds after powering up the 4 unused LEDs will turn on solid for 5 seconds, then turn off.

RX

On normal operation of FPC-FD2, the RX LED will flash when a message is received on the field port of the

ProtoCessor.

TX

On normal operation of FPC-FD2, the TX LED will flash when a message is sent on the field port of the

ProtoCessor

RUN

RUN LED will flash 20 seconds after power up, signifying normal operation. The FPC-FD2 will be able to

access RUINET once this LED starts flashing. During the first 20 seconds, the LED should be off

PWR

UNUSED

R1 RS485 TX

R1 RS485 RX

SYS ERR

COMM ERR

Config ERR

Node Offline

RUN

This manual suits for next models

4

Table of contents

Popular Control Unit manuals by other brands

Truma

Truma Panel MES Module A Operating instructions & installation instructions

Siemens

Siemens SENTRON product manual

Allmatic

Allmatic BIOS2 ECO Manual for installation

SEW-Eurodrive

SEW-Eurodrive Movidrive MDX61B manual

Honeywell

Honeywell ADEMCO 4100SM Installation and setup guide

HBM

HBM QuantumX MX840 operating manual