4

5.2.10 Real-time analog output of signals with normalized voltage 66......................

5.2.11 Real-time (via EtherCAT) and parallel (via Ethernet) output of signals

to a data recorder 67.........................................................

5.2.12 FireWire setup 68............................................................

5.2.13 Firmware update via Ethernet 70...............................................

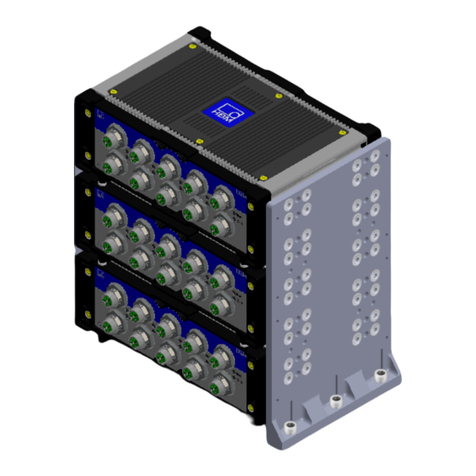

5.2.14 Connecting more than 12 modules 72...........................................

5.2.15 Bridging greater distances 74..................................................

5.2.16 FireWire with opto-hub and glass fiber cable 75..................................

6 Modules and Transducers 76...............................................

6.1 General 76..........................................................................

6.1.1 Shielding design 76...........................................................

6.1.2 Adjustable sensor supply for active transducers 78...............................

6.1.3 TEDS 79....................................................................

6.1.4 Auto Cal / Auto Adjustment 82.................................................

6.2 MX840 universal amplifier 83..........................................................

6.2.1 MX840 pin assignment 85.....................................................

6.2.2 MX840 status display 86......................................................

6.3 MX840A universal amplifier 87.........................................................

6.3.1 MX840A pin assignment 89...................................................

6.3.2 MX840A status display 90.....................................................

6.4 MX440A universal amplifier 91.........................................................

6.5 MX410 highly dynamic universal amplifier 92............................................

6.5.1 MX410 pin assignment 93.....................................................

6.5.2 MX410 status display 94......................................................

6.6 MX460 frequency measuring amplifier 95...............................................

6.6.1 MX460 pin assignment 96.....................................................

6.6.2 MX460 status display 97......................................................

6.7 MX1609/1609T/MX1609P thermocpuples modules 98....................................

6.7.1 Thermocouple with TEDS functionality (RFID) 100.................................

6.7.2 MX1609/MX1609T status display 101............................................

6.8 MX471 CAN module 102...............................................................

6.8.1 General information 102........................................................

6.8.2 MX471 pin assignment 103.....................................................

6.8.3 Receiving CAN messages 104..................................................

6.8.4 LED status display 105.........................................................

6.9 MX1601 amplifier 106.................................................................

6.9.1 MX1601pin assignment 107....................................................

6.9.2 MX1601status display 108......................................................

6.10 MX1615 amplifier 109.................................................................

6.10.1 MX1615 pin assignment 110....................................................

6.10.2 MX1615 status display 111.....................................................

6.11 Transducer technologies and Ausgabe 112...............................................

6.11.1 Strain gauges full bridges 112...................................................

6.11.2 Strain gauge full bridges, inductive full bridges 113.................................

6.11.3 Piezoresistive full bridge 114....................................................

6.11.4 Strain gauge half bridge 115....................................................