FILTRABOX COMPACTX User manual

USER MANUAL

1

2

TABLE OF CONTENTS

i. INTRODUCTION –pg. 3

ii. SPECIFICATIONS –pg. 4

iii. MACHINE DIAGRAM –pg. 5

iv. MACHINE DIAGRAM: USER INTERFACE –pg. 6

v. MACHINE DIAGRAM: MODULES –pg. 6

vi. ASSEMBLY INSTRUCTIONS –pg. 7

vii. INSTALLATION INSTRUCTIONS –pg. 8

viii. QUICK START INSTRUCTIONS

a. AUTHENTICATION –pg. 9

b. CALIBRATION –pg. 10

c. AIRFLOW SETTING –pg. 11

ix. FILTER REPLACEMENT INSTRUCTIONS

a. CHECK FILTER WARNING –pg. 13

b. FILTER CHECK FEATURE - pg. 14

c. REPLACING THE DUST PRE-FILTER –pg. 15

d. REPLACING THE HEPA DUST FILTER –pg. 15

e. OXY-CARBON GAS FILTER REPLACEMENT PROCEDURE –pg. 16

x. BLOWER MODULE REPLACEMENT –pg. 17

xi. ELECTRONICS MODULE REPLACEMENT –pg. 18

xii. SETTINGS

a. OPERATING MODE –pg. 19

b. FILTER CHECK –pg. 20

c. SELECT # OF BLWRS –pg. 20

d. NEW APPLICATION CALIBRATION –pg. 20

e. SERVICE MENU –pg. 20

xiii. EZ-LINK CONTROLLER SET-UP AND PIN-OUT - pg. 21

xiv. SUPPORT –pg. 23

xv. WARRANTY –pg. 24

3

INTRODUCTION

Thank you for purchasing the premium engineered Filtrabox Fume extractor. Its

modular construction allows for high performance, easy serviceability and longer

life. In addition, the new "slim-line" design reduces the width of the extractor for

the most efficient floor layouts.

MICRO is designed for the entry level laser user who wants a more economical

solution yet still needs excellent performance and extreme space savings. The

tiny, yet powerful digital Micro-Blower Module easily extracts dust and fumes

from smaller laser applications, circulating the air through the filters and

outputting the clean air back into the room.

COMPACT Xis designed for laser users who need both compact dimensions and

high performance for demanding substrates or volume production. Its single

Blower Module easily extracts dust and fumes, circulating the air through the

filters, outputting the clean air back into the room.

EXPAND X-1 is designed for laser users who need more filter capacity as well as

greater airflow for demanding substrates and higher volume production. Its single

Blower Module easily extracts dust and fumes, circulating the air through the

filters, outputting the clean air back into the room. The EXPAND X-1 also has a

unique feature, made possible by our PATENT PENDING modular designs, which

allows the EXPAND X-1 to be UPGRADED into an EXPANDX-2 simply by adding a

Blower Module. The EXPAND X-1 can grow with your business!

EXPAND X-2 is designed for laser users who need more filter capacity as well as

extreme airflow for demanding substrates and commercial/industrial volume

production. With 2 Blower Modules as standard equipment, the EXPANDX-2 can

often be set-up to extract from two lasers simultaneously! Its dual Blower

Modules easily extracts dust and fumes, circulating the air through the filters,

outputting the clean air back into the room.

Servicing and maintaining the Filtrabox is a snap. The machine is made up of

modular parts, making it easy for you to swap-out and swap-in any module by

fastening a few screws and snapping a few cable connections per module.

4

SPECIFICATIONS

Compact X

Voltage

120V / 240V

Frequency (Hz)

50 / 60

Wattage (kW)

1.1

Blower Type

1x Brushless

Length

(mm/inches)

525.65 / 20.695

Width

(mm/inches)

395.20 / 15.559

Height

(mm/inches)

746.40 / 29.386

Weight (kg/lbs)

45/99

Max Flow (CFM)

235

Pressure: (in. H2O)

42 (High Pressure)

Construction

Steel

Design

Modular/Independent Filters

Operating

Decibels

50

Display/Control

LCD/Push Button

Flow Control

Auto-Compensation

Warranty

1 year

Pre-Filter

FIL-P-CX-427

Cylindrical Pre-Filter

Media: F9 Glassfiber

Filtration Area: 6m²

HEPA Filter

FIL-P-CX-417

Rigid Aluminum HEPA Filter

Efficiency: 99.999% @ 0.3

Media: Glassfiber

Filtration Area: 6m²

Gas Filter

FIL-G-CX-407

OXY-CARBON Filter

Dual Action: Oxidation/Adsorption

Carbon Weight: 40 lbs

5

MACHINE DIAGRAM

6

MACHINE DIAGRAM –USER INTERFACE

.

MACHINE DIAGRAM –MODULES

7

ASSEMBLY INSTRUCTIONS

UNPACKING

! Useful Tip: The Filtrabox is shipped in custom packaging for maximum

protection during transport. Consider keeping the packaging should you wish to

ship the product again.

! Attention: The OXY-Carbon Gas Filter is HEAVY. Each filter weighs

approximately 50lbs each. Take appropriate care and precaution when lifting

the filter.

Remove all the packaging and place all of the parts on the floor. Take inventory of the parts included

with your kit:

1. Main Chassis + Blower Module (Pre-Installed)

2. Dust Pre-Filter

3. HEPA Dust Filter

4. OXY-Carbon Gas Filter

5. Lid Module

6. Threaded Inlet Adapter: designed to fit the with included 4” flex hose

7. Flex Hose: 4” diameter x 8 feet with hose clamp

a. Other hose adapters are optional

8. Power Cord: rated to 15 amps

8

INSTALLATION INSTRUCTIONS

! Important Note: The Calibration system will take all the bends and restrictions

of the flex hose into account and provide optimal performance.

1. Screw the supplied 4” Flex Hose onto the inlet of the machine. Insert the hose into the threads

and turn anti-clockwise until it can longer turn. See figure below.

2. Secure the other end of the supplied 4” Flex Hose to your laser with the supplied Hose Clamp.

3. Place the Filtrabox in the final position that it will be regularly used. This is important for

Calibration as the system will take all the bends and flow restrictions of the flex hose into

account and provide optimal performance. Engage the brakes on the two front wheels to hold

the machine in place.

4. Install the supplied power cord onto the back of the Filtrabox and turn it on with the Main

Power Switch located on the bottom of the User Interface.

9

QUICK START INSTRUCTIONS:

AUTHENTICATION, CALIBRATION & AIRFLOW SETTING

SAFETY

! Before connecting the device to a power source, ensure that the main power

switch in the rear of the device is in the off position “0”.

! Avoid plugging or unplugging the unit while it is powered ON ( “I” ).

AUTHENTICATION

! Device will not work until AUTHENTICATION has been performed. Filtrabox is

shipped in LOCKED mode by default.

To ensure that you have received a NEW and AUTHENTIC Filtrabox product, the device requires an

AUTHENTICATION CODE to UNLOCK its functions.

1. Acquire your AUTHENTICATION CODE by visiting www.filtrabox.com, or if you do not have

access to the internet by, calling 514.840.9696 ext. 102

2. Turn your Filtrabox ON using the main power switch located on the front of the device.

Filtrabox will request an UNLOCK code which is also known as the AUTHENTICATION CODE.

3. Once you have your AUTHENTICATION CODE, enter it into the Filtrabox via the buttons on

the User Interface on the front of the device to unlock it.

4. EXAMPLE: If your activation code is 123, enter 000123 into the system. (This is only an

example. 123 is not necessarily your activation code.)

5. Select the active digit by using the “left”and “right”arrows (indicated by the blinking

cursor).

6. Change the digit’s value with “up and down”arrows and move onto the next digit, by

pressing the “right” arrow.

7. Once you have entered your AUTHENTICATION CODE, press the “OK”button, which is

located to the left of the display to confirm your entry.

8. The screen will prompt you to “PRESS OK TO CALIBRATE” but DO NOT PRESS ANY BUTTONS

until you have read the CALIBRATION section on the next page.

10

CALIBRATION

! Device must be calibrated to your specific laser engraver to function properly.

! Failure to calibrate the device prior to usage may significantly reduce the life of

your filters.

Once your Filtrabox has been UNLOCKED with the AUTHENTICATION CODE, it

is ready to be CALIBRATED to your specific laser engraver.

1. First, hook up the Filtrabox fume extractor to the Laser Engraver, with the supplied hose or

with the hose you intend to permanently use for the application. Arrange the laser, Filtrabox

and the hoses into their desired locations. This is important because the calibration process

takes the restrictions caused by the bends in the hose and positioning of the equipment into

account.

2. ! Pressing the “OK” button will trigger the Calibration process which will take

approximately one minute. If the calibration process fails, try restarting the system and

ensuring that nothing is obstructing the inlet or hose. If the calibration process continues to

fail, contact Filtrabox Technical support for help.

3. If you have previously set the number of blowers and wish only to Calibrate Filtrabox to a

new application, press the “Menu” button. Press the right arrow key to advance the screen

until you reach the “New Application Calibration” section. Press the “OK” button to initiate

Calibration. The Calibration process will take approximately one minute.

11

AIRFLOW % SETTING

! USEFUL TIP 1: Use the “4-6 second rule” to determine adequate evacuation of

the laser; the “Airflow %” setting should be set to the value where you can

observe full evacuation of the fumes from the laser enclosure within 4-6 seconds

from the instant that the laser stops engraving/cutting. Check by opening the laser

top cover 4-6 seconds after the laser stops. There should NOT be any fumes visible.

If you cannot achieve the 4-6 second rule, you can try the 6-8 second rule, which is

also acceptable.

Set your “Airflow %” to the lowest possible setting that will adequately evacuate

the fumes from your laser. This ensures that you are using your filters to their

maximum potential which minimizes costs.

! USEFUL TIP 2: Start by setting your Filtrabox at 15% for a small sized laser or

25% for a medium sized laser, or 40% for a large sized laser and incrementally

increase up from those starting points, using the 4-6 second rule to determine the

minimum adequate evacuation setting.

SETTING THE AIRFLOW% SETTING

1. The Status screen is the first screen shown once the device has finished calibrating or finished

booting up. The device will display the current flow setting.

2. Turn on the blower by pressing the “Power” button while in the “MANUAL” setting.

3. Set the “Airflow %” to the desired starting point by pressing the “UP” or “Down” buttons.

! USEFUL REMINDER: Start by setting your Filtrabox at 15% for a small sized

laser or 25% for a medium sized laser, or 40% for a large sized laser and

incrementally increase up from those starting points, using the 4-6 second rule

to determine the minimum adequate evacuation setting.

4. Start engraving/cutting on the most smoke/odor generating substrate you will typically use.

5. Adjust the “Airflow %”until you see significant movement of the fumes towards the laser intake

vents.

6. Check to see if you have achieved the adequate evacuation flow using the 4-6 second rule or the

6-8 second rule.

7. Continue adjusting your flow until you are satisfied with the performance. The “Airflow %”

value will be automatically saved to memory.

12

! The AUTO-COMPENSATION FLOW CONTROL feature, which is standard on

the Filtrabox, will maintain the set-point “Airflow %” by automatically

increasing power to the blowers as the filters get obstructed by the dust. You

do not have to manually change the “Airflow %” setting again – unless you

change your laser or use a more fume generating substrate. Note: “Airflow

%”represents the Airflow potential of your system.

8. When the laser is not in use, press the “Power” button to turn the blower(s) off.

9. Filtrabox has an EZ-link feature that allows you to turn the blowers ON or OFF remotely from the

laser (if this feature is available on your laser). See the EZ-LINK section of the manual.

YOUR FILTRABOX LASER EXTRACTOR IS

NOW SET-UP FOR OPERATION.

13

FILTER REPLACEMENT INSTRUCTIONS

! When the “Check Filter” warning comes on, increasing the “Airflow %” value

WILL NOT increase actual airflow. The “Check Filter” warning indicates that the

“Airflow %” set-point can no longer be achieved despite the fact that the power

applied to the blower by the “AUTO-COMPENSATION FLOW CONTROL” feature

is at maximum value. This is most likely due to airflow blockage in the pre-filter

or HEPA filter from normal usage.

The Filtrabox Compact and Expand systems have 3 types of filters; Pre-Filter, HEPA filter and OXY-

Carbon Filter.

1. Pre-Filter FIL-P-CX-427: Collects fine dust

2. HEPA Filter FIL-P-CX-417: Collects ultra-fine dust

3. OXY-Carbon Filter FIL-G-CX-407: Adsorbs and destroys odor causing gases.

All three filters will need to be independently replaced at some point in time during the course of

normal usage.

“CHECK FILTER” WARNING

514.840.9696 ext. 102

The “Check Filter” warning will appear on the screen when either Dust filters (Pre-Filter and/or the

HEPA) filter need replacement.

When the “Check Filter” warning comes on, increasing the “Airflow %” value WILL NOT increase actual

airflow. The “Check Filter” warning indicates that the “Airflow %” set-point can no longer be achieved

despite the fact that the power applied to the blower by the “Dynamic Flow Control” feature is at

maximum value. This is most likely due to airflow blockage in the Pre-filter or HEPA filter from normal

usage.

14

“FILTER CHECK” FEATURE

! Useful Tip: Check for obstructions in the hose before ordering a new filter. An

obstruction in the hose may cause an erroneous “CHECK FILTER” WARNINGS.

! The Pre-Filter captures the majority of dust generated by the laser. Therefore,

it is the most frequently replaced dust filter in the system.

or call 514.840.9696 ext. 102

1. If the “CHECK FILTER”warning comes on, go to the User Interface and press the “Menu”

button. Press the “left or right arrow” button to scroll through the menu functions until you

find the “CHECK FILTER” feature.

2. Press the “OK” button to initiate the “CHECK FILTER” process.

3. Filtrabox will assess the status of all the Dust Filters in your systems and then prompt you to

remove the Pre-Filter. Follow the instructions on the screen.

4. To remove the Pre-Filter first loosen all four Strap Clamps on the Lid, then unhook the Strap

Clamps and pull the lid straight up by the two Handles.

5. Remove the topmost Filter Alignment Ring and the Pre-Filter and set them aside, then put

the Lid back onto the HEPA Filter as in the image below. Hook the Strap Clamps back onto

to the Lid and ensure that they are tight.

6. Follow the prompt on screen and press the Enter Button to continue.

7. Filtrabox will then advise you to replace either the HEPA or the Pre-Filter depending on

their actual conditions. Or, the system will advise you to consider upgrading to a more

powerful model if the Airflow% setting is too high, which would cause the filters to be

inefficiently used (causing frequent filter changes).

8. When the filter check is complete, replace the Pre-Filter and the topmost Filter Alignment

Ring making sure that the Strap Clamps are tightened.

15

REPLACING THE DUST PRE-FILTER FIL-P-CX-427

or call 514.840.9696 ext. 102

! Important Note: The Filter Alignment Rings must be centered correctly into

each filter. They should fit inside both filters when installed correctly.

! To avoid any risk of electrical discharge, turn off and unplug the Filtrabox

before doing any activities that require disassembly of the unit.

1. Loosen all four Strap Clamps on the Lid by pressing the lever on the clamps. Unhook the Strap

Clamps and remove the Lid by lifting it straight up off the assembly.

2. Set aside the topmost Filter Alignment Ring.

3. Remove and replace the old Pre-Filter and ensure that the new one is centered correctly onto

the HEPA Filter and that it is oriented the right way up on the next Filter Alignment Ring.

4. Ensure that the new Pre-Filter is the right side up by following the label.

5. Replace the topmost Filter Alignment Ring that was set aside earlier onto the new Pre-Filter.

6. Replace the Lid back onto the machine and tighten all four Strap Clamps back onto the hooks.

7. Check the Machine Diagram on page 4 if necessary.

REPLACING THE HEPA DUST FILTER FIL-P-CX-417

or call 514.840.9696 ext. 102

! Important Note: The Filter Alignment Rings must be centered correctly into

each filter. They should fit inside both filters when installed correctly.

! To avoid any risk of electrical discharge, turn off and unplug the Filtrabox

before doing any activities that require disassembly of the unit.

1. Loosen all four Strap Clamps on the Lid by pressing the lever on the clamps. Unhook the Strap

Clamps and remove the Lid by lifting it straight up off the assembly.

2. Set aside the topmost Filter Alignment Ring, the Pre-Filter, and the next Filter Alignment Ring.

3. Remove and replace the old HEPA Filter and ensure that the new one is centered correctly onto

the Gas Filter and that it is oriented the right way up on the next Filter Alignment Ring.

4. Replace one of the Filter Alignment Rings (they are all the same) that was set aside earlier onto

the new HEPA Filter.

5. Replace the Pre-Filter and the topmost Filter Alignment Ring that were set aside earlier onto

the new HEPA Filter as well.

6. Ensure that the new HEPA Filter and Pre-Filter are the right side up by following the labels.

7. Replace the Lid back onto the machine and tighten all four Strap Clamps back onto the hooks.

8. Check the Machine Diagram on page 4 if necessary.

16

REPLACING THE OXY-CARBON GAS FILTER FIL-G-CX-407

or call 514.840.9696 ext. 102

! When laser odor becomes evident, it is time to change the GAS FILTER.

! To avoid any risk of electrical discharge, turn off and unplug the Filtrabox

before doing any activities that require disassembly of the unit.

! Attention: The OXY-Carbon Gas Filter is HEAVY. Each filter weighs

approximately 50lbs each. Take appropriate care and precaution when lifting

the filter.

1. Loosen all four Strap Clamps on the Lid by pressing the lever on the clamps. Unhook the Strap

Clamps and remove the Lid by lifting it straight up off the assembly.

2. Set aside the three Filter Alignment Rings, the Pre-Filter, and the HEPA Filter.

3. Remove and replace the old Gas Filter and ensure that the new one is centered correctly onto

the Base Module.

4. Replace one of the Filter Alignment Rings (they are all the same) that was set aside earlier onto

the new Gas Filter and that it is oriented the right way up.

5. Replace the HEPA Filter and the next Filter Alignment Ring that were set aside earlier onto the

new Gas Filter and that it is oriented the right way up.

6. Replace the Pre-Filter and the topmost Filter Alignment Ring that were set aside earlier onto

the HEPA Filter and that it is oriented the right way up.

7. Ensure that all the Filters are the right side up by following the labels.

8. Replace the Lid back onto the machine and tighten all four Strap Clamps back onto the hooks.

9. Check the Machine Diagram on page 4 if necessary.

17

BLOWER MODULE REPLACEMENT

! To avoid any risk of electrical discharge, turn off and unplug the Filtrabox

before doing any activities that require disassembly of the unit.

! Replacement modules can be purchased from your dealer or:

info@filtrabox.com or call 514.840.9696 ext. 102

The Compact X comes standard with one Blower Module that can be easily replaced by removing a

few screws and disconnecting/connecting two cables.

1. !IMPORTANT! Ensure that the Filtrabox is powered off and unplugged.

2. Loosen all four Strap Clamps on the Lid by pressing the lever on the clamps. Unhook the

Strap Clamps and remove the Lid by lifting it straight up off the assembly.

3. Remove all three filters and all three Filter Alignment Rings between them; set these parts

aside.

4. Unplug the Fan Sensor plug from its socket on the top of the machine.

5. Remove all eight Phillip’s-head screws holding down the Blower Module.

6. Pull up the Blower Module by the two handles and unplug the wire harness on the module.

Once unplugged, the old blower module can be removed.

7. Plug in the wire harness for the new module then insert it into the machine.

8. Screw the eight Phillip’s-head screws back in.

9. Plug in the new Fan Sensor.

10. Reinstall all the filters and the lid with all four Strap Clamps as it was before. Refer to the

Machine Diagram on page 4 if necessary.

11. Plug in and power-on the unit, then go to the User Interface and press the “Menu” button.

Press the right arrow key to advance the screen until you reach the “New Application

Calibration” section. Press the “OK” button to initiate Calibration. The Calibration process

will take approximately one minute.

18

ELECTRONICS MODULE REPLACEMENT

! To avoid any risk of electrical discharge, turn off and unplug the Filtrabox

before doing any activities that require disassembly of the unit.

The Electronics Module houses all the main electrical components and the main electronics

assemblies. In the event of damage or a malfunction, the entire module can be removed from

Filtrabox by removing a few screws and disconnecting a few cables. Contact Filtrabox to order.

1. !IMPORTANT! Ensure that the Filtrabox is powered off and unplugged.

2. Remove all six Phillip’s-head screws holding the Electronics Module in place.

3. Pull the Electronics Module out and place it on the floor in front of the machine with all the

wires still connected.

4. Disconnect all five wires that connect the Electronics Module to the rest of the machine:

a. The large white 5-pin connector

b. The two wires on the power switch

c. The ribbon cable on the main board

d. The small 2-pin JST connector

5. Remove the old Electronics Module and replace it with the new one by reconnecting the

wires that were disconnected in step 4.

6. Insert the new module into the machine and reuse the six Phillip’s-head screws to hold it in

place.

12. Plug in and power-on the unit, then go to the User Interface and press the “Menu” button.

Press the right arrow key to advance the screen until you reach the “New Application

Calibration” section. Press the “OK” button to initiate Calibration. The Calibration process

will take approximately one minute.

19

SETTINGS

Press the “Menu” button and then use the “Left or Right” buttons to scroll through the settings

menus. Press the “OK” button to select the setting:

OPERATING MODE SETTING

There are 3 Modes of Operation. In all three modes, the user always controls the “Airflow %”setting by

simply pushing the “UP or Down” buttons at any time. To select the mode, press the “Up or Down”

arrows to scroll the options below and press the “OK” button to confirm your selection.

1. Manual Mode (On/Off)

This mode allows the user to manually choose the on/off state of the blowers in the

Filtrabox. This is the default mode. Toggle “ON/OFF”by pressing the “Power”arrow

key. The blower(s) will be engaged to the previously set “Airflow %”

2. Link On/Off

This mode uses the DB9 connection at the rear or the Filtrabox. The blowers will be

engaged at the previously set “Airflow %” when Laser requests it. (If feature is available

on the Laser.) When the Laser does not require any airflow, the system automatically

deactivates the blowers. If there is no laser system connected, the blowers will never

engage. See the Controller Set-up and Pin-Out example at the end of the manual.

3. Link On/Idle

This mode uses the DB9 connection at the rear or the Filtrabox. The blowers will be

engaged at the previously set “Airflow %” when Laser requests it. (If feature is available

on the Laser.) When the Laser system does not require operating airflow, the system

continues idle at a very low setting to contain fumes from the off-gassing of lasered

materials, and off-gassing of dust in the Filtrabox or the Laser enclosure. See the

Controller Set-up and Pin-Out example at the end of the manual.

This manual suits for next models

1

Table of contents

Other FILTRABOX Scrubber manuals

Popular Scrubber manuals by other brands

ECOFLEX

ECOFLEX 9087350020 Instructions for use

CDA

CDA ECH Manual for installation, use and maintenance

Tennant

Tennant 5500 Complete Operator and parts manual

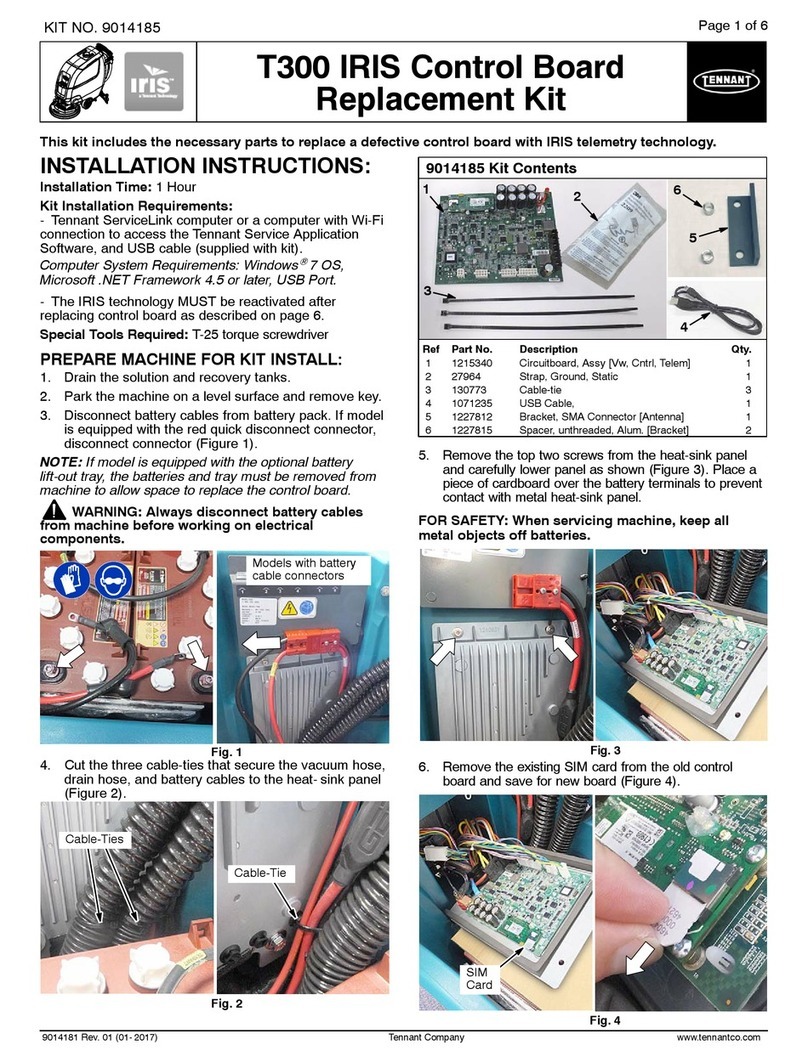

Tennant

Tennant IRIS T300 installation instructions

Nilfisk-Advance

Nilfisk-Advance BA 450 Service manual

Tornado

Tornado CASCADE 20SP Series Operation & maintenance manual