Finest 226 User manual

226

228

AUTOMOTIVE MULTIMETER

USER’S MANUAL

FINE INSTRUMENTS CORPORATION

- TEL: (82-31) 470-8888 - FAX: (82-31) 470-8887

© Copyright 2003 Fine Instruments Corp. All right reserved.

Specifications subject to change without notice.

Litho in Korea.

a world leader in test & measurement

Room # 601, DAEWOO TECHNOPIA, 768-1, WONSI-DONG, DANWON-GU,

ANSAN-SI, GYEONGGI-DO, SOUTH KOREA

SOURCES LIKE SMALL HAND-HELD RADIO

TRANSCEIVERS, FIXED STATION RADIO AND

TELEVISION TRANSMITTERS, VEHICLE RADIO

TRANSMITTERS AND CELLULAR PHONES

GENERATE ELECTROMAGNETIC RADIATION

THAT MAY INDUCE VOLTAGES IN THE TEST

LEADS OF THE MULTIMETER. IN SUCH CASES

THE ACCURACY OF THE MULTIMETER CAN-

NOT BE GUARANTEED DUE TO PHYSICAL

REASONS.

DO NOT FORGET INSTALL THE EXTRA

BATTERY COVER AFTER REPLACING THE

BATTERY FOR PROTECTION.

WARNING!

1

Measurement Limits:

DC Voltage : 0.1 mV to 600 V

AC Voltage : 1 mV to 600 V

RPM : 30 to 9000 RPM

Resistance : 0 to 40 M

Frequency : 0.5 Hz to 200 kHz [ 226 only ]

Pulse Width : 0.5 to 1999.9 mS

Dwell : 0 ° to 356.4 °

% Duty Cycle : 0 to 99.9 %

Temperature : -40 to +2,498 [ 228 only ]

( -40 to +1,370 )

Continuity check : Beep sounds at approx. < 100 in the 4 K

range

WARNING!

READ “ SAFETY CONSIDERATIONS” BEFORE USING THIS

METER.

This instrument is handheld and battery operated. It is designed

and tested according to IEC Publication 1010-1 (EN61010-1),

(Overvoltage Category III), the EMC Directive (EN 50081-1 and

EN 50082-1), UL 1244 & UL 201 and other safety standards (see “

Specifications”).

This User’s Manual tells you how to use this instrument. You may

also need a manual that provides technical information for the

vehicle you plan to test. The most important information resources

are the vehicle’s service repair manuals.

This User’s Manual should be used as a guide to get you started in

troubleshooting. Your real learning can best be accomplished

through experiences.

Features:

¥Accurate mS-Pulse Width function to test on-time of fuel

injectors

¥High-speed 41 segment analog bar graph updated 20

times/second — as fast as the eye can follow

¥Accurate automotive electronics test and advanced

measurements with dc/ac Volts, Resistance.....

¥Direct reading of Dwell without using Duty Cycle to Dwell

conversion chart when testing electronic fuel injection, feedback

carburetors, and ignition systems

¥RPM measurement for automotive engines with 1 to 8 Cylinders

using the Inductive Pickup

1. INTRODUCTION

1. Introduction 3

2. International Symbols 4

3. Explanation of Controls and Indicators 8

4. Power - on options 17

5. Basic electrical tests and measurements 18

6. Basic automotive diagnostic testing 37

Battery tests 37

Voltage drop tests 41

Starter motor tests 46

Charging system tests 48

Ignition system tests 51

Summary of automotive electrical system tests 57

7. Maintenance and replaceable parts 59

8. Specifications 61

Electrical specifications 61

General specifications 63

CONTENTS

2 3

■Keep cigarettes, sparks, and open flame away from battery at all

times.

■Keep yourself clear of all moving or hot engine parts.

■Always avoid working alone.

■Do not try to measure any voltage that exceeds 600 V dc or ac

rms.

■Voltages above 25 V dc or ac rms may constitute a serious

shock hazard.

■Do not attempt to use this instrument if either the instrument or

the test leads have been damaged.

■Use a clamp current probe.

■Avoid electrical shock: do not touch the test leads, tips or the

circuit being tested.

■Select the proper function and range for the measurement.

Do not try voltage measurements that may exceed the ratings

marked on the input limit for switch or terminal.

■Disconnect the live test lead before disconnecting the common

test lead.

International symbols

Dangerous Voltage ( Risk of electric shock)

Alternating Current (ac)

Direct Current (dc)

Either dc or ac

¥This instrument exercises 4 step adjustable +/- triggers on 1 to 8

Cylinders, motorcycles and conventional engines for accurate

measurements of RPM, Dwell, Duty-cycle, and mS-Pulse Width

of injectors.

¥Accurate non-automotive Frequency measurements with 20000

count on the high resolution 4000 count display [ 226 Only ]

¥Temperature measurement up to 2,498 ˚F (or 1,370 ˚C) for

catalytic converters, fan switch on/off,.... [ 228 Only ]

¥Non-TRMS

Electricity is dangerous and can cause injury and death. Always

treat it with the greatest of respect and care. If you are not quite

sure how to proceed, stop and take advice from a qualified person.

■Exhaust gas contains carbon monoxide which is odorless, causes

slower reaction time, and can lead to serious injury. When testing

vehicle with engine running, testing should be always done in a

well-ventilated area or route exhaust gas outside.

■Set the parking brake and block the wheels before testing or

repairing the vehicle, unless instructed otherwise. It is

especially important to block the wheels on front-wheel drive

vehicles: The parking brake does not hold the drive wheels.

The ignition or fuel system must always be disabled when

performing starting system tests.

■Always wear an eye shield when working near batteries.

■Do not smoke or allow open flames or sparks in the work area.

Gasoline fumes and gases produced by batteries are highly

explosive.

2. SAFETY CONSIDERATIONS

4 5

Ground (maximum permitted voltage between terminal

and ground)

Caution! Refer to the user’s manual before using this

Meter.

Double Insulation (Protection Class ll)

WARNING!

OBSERVE ALL SAFETY PRECAUTIONS WHEN MEASURING

HIGH VOLTAGES. TURN OFF POWER TO THE CIRCUIT

UNDER TEST, SET THIS METER TO THE DESIRED FUNCTION

AND RANGE, CONNECT THE TEST LEADS TO THIS METER

AND THEN TO THE CIRCUIT UNDER TEST. REAPPLY

POWER. IF AN ERRONEOUS READING IS OBSERVED,

DISCONNECT POWER IMMEDIATELY AND RECHECK ALL

SETTINGS AND CONNECTIONS.

Don’t Forget!

•To maintain accuracy of the Meter, replace the discharged

battery immediately when the Low-Battery symbols, ,

appears on the display of the Meter.

•Keep the Meter away from spark plug or coil wires to avoid

measuring error from external interference.

•Remove the test leads from the test points before changing

functions to avoid damaging the Meter when testing voltage.

•Do not exceed the input limits shown in the table below:

FUNCTION (+) TERMINAL MAXIMUM INPUT

VΩRPM 600 V

VΩRPM 600 V

* Ω

**Hz

RPM

Duty Cycle (%) VΩRPM 500 V DC/AC

Dwell

***Temperature VΩRPM 60 V DC or 24 V AC RMS

*Ohms can be measured only in a nonpowered circuit.

* * Hz(non-automotive Frequency measurement) function is available in Model: 226

Only.

* * * Temperature mode is available in Model: 228 Only.

V

V

mV

6 7

VΩRPM 600 V

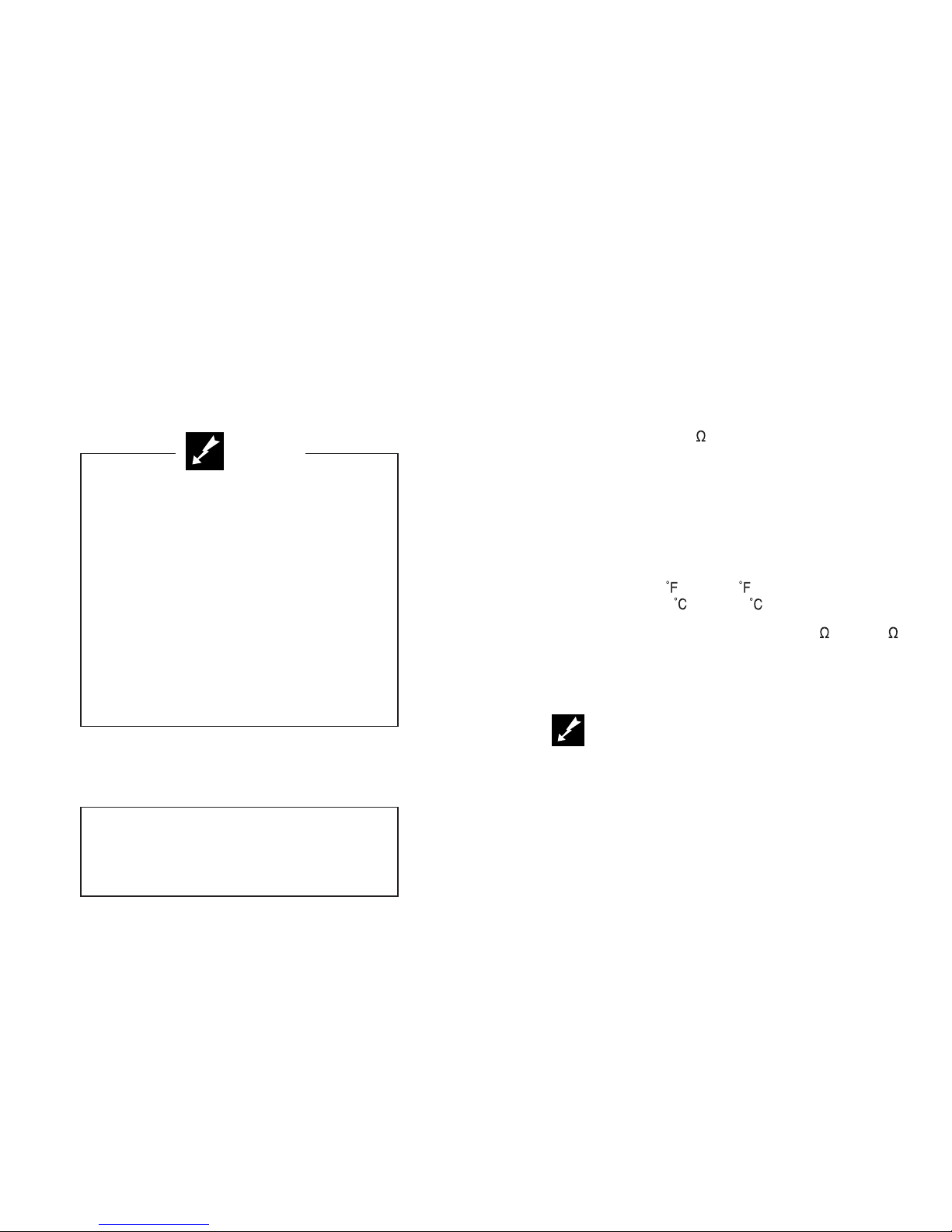

1 – DIGITAL DISPLAY. Digital readings are displayed on a

4000 count display with polarity indication and automatic

decimal point placement. When this Meter is turned on, all

display segments and symbols appear briefly during a

selftest. The display updates four times per second.

2 – ANALOG BAR GRAPH. The bar graph provides an analog

representation of readings and updates 20 times per second.

The 2 x 41 segment bar graph illuminates from left to right as

the input increases. The bargraph is easier to read when the

data causes the digital display to rapidly change. It is also

useful for trend setting or directional data.

The bar graph is not displayed when measuring RPM, Pulse

Width, Dwell, Duty cycle and Frequency.

3 – ON/OFF . Selects meter’s power ON or power OFF.

4 – DC/AC. Toggle between volts dc and ac;

Toggles between 2-Cycle engines (or DIS* 4-

Cycle engines) and 4-Cycle engines when the

Meter is in the RPM mode (The change in the

number of Cycles is indicated by the number

preceding STR on the LCD display);

Toggles between ˚C and ˚F in the temperature

mode [ 228 Only ];

Toggles between Ωand in the Ω/ function.

* DIS = Distributorless Ignition System

5 – RANGE. Press the RANGE button to select the Manual

Range mode and turn off the “AT” symbol. (The

Meter remains in the range it was in when manual

ranging was selected.)

3. EXPLANATION OF CONTROLS AND INDICATORS

8 9

* * 11 RPM, V, Ω[ 226 Only ]

Hz

**

To exit the Manual Range mode and return to

autoranging, press and hold down the RANGE

button for 2 seconds. The “AT” symbol turns back

on.

When the Meter is in the Dwell mode, press the

CYL (RANGE) button to toggle between

1,2,3,4,5,6,8 cylinder engines. The change in the

number of cylinders is indicated by the number

preceding CYL on the LCD display.

6 – HOLD ( Fix Hold

TM

). Automatically captures a stable

reading, beeps to acknowledge, and holds it on

the LCD.

When the Meter is in the mS-Pulse mode, press

this button to measure Dwell.

To measure Duty cycle (or Duty factor) in percent,

press this button again; % is displayed on the

LCD.

To measure automotive Frequency (Hz), press

this button again.

You can step through mS-Pulse, Dwell, Duty

cycle (%) and automotive Frequency (Hz)

measurement mode by pressing this button.

Press any other button to exit these modes.

10 11

7 – Toggles between a Negative (–) and Positive (+)

Trigger Slope when the Meter is in the Pulse

Width or Duty cycle (%) mode; Press this button

down for 2 seconds to toggle between a negative

(–) and positive (+) trigger slope. The change in

the trigger slope is indicated by a + or - shown at

the lower left corner of the display. The Meter

defaults to a – trigger slope. Once the trigger

slope is selected, press this button repeatedly to

adjust trigger level if the Meter reading is too high

or unstable.

•The Trigger Level has Four steps and is different for each

function combination.

Press this button to move one step at a time for selecting a

suitable trigger level. The change in the number of step is

indicated by the number above the “TRIG” symbol at the lower

left corner of the LCD.

•The step number on the LCD is a good indication of the

Trigger Level.

FUNCTION TRIGGER LEVEL

STEP RPM, mS-Pulse, Dwell, Duty %

3+8 V

2+6.25 V

1+3.2 V

0+1.6 V

8 – ROTARY SWITCH. Describes functions that are selected by

setting the rotary selector switch.

Adp mV Millivolts dc or adaptor (current probe)

VVolts dc/ac

Ω/Resistance/Continuity test

RPM RPM measurement on 2 or 4 stroke engines

using the Inductive Pickup on a spark plug wire

mS-Pulse Pulse Width, Dwell, Duty cycle (%) or automotive

Hz(Automotive Hz) measurement

Hz Frequency (Non-automotive Hz) measurement

[ 226 Only ]

TEMP Temperature [ 228 Only ]

9 – CE. This Meter is CE-marking certificated.

10 – COM (Common Terminal). The black test lead is plugged

into this terminal for all measurements. When measuring

temperature, a thermocouple adapter is plugged into this

terminal.

11 – . The red test lead is plugged into this terminal

for all measurements. When measuring

temperature, a thermocouple adapter is

plugged into this terminal.

Dwell,

Duty%,

Hz

RPM, V, Ω

TEMP

[ 228 Only ]

RPM, V, Ω

Hz

[ 226 Only ]

12 – The maximum voltage that the Meter can

measure is 600 V dc or ac rms.

13 – AC . Displayed when AC measurement function is selected.

14 – (Negative Polarity) . Automatically indicate negative

inputs.

15 – AT . DIsplayed when the Auto Range mode is selected.

16 –

88

. Displayed when a certain step of 4 trigger level steps is

selected in the RPM, Pulse Width, Dwell or Duty % mode.

17 – TRIG . Displayed when a – or + trigger slope is selected

while the Meter is in the RPM, Pulse Width, Dwell or Duty %

mode. The Meter defaults or a – (negative) trigger slope.

12 13

18 – ± . Indicates a – (negative) or + (positive) trigger slope when

a trigger slope is selected.

A negative (–) trigger slope should be selected to measure

low (–) time and a positive (+) trigger slope should be

selected to measure high (+) time. For example, when

measuring a Duty cycle of Mixture Control Solenoid, the low

(–) time is the On time in most cases.

19 – (Overload Indication) . Displayed on the LCD when

input value is too large to display.

20 – (Low Battery) . Battery life warning. When is

first turned on, at least 8 hours of battery life remain.

Replace the battery immediately. Never leave a weak or

dead battery in the Meter. Even leak-proof types can leak

and damage the Meter.

21 – . Displayed when the Meter is in the continuity test

function.

22 – HOLD . Displayed when the Hold mode is selected.

23 –

88

STR. Displayed when either 2 or 4 strokes are selected in

the RPM mode. Press the STR button to toggle between 2-

stroke engines and 4-stroke engines.

14 15

24 –

88

CYL . Displayed when a certain number of cylinders is

selected in the RPM or Dwell mode. Press the CYL button to

toggle between 1,2,3,4,5,6,8 cylinder engines.

When the Meter is in the Temperature mode, °

CC

or °

FF

is

displayed from °

88

. Press the °C/°F button to toggle between

°

CC

and °

FF

.

25 – DWL¡. Displayed when the Dwell mode is selected.

26 – % . Displayed when the Duty cycle mode is selected.

27 – mS (Milliseconds, 1 x 10-

3

seconds) . Displayed when the

mS-Pulse Width mode is selected.

28 – The following symbols indicate the unit of the value

displayed.

DWL° The number of degrees of distributor rotation

when the points remain closed, measured for

1 to 8 cylinders.

%Percent, used for duty cycle measurement

°C/°F Centigrade or Fahrenheit temperature

measurement

VVolts

mV Millivolts (1 x 10-

3

Volts)

ΩOhms

KΩKilohm (1 x 10

3

Ohms)

MΩMegohm (1 x 10

6

Ohms)

Hz Hertz (1 cycle/sec)

KHz Kilohertz (1 x 10

3

cycles/sec)

29 – RPM . Displayed when the RPM mode is selected. In this

mode, revolutions per minute on 2 or 4 stroke engines are

measured using the Inductive Pickup on a spark plug wire.

30 – ANALOG DISPLAY SCALE. Displayed with 41 position

analog pointers.

Using Inductive Pickup

The Meter comes with an Inductive Pickup. The Inductive Pickup

takes the magnetic field generated by the current in the spark plug

wire and converts it to a pulse that triggers the Meter’s RPM

measurement.

Using (Optional) Clamp-on Current Probe

The Meter sometimes has to be used to make a high current

measurement. In higher current applications where high accuracy

is not needed, a clamp-on current probe is very useful.

There are two basic types of current probes; current transformers

(CT), which measure ac current only and Hall effect probes, which

can measure ac or dc current.

The output of a Hall effect probe is typically 1000 to 1, however the

current is converted to a voltage. For example, 1 millivolt equals 1

amp dc or ac so that 100 amps ac is converted to 100 mV ac. The

probe leads are connected to the “V” and “COM” input terminals

and the Meter function switch is set to “mV” setting.

A Hall effect ac/dc current probe is optionally supplied with the

Meter.

16 17

The Meter has two power-on options.

Auto-Power-Off Mode

The meter automatically turns off after approximately 20 minutes of

no activities to extend the battery life.

To disable the Auto-power-off mode, turn the Meter on by pressing

the ON/OFF button while holding down the HOLD button for more

than 2 seconds.

Continuous Turn-on of LCD Segments

Each time the Meter is powered on by pressing the ON/OFF

button, all LCD segments will turn on for two seconds as part of a

selftest routine.

To turn all LCD segments on continuously, turn the Meter on by

pressing the ON/OFF button while continuously pressing the

RANGE button.

4. POWER-ON OPTIONS

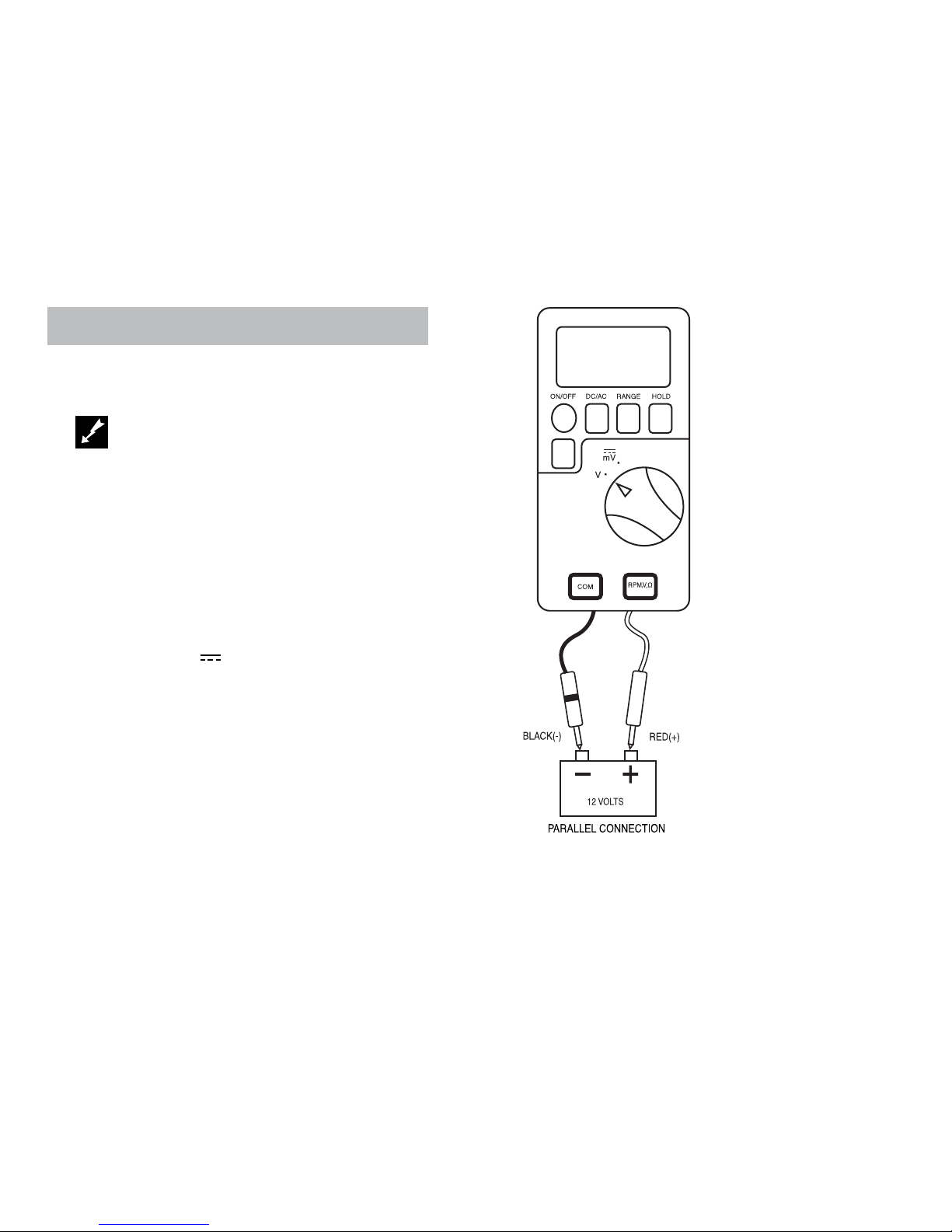

Voltage Measurements

WARNING!

TO AVOID THE RISK OF ELECTRICAL SHOCK AND

INSTRUMENT DAMAGE, INPUT VOLTAGES MUST NOT

EXCEED 600 V DC OR AC RMS. DO NOT ATTEMPT TO TAKE

ANY UNKNOWN VOLTAGE MEASUREMENT THAT MAY BE IN

EXCESS OF 600 V DC OR AC RMS.

NOTE: When taking voltage measurements, this Meter must

be connected in PARALLEL with the circuit, or circuit

element under test.

To measure voltage:

• Select the Voltage (V or mV) range with the rotary switch.

• Press the DC/AC button to select AC or DC.

Insert

• Black lead in COM jack.

• Red lead in RPM, V, Ωjack.

Touch the Black probe to the negative (–) circuit or to ground.

Touch the Red probe to the circuit coming from the power source.

5. BASIC ELECTRICAL TESTS AND MEASUREMENTS

18 19

■■Accuracy

A measurement range determines

the highest value the Meter can

measure. Most Meter functions

have more than one range. Being

in the right measurement range

is very important when measuring.

Selection of a lower range will

move the decimal point one

place and increase the accuracy

of the reading.

An

O.F.L

(overload) display

means the range is too low;

select the next higher range.

■■Analog Bar Graph

The bar graph is easier to read

when the data causes the digital

display to rapidly change. It is

also useful for trend setting or

directional data.

Resistance Measurements

Resistance is measured in Ohms (Ω) and the values can greatly

vary from a few Milliohms (mΩ) for contact resistance to billions of

ohms for insulators. The Meter can measure down to about 0.1

Ohms and measure as high as 40 MΩ.

WARNING!

TURN OFF POWER AND DISCHARGE ALL CAPACITORS ON

CIRCUIT TO BE TESTED BEFORE ATTEMPTING INCIRCUIT

RESISTANCE MEASUREMENTS. ACCURATE MEASUREMENT

IS NOT POSSIBLE IF EXTERNAL OR RESIDUAL VOLTAGE IS

PRESENT.

NOTE: The resistance in the test leads can affect accuracy in

the 400 Ωrange. Short the leads together and subtract

the test lead resistance from the resistance

measurements.

20 21

To measure resistance:

•Select the Resistance (Ω)

setting with the rotary switch.

•If a more accurate measurement

is desired, select the proper

Resistance range using the

RANGE button.

Insert:

•Black lead in COM jack.

•Red lead in RPM, V, Ωjack.

Touch the test lead probes

across the resistance or circuit

to be tested.

■■Accuracy

Rapidly changing display

readings (noise) can sometimes

be eliminated if you change to a

higher range.

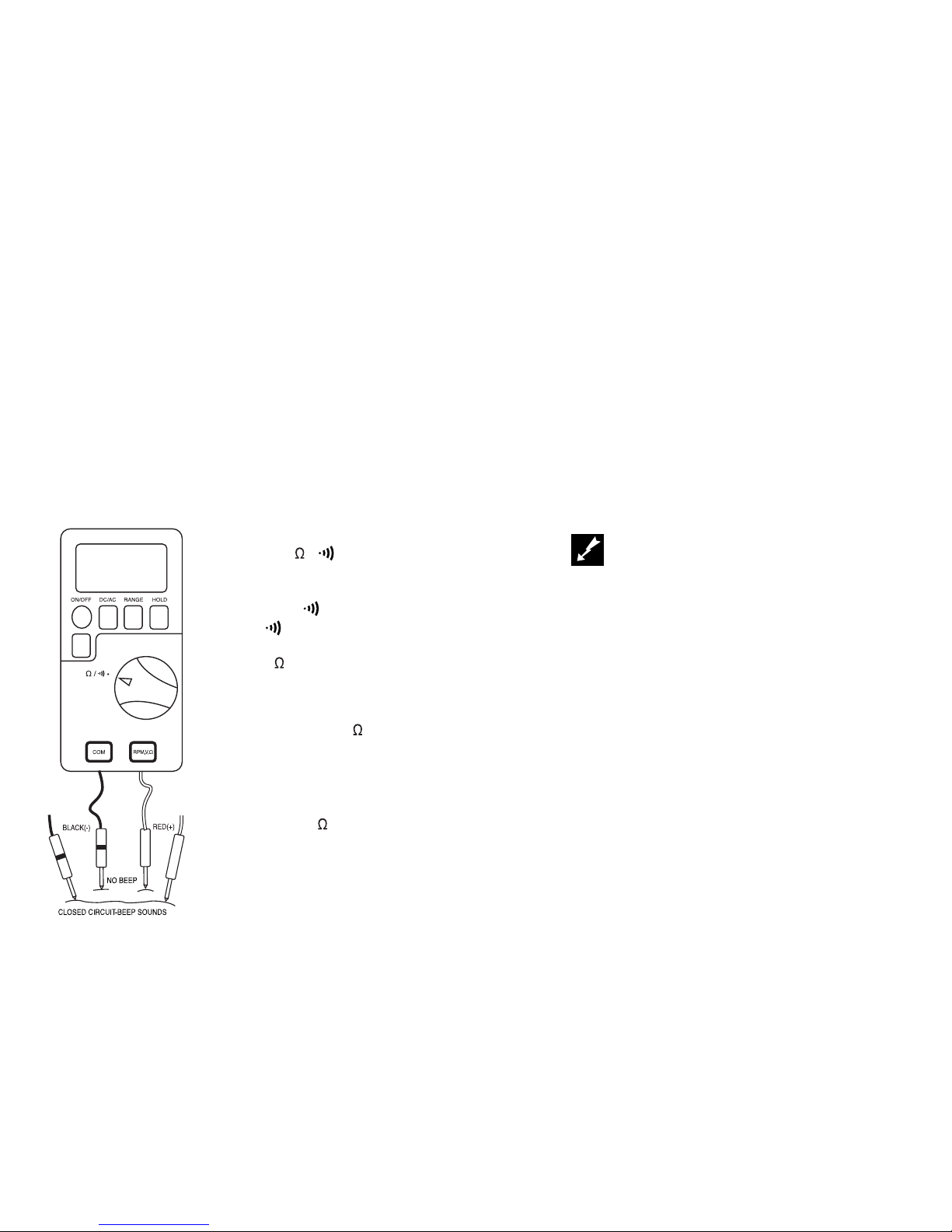

Continuity Test

A DMM with a continuity beeper allows you to quickly and easily

distinguish between an open and a closed circuit. The Meter beeps

when it detects a closed circuit or short, so you do not have to look

at the Meter during the test. This can be a valuable troubleshooting

aid when determining: good or blown fuses and fusible links, open

or shorted conductors and wires, the operation of switches, etc.

NOTE: Turn the power off to the circuit to be tested. A beeper

tone does not necessarily mean zero resistance.

22 23

To test circuit continuity:

•Select the / setting with the

rotary switch and press the

DC/AC button to select the

continuity ( ) range.

The symbol appears on the

display and the Meter defaults to

the 4 K range.

Insert:

•Black lead in COM jack.

•Red lead in RPM, V, jack.

Connect one test probe to each end

of the circuit to be tested.

•If circuit is closed, the Meter will

beep @ < 100 .

•If circuit is open, there is no beep.

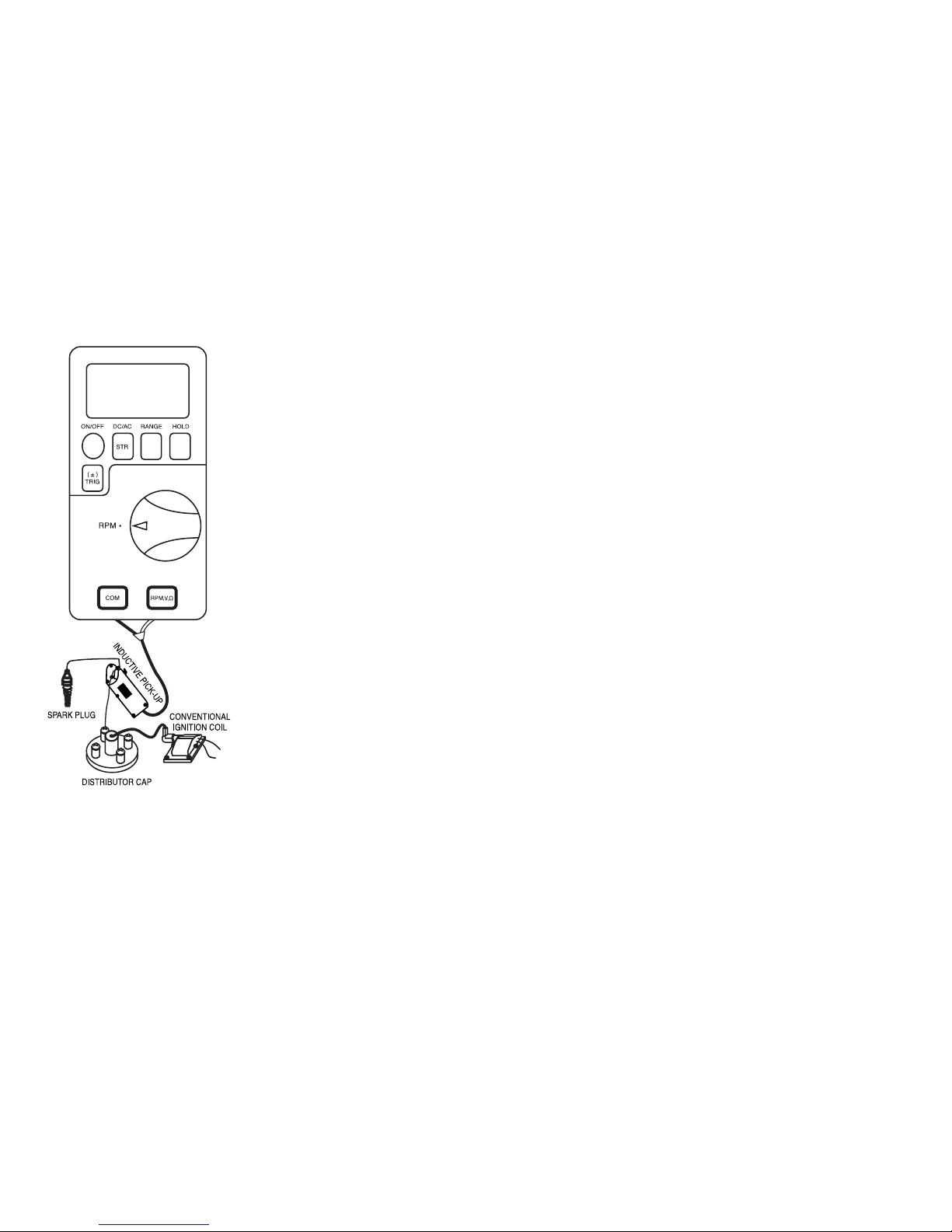

RPM Measurements Using the Inductive Pickup

RPM refers to revolutions per minute. Using the inductive pickup,

which comes with the Meter, RPM can be measured by clamping it

around any spark plug wire of a two stroke or a four stroke

automotive engine. The inductive pickup takes the magnetic field

generated by the current flown in the spark plug wire and converts

it to a pulse that triggers the Meter’s RPM measurement.

Using the inductive pickup allows you to make RPM

measurements on any 2 or 4 stroke automotive engine with any

number of cylinders without physically touching any wires.

WARNING!

THE IGNITION SYSTEM CAN GENERATE A POTENTIAL

SHOCK HAZARD. ENSURE THAT THE ENGINE IS OFF

BEFORE CONNECTING OR REMOVING THE INDUCTIVE

24

To measure RPM:

•Select the RPM range with

the rotary switch.

•Press the DC/AC button to

select either 2 or 4 stroke

engine.

Insert:

•The DUAL BANANA CON-

NECTOR into the input jacks

as shown. Ensure that the

plug with the GROUND TAB

goes into the COM jack.

Connect the inductive pickup

to a spark plug wire and start

the engine. If no reading is

received, unhook the pickup,

turn it over and connect again.

If the reading is too high or

unstable, adjust trigger level.

NOTE:

1. Position the pickup as far

away from the distributor

and the exhaust manifold

as possible.

2. Position the pickup within

six inches of the spark

plug or move it to another

plug wire if no reading or

an erratic reading is

received.

25

Pulse Width Measurements

Pulse Width is the length of time an actuator is energized. For

example, fuel injectors are activated by an electronic pulse from

the Engine Control Module (ECM). This pulse generates a

magnetic field that pulls the injector nozzle valve open. The pulse

ends and the injector nozzle is closed. This Open to Close time is

the Pulse Width and is measured in milliseconds (mS).

The most common automotive application for measuring pulse

width is on fuel injectors. You can also measure the pulse width of

the fuel mixture control solenoid and the idle air control motor.

This exercise shows how to measure Pulse Width on Port Fuel

Injectors.

To measure pulse width (mS):

•Select the mS-Pulse range with

the rotary switch.

•Press the ± TRIG button for 2

seconds until the negative (–)

trigger slope is displayed on the

lower left side of the display.

NOTE: The applied time for

most fuel injectors is

dis-played on the

negative (–) slope.

Insert:

•Black lead in COM jack.

•Red lead in RPM, V, Ωjack.

Connect:

•Jumper wires between the fuel

injector and the harness

connector.

•Black test probe to a good

ground at the fuel injector or the

negative (–) vehicle battery post.

•Red test probe to the fuel

injector solenoid driver input on

the jumper cable.

Start the engine. A pulse width in

milliseconds should be read.

If reading is too high or unstable,

adjust the trigger level pressing the

±TRIG button repeatedly.

26 27

Dwell Measurements

Dwell is the number of degrees of distributor rotation where the

points remain closed. Dwell can be measured for 1,2,3,4,5,6,8

cylinder engines using the Meter so you need to determine how

many cylinders are in the engine to measure Dwell.

In the Dwell mode, the Meter defaults to 4 cylinders so DWL°,

44

CYL and TRIG on the display. If you want to select the other

number of cylinder, press the CYL (RANGE) button repeatedly to

select the required number of cylinders.

This exercise shows how to measure Dwell.

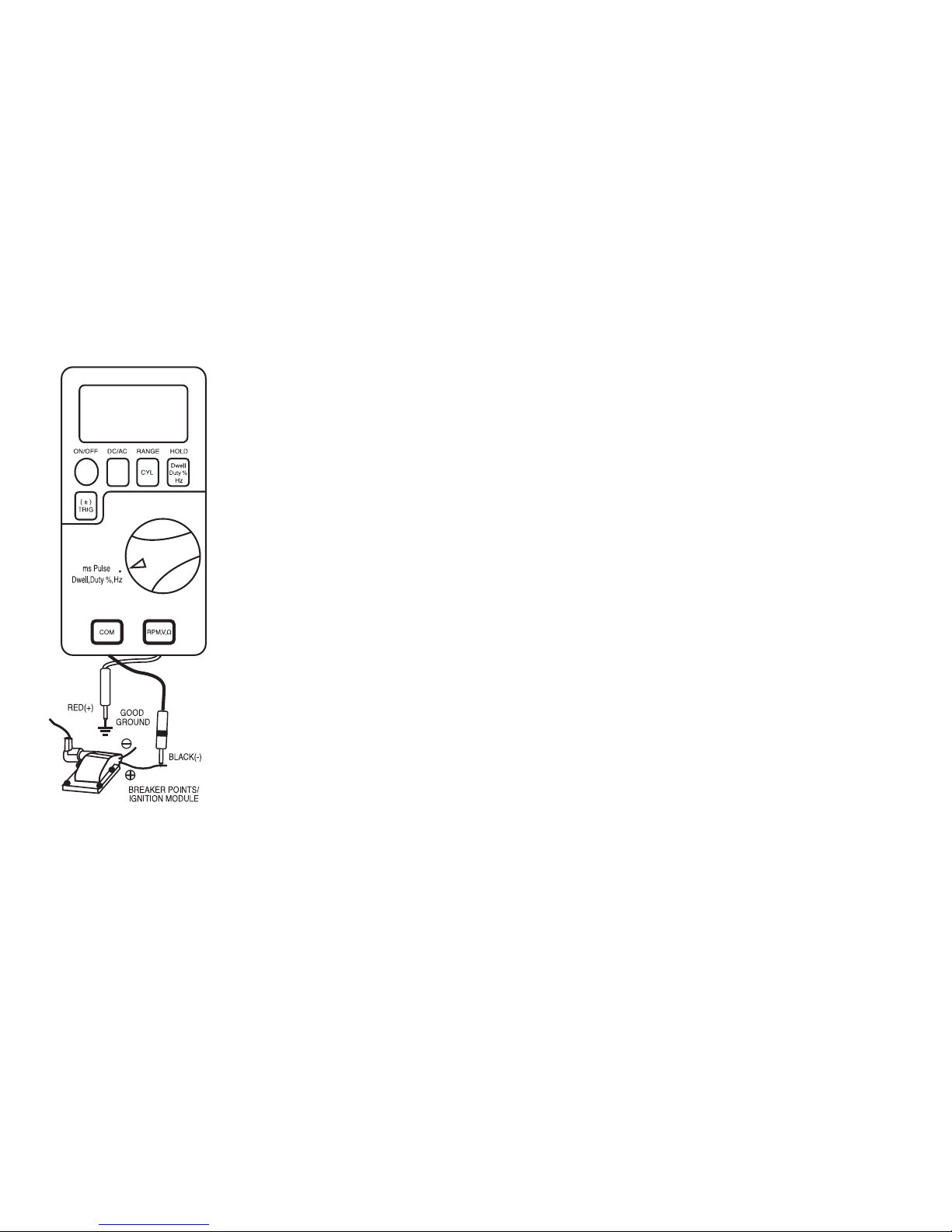

To measure Dwell:

•Select the mS-Pulse range

with the rotary switch.

•Press the HOLD (DWELL)

button until DWL°,

4

CYL,

TRIG, and – appear on the

display.

Insert:

•Black lead in COM jack.

•Red lead in RPM, V, Ωjack.

Connect:

•Red test probe to a good

ground or the negative (–)

vehicle battery post.

•Black test probe to the wire

that connects to the breaker

points.

Press the CYL (RANGE) button

repeatedly to select the required

number of cylinders.

Start the engine and observe the

reading.

Adjust trigger level pressing the

±TRIG button repeatedly, if the

reading is too high or unstable.

28 29

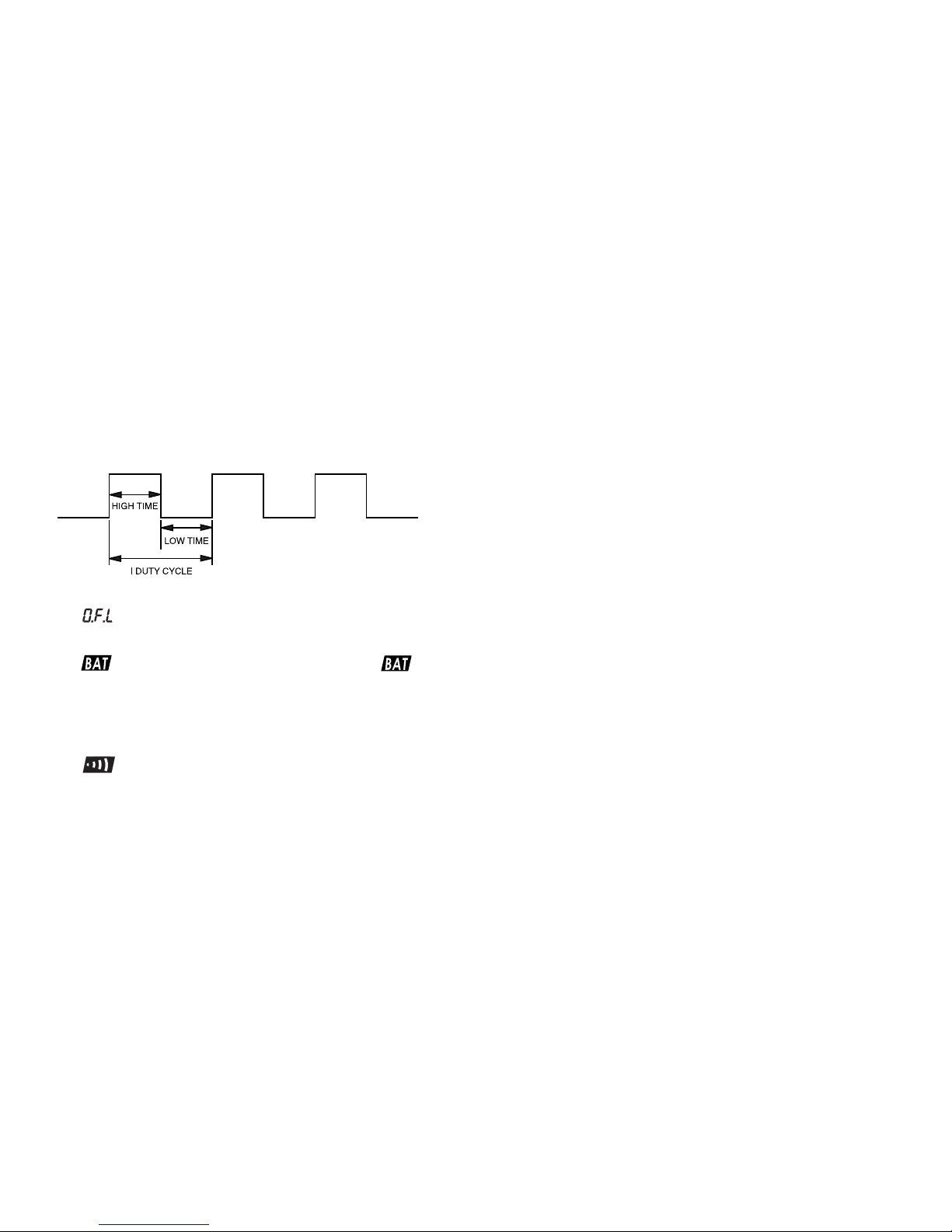

Duty Cycle Measurements

Duty Cycle is the percentage (%) of time that voltage is positive

compared to negative: On compared to Off. There are many

signals on a vehicle where you might be required to measure duty

cycle. Signals from Mixture Control Solenoid of a feedback

carburetor, signals from Cam or Crank sensors and the control

signals for fuel injectors are good examples.

This exercise shows how to measure duty cycle on the signal for

the mixture control solenoid of a feedback carburetor using the

Meter.

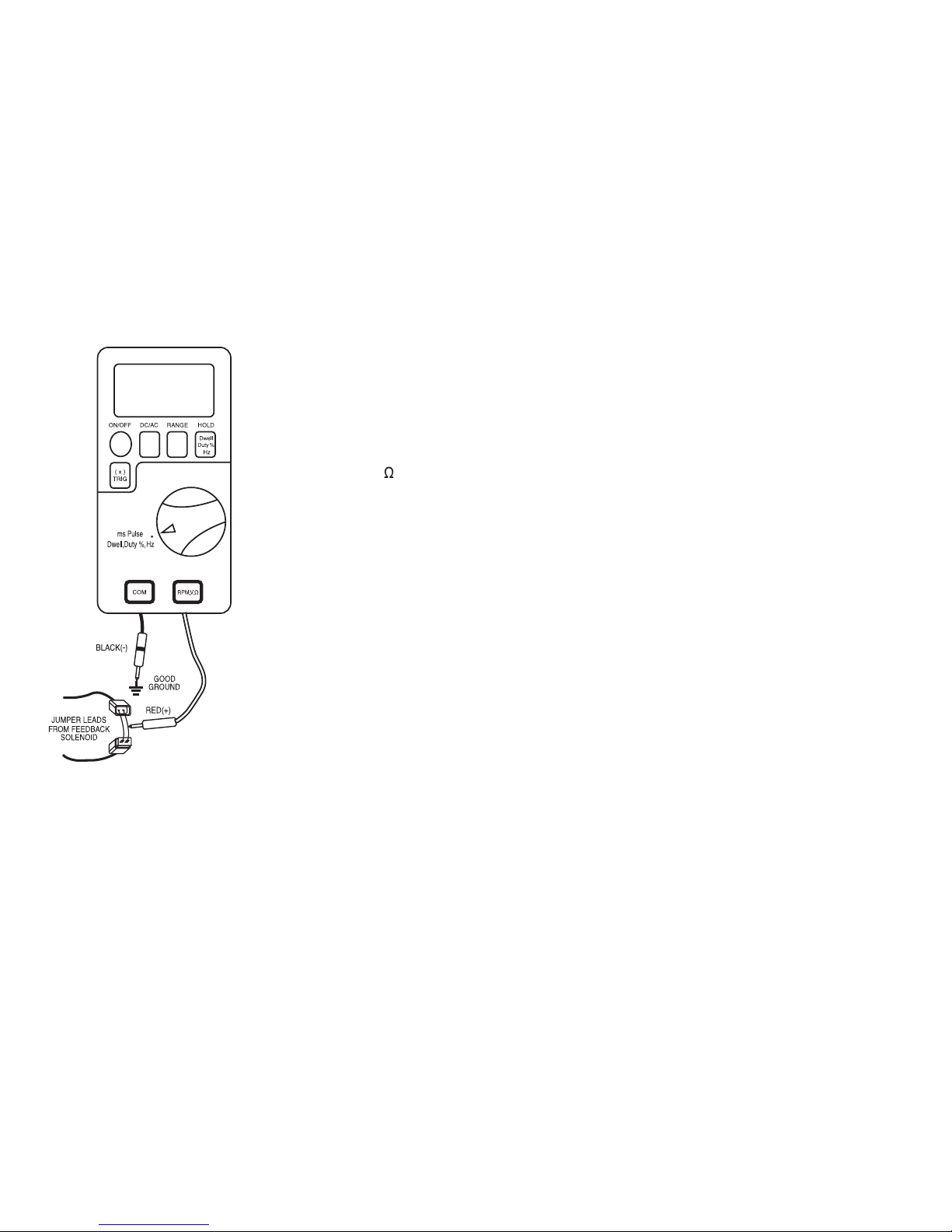

To measure duty cycle (%):

•Select the mS-Pulse range

with the rotary switch.

•Press the HOLD (DUTY %)

button until % appears on

the right side of the display.

Insert:

•Black lead in COM jack.

•Red lead in RPM, V, jack.

Connect:

•Black test probe to a good

ground at the carburetor or

the negative (–) vehicle

battery post.

•Red test probe to the

solenoid signal.

Press the ± TRIG button for 2

seconds to toggle between the

negative (–) and positive (+)

slope.

Start the engine. A duty cycle

of approximately 50 % should

be read.

Adjust the trigger level

pressing the ± TRIG button

repeatedly if reading is too

high or unstable.

30 31

Most car have the points of the

solenoid closed for a duty cycle

between 50 ~ 70%.

Once the engine warms up and

goes into open loop, the duty

cycle should fluctuate.

NOTE: Consult the car’s service

manual to verify slope

assigned to position for

each component.

Frequency (Automotive Hz) Measurements

[ Model: 228 Only ]

Frequency (Hz) is the number of times a voltage pattern repeats

positive compared to negative, On Compared to Off, during 1

second of time. There are many sensors and signals on a vehicle

that have a frequency that can be measured. Wheel Speed

sensors, Vehicle Speed sensors, Fuel Injector control signals,

Cam and Crank outputs and engine reference signals are good

examples.

This example measures the frequency output of a digital Mass Air

Flow sensor. Depending on the type of MAF sensor, the output

can be from several hundred to ten thousand Hz.

NOTE: Although similar in appearance, MAF sensors made by

different manufacturer function differently, have

different frequency range’s square waves and are not

Interchangeable. Voltage level of square waves should

be consistent. Frequency should change smoothly

with engine load and speed.

32 33

Frequency (Non-Automotive Hz) Measurements

[ Model: 226 Only ]

The Meter has two frequency measurement modes: The non-

automotive Hz measurement (Approximate Trigger Level: 300 mV)

mode for the general frequency counter mode and the automotive

Hz measurement mode for the automotive mesurement.

In the non-automotive Hz measurement mode, the Meter

autoranges to one of four ranges: 199.99 Hz, 1999.9 Hz, 19.999

KHz and 199.99 KHz.

If the input signal is below the trigger level, frequency

measurement will not be taken. If your readings are unstable, the

input signal may be near the trigger level for that range. You can

usually correct this by selecting a lower range using the RANGE

button. If your readings seem to be a multiple of what you

expected, your input signal may have distortion or ringing like the

signals from electronic motor controls. In this case, use the

automotive Hz measurement mode to get the correct readings.

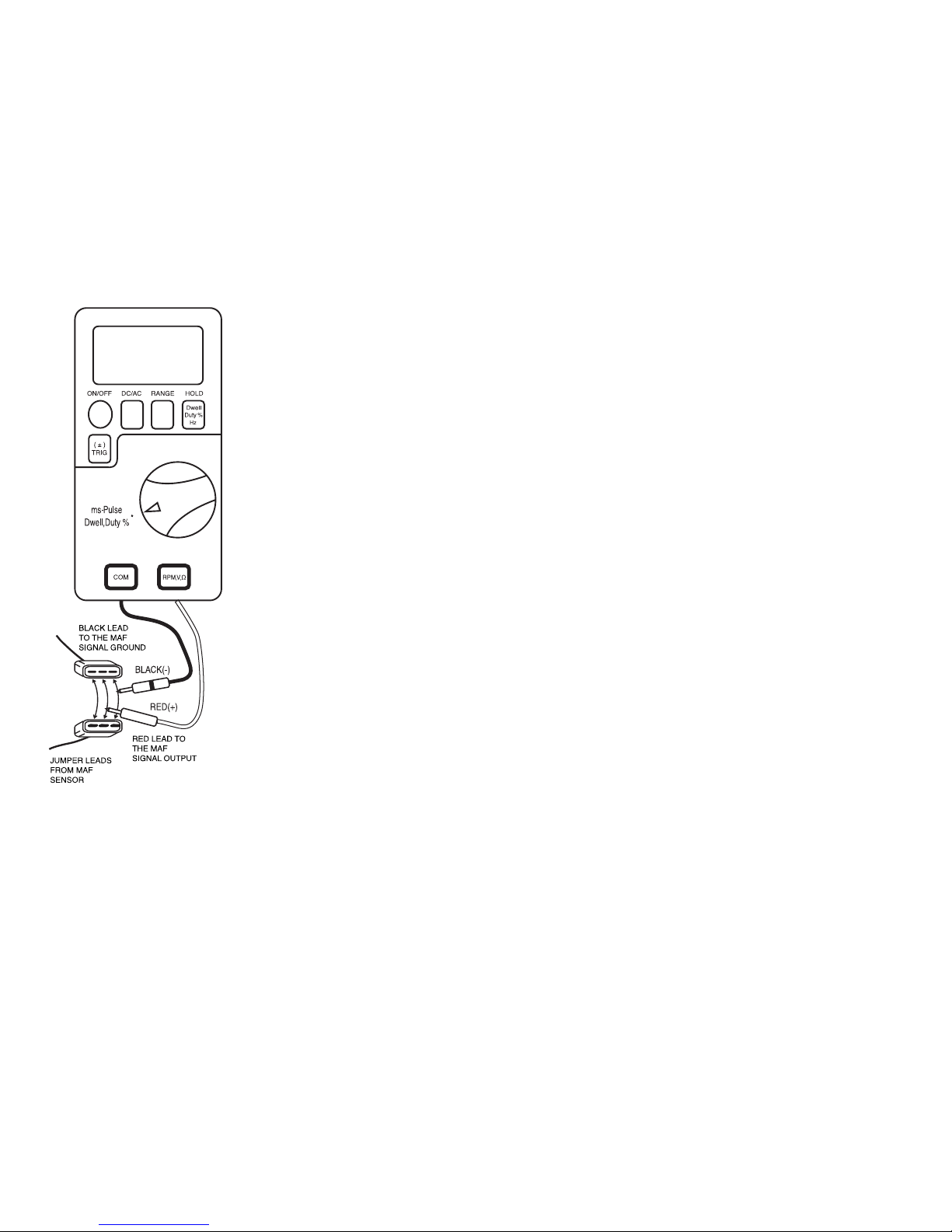

To measure frequency (Hz):

•Select the mS-Pulse range

with the rotary switch.

•Press the HOLD (Hz) button

until Hz appears on the right

side of the display.

Insert:

•Black lead in COM jack.

•Red lead in RPM, V, Ωjack.

Connect:

•Jumper wires between the

MAF sensor and the harness

connector.

•Black test probe to the

ground jumper wire.

•Red test probe to the signal

output jumper wire.

Start the engine. At idle, note

the frequency displayed on the

Meter. Move the throttle and

note the change in frequency

displayed.

If reading is unstable, adjust

the trigger lever pressing the ±

TRIG button repeatly.

To measure frequency (Hz).

•Select the Hz setting with the

rotary switch.

Insert:

•Black lead in COM jack.

•Red lead in RPM, V, ΩHz

jack.

Connect:

•The Black test probe to

GROUND side.

•The Red test probe to the

“SIGNAL OUT” wire of the

object to be tested.

NOTE: The display will show

00.00 Hz for frequen-

cies below 0.5 Hz.

34 35

Temperature Measurements [ Model: 228 Only ]

CAUTION!

DO NOT ALLOW TEMPERATURE PROBES TO CONTACT ANY

LIVE VOLTAGE THAT MAY EXCEED 30 V AC RMS OR 42 V AC

PEAK OR 60 V DC. UNPLUG TEMPERATURE PROBE BEFORE

TAKING MEASUREMENTS OTHER THAN TEMPERATURE. TO

AVOID HEAT DAMAGE TO THE METER, KEEP IT AWAY FROM

SOURCES OF VERY HIGH TEMPERATURE. THE LIFE OF

TEMPERATURE PROBE IS ALSO REDUCED WHEN EXPOSED

TO VERY HIGH TEMPERATURES (OPERATING RANGE IS -40

°F TO 2,498 °F).

NOTE: This Meter automatically defaults to the Centigrade

scale. To measure in Fahrenheit, toggle the DC/AC

button when the rotary switch is set to TEMP position.

To measure temperature:

•Select the TEMP setting with

the rotary switch.

•Press the DC/AC button to

toggle between °C and °F.

Insert:

•The thermocouple adaptor and

thermocouple into TEMP

(RPM, V, Ω) and COM jack.

Touch the end of K– type

thermocouple to the area or

surface of the object to be

measured.

NOTE: To avoid error, it is very

important to use a

thermocouple adaptor

whose materials match

the thermocouple you

are using.

These basic diagnostic tests begin by checking the main source of

power and the chassis ground circuit connections. Ground circuits

are one of the least understood but potentially most troublesome

areas of automotive electronics. One of the most frustrating

electrical problems you will encounter in an automobile is a high

resistance ground. This can create some very strange symptoms

that seem to be unrelated to the cause. The symptoms can include

problems with turn signals, lights that stay dim, the wrong lights

turning on, transmission shifting problems, gauges that change

when certain accessories are operated, or even lights that will not

turn on at all. You can find a bad ground by checking the voltage

between the component’s ground wire and a clean chassis ground

or the negative vehicle battery terminal. An excessive voltage drop

in a ground circuit affects the entire electrical circuit. This is why it

is so important to make sure the basic circuits are in good shape

before checking trouble codes in the on-board computer and

individual components.

Battery Tests

(1) No Load Test

This test checks for battery charge state. A fully charged battery

will display at least 12.6V. Since voltage tests only show the

charge state, not the battery condition, you should also perform a

load test to indicate the battery’s performance.

6. BASIC AUTOMOTIVE DIAGNOSTIC TESTING

36 37

This manual suits for next models

1

Table of contents

Other Finest Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Kestrel

Kestrel 2000 manual

Dynastream Innovations

Dynastream Innovations AMP 231 user guide

Capintec

Capintec AreaExpert user guide

Electro Industries/GaugeTech

Electro Industries/GaugeTech Shark 270 quick start guide

Hanna Instruments

Hanna Instruments HI764 instruction manual

YOUYANG

YOUYANG PAPI 400 user manual