FIP FLS M9.06 User manual

1

FLS M9.06

PH/ORP MONITOR

SAFETY INSTRUCTIONS

PACKING LIST

General Statements

• Do not install and service the product without following the Instruction

Manual.

• This item is designed to be connected to other instruments which can be

hazardous if used improperly. Read and follow all associated instrument

manuals before using with it.

• Product installation and wiring connections should only be performed by

quali ed staff.

• Do not modify product construction.

Installation and Commissioning Statements

• Remove power to the instrument before wiring input and output connections.

• Do not exceed maximum speci cations using the instrument.

• To clean the unit, use only chemical compatible products.

Please verify that the product is complete and without any damage.

The following items must be included:

• M9.06 pH/ORP Monitor & Transmitter

• Instruction Manual for M9.06 pH/ORP Monitor & Transmitter

2

DESCRIPTION

CONNECTIONS TO INSTRUMENTS

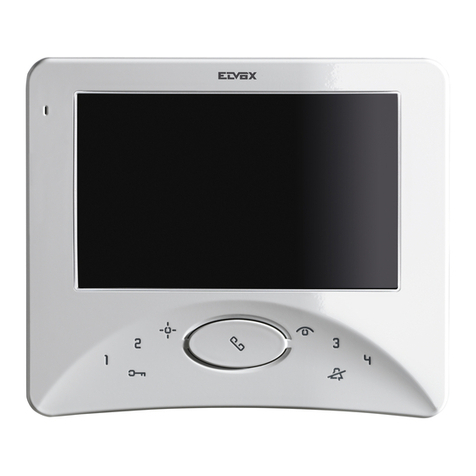

The new FLS F9.06 is a powerful pH/ORP monitor designed to satisfy a

broad range of applications. A 4” wide full graphic display shows measured

values clearly together with many other useful information. Moreover, due to

the multicolor bright backlight, measurement status can be determined easily

also from very long distance. A tutorial software guarantees a mistake-proof

and fast set up of every parameter. A calibration based on automatic buffer

recognition plus a in line adjustment allow to achieve a precise and a reliable

measurement in every conditions.

F3.00 F3.20 F6.30 F3.10 F3.05 F6.60 F6.61 F111

M9.06--------

ULF F3.80 pH/

ORP200

pH/

ORP400

pH/

ORP600

C150/

200

C100/

C300 C6.30

M9.06 - - X X X ---

TECHNICAL DATA

General

• Associated sensors: FLS pH/ORP electrodes and FLS temperature sensors

• Materials:

- Case: ABS

- Display window: PC

- Panel & Wall gasket: silicone rubber

- Keypad: 5-button silicone rubber

• Display:

- LC full graphic

- Backlight version: 3-colors

- Backlight activation: User adjustable with 5 levels of timing

- Update rate: 1 second

- Enclosure: IP65 front

• pH input range: -2÷16pH

• pH measurement resolution: ± 0.01 pH

• ORP input range: -2000÷ +2000mV

• ORP measurement resolution: ± 1 mV

• Temperature input range: -50÷150°C (-58÷302°F) (with Pt100-Pt1000)

• Temperature measurement resolution: 0,5°C/°F (Pt100-Pt1000)

3

Electrical

• Supply Voltage: 12 to 24 VDC ± 10% regulated

• 2 x Current output:

- 4-20 mA, isolated, fully adjustable and reversible

- Max loop impedance: 800 Ω @ 24 VDC - 250 Ω @ 12 VDC

• 2 x Solid State Relay output:

- User selectable as ON-OFF, proportional frequency, proportional pulse,

timed pulse

- Optically isolated, 50 mA MAX sink, 24 VDC MAX pull-up voltage

- Max pulse/min: 300

- Hysteresis: User selectable

• 2 x Relay output:

- User selectable as ON-OFF, proportional frequency, proportional pulse,

timed pulse

- Mechanical SPDT contact

- Expected mechanical life (min. operations): 107

- Expected electrical life (min. operations): 105 N.O./N.C. switching capacity

5A/240VAC

- Max pulse/min: 60

- Hysteresis: User selectable

Environmental

• Operating temperature: -20 to +70°C (-4 to 158°F)

• Storage temperature: -30 to +80°C (-22 to 176°F)

• Relative humidity: 0 to 95% not condensing

Standards & Approvals

• Manufactured under ISO 9001

• Manufactured under ISO 14001

• CE

• RoHS Compliant

• GOST R

4

DIMENSIONS

Mechanical installation

The pH/ORP monitor & transmitter is available just in one packaging for panel

or wall installation. The panel version is installed using the panel mounting

kit (M9.SN1), while the wall mounting version is got xing the panel mounting

version on the wall mounting kit (M9.KWX). The mounting kits can be ordered

directly connected to the monitor or separately and then simply installed on it.

PANEL MOUNTING

WALL MOUNTING

INSTALLATION

5

Panel installation

Fix instrument on the panel rotating by hand the xing snails (M9.SN1).

Wall installation

Use the panel mounting kit (M9.SN1) to x the M9.06 on the dedicated frontal

cutout of the wall mounting kit (M9.KWX).

Tighten front screws of box and waterproof connectors of cables, internally

mount caps on screw sites to get a IP65 watertight installation.

6

WIRING

REAR TERMINAL VIEW

General recommendation

Always ensure the power supply is switched off before working on the device.

Make wiring connections according to wiring diagrams.

• Terminals accept 26 to 12 AWG (0.08 to 2.5 mm2)

• Strip around 10 mm (0.4”) of insulation from the wire tips and tin bare ends to

avoid fraying.

• Ferrules are suggested when connecting more than one wire to a single

terminal.

• Remove the upper part of the terminals for an easy cabling.

• Insert wire tip or ferrule completely into the terminal and x with the screw

until nger tight.

• Do not route the sensor, DC power, or 4-20mA cables in conduit containing

AC power wiring. Electrical noise may interfere with sensor signal.

• Routing the sensor cable in grounded metal conduit can help prevent

electrical noise and mechanical damage.

• Seal the cable entry points to prevent moisture damage.

Wall Installation

Pull the electrical cables through liquid tight connectors.

Use electrical cables with the proper external diameter for the liquid tight

connector.

PG11/PG9: external diameter between 2-7 mm (0.079-0.276”)

7

POWER/LOOP WIRING DIAGRAM

PROBE WIRING DIAGRAM

Refer to dedicated sensor manual for its wiring.

In case a temperature sensor (Pt100-Pt1000) is not available, place a brigde

connection between 28 - 29 and between 29 - 30.

Stand-alone application,

no current loop used

pH/ORP probe connection

Connection to a PLC/Instrument with a separate power supply

or

Connection to a PLC with built-in

power supply

Power Supply

12 - 24 VDC

12 - 24 VDC

+ VDC

- VDC

2

1

+IN

25

26

REF pH

28

27

29

30

PT100/1000

SIGNAL

SHIELD

Power Supply

12 - 24 VDC

4 - 20 mA

Input 2

PLC Terminals

4 - 20 mA

Input 1

+ VDC

- VDC

2

1

- LOOP 2

+ LOOP 1

+ LOOP 2

- LOOP 1

21

22

23

24

Power Supply

12 - 24 VDC

12 - 24 VDC

PLC

4 - 20 mA

Input 2

4 - 20 mA

Input 1

+ VDC

- VDC

2

1

- LOOP 2

+ LOOP 1

+ LOOP 2

- LOOP 1

21

22

23

24

Power Supply

12 - 24 VDC

12 - 24 VDC

PLC

4 - 20 mA

Input 2

4 - 20 mA

Input 1

+ VDC

- VDC

2

1

- LOOP 2

+ LOOP 1

+ LOOP 2

- LOOP 1

21

22

23

24

Power Supply

12 - 24 VDC

12 - 24 VDC

PLC

4 - 20 mA

Input 2

4 - 20 mA

Input 1

+ VDC

- VDC

2

1

- LOOP 2

+ LOOP 1

+ LOOP 2

- LOOP 1

21

22

23

24

Power Supply

12 - 24 VDC

12 - 24 VDC

PLC

4 - 20 mA

Input 2

4 - 20 mA

Input 1

+ VDC

- VDC

2

1

- LOOP 2

+ LOOP 1

+ LOOP 2

- LOOP 1

21

22

23

24

8

Internal PLC

connection

N.O.

COM

4

3

PLC

Imax = 50 mA

Power sup.

Power sup.

O.C. IN

O.C. IN

SOLID-STATE RELAY WIRING DIAGRAM

(FOR SSR1 AND SSR2)

Connection to a PLC with NPN input Connection to a PLC with PNP input

N.O.

COM

4

3

PLC

Imax = 50 mA

Power sup.

Power sup.

O.C. IN

O.C. IN

Internal PLC

connection

Connection to a PLC / Instrument

digital input with separate Power

Supply

Connection to a PLC / Instrument

digital input for Voltage Free Contacts

(REED)

N.O.

COM

3

4

Power Supply

12 - 24 VDC

12 - 24 VDC

PLC / Instrument

Digital INPUT

Digital INPUT

Imax = 50mA

lmax = 50mA

lmax = 50mA

PLC

DIGITAL INPUT N

DIGITAL INPUT 2

DIGITAL INPUT 1

REF PLC

N.O.

Imax = 50 mA

Imax

COM

3

4

lmax = 50mA

lmax = 50mA

PT100 - PT1000

two wires connection

PT100 - PT1000

three wires connection

28

27

29

30

PT100/1000

REF pH

28

27

29

30

PT100/1000

REF pH

Pt100 - Pt1000

no connection

27

28

29

30

PT100/1000

9

SOLID-STATE RELAY WIRING DIAGRAM

(FOR SSR1 AND SSR2)

RELAY WIRING DIAGRAM

(FOR RELAY 1 & RELAY 2)

HOLD AND REED CONNECTION

The alarm is OFF during normal

operation and goes ON according to

Relay settings

The alarm is ON during normal

operation and goes OFF according to

Relay settings

The alarm is off during normal

operation and goes ON according to

Relay setting.

If Imax > 50 mA use external Relay

Connection to an User

NO

10

11

12

RELAY 2

NC

COM

Alarm

AC or DC

Power NO

10

11

12

RELAY 2

NC

COM

Alarm

AC or DC

Power

N.O.3

4 COM

AC or DC

Power

User

Imax = 50mA

N.O.3

4 COM

AC or DC

Power User

Imax = 50mA

lmax = 50mA

N.O.3

4 COM

AC or DC

Power

User

Imax = 50mA

N.O.3

4 COM

AC or DC

Power User Imax = 50mA

lmax = 50mA

N.O.

N.O.

N.C.

COM

4

3

COM

External Relay

V= 12-24 VAC/VDC

Imax = 50 mA

Imax

Imax

+V

-V lmax = 50mA

- HOLD

+ HOLD

18

17

19

20 - REED

+ REED

12-24

VDC

10

↓

↓

OPERATIONAL

OVERVIEW

The M9.06 pH/ORP monitor and

transmitter features a full graphic

display and a ve-button keypad

for system set-up, calibration and

operation. Full graphic display has

a white backlight during standard

conditions, a green backlight in case a

external device control is

activated (ON/OFF, PROPORTIONAL

FREQUENCY, PROPORTIONAL

PULSE and TIMED PULSE), a red

backlight in case a set alarm is

activated (O.V.A. and O.T.A., always

with priority).

The ve push buttons of the keypad

are used to navigate display levels and

modify settings.

The function of each button may change

according to display level;

please refer to following table:

VIEW LEVEL

MENU DIRECTORY

pH/ORP or temperature

item code -

software release

pH/ORP or temperature -

analog output 1

pH/ORP or temperature -

analog output 2

pH/ORP direct access to calibration*

pH/ORP - last calibration

Settings

Calibration

Outputs

Options

View data

↓

↓

*"pH/ORP direct access to calibration" includes the "in-line adjustment" option to align on site the

measurement with a instant reference value.

11

EDIT LEVEL

PUSH BUTTON

MENU LEVEL

pH/ORP Probe Calibration

Temperature Probe Calibration

1 SSR

2 SSR

3 RELAY

4 RELAY

Output Test

Language

Output Assigment

Filter

Hold

Backlight

Reed

Password

Contrast

Default Data

Probe Signal

Input Activation

Output Activation

Calibration Data

Statistic Reset

to modify an item

to scroll right

to return to Menu without saving

to save new settings

↓

↓

Probe Unit

Temperature Unit

Manual Temperature

4-20mA1

4-20mA2

12

OUTPUT MODE

The M9.06 pH/ORP monitor and transmitter features 2 solid state relays and 2

mechanical relays in addition to 2 analog output 4-20mA.

Only the second mechanical relay can be set as an alarm (icon is 4ALR)

related to the feedback of external device managing. Icon will turn to 4OTA

(Over Time Alarm) in case the setpoint has not been reached within set

maximum timing.

Icon will turn to 4OVA (Over Values Alarm) in case measured values overstep

the set value band. In addition to the type of failure, a reference number

correlated to the involved digital output is reported by the out put number.

PROCEDURE FOR OUTPUTS SETTING

- go to the “Options” menu

- enter into the “Outputs activation” sub menu

- enable output(s)

- go to the “Outputs” menu

- set the operating mode for each enabled output

Monitor without digital

output activated

In case a digital output

is enabled, a icon will

appear

In case a digital output

is set, icon reports the

operating mode

In case set digital

output is activated, the

icon will turn to black

pH

ENT ER T O CONFIGURE ENT ER T O CONFIGURE

1 OFF

1 OFF

1 OFF

1 OFF

1 OFF

1 OFF

1 OFF

1 OFF

1 OFF

1 OFF

1 OFF

pH

ENT ER T O CONFIGURE

1 PRP

1 PRP

1 PRP

1 PRP

pH

ENT ER T O CONFIGURE

1 PRP

pH

13

Digital outputs can be set in the following way:

ON-OFF MODE (icon reports O-F)

alkaline dosing

PROPORTIONAL MODE (icon

reports PRP) alkaline dosing

TIMED MODE (icon reports TMD)

acid dosing

FREQUENCY MODE (icon reports FRQ)

ON-OFF MODE (icon reports O-F)

acid dosing

PROPORTIONAL MODE (icon

reports PRP) acid dosing

TIMED MODE (icon reports TMD)

alkaline dosing

Hysteresis

Setpoint

Output relaxed

Output energized

Time

pH

Set Point I + His

Set Point I

Prop. Band

Relay

Prop

pH

Set Point I + His

Set Point I

Relay

Timed

pH

Endpoint

100 pulses

from 0 to max

pulses / min

Starting point

0 pulses

5 10

Set Point I + His

Set Point I

Prop. Band

Relay

Prop

pH

Set Point I + His

Set Point I

Relay

Timed

pH

Hysteresis

Setpoint

Output relaxed

Output energized

Time

pH

14

ORDERING DATA

Part No. Description

/Name

Power

supply

Wire power

Technology

Sensor

Input Output

M9.06.P1

Panel mount

pH/ORP

monitor

12 - 24 VDC 3/4 wire pH/ORP

2*(4-20mA),

2*(S.S.R.),

2*(mech. relay)

M9.06.W1

Wall mount

pH/ORP

monitor

12 - 24 VDC 3/4 wire pH/ORP

2*(4-20mA),

2*(S.S.R.),

2*(mech. relay)

M9.06.W2

Wall mount

pH/ORP

monitor

110 - 230 VAC 3/4 wire pH/ORP

2*(4-20mA),

2*(S.S.R.),

2*(mech. relay)

ACCESSORIES

SPARE PARTS

Part No. Name Description

M9.KW1 Wall mounting kit 144x144mm plastic box for wall installation

of all panel mount monitors

M9.KW2 Wall mounting kit with

power supply

144x144mm plastic box and 110/230VAC to 24 VDC power

supply for wall installation of all panel mount monitors

Part No. Name Description

M9.SN1 Fixing snails 2 xing snails for panel installation of FLS monitors

15

NOTE

FIP - Formatura Iniezione Polimeri S.p.A.

Loc. Pian di Parata

16015 Casella

Genova - Italy

Tel. +39 010 96211

Fax +39 010 9621209

www.flsnet.it

IMM906E - 05/2014

This manual suits for next models

3

Table of contents

Other FIP Monitor manuals