Fire Pump 8100 Series User manual

C

e

S

e

e

ntri

f

e

rie

s

f

ug

a

s

81

0

a

l S

p

0

0,

8

p

lit C

8

15

0

ase

0

, 82

0

Fire

0

0,

9

Install

a

M

e

Pu

m

9

10

0

a

tion, Op

e

M

aintena

n

m

ps

0

e

ration, a

n

n

ce man

u

n

d

u

al

Series 8100/8150/8200/9100 Fire Pump

1 AC6102 Rev 03

AC61

0

0

2 Rev 03

EC De

c

Pump su

p

We, the ma

declare un

d

Horizontal

S

8150, 8200

fulfills the r

e

Directive(s)

Directives:

-

-

Standards

u

-

-

-

Pump su

p

We, the ma

n

declare und

e

Horizontal

S

8150, 8200,

fulfills the r

e

Directive, S

t

Directives:

-

Standards

u

-

-

The pump c

service until

has been d

e

Directive.

The technic

a

request by t

authorized

r

Community:

M

C

o

L

o

V

i

3

6

V

i

Brian Bu

s

Product

L

c

laration o

f

p

plied compl

e

nufacturer:

A-

C

82

0

Mo

r

US

A

d

er our sole res

p

S

plit Case Cent

r

,

and 9100; to

w

e

levant provisio

n

, Standard(s) o

r

Machinery D

i

Low Voltage

u

sed:

EN 809:199

8

EN ISO 121

0

EN 60204-1:

2

p

plied without

n

ufacturer:

A-

C

820

Mo

r

US

A

e

r our sole resp

o

S

plit Case Centri

f

and 9100; to w

h

levant provision

s

t

andard(s) or oth

Machinery D

i

u

sed:

EN 809:199

8

EN ISO 121

0

overed by this d

e

the equipment i

e

clared in confor

m

a

l file can be su

p

h

e competent n

a

epresentative e

s

auro Caldarde,

o

E Engineering

o

wara S.r.l. Uni

p

i

a Vittorio Lomb

6

075 Montecchi

o

i

cenza, Italy.

s

cher

L

ine Manage

r

f

Confor

m

e

te with drive

r

C

Fire Pump Sy

s

0

0 N. Austin Av

e

r

ton Grove, IL 6

0

A

,

p

onsibility that t

h

r

ifugal Fire Pum

w

hich this declar

n

s of the followi

n

r

other normativ

e

i

rective (2006/4

2

Directive (2006/

9

8

+A1:2009.

0

0:2010.

2

006+A1:2009.

drive

r

C

Fire Pump Sys

t

0 N. Austin Ave.

r

ton Grove, IL 6

0

A

,

o

nsibility that the

f

ugal Fire Pump,

h

ich this declara

t

s

of the followin

g

er normative do

c

i

rective (2006/4

2

8

+A1:2009.

0

0:2010.

e

claration must

n

n

to which it is to

m

ity with the pro

p

plied, in respon

s

a

tional authoritie

s

s

tablished in the

Manager,

p

ersonale,

ardi 14,

o

Maggiore,

Mort

o

m

ity

r

s

tems

e

.

0

053,

h

e product

p, Series 8100,

a

tion relates,

n

g European

e

document(s):

2

/EC).

9

5/EC).

t

ems

0

053,

product

Series 8100,

t

ion relates,

g

European

c

ument(s):

2

/EC).

n

ot be put into

be incorporated

visions of the

s

e to a reasone

d

s

, through our

European

o

n Grove, Illinoi

s

August 8, 201

4

d

s

4

2

Series 8100/8150/8200/9100 Fire Pump

3 AC6102 Rev 03

AC6102 Rev 03 4

Table of contents

1 Introduction …………………………………………………. 8

1.1 General …………………………………………… 8

1.2 Target Group ………………………………........... 8

1.3 Safety symbols used in this manual ……........... 8

1.4 Manufacturer ………………………………........... 8

1.5

A

dditional technical documents ………………… 8

2 Safety ………………………………………………………… 8

2.1 General …………………………………………… 8

2.2 Intended use …………………………………….. 8

2.3 Improper use ……………………………............ 8

2.4 Warning and Instruction Labels ……………….. 9

2.5 Personnel qualifications and training ………… 9

2.6 Safety awareness ………………………………… 9

2.7 Safety instruction for the user …………………. 9

2.8 Safety instructions for maintenance, inspection,

and installation ……………………………………. 9

2.9 Noise Emissions ………………………………….. 9

2.10 Unauthorized modification and manufacture of

spare parts ………………………………………… 9

2.11 Product Warranty …………………………………. 10

2.11.1 Coverage ………………………………………….. 10

2.11.2 Limitations ……………………………………….... 10

2.11.3 Warranty Claim …………………………………… 10

3 Applications ………………………………………………... 10

4 Operational Limits …………………………………………. 10

4.1 Pumped liquids ……………………………………. 10

4.2 Liquid temperature ……………………………….. 10

4.3 Pressure limits ……………………………………. 10

4.4

A

mbient temperature …………………………….. 10

4.5 Pump speed ………………………………………. 10

5 Delivery, handling, and storage ………………………… 11

5.1 Delivery ……………………………………….…. 11

5.2 Handling ………………………………………… 11

5.2.1 Bare shaft pump (Model 100) …….……………. 11

5.2.2 Complete pump unit (Model 150M) …………… 11

5.2.2.1 Bases supplied with lifting holes …….………… 11

5.2.2.2 Bases supplied without lifting holes …………… 11

5.2.3 Engine driven pump units (Model 150E) ……… 12

5.3 Storage ………………………….…………………. 12

5.3.1 Temporary storage ……………………………… 12

5.3.2 Long Term Storage ……….…………………… 12

6 Description ……………………………………………..…. 13

6.1 General …………………………………………… 13

6.2 Designation ………..……………………………. 13

6.3 Nameplate ………..……………………………… 13

6.3.1 Pump nameplate ………………………………… 13

6.3.2 Pump unit nameplate …………………………… 13

6.4 Design detail ……………………………………… 14

6.4.1 Casing …………..…………………………………. 14

6.4.2 Impeller …………………………………………….. 14

6.4.3 Shaft ……………………………………………… 14

6.4.4 Shaft sleeves ……………………………………… 14

6.4.5 Stuffing box ……………………………………… 14

6.4.6 Casing rings ……………………………………….. 14

6.4.7 Bearings ……………………………………..…….. 14

6.4.8 Bearing housings …….………………………..…. 14

6.4.9 Baseplate ………………………………………….. 14

6.4.10 Coupling ………………………………..………….. 14

6.4.11 Coupling Guard ………………….…….…………. 14

6.4.12 Rotation ……………………………………………. 14

6.5 Noise characteristics ……………………….……. 15

6.6 Scope of supply …………………….…………….. 15

6.7 Dimension and weights ………………………….. 15

7 Installation …………………….……..….…………………. 15

7.1 Location ……………………………………..…….. 15

7.2 Foundation ………………………………….…….. 15

7.3 Leveling the baseplate …………………….…….. 16

7.4 Grouting …………………………………..……….. 16

7.5 Initial Alignment ……………………………….….. 17

7.5.1 Straightedge method of alignment …………….. 17

7.5.1.1

A

ngular alignment ……………………….……….. 14

7.5.1.2 Parallel Alignment ………………………….…….. 17

7.5.2 Dial indicator method of alignment …………….. 17

7.5.2.1

A

ngular alignment ……………………….……….. 18

7.5.2.2 Parallel Alignment ………………………….…….. 18

7.5.3

A

lignment of grid couplings …….…………..….. 18

7.5.3.1 Mount seal and hubs …………………….………. 18

Series 8100/8150/8200/9100 Fire Pump

5 AC6102 Rev 03

7.5.3.2 Gap and Angular alignment (X-Y) ……………… 18

7.5.3.3 Parallel Offset Alignment (P) …………...………. 18

7.5.3.4 Insert Grid …………………………………………. 18

7.5.3.5 Pack with grease and assemble covers ………. 18

7.6 Pipe connections …………………………………. 19

7.6.1 Suction and discharge piping general

precautions ……………………………………… 19

7.6.2 Maximum forces and moments allowed on

pump flange ……………………………………… 20

7.6.2.1 8100 series Horizontal split case maximum

forces and moments allowed …………………… 20

7.6.2.2 8200 series Horizontal split case maximum

forces and moments allowed …………………… 20

7.6.2.3 9100 series Horizontal split case maximum

forces and moments allowed …………………… 20

7.6.3 Suction piping …………………………………… 22

7.6.4 Discharge piping …….……………………………. 23

7.6.5 Bypass piping …………………………………… 23

7.6.6 Cooling system ……………………..…………… 23

7.6.7 Exhaust system …………………………….…… 23

7.6.8 Pressure gages ………………………….……… 24

7.6.9 Stuffing box lubrication ………………………… 24

7.6.9.1 General guidelines ……………………………… 24

7.6.9.2 Packing …………………………………………… 24

7.7 Final Alignment …………………………………… 24

7.8 Electrical Connection …………………………… 24

8 Start-up, operation and shutdown ……………...……… 25

8.1 Start-up …………………………………………… 25

8.1.1 Preparation for start-up ………………………… 25

8.1.2 Priming …………………………………………… 25

8.2 Coupling Guard ………………..………………… 25

8.2.1 Removing the coupling guard ……………….… 26

8.2.2 Installing the coupling guard ……………………. 26

8.3 Operation ………………………………………… 27

8.3.1 General procedure ……………………………… 27

8.3.2 Optional Checklist ………………………………… 27

8.4 Shutdown ………………………………………… 27

8.5 Returning to service ……..……………………… 27

8.6 Freeze protection ……………..………………… 27

8.7 Field testing ……………………………………… 27

9 Maintenance …….......................................................... 28

9.1 General …………………………………………… 28

9.2 Maintenance interval ……………………………. 28

9.3 Lubrication ……………………………………….. 28

9.3.1 Lubricating grease requirements ……………… 28

9.3.2 Grease lubrication ………………………………. 29

9.3.3 Lubrication procedure ……………………………. 29

9.4 Packed stuffing box …………..………………… 29

9.4.1 Packing specifications …………………………… 29

9.4.2 Packing maintenance ……………………………. 29

9.4.3 Removal of packing ………………………………. 29

9.4.4 Installing packing …………………………………. 29

9.4.5 Packing adjustment ………………………………. 30

10Service ……………………………………………………… 31

10.1 Tools required …………………………………….. 31

10.2 Dismantling ………………………………………... 31

10.2.1 Rotating Element …………………………………. 31

10.2.2 Bearing housing ………………………………….. 31

10.2.3 Shaft seal - gland packing ………………………. 31

10.2.4 Shaft sleeve ……………………………………….. 31

10.2.5 Impeller and casing wear rings …………………. 32

10.3 Examination of parts ……………………………... 32

10.3.1 Casing and impeller ……………………………… 32

10.3.2 Shaft and sleeve ………………………………….. 32

10.3.3 Gaskets and O-rings ……………………………... 32

10.3.4 Bearings …………………………………………… 32

10.3.5 Bearing isolators and lip seals …………………. 32

10.4

A

ssembly ………………………………………….. 32

10.4.1 Wear Rings ……………………………………….. 32

10.4.2 Impeller …………………………………………….. 33

10.4.2.1 Series 8100, 8150 and 9100 …….……………… 33

10.4.2.2 Series 8200 ……………………………………….. 34

10.4.3 Bearings and bearing housings ………………… 34

10.4.3.1 Series 8100 ……………………………………….. 34

10.4.3.2 Series 8200 ……………………………………….. 35

10.4.3.3 Series 9100 ……………………………………….. 35

10.4.3.4 Series 8150 ……………………………………….. 35

10.4.4 Rotating Element …………………………………. 35

10.4.4.1 Series 8100 ……………………………………….. 35

10.4.4.2 Series 8200 ……………………………………….. 35

10.4.4.3 Series 9100 ……………………………………….. 35

10.4.4.4 Series 8150 ……………………………………….. 36

10.4.5 Casing Gaskets …………………………………… 36

10.4.6 Stuffing Box Assembly – Packing ……………… 36

10.5 Tightening torques ……………………………….. 36

10.5.1 Casing Bolts ………………………………………. 36

10.5.1.1 Tightening sequence …………………………….. 36

10.5.2 Other Bolt Locations …………………………… 37

AC6102 Rev 03 6

10.6 Spare Parts ………………………………………... 37

10.6.1 Ordering Spare Parts …………………………….. 37

10.6.2 Storage of spare parts …………………………… 37

11Troubleshooting …………………………………………… 39

12Replacement Parts ………………………………………… 41

12.1 Series 8100 Horizontal Split Case Fire Pump … 41

12.2 Series 8200 Horizontal Split Case Fire Pump … 43

12.3 Series 9100 Horizontal Split Case Fire Pump … 45

12.4 Series 8150 Horizontal Split Case Fire Pump … 47

A Appendix …………………………………………………..… 49

A

1 Coupling Guard Removal - non CE version …... 50

A

2 Changing pump rotation …………………………. 51

Series 8100/8150/8200/9100 Fire Pump

7 AC6102 Rev 03

AC6102 Rev 03 8

1 Introduction

1.1 General

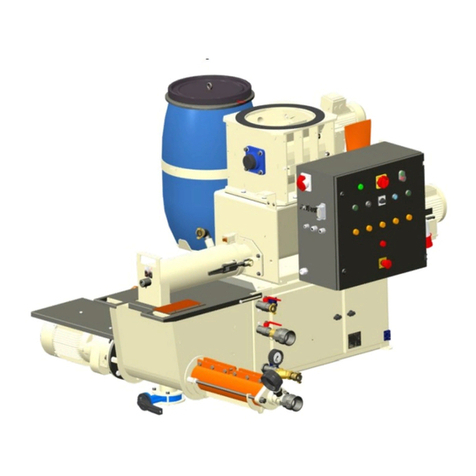

The A-C Fire Pump product line of horizontal split case

centrifugal fire pumps are the product of careful

engineering and skilled workmanship and, if properly

installed, maintained, and operated, should deliver

efficient and trouble-free service.

This manual introduces the user to the pump unit and its

intended uses. It is extremely important that the

instructions for operating the pump safely are read,

understood and followed prior to handling the pump.

These instructions do not consider local regulations. The

user alone is responsible for ensuring that such

regulations are observed, including by those who are

installing the pump unit.

CAUTION

Read this manual carefully before installing,

operating, using and maintaining the pump.

Improper use of the pump can cause

personal injury and damage to property, and

may void the warranty.

NOTICE

Save this manual for future reference, and

keep it readily available at the location of the

unit.

1.2 Target Group

This manual is intended for use by personnel with

qualified training and experience in the operation and

maintenance of pumps used for fire suppression.

1.3 Safety symbols used in this

manual

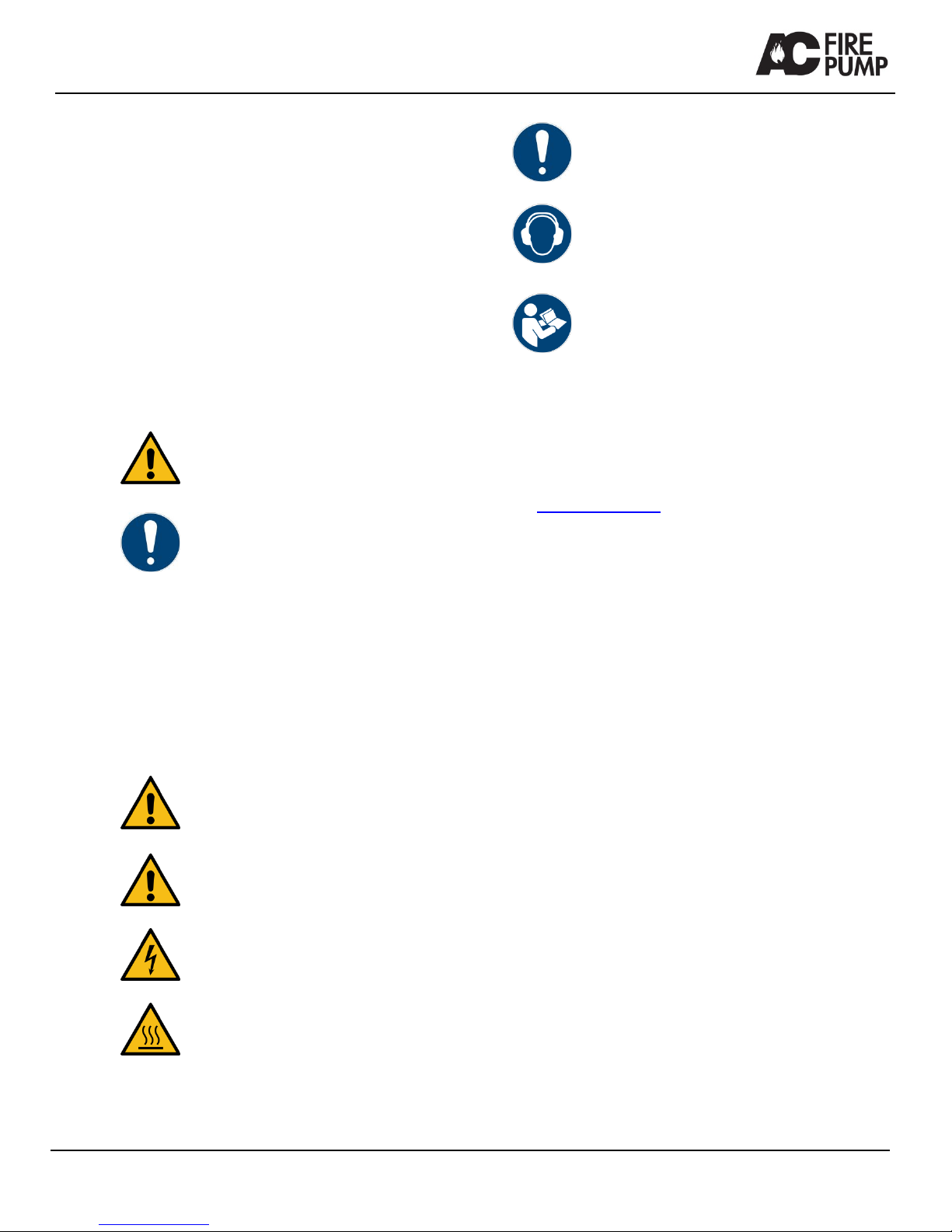

WARNING

If these safety instructions are not followed, it

could result in serious personal injury or death,

or property damage.

CAUTION

If these safety instructions are not followed, it

could result in equipment malfunction of

damage.

WARNING

Electric Shock Hazard, failure to follow safety

instructions could result in personal injury or

death.

WARNING

The surface of the pump may be so hot that it

may cause burns or personal injury.

NOTICE

Instructions that are not safety related but

pertain to the operation of the pump.

WARNING

The sound pressure is so high that hearing

protection must be used.

NOTICE

Read the installation, operation and

maintenance instructions.

1.4 Manufacturer

A-C Fire Pump Systems

8200 N. Austin Avenue

Morton Grove, Illinois 60053

USA

Tel.: +1-847-966-3700

Web: www.acfirepump.com

1.5 Additional technical documents

Order-related documents.

Operating and maintenance instructions, motor, (if

applicable).

Operating and maintenance instructions, engine, (if

applicable).

Supplier documentation, (coupling, etc.).

Documentation on accessories, (if applicable).

General dimensional drawing of the pump unit.

Performance curve of the pump.

2 Safety

2.1 General

This manual contains general installation, operating and

maintenance instructions that must be observed to ensure

safe pump operation and to prevent personal injury and

damage to property.

2.2 Intended Use

The standard horizontal split case pump is designed for

use in the fire suppression applications, with each pump

being designed according to customer requirements.

The pump must only be operated with the operating limits

described in this manual and other applicable documents

listed in section 1.5, Additional technical documents.

2.3 Improper Use

The operational safety of the pump unit can only be

guaranteed, if the pump is used in accordance with the

specifications in the sections of this manual. The

operational limits as stated on the pump unit’s nameplate

must never be exceeded.

Serie

s

9

s

8100/8150/820

2.4

W

The safety

i

must be ob

s

missing or i

representat

2.5

P

t

r

All personn

e

inspection

a

qualified to

not already

appropriate

0/9100 Fire Pu

m

W

arning an

d

i

nstructions lab

e

s

erved and legi

b

llegible, contac

t

ive for a replac

e

P

ersonnel

q

r

aining

e

l involved in th

a

nd maintenanc

e

perform the wo

r

possess the ne

training and in

s

m

p

d

Instructi

o

e

ls placed direc

t

b

le at all times.

I

t

your local A-C

e

ment.

WARNING

Rotating Com

p

Disconnect an

before servici

n

without all gu

a

Consult install

instruction sh

e

operating or s

e

to follow instr

u

result in injury

WARNING

Eyebolts or lifti

n

are for lifting o

n

to which they

a

Failure to follo

w

result in prope

r

WARNING

Do not operat

e

flow (closed s

h

Explosion cou

to follow thes

e

could result in

damage, seve

or death.

CAUTION

Do not run pu

m

damage may

o

pump seal reg

Replace as re

q

lubrication req

consult servic

e

Failure to foll

o

could result in

damage.

CAUTION

Coupler align

m

Level and gro

u

use! Check ali

grouting, after

after servicing

required. Con

s

instructions fo

to follow thes

e

could result in

property dam

a

q

ualificatio

n

e operation, ins

t

e

of the pump u

r

k involved. If th

cessary knowle

d

s

truction must b

e

o

n Labels

t

ly on the pump

I

f the labels are

Fire Pump

p

onents.

d lockout powe

r

n

g. Do not oper

a

a

rds in place.

ation and servi

c

e

et before

e

rvicing. Failur

e

u

ctions could

or death.

n

g lugs if provid

e

n

ly the compone

n

a

re attached.

w

instructions co

u

r

ty injury or deat

h

e

at or near zer

o

h

utoff valve).

ld result. Failur

e

e

instructions

property

re personal inju

m

p dry. Seal

o

ccur. Inspect

ularly for leaks.

q

uired. For

uirements,

e

instructions.

o

w instructions

injury or prope

r

m

ent is required

u

t pump before

gnment before

system is filled

,

pump, and as

s

ult the service

r details. Failur

e

e

instructions

injury, or

a

ge.

n

s and

t

allation,

nit must be

e personnel do

d

ge and skill,

e

provided.

r

a

te

c

e

e

e

d

n

ts

u

ld

h

.

o

e

ry

r

ty

!

,

e

2.6

The

s

safet

y

and

s

2.7

G

c

t

E

r

p

2.8

The

u

and i

n

quali

f

Allo

w

pum

p

drain

e

Work

when

shut

d

obse

r

Imm

e

must

Befo

r

secti

o

follo

w

2.9

The

p

85 d

B

reco

m

pers

o

2.1

0

Chan

perm

the p

u

and

a

are u

s

for o

u

Safety

A

s

afety direction

s

y

regulations as

s

afety rules issu

Safety i

G

uards which a

c

ontact with mo

v

t

he pump is in

o

E

lectrical hazar

d

r

elevant safety

r

p

ump is installe

d

Safety i

mainte

n

installa

t

u

ser must ensu

r

n

stallation work

f

ied personnel

w

w

the pump to c

o

p

must be depre

e

d.

k

in the pump un

n

it is completel

y

d

own procedure

r

ved without fail

e

diately after co

m

be re-installed.

r

e putting into o

p

o

n 8, Start-up,

o

w

ed.

Noise

E

p

ump unit produ

B

(A). When perf

o

m

mended that h

o

nnel operating

t

WAR

N

The s

prote

c

0

Unauth

o

manufa

n

ging or modifyi

n

itted after cons

u

ump can only b

e

a

ccessories, wh

i

sed. A-C Fire P

u

tcomes that re

s

A

wareness

s

contained in th

s

well as any int

e

ed by the user

m

nstruction

s

re installed to p

r

ving parts must

o

peration.

d

s must be pre

v

r

egulations of t

h

d

.

nstruction

s

n

ance, ins

p

t

ion

r

e that all maint

e

shall be perfor

m

w

ho are familiar

o

ol down to am

b

ssurized and th

e

n

it must always

b

y

stopped and d

e

described in thi

.

m

pletion of the

w

p

eration, the pr

o

o

peration and s

h

E

missions

u

ces a sound pr

e

f

orming the wee

k

earing protecti

o

the equipment.

N

ING

ound pressure i

c

tion must be u

s

o

rized mo

d

cture of s

p

n

g the pump or

p

u

lting A-C Fire

P

e

guaranteed if

i

ch are authoriz

e

ump does not a

s

ult from using

n

A

is manual, heal

t

e

rnal work, ope

r

m

ust be observ

e

s

for the u

s

revent accident

a

not be remove

d

v

ented. Refer to

h

e region in whi

c

s

for

p

ection and

e

nance, inspecti

m

ed by authoriz

with this manu

a

b

ient temperatur

e

e

liquid must b

e

b

e performed o

n

e

-energized. Th

i

s manual must

w

ork, all guardi

n

o

cedure; outline

h

utdown; must

b

e

ssure level ex

c

kly functional te

o

n be worn by th

s so high that h

s

ed.

d

ification a

n

p

are parts

p

ump unit is onl

P

ump. The safet

original spare p

e

d by A-C Fire

P

ssume respons

i

n

on-original par

t

A

C6102 Rev 03

t

h and

r

ating

e

d.

s

e

r

a

l

d

while

the

c

h the

on

ed and

a

l.

e

, the

e

n

ly

e

be

n

g

d in

b

e

c

eeding

st, it is

e

earing

n

d

y

t

y of

arts

P

ump

i

bility

t

s.

AC6102 Rev 03 10

2.11 Product Warranty

2.11.1 Coverage

A-C Fire Pump undertakes to remedy defects in their

products under these conditions:

The faults are due to defects in design, materials, or

workmanship.

The faults are reported to a local sales and service

representative within the warranty period, as

described in the Terms and Conditions of Sale

provided with the Sales Contract.

The product is used only under the conditions that

are described in this manual.

The monitoring equipment that is incorporated in the

product is correctly connected and in use.

All service and repair work is performed by qualified

personnel.

2.11.2 Limitations

The warranty does not cover defects that are caused by

these situations:

Deficient maintenance.

Improper installation.

Modifications or changes to the product that are

made without consulting an A-C Fire Pump

authorized representative.

Incorrectly executing repair work.

Normal wear and tear.

A-C Fire Pump assumes no liability for these situations:

Bodily injuries.

Material damages.

Economic losses.

2.11.3 Warranty Claim

A-C Fire Pump products are manufactured to the highest

quality standards with expected reliable operation and

long life. However, should the need for a warranty claim

arise, contact your local sales and service representative.

3Applications

A-C Fire Pump Horizontal Split Case Centrifugal Fire

Pumps are designed to provide water to stand pipe,

sprinkler, and hydrant systems for fire suppression in

industrial and commercial facilities.

WARNING

Using the pump in an application other than

as described is considered improper use. A-C

Fire Pump shall assume no liability for

product that is used improperly.

4 Operational Limits

WARNING

Do not operate the pump at pressures, flow

rate or liquid temperature other than those for

which the pump has been rated. Failure to

follow these instructions could result in

serious personal injury or death, or property

damage.

Pumps are not to be operated outside the operating limits

as stated on the nameplate.

4.1 Pumped liquids

The pumps are suitable for clean water that does not

contain solid particles or fibers.

4.2 Liquid temperature

Maximum permissible liquid temperature for motor driven

pump units is 105°F [40°C].

Maximum permissible liquid temperature for engine driven

pump units is dependent on the cooling water

requirements as identified in the Engine Manufacturer’s

Installation Manual.

The pump is designed to handle temperatures up to 250°F

[120°C].

4.3 Pressure limits

The maximum working pressure for the horizontal split-

case series of pumps are as follows:

Type Casing

Material

Maximum

Working

Pressure

psi [bar]

8100 Cast Iron 225 [15]

Ductile Iron 375 [25]

8150 Ductile Iron 325 [22]

8200 Cast Iron 450 [30]

Ductile Iron 650 [45]

9100 Cast Iron 250 [17]

Ductile Iron 375 [25]

Table 1 Maximum Working Pressure

4.4 Ambient temperature

Maximum ambient temperature for motor drive pump units

is 105°F [40°C], based on the maximum ambient rating of

the motor.

Maximum ambient temperature for engine driven pump

units is identified in the engine manufacturer’s installation

manual.

4.5 Pump Speed

The pump speed is listed on the nameplate on the pump

unit.

Serie

s

11

s

8100/8150/820

5

D

s

5.1

D

The pump i

s

specially d

e

similar veh

determine

w

transport o

r

Pumps and

mounted on

packaged i

n

or attached

t

If any dam

a

agent.

5.2

H

5.2.1

B

The bare s

h

Place a nyl

o

pulled tight

0/9100 Fire Pu

m

D

elivery, h

a

torage

D

elivery

s

delivered from

e

signed for tran

s

icle. Upon recei

p

w

hethe

r

any da

m

handling.

drive

r

s are norm

a baseplate. Pa

r

n

a separate con

t

t

o the baseplate.

ge has occurre

d

H

andling

WARNING

Lifting devic

must only b

e

Eyebolts or

for lifting th

e

attached. D

o

suspended l

device or ri

g

personal inj

u

NOTICE

Dispose of a

with local re

g

B

are Shaft P

u

h

aft pump shoul

d

o

n sling around

choker hitches.

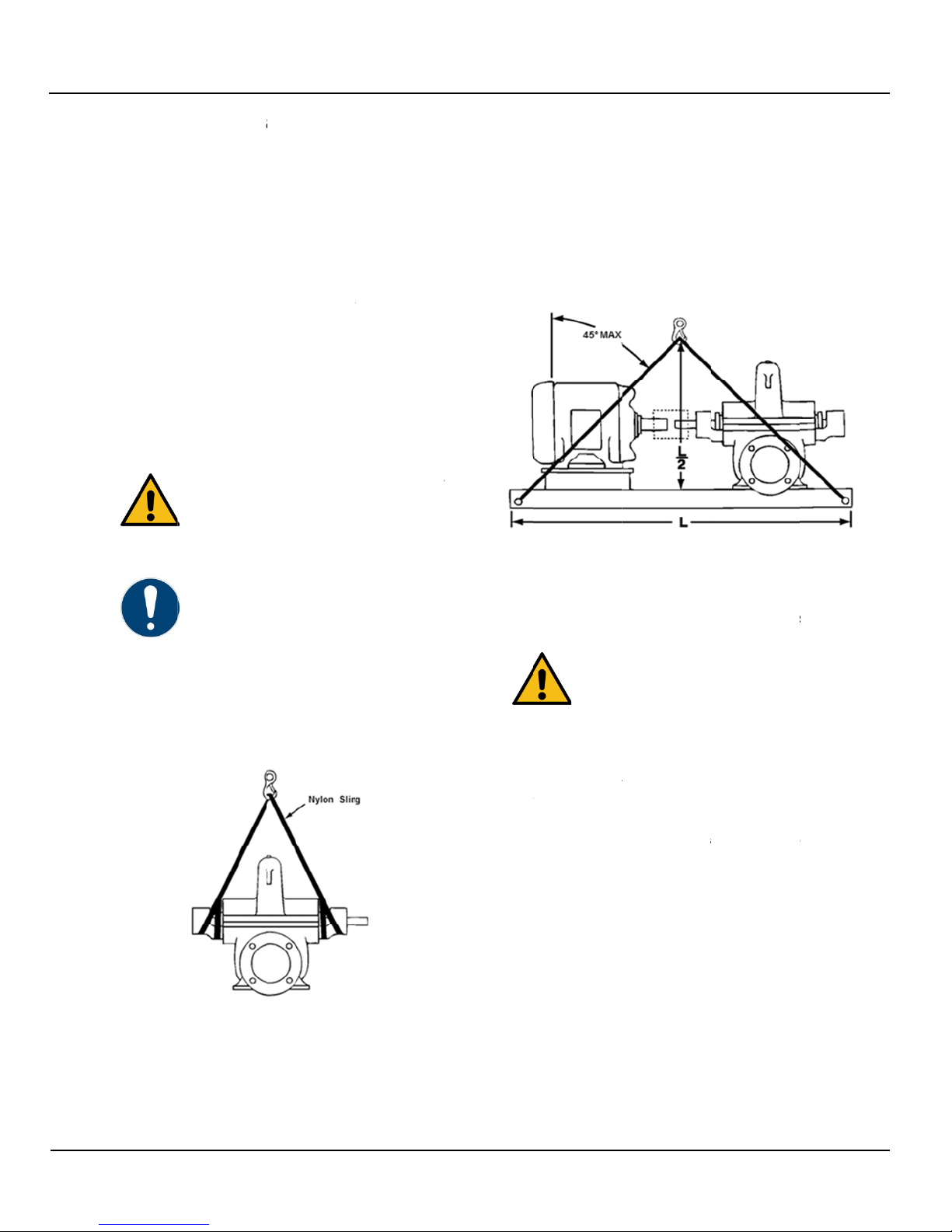

Fig. 1 How t

o

m

p

a

ndling, a

the factory in

a

s

port by fork-lift

t

p

t, check the pu

m

age has happe

n

ally shipped fro

m

r

ts and accesso

r

t

ainer and shipp

e

d

, promptly notif

y

es must be suff

i

e

used by autho

lifting lugs, if pr

o

e

components t

o

o

not stand und

e

oads. A failure

i

g

ging can result

u

ry or death, or

l

l packing materi

a

g

ulations.

u

mp (Model

d

be lifted as sh

both bearing s

u

o

lift a Model 1

0

nd

a

container

t

ruck or a

mp visually to

n

ed during

m

the factory

r

ies can be

e

d with the pum

p

y

the carrier’s

i

ciently strong a

rized personnel

o

vided, are onl

y

o

which they are

e

rneath

i

n the lifting

in serious

property dama

g

a

ls in accordanc

e

100)

own in Fig. 1.

pports using

0

0

p

nd

.

y

g

e.

e

5.2.

2

5.2.

2

Larg

e

ends

the h

o

the p

o

base.

hook

s

will b

e

5.2.

2

Pum

p

show

n

housi

n

the m

Make

cond

u

place

positi

o

2

Comple

t

2

.1 Bases su

e

bases are sup

p

of the base, as

s

o

les provided in

t

o

ints of the hook

s

Attach nylon sli

n

s

. Size the equip

m

e

less than 45° f

r

Fig. 2 How to

2

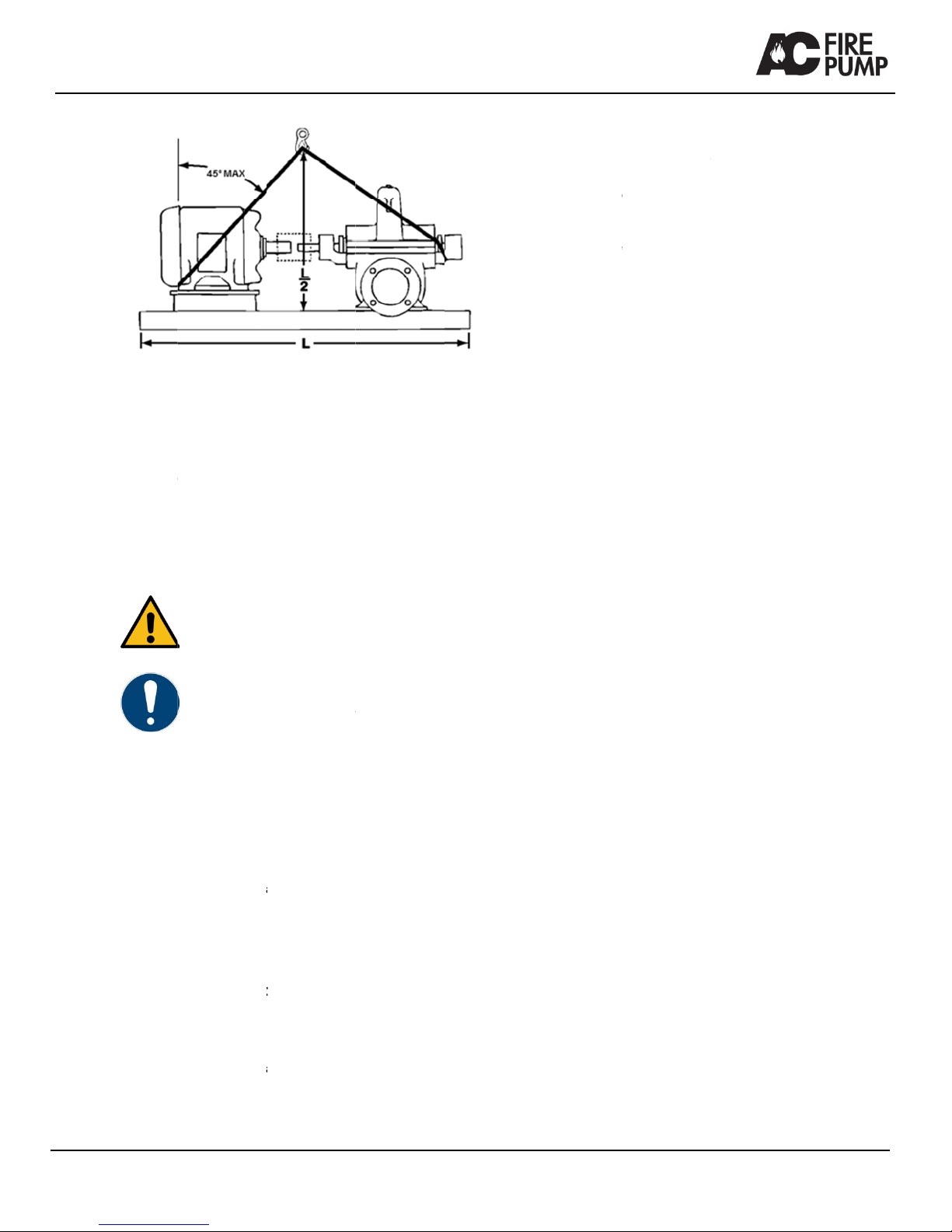

.2 Bases su

WAR

N

Do n

o

casin

g

p

units supplied

w

n in Fig. 3. Plac

e

ng. Place the re

m

m

oto

r

as close to

t

e

sure the sling d

o

u

it box. Join the

f

over the lifting

h

o

ning the sling u

t

e Pump uni

t

u

pplied with li

p

lied with lifting h

s

hown in Fig. 2.

P

t

he four corners

s

do not touch t

h

n

gs, chains, or

w

ment for the loa

d

r

om the vertical.

lift a Model 150

M

u

pplied witho

u

N

ING

o

t use the lugs

o

g

to lift the pum

p

w

ith bases witho

e

one sling arou

n

m

aining sling ar

o

the mounting fe

e

o

es not damage

f

ree ends of the

s

h

ook. Use extre

m

nder the motor

s

A

t

(Model 15

0

fting holes

oles in the sides

P

lace lifting hoo

k

of the base. Be

s

h

e bottom of the

p

w

i

r

e rope to the li

f

d

, so that the lift

a

M

pump unit larg

e

u

t lifting hole

s

o

n the pump up

p

p

unit.

ut lifting holes,

a

n

d the outboard

b

o

und the back e

n

e

t as possible.

the housing cov

s

lings together a

n

m

e care when

s

o it cannot slip o

A

C6102 Rev 03

0

M)

or the

k

s in

s

ure

p

ump

f

ting

a

ngle

e

base

s

p

er

a

s

b

earing

n

d of

er or

nd

o

ff.

AC61

0

0

2 Rev 03

Fig.

3

5.2.3 E

1

5

Before liftin

manufactur

e

5.3

S

5.3.1 T

If the pump

arrival, stor

e

changes in

covers in pl

of the pum

p

Shaft exten

should be

c

preventativ

e

Rotate the

p

the bearing

s

corrosion,

a

5.3.2 L

Storage lon

g

storage. Fol

with the foll

o

Remove th

e

Apply a corr

Corporation

3

How to lift a M

o

ngine drive

n

5

0E)

g

engine driven

e

r’s instructions

S

torage

CAUTION

Damage du

e

corrosion a

n

unit.

NOTICE

For special

p

engines, an

d

manufacture

storage proc

e

emporary S

t

is not to be ins

t

e

it in a clean, d

ambient tempe

r

ace to keep dirt

p

casing.

sions and other

oated with an e

a

e

such as Valvo

p

ump shaft 10-1

s

with lubricant

a

nd to prevent f

a

ong Term S

t

g

er than six mon

low the same pr

o

o

wing additions.

gland and the p

a

o

sion inhibiting

o

VpCI-329, to th

e

o

del 150M pum

p

n

pump unit

pump unit, refe

.

e

to dirt and hu

m

n

d contaminatio

n

p

rotection of elec

t

d

couplers, refer

t

r’s instruction fo

r

e

dures.

t

orage

t

alled and oper

a

ry place having

r

ature. Leave pi

p

and other forei

g

exposed machi

a

sily removable

line Tectyl 502-

C

5 times twice a

and to retard o

x

a

lse brinelling o

f

t

orage

t

hs is considere

d

o

cedu

r

e for tem

p

a

cking from the

s

o

il soluble produ

c

e

interior of the p

u

p

unit large bas

e

s

(Model

r to the engine

m

idity resulting i

n

of the pump

t

ric motors, dies

e

t

o the

r

their long term

a

ted soon after

slow moderate

p

ing connection

g

n material out

ne surfaces

rust

C

.

month to coat

x

idation,

f

the bearings.

d

long term

p

ora

r

y storage

s

tuffing box.

c

t such as Corte

c

u

mp casing and

e

n

e

l

c

the st

the m

Seal

t

Add 1

seal

a

seals

.

Rotat

e

mont

h

t

uffing box. [Pre

p

m

anufacturer’s in

s

t

he end of the st

u

1

/2oz [14g] of Co

a

ll vents and app

.

e the pump shaf

t

h

s to prevent the

p

are the corrosio

n

s

tructions].

u

ffing box with w

a

o

rtec VpCI-329 t

o

p

ly waterproof ta

p

t

10-15 turns tim

e

e

shaft from seizi

n

n

inhibiting soluti

o

aterproof tape

o

the bearing fra

m

p

e around the gr

e

e

s at least every

n

g up.

12

o

n per

m

es,

e

ase

three

Serie

s

13

s

8100/8150/820

6

D

6.1

G

The horizo

n

stage [seri

e

8200] non

s

6.2

D

The fire pu

m

on the nam

e

represents:

Code

H

10

8

17

F-S

Ta

b

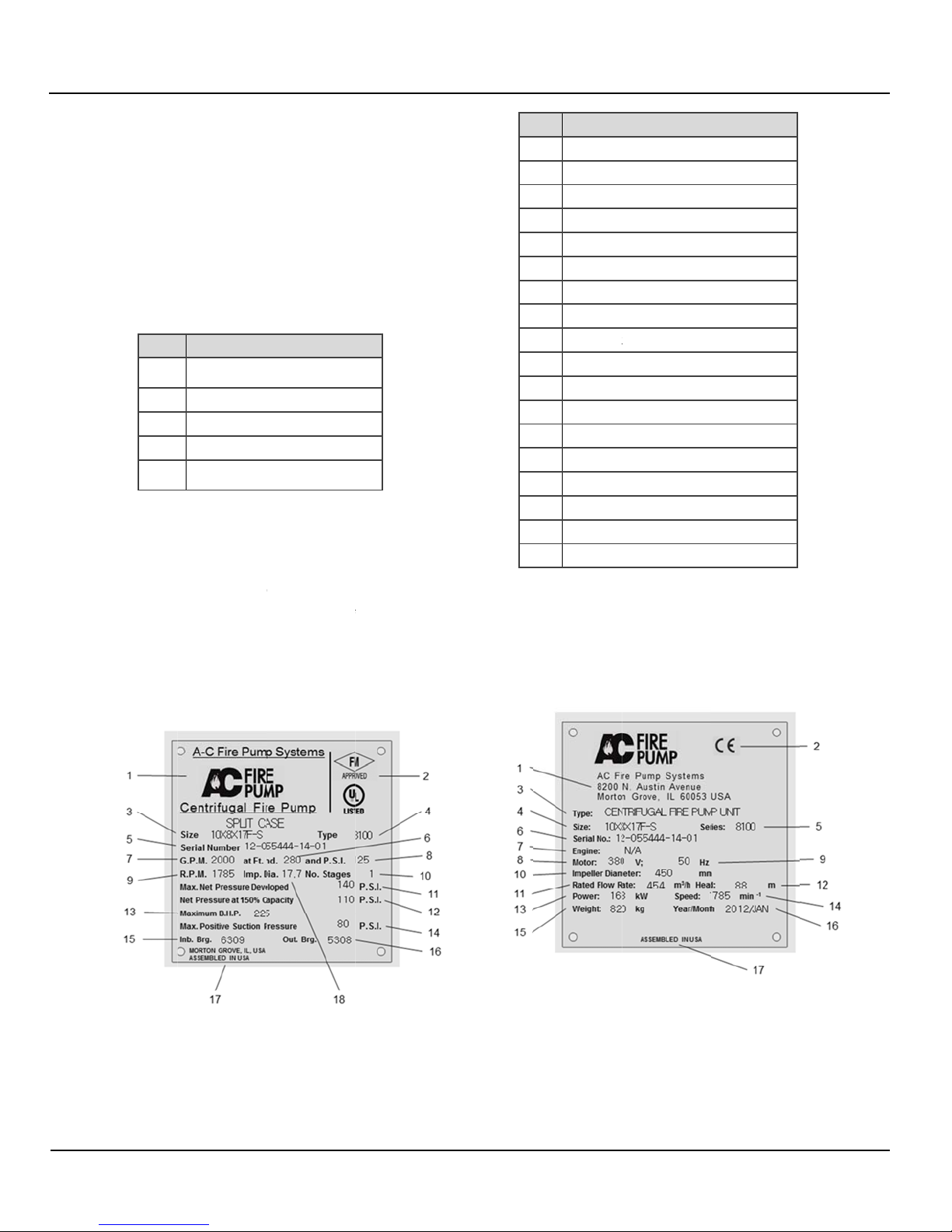

6.3

N

6.3.1 P

The namep

attached to

referenced

used to ord

e

digit of the

s

orders of m

0/9100 Fire Pu

m

D

escriptio

n

G

eneral

n

tal split case c

e

e

s 8100, 8150,

a

s

elf-priming pu

m

D

esignatio

n

m

p can be ident

e

plate; for exa

m

Description

No prefix=Ca

H=Ductile iro

n

Suction inlet

s

Discharge ou

Nominal imp

e

S-small, M-m

capacity imp

e

b

le 2 Key for s

N

ameplate

ump name

p

l

ate shows all i

m

the upper casi

n

by the serial nu

m

e

r all spare and

s

erial number i

n

ore than one p

u

Fig. 4 Name

p

m

p

n

e

ntrifugal fire pu

a

nd 9100] and t

w

m

p.

n

i

fied by size de

s

m

ple, H10 X 8 X

st iron A48;

n

A536

s

ize ANSI

tlet size ANSI

e

ller diamete

r

edium, L-large

e

lle

r

ize designation

p

late

m

portant data o

f

n

g. Records for

t

m

ber and it mu

s

replacement p

a

n

dicates the spe

c

u

mp].

p

late of a Fire p

u

mp is a single

w

o stage [series

s

ignation stated

17F-S

f

the pump. It is

t

he pump are

s

t, therefore, be

a

rts. [The last

c

ific pump on

u

mp

I

t

6.3.

2

The

n

It is

a

t

em Descript

i

1 Manufact

2 Approval

3 Size

4 Model Ty

5 Serial nu

m

6 Head [fe

e

7 Rated flo

w

8 Rated pr

e

9 Speed [

R

10 Number

o

11 Net pres

s

12 Net pres

s

13 Maximu

m

14 Maximu

m

15 Inboard

b

16 Outboard

17 Country

o

18 Impeller

d

Table 3 N

a

2

Pump u

n

n

ameplate sho

w

a

ttached to the

u

Fig. 5 N

a

i

on

ure

r

Agencies

pe

m

be

r

e

t]

w

rate [GPM]

e

ssure [psi]

R

PM]

o

f stages

s

ure developed [

p

s

ure at 150% of

f

m

power [BHP]

m

suction pressu

r

b

earing numbe

r

bearing numbe

r

o

f origin

d

iameter [in]

a

meplate of a F

i

n

it namepla

t

w

s all important

d

u

pper casing.

a

meplate of a Fi

A

p

si]

f

low [psi]

r

e [psi]

r

i

re-pump

t

e

d

ata of the pum

p

re pump unit

A

C6102 Rev 03

p

unit.

AC6102 Rev 03 14

Item Description

1 Manufacturer

2 CE Mark

3 Type

4 Pump Size

5 Model series

6 Serial number

7 Engine type [engine driven pump units]

8 Motor voltage

9 Frequency

10 Impeller diameter [mm]

11 Rated flow rate [m3/hr]

12 Head [m]

13 Power [kW]

14 Speed [RPM]

15 Pump unit weight [kg]

16 Date of manufacture

17 Country of origin

Table 4 Nameplate of a Fire pump unit

6.4 Design detail

6.4.1 Casing

The pump casing is made from Cast Iron or Ductile Iron,

and is an axially-split double suction volute design with the

suction and discharge flanges and mounting feet cast

integrally with the lower casing half.

Tapped and plugged holes are provided for priming, vent,

drain, and gauge connections. The upper casing half can

be removed without disturbing the suction or discharge

piping. Pump flanges are made with ANSI Class 125 or

250 drillings, and come in the following combinations,

[Suction/Discharge]: 125/125; 125/250; and 250/250.

The suction and discharge are on a common centerline in

the vertical direction for all pump model types; and on a

common horizontal centerline for model types 8100, 8150,

and 9100.

6.4.2 Impeller

The impeller is an enclosed double suction type made of

bronze, which is statically and hydraulically balanced. The

impeller is firmly secured to the shaft by a key positioned

by shaft sleeves and both locked in place by shaft sleeve

lock nuts.

6.4.3 Shaft

The shaft is made of AISI 1045 or 4140 steel and of ample

size to operate under load with a minimum deflection.

6.4.4 Shaft sleeves

The shaft sleeves are made of bronze and protect the

shaft from wear and from contact with the pumped liquid.

Shaft sleeves are locked in place by threaded bronze

shaft sleeve nuts. An O-ring is furnished under the sleeve

to prevent leakage.

6.4.5 Stuffing Box

The stuffing box consists of die formed, graphite coated,

synthetic fiber packing rings; and a split type gland to

permit removal and access to the packing. The 8100

stuffing box housing is made of cast iron, and is separate

from the pump casing. The stuffing box housing is drilled

and tapped for drain connections.

6.4.6 Casing Rings

The casing rings are made of bronze and are installed

with an anti-rotation device and designed to restrict

leakage across the ring fit.

6.4.7 Bearings

The bearings are grease lubricated rolling type selected to

carry radial and thrust loads. The outboard bearing is

retained to handle the axial thrust.

6.4.8 Bearing Housings

The bearing housings are bolted to the pump and are

piloted to positive alignment of the rotating element. The

housings provide a fit for the inboard bearing that allows

freedom for thermal expansion while the outboard

bearing(s) are clamped in place in order to take all the

thrust loads and keep the rotating element in its proper

axial location. Openings for adding grease and draining

grease are provided.

6.4.9 Baseplate

The baseplate is welded construction, manufactured from

steel and is sufficiently rigid to support the pump and the

driver.

6.4.10 Coupling

The coupling is of the flexible type. The coupling hubs are

secured to the driver and the driven shafts by a setscrew

located over the key.

6.4.11 Coupling Guard

The coupling guard is made of metal, and meets the

requirements of EN ISO 13857.

6.4.12 Rotation

Pumps have a clockwise or counterclockwise rotation

when viewed from its driven end.

Series 8100/8150/8200/9100 Fire Pump

15 AC6102 Rev 03

6.5 Noise characteristics

The maximum measured A-weighted sound pressure level

[LpA] for the pump and motor, measured at a distance of

3.3 ft. [1m] from the pump, under full load, in accordance

with EN ISO 3746 is 90dB.

The maximum measured A-weighted sound pressure level

[LpA] for the pump and diesel engine, measured at a

distance of 3.3 ft. [1m] from the pump, under full load, in

accordance with EN ISO 3746 is 106dB.

6.6 Scope of supply

The pump unit includes the following items:

Pump

Driver, (motor or engine)

Baseplate

Coupling

Coupling guard

6.7 Dimensions and weights

Refer to the general dimensional drawing supplied with

the pump unit

7 Installation

This section describes the installation of a complete

pump unit.

CAUTION

Installations should be performed by persons

qualified in the setting up of pumping

equipment.

WARNING

All electrical work should be carried out by

qualified personnel.

7.1 Location

WARNING

Engine-driven pump units:

The engine must be provided with adequate

ventilation to satisfy the requirements of the

combustion system, and allow adequate

dissipation of radiated heat and exhaust

emissions.

Install the pump in a well-ventilated, dry place above the floor

level wherever possible. Take care to prevent the pump from

freezing during cold weather when not in operation.

The pump should be installed with sufficient space around it

to facilitate ventilation and accessibility for inspection,

maintenance and service. A clear space with ample head

room should be allowed for the use of an overhead crane or

hoist to lift the unit.

Install the pump as near to the suction supply as possible,

with the shortest and most direct suction pipe practical. The

total dynamic suction lift (static lift plus friction losses in

suction line) should not exceed the limits for which the pump

was sold.

When installing the pump, consider its location in relation to

the system to assure that sufficient Net Positive Suction Head

[NPSH] is available at the pump inlet connection. Available

NPSH [NPSHA] must always equal or exceed the required

NPSH [NPSHR] of the pump.

The pump must be primed before starting. Whenever

possible, the pump should be located below the fluid level to

assure priming. This condition provides a positive suction

head on the pump. It is also possible to prime the pump by

pressurizing the suction vessel.

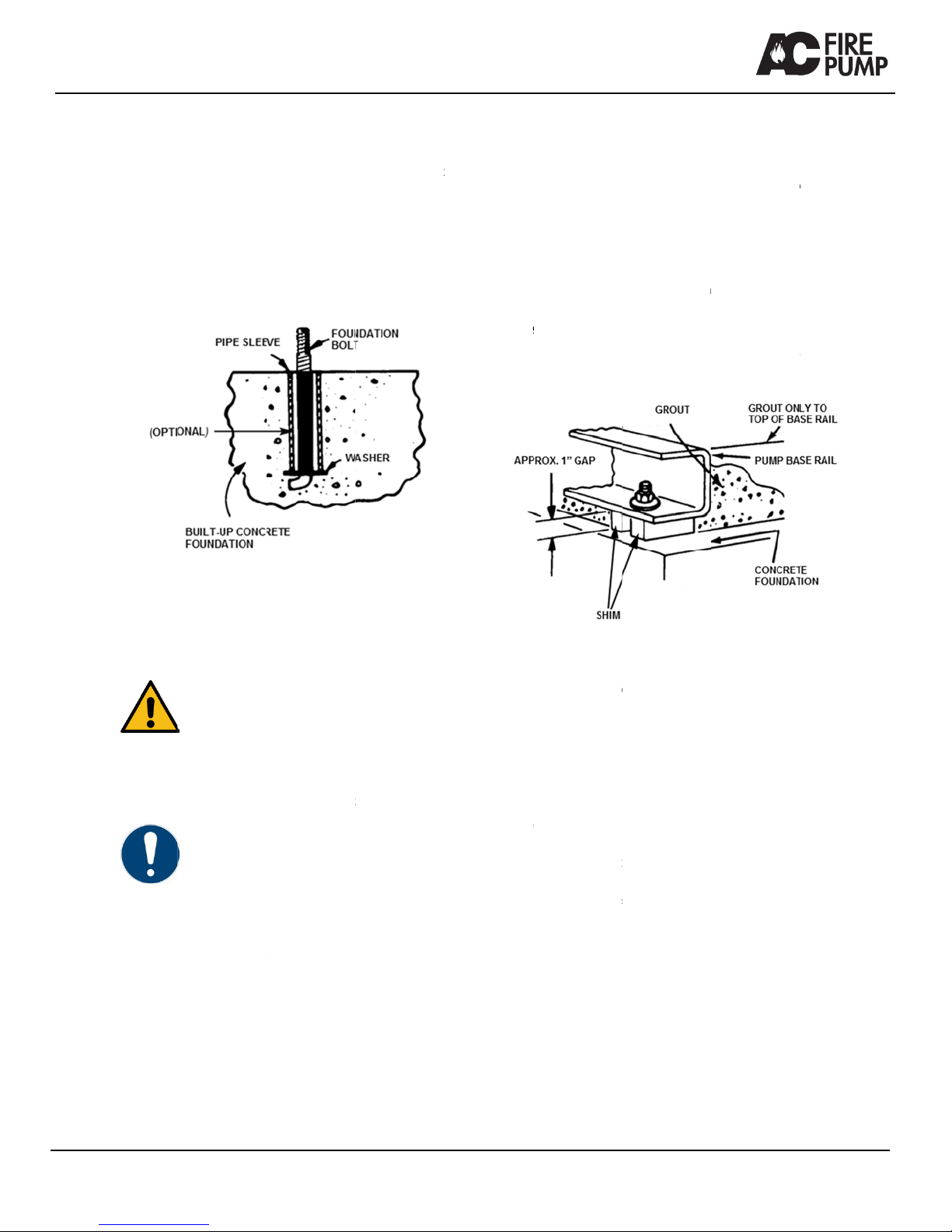

7.2 Foundation

We recommend that the pump unit should be installed on a

concrete foundation, sufficiently substantial to absorb

vibration and to form a permanent, rigid support for the

baseplate.

A base of concrete weighing 3 to 5 times the weight of the

pump unit is recommended.

The foundation should be 3 to 6 inches [75 to 150mm] longer

and wider than that of the baseplate that will be installed.

Foundation bolts must match those of the base plate. The

foundation should be poured without interruption to within 1/2

to 1-1/2 inches [12.7 to 38.1mm] of the finished height. The

top surface of the foundation should be well scored and

AC61

0

0

2 Rev 03

grooved be

f

surface for t

h

Foundation

6. An option

the top of th

e

alignment t

o

bolt length f

o

washers. T

h

several day

s

In installati

o

particularly

mass of at

l

7.3

L

Use blocks

a

anchor bolt

s

baseplate a

p

foundation,

w

plate, as sh

o

By adding o

plumb the p

u

have to be l

e

Draw ancho

motor shaft

s

o

re the concrete

h

e grout.

bolts should be

s

al 4 inch [102m

m

e

concrete will a

l

o

match the hole

s

o

r grout, shims, l

o

h

e foundation sh

o

s

before the bas

e

o

ns where lower

important, we r

e

l

east 5 times th

a

Fig. 6

L

eveling the

WARNING

Lifting devic

e

must only b

e

Eyebolts or l

lifting the co

m

attached. D

o

loads. A fail

u

can result in

or property

d

NOTICE

This proced

u

foundation h

a

hold down b

o

the pump un

pump and d

r

aligned at th

e

mounted, co

n

recommend

a

assume res

p

a

nd shims unde

r

s

and midway be

t

p

proximately 1 i

n

w

ith studs exten

d

o

wn in Fig. 7.

r

removing shim

s

u

mp shaft and fl

a

e

vel.

r

nuts tight agai

n

s

or coupling hub

sets; this provid

e

s

et in concrete a

s

m

] long sleeve ar

o

low some flexibi

l

s

in the base plat

o

wer base plate

o

uld be allowed

t

e

plate is shimm

e

sound and vibr

a

e

commend a fo

u

a

t of the compl

e

Foundation

baseplate

e

s must be suffi

c

e

used by author

i

ifting lugs, if pro

v

m

ponents to whi

c

o

not stand unde

r

u

re in the lifting

d

serious person

a

d

amage.

u

re assumes tha

t

a

s been prepare

d

o

lts extending u

p

i

t. It must be un

d

r

iver have been

m

e

factory. If the d

n

sult AC Fire Pu

m

a

tions. AC Fire P

p

onsibility for fina

r

the baseplate f

o

t

ween bolts, so

a

n

ch [25.4mm] ab

o

d

ing through hol

e

s

under the bas

e

a

nges. The base

n

st base, and ob

s

s for alignment.

(

e

s a bonding

s

shown in Fig.

o

und the bolts a

t

l

ity in bolt

e. Allow enough

flange, nuts and

t

o cure for

e

d and grouted.

a

tion levels are

u

ndation with a

e

te pump unit.

c

iently strong an

d

i

zed persons.

v

ided, are only f

o

c

h they are

r

neath suspend

e

d

evice or rigging

a

l injury or death,

t

a concrete

d

with anchor or

p

ready to receiv

e

erstood that the

m

ounted and rou

g

river is to be fiel

d

m

p for

ump cannot

l alignment.

o

r support at the

a

s to position the

o

ve the concrete

e

s in the base

e

, level and

p

late does not

s

erve pump and

(

Temporarily

t

d

o

r

e

d

e

g

h

d

remo

v

chec

k

If alig

n

appr

o

retigh

align

m

align

m

NOT

E

mutu

a

facilit

y

Chec

k

pum

p

Pour

g

Grou

t

pipin

g

grouti

7.4

Grou

t

weig

h

appr

o

unit,

(

Build

grout

.

and t

h

be co

After

t

found

align

m

Appr

o

when

to th

e

from

c

v

e coupling gua

r

k

ing alignment.)

nment needs im

p

o

priate positions

h

tening of the an

c

m

ent. Repeat thi

s

m

ent” is reached

E

: Reasonable a

a

lly agreed upon

y

(final operator)

.

k to make sure t

h

p

flanges without

grout in the bas

e

t

ing) and allow g

r

g

to pump. (24 h

o

i

ng procedure.)

Fig.

7

Groutin

g

t

compensates f

o

h

t of the pump u

n

o

ved, non-shrinki

(

see Fig. 7).

a strong form ar

o

.

Soak the top of

h

en remove any

o

mpletely filled wi

the grout has th

o

d

ation bolts and t

m

ent after the fo

u

o

ximately 14 day

s

the grout has th

e

exposed edges

c

oming in conta

c

r

d, see section 8

p

rovement, add

s

under the basep

c

hor nuts will shi

f

s

procedure until

.

lignment is defin

e

by pump contra

.

h

at the piping c

a

placing pipe str

a

e

plate completel

rout to dry thoro

u

o

u

r

s is sufficient

7

Leveling of pu

m

g

or

uneven found

a

n

it, and prevents

ng grout, after s

e

o

und the founda

t

the concrete fo

u

surface water. T

i

th grout.

o

roughly harden

e

t

ighten if necess

a

u

ndation bolts ar

e

s after the grout

h

oroughly dried,

a

of the grout to p

c

t with the grout.

.2 Coupling Gua

s

hims or wedge

s

late, so that

f

t the shafts into

c

a “reasonable

e

d as that which

ctor and the acc

e

a

n be aligned to t

h

a

in on either flan

g

y (see section 7

.

u

ghly before atta

time with appro

v

m

p unit

a

tion, distributes

shifting. Use an

e

tting and levelin

t

ion to contain th

u

ndation thoroug

h

he base plate s

h

e

d, check the

a

ry. Check the

e

tightened.

has been poure

d

a

pply an oil base

revent air and m

16

rd, for

s

at

closer

is

e

pting

he

g

e.

.

4

ching

v

ed

the

g the

e

h

l

y

,

h

ould

d

or

paint

oisture

Serie

s

17

s

8100/8150/820

7.5 I

n

When a co

m

the

factory,

means of

s

h

The pump/

d

transport a

n

parallel, or

a

vertical plan

Proper align

This should

set and gro

u

Alignment s

h

driver only

u

recommend

temperatur

e

All measure

m

foot bolts tig

There are t

w

flexible cou

p

are not par

a

are parallel

There are t

h

misalignme

n

1.

2.

3.

0/9100 Fire Pu

m

n

itial Align

m

WARNING

Disconnect

a

performing

a

instructions

injury.

NOTICE

The alignme

motor driven

for Engine-d

r

the Engine

m

WARNING

Replace co

u

alignment.

F

could result

CAUTION

Misalignmen

and bearing

bearing failu

r

NOTICE

Alignment s

h

the pipes; if

n

the pump, a

n

driver.

NOTICE

Read Coupli

n

supplied wit

h

perform alig

n

m

plete pump uni

the coupling ha

s

h

ims inserted u

n

d

river could hav

e

n

d installation.

M

a

combination of

t

e

s.

ment is essentia

be performed af

t

u

t has dried thor

o

h

ould be made

b

u

ntil the coupling

ed tolerances, a

s under normal

c

m

ents should be

htened.

w

o types of misa

l

p

lings: angular

m

a

llel, and parallel

b

ut not on the s

a

h

ree methods co

m

n

t:

Straight edg

e

Dial indicato

r

Laser Align

m

manufacture

r

m

p

m

ent

a

nd lock out po

w

a

lignment. Failu

r

could result in

s

nt procedures th

a

pump units. Ali

g

r

iven pump units

m

anufacturer’s In

u

pler guard afte

r

F

ailure to follow

in serious pers

o

t causes excess

i

l

oads that result

r

e and ultimate s

e

h

ould be made b

e

n

ot, it may not b

e

n

d it will be diffic

u

n

g Manufacturer

h

the pump unit

b

n

ment.

t comes pre-as

s

s

been accurat

e

n

der the pump a

n

e

become misali

g

M

isalignment can

t

hese, and in th

e

l for correct pum

t

er base plate h

a

o

ughly according

b

y moving and s

h

hubs are within

n

d should be m

a

c

onditions.

taken with the

p

l

ignment encoun

m

isalignment, in

w

misalignment,

w

a

me axis.

m

monly used to

e

and calipers.

r

m

ent Equipment (

r

’s instructions f

o

w

er before

r

e to follow the

s

s

erious persona

l

a

t follow are for

g

nment procedur

e

are available in

stallation Manua

r

performing

these instructio

n

o

nal injury.

i

ve wear, vibrati

o

in premature

e

izing of the pu

m

e

fore connecting

e

possible to mo

v

u

lt to move the

instructions

b

efore attempting

s

embled from

e

ly aligned by

n

d driver.

g

ned during

be angular,

e

horizontal and

p operation.

a

s been properly

to instructions.

h

imming the

the

a

de at operating

ump and driver

tered with

w

hich the shafts

w

here the shafts

determine

see

o

r use).

s

e

l

e

s

l.

n

s

o

n,

m

p.

v

e

to

7.5.

1

The

m

calip

e

dial i

n

7.5.1

With

c

gap

b

shim

e

the h

u

(see

F

7.5.1

With

c

the ri

m

vertic

a

equip

rims,

v

manu

7.5.

2

The

d

accu

r

guide

1

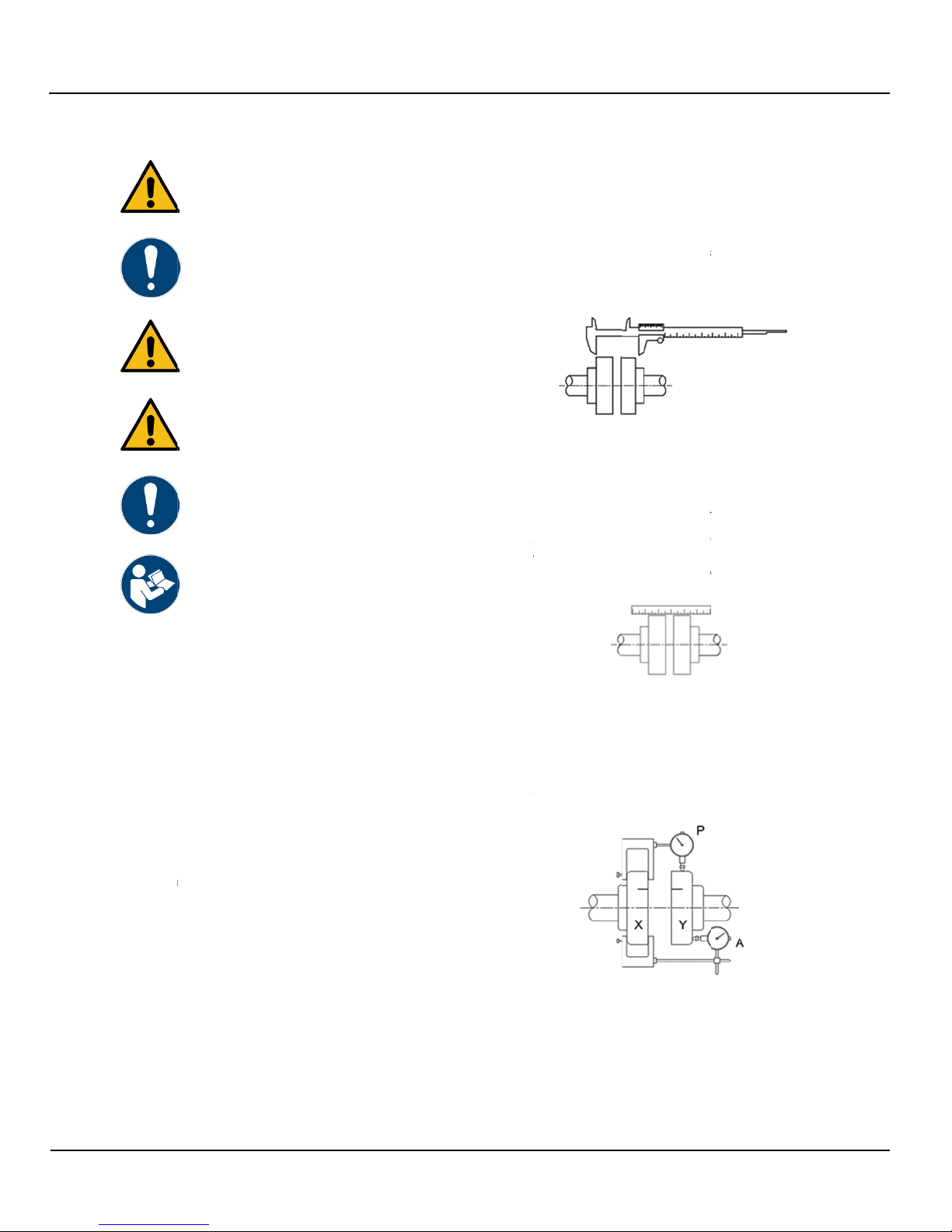

Straight

e

m

ost simple alig

n

e

rs. This method

n

dicator or laser i

.1

A

ngular

A

c

oupling hubs st

a

b

etween the cou

p

equipment until

t

u

bs are within th

e

F

ig. 8).

Fig. 8 A

n

.2 Parallel

A

c

oupling hubs st

a

m

of the couplin

g

al and horizontal

p

ment until the st

r

vertical and hori

z

u

facturer’s guidel

i

Fig

2

Dial indi

c

d

ial indicator sho

u

r

acy is required.

C

e

line for accepta

b

F

e

dge metho

d

n

ment check is w

is the least acc

u

i

s not available.

A

lignment

a

tionary, use cal

i

p

ling hubs at 90°

t

he gap differen

c

e

coupler manuf

a

n

gular Alignment

A

lignment

a

tionary, lay stra

g

hub at 90° inte

r

l

alignment offse

t

r

aight edge lies f

z

ontal. Check th

e

ine for permissib

g

. 9 Parallel Align

c

ator metho

d

u

ld be used whe

n

C

heck the coupl

e

b

le alignment tol

e

ig. 10 Dial Indic

a

A

d

of alignme

n

ith a straight ed

g

u

rate, but will ser

v

i

pers to measur

e

intervals. Adjust

c

e at all points ar

o

a

cturers guidelin

e

ight edge flat ag

a

r

vals to determin

e

t

s. Adjust and/or

f

lat against both

h

e

coupler

b

le gap, (see Fig.

ment

d

of alignme

n

n

greater alignm

e

e

r manufacturer’

s

e

rances.

a

to

r

A

C6102 Rev 03

n

t

g

e and

v

e if a

e

the

and/or

o

und

e

s,

a

inst

e

shim

h

ub

9).

n

t

e

nt

s

AC61

0

0

2 Rev 03

7.5.2.1

A

To check a

n

coupling hal

f

face of the

o

both couplin

rotate both

c

match; ens

u

the same s

p

for accepta

b

7.5.2.2 P

To check p

a

coupling hal

f

outside dia

m

10). Set the

so that the i

n

button alwa

y

manufactur

e

7.5.3

A

The followin

alignment o

f

Protection

P

Couplings.

Alignment i

s

which has b

e

applications

dial indicato

r

7.5.3.1

M

Clean all m

e

seals lightly

place on sh

a

mount hubs

Reposition

h

specified in

t

should be a

p

the setscre

w

7.5.3.2

G

Use a spac

e

Table 5. Ins

e

intervals an

d

face with fe

e

maximum

m

installation l

i

7.5.3.3 P

Align so tha

t

limits specifi

also at 90° i

n

The clearan

c

A

ngular Align

m

n

gular alignment,

f

(X), and positio

o

pposite couplin

g

g hubs as show

n

c

oupling halves t

o

u

ring that the indi

c

p

ot. Check the c

o

b

le alignment tol

e

a

rallel Align

m

a

rallel alignment,

f

(X), and positio

m

eter of the opp

o

dial to zero, rota

t

n

dex lines match

y

s indicates off t

h

e

r’s guideline for

A

lignment of

g

procedure is i

n

f

Rexnord Indust

r

P

roducts, Inc., Ty

p

s

shown using a

s

e

en prove to be

a

.

However, for s

u

r

s is recommend

M

ount Seal an

d

e

tal parts using n

with coupling m

a

a

fts before moun

with flange face

s

h

ubs on shafts a

s

t

able 5. The len

g

p

proximately eq

u

w

s.

G

ap and Angul

e

r bar equal to th

e

rt bar, as show

n

d

measure clear

a

e

ler gage. The di

f

m

easurements m

u

mits specified in

Fig. 11 U

s

a

rallel Offset

A

t

a straight edge

ed in Table 5 on

n

tervals, (see Fi

g

c

e must not exc

e

m

ent

mount dial indic

a

n the dial indicat

o

g

half (Y). Scribe

n

in Fig. 10. Set

t

o

gether, so that

t

c

ator button alw

a

o

upler manufactu

e

rances.

m

ent

mount dial indic

a

n the dial indicat

o

o

site coupling hal

f

t

e both coupling

; ensuring that t

h

h

e same spot. C

h

acceptable align

g

rid couplin

g

n

tended for mou

n

r

ies, LLC and Cl

a

p

e T10 Close C

o

s

pacer bar and s

t

a

ccurate for ma

n

u

perior final align

ed, per 7.5.2.

d

Hubs

on-flammable s

o

a

nufacturer supp

ting shaft hubs. I

s

flush with the s

s

required achie

v

g

th of engageme

n

u

al to the shaft di

a

ar Alignment

(

i

ckness to the g

a

n

above to the s

a

a

nce between th

e

f

ference in mini

m

u

st not exceed t

h

Table 5.

s

ing Spacer Ba

r

A

lignment (P)

rests squarely, (

o

both hubs as sh

g

. 12). Check wit

h

e

ed the Parallel

O

a

tor (A) to the

o

rs button on th

e

index lines on

he dial to zero,

t

he index lines

a

ys indicates off

rer’s guideline

a

tor (P) to the

o

rs button on th

e

f

(Y), (see Fig.

halves together,

h

e indicator

h

eck the coupler

ment tolerances

.

g

s

n

ting and

a

rke Fire

o

upled Grid

t

raight edge,

n

y industrial

ment, the use of

o

lvent. Coat the

lied grease and

nstall keys and

haft ends.

v

ing the hub gap

n

t on each shaft

a

meter. Tighten

(

X-Y)

a

p specified in

a

me depth at 90°

e

bar and hub

m

um and

h

e angular

o

r within the

own above and

h

feeler gages.

O

ffset installation

e

e

.

limits

If adj

u

remo

v

align

t

of th

e

Tight

e

in all

d

until t

h

7.5.

3

Com

p

suppl

furnis

ends

will e

n

halve

s

Spre

a

seat

w

7.5.

3

Com

p

with

a

with t

o

groo

v

cove

r

on th

e

faste

n

specified in Tab

l

u

stment is need

e

v

e an equal amo

t

he height. To c

o

e

motor foot with

a

e

n the motor bol

t

d

irections, if a c

o

he desired resul

t

Fig.

3

.4 Insert Gri

d

p

letely pack gap

a

ied grease befor

e

hed in two or m

o

extend in the sa

m

n

sure correct gri

d

s.

Fi

g

a

d the grid slightl

w

ith a soft mallet

Fi

g

3

.5 Pack wit

h

p

letely pack the

s

a

s much grease

a

o

p of the grid. P

o

v

es in the cover.

P

r

half and assem

b

e

same side, (se

e

n

ers tightening t

o

l

e 5.

e

d, loosen the m

o

o

unt of shims un

d

o

rrect side misali

g

a mallet.

t

s and check ag

a

o

rrection is mad

e

t

is obtained.

12 Using Straig

h

d

and grooves wit

h

r

e inserting grid.

W

o

re segments, in

s

m

e direction as

s

d

contact with n

o

g

. 13 Grids mag

n

y to pass over t

h

, (see Fig. 14).

g

. 14 Seating th

e

h

grease and

a

s

paces between

a

s possible and

w

o

sition seals on

h

Position gaskets

b

le covers so th

a

e

Fig. 15). Secu

r

o

torque specifie

d

o

tor bolts and ad

d

d

er each motor f

o

g

nment, strike th

a

in. Re-check ali

g

e

. Repeat the pro

h

t edge

h

coupling manu

f

W

hen grids are

s

tall them so tha

t

s

hown in Fig. 13.

o

n-rotating pin in

n

ified

h

e coupling teeth

e

grid

a

ssemble cov

e

and around the

g

w

ipe off excess f

h

ubs to line up w

i

on flange of low

a

t the match mar

k

r

e cover halves

w

d

in Table 5.

18

d

or

o

ot to

e side

g

nment

cess

f

acturer

t

all cut

This

cover

and

e

rs

g

rid

f

lush

i

th the

w

er

k

s are

w

ith

Serie

s

19

s

8100/8150/820

Size

P

O

M

A

IN

C

1040T 0.0

1050T 0.0

1060T 0.0

1070T 0.0

1080T 0.0

0/9100 Fire Pu

m

Fig. 15 Cove

r

WARNING

Do not oper

a

lubrication.

CAUTION

Ensure that

t

cover.

Fig. 16 Misalig

n

Insta

l

P

arallel

O

ffset (P) An

g

(

x

X

C

H

MAX

mm

MAX

INCH

1 0.15 0

1 0.20 0

1 0.20 0.01

1 0.20 0.01

1 0.20 0.01

Table 5 Misal

m

p

r

installation

a

te coupling wit

h

t

he lube plugs ar

e

n

ment and End

F

l

lation Limits

g

ular

x

-y) Hub G

a

± 10

%

MAX

mm

MAX

INCH

0.08 0.13

0.10 0.13

0.13 0.13

0.13 0.13

0.15 0.13

ignment and En

d

h

out proper

e

installed in the

F

loat

a

p

%

End Float

(Min) 2 x

F

MAX

mm

MAX

INCH

M

A

m

m

3 0.21 5.

3

3 0.21 5.

3

3 0.26 6.

5

3 0.26 6.

5

3 0.29 7.

3

d

float

F

A

X

m

3

6

3

8

5

5

5

8

3

2

7.6

7.6.

1

Whe

n

follo

w

1.

P

2.

D

a

3.

U

i

4.

W

t

c

5.

I

s

d

6.

I

u

r

7.

M

8.

W

d

9.

R

Maxi

m

vary

w

force

s

misal

i

prem

a

1.

P

2.

N

3.

A

p

s

a

4.

D

a

f

t

e

The t

a

mom

e

Horiz

o

SIZE

F

Ti

T

in.

l

1040T 10

1050T 20

1060T 20

1070T 20

1080T 20

Pipe co

n

CAU

T

Do n

o

at the

strain

pump

dama

1

Suction

a

precauti

o

n

installing the p

u

w

ing precautions:

P

iping should al

w

D

o not move pu

m

a

lignment impos

s

U

se pipe hange

r

i

ntervals to provi

W

hen expansio

n

t

hey must be ins

t

c

losest to the pu

m

I

t is usually advi

s

s

uction and disc

h

d

ecrease the los

I

nstall piping as

s

u

nnecessary be

n

r

adius 90° fitting

s

M

ake sure that

a

W

he

r

e flanged

jo

d

iamete

r

s match

R

emove burrs a

n

m

um forces and

w

ith the pump si

z

s

and moments

t

ignment, hot be

a

a

ture pump failu

r

P

revent excessi

v

N