OM--05358SUPER T-SERIES

PAGE B -- 3INSTALLATION

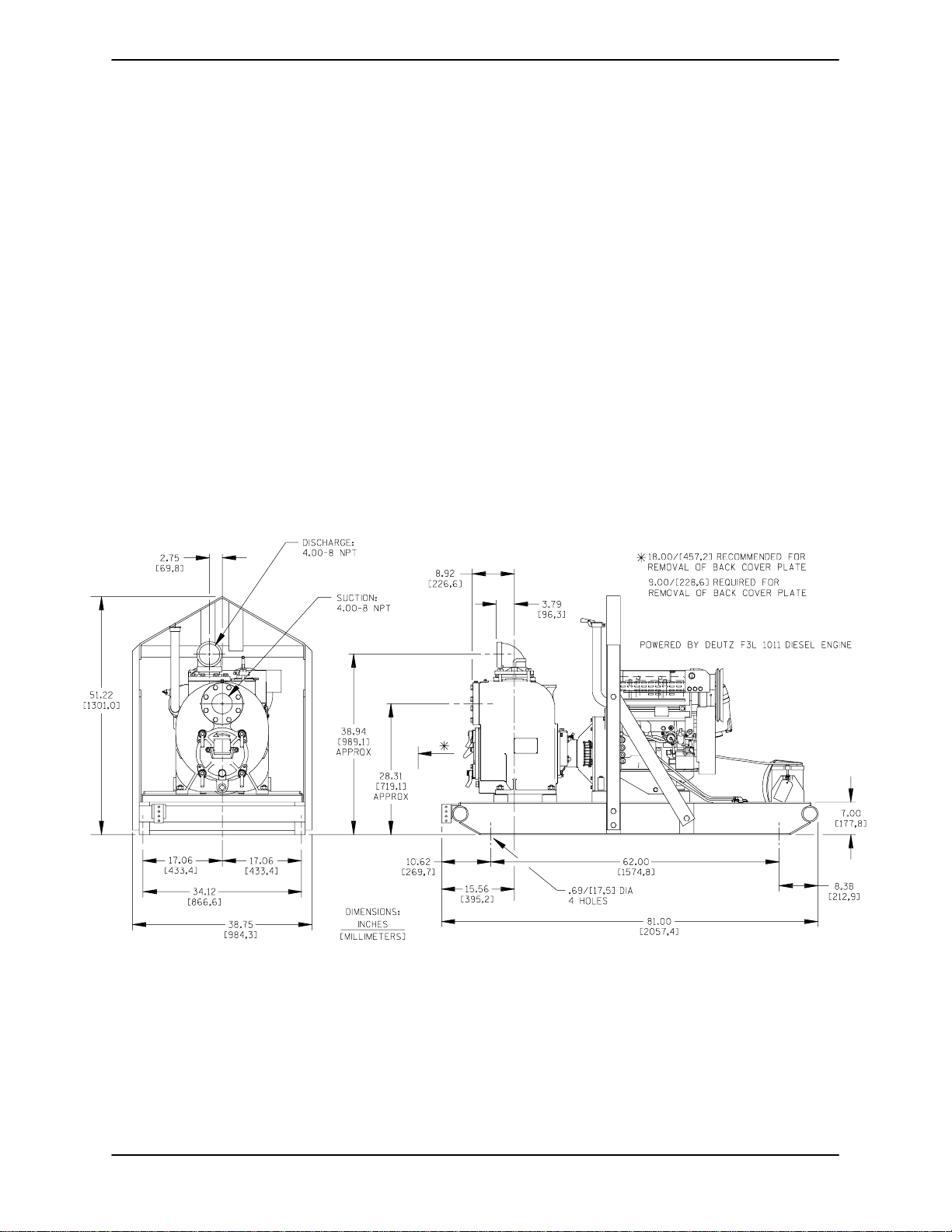

Clearance

It is recommended that 18 inches (457 mm) of

clearance be providedin front of the back coverto

permitremovalofthecoverandeasyaccess tothe

pump interior. A minimum clearance of 9inches

(229mm)must bemaintainedtopermit removalof

the cover.

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by in-

creased suction lift, discharge elevation, and fric-

tion losses. See the performance curve and oper-

ating range shown on Page E-1 to be sure your

overall application allows pump to operate within

thesafeoperationrange.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatiblewiththeliquidbeingpumped.Ifhoseis

used in suction lines, it must be the rigid-wall, rein-

forced type toprevent collapse under suction. Us-

ing piping couplings in suction lines is not recom-

mended.

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make mini-

mum use of elbows and fittings, which substan-

tiallyincreasefrictionloss.Ifelbowsarenecessary,

use the long-radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it ex-

actly with the pump port. Never pulla pipe line into

place by tightening the flange bolts and/or cou-

plings.

Lines near the pump must be independently sup-

ported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose-type

linesareused,theyshouldhaveadequatesupport

to secure them when filled with liquid and under

pressure.

Gauges

Most pumps are drilled and tapped for installing

dischargepressureandvacuumsuctiongauges.If

these gauges are desired for pumps that are not

tapped, drill and tap the suction and discharge

lines not less than 18 inches (457,2 mm) from the

suction and discharge ports and install the lines.

Installation closer tothe pump may result in erratic

readings.

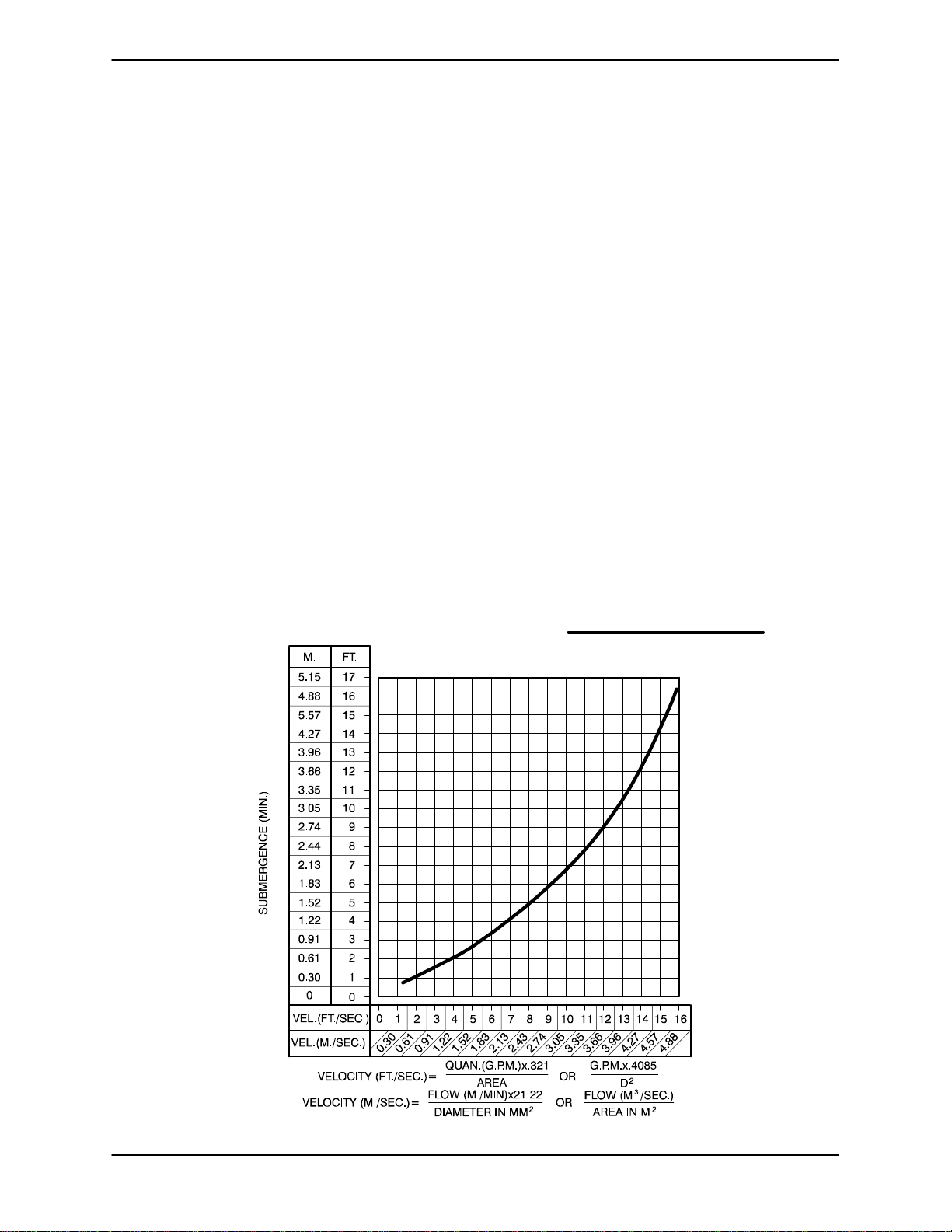

SUCTION LINES

Toavoidairpocketswhichcouldaffectpumpprim-

ing, the suction line must be as short and direct as

possible.Whenoperationinvolvesasuctionlift,the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

Fittings

Suction linesshouldbe the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be in-

stalled withthe flatpart ofthe reducersuppermost

to avoid creating air pockets. Valves are not nor-

mally used in suction lines, but if a valve is used,

install it with the stem horizontal to avoid air pock-

ets.

Strainers

If a strainer is furnished with the pump, be certain

touseit;anysphericalsolidswhichpassthrougha

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the cross section of the suction

line, and that the openings will not permit passage

of solids larger than the solids handling capability

of the pump.

This pump is designedto handleup to 3 inch (76,2

mm) diameter spherical solids.