Operating Instructions

Building regulations

Installation of the Firebelly woodburning stove must comply with all local building regulations, including

those referring to national and European standards. It is a good idea to consult your local chimney

sweep to check the suitability of the chinmney and ensure there is adequate updraft and suggest any

remedies to potential chimney problems. Document J of the Building Regulations contains further

information regarding the installation of solid fuel appliances and can be viewed at www.odpm.gov.uk

Lighting the stove

When lighting the stove for the rst time it should not be stoked excessively as all the materials must

be given time to adapt to the effects of heat. The paint will take some time to fully cure and during this

period some odours will be evident. It is recommended that doors or windows should be opened the

rst time the stove is red.

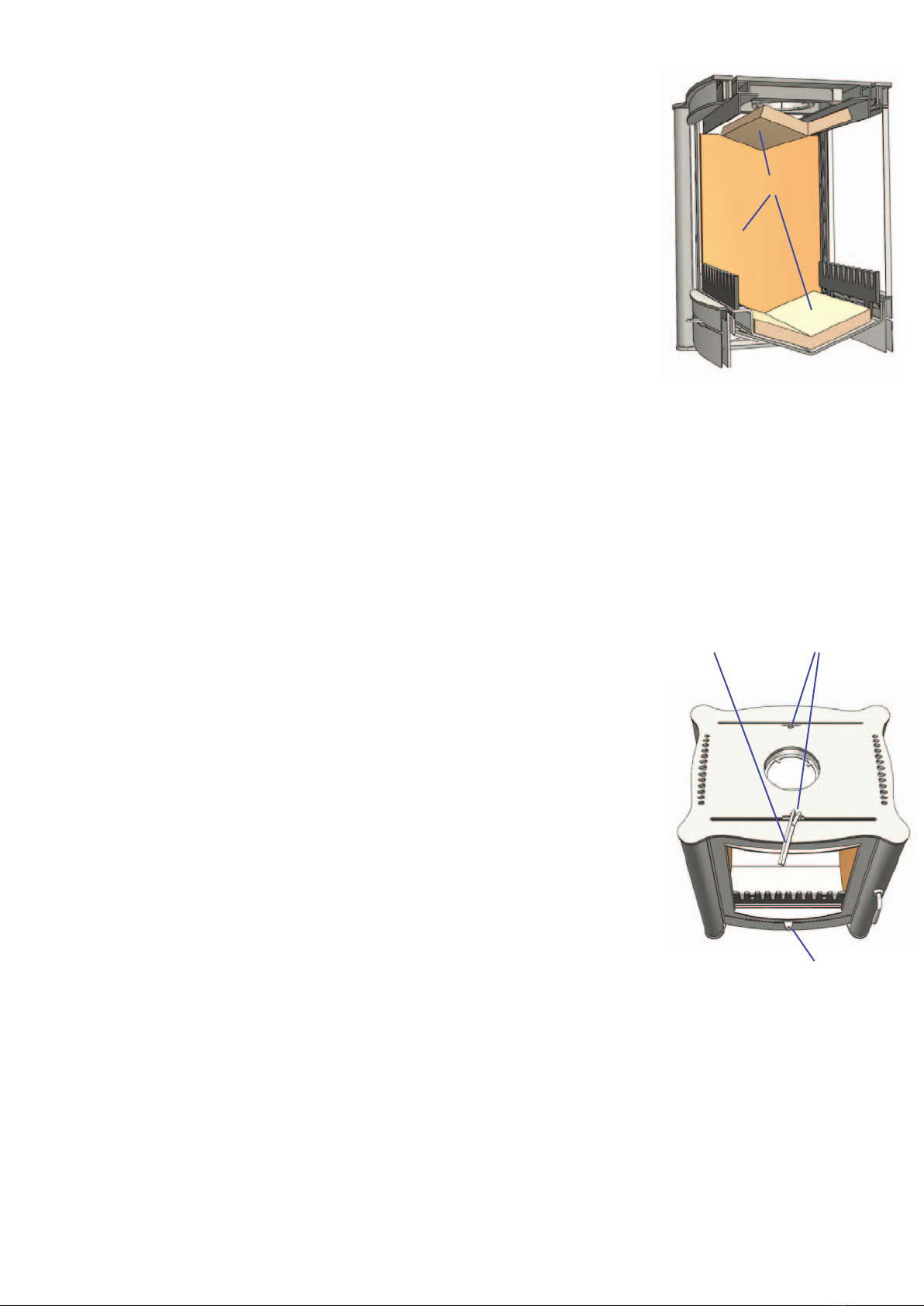

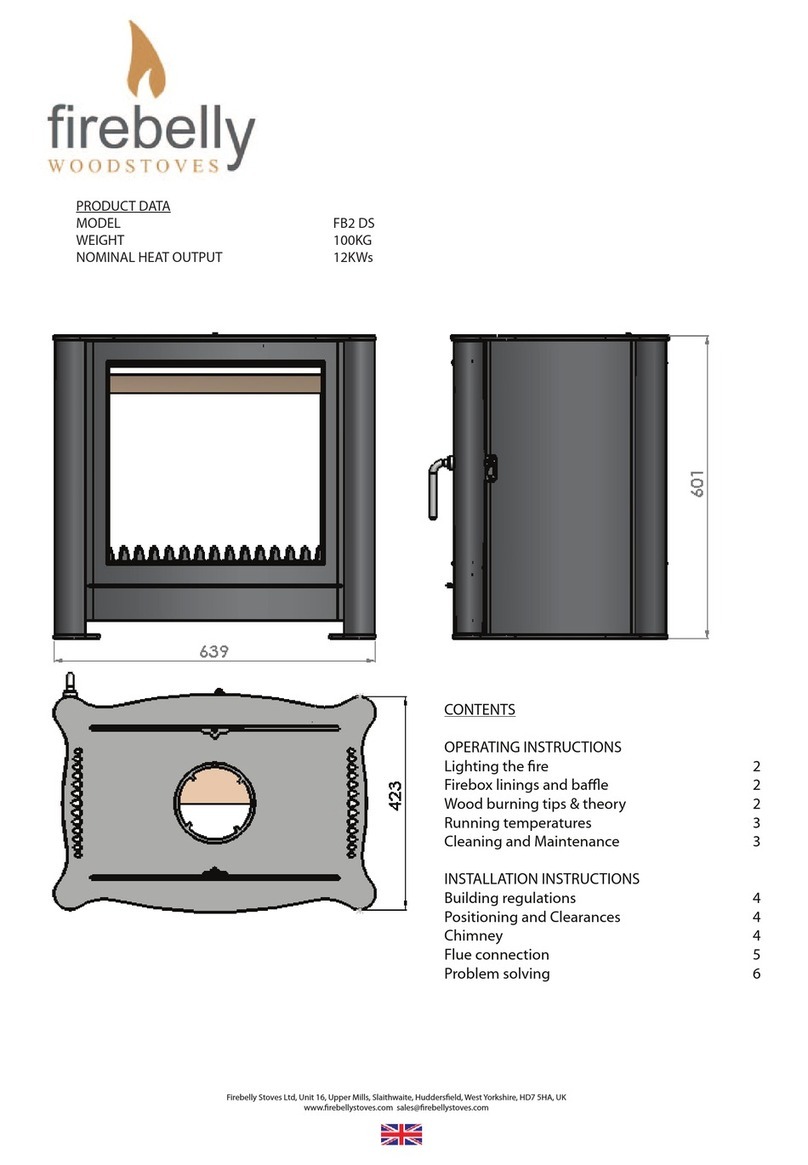

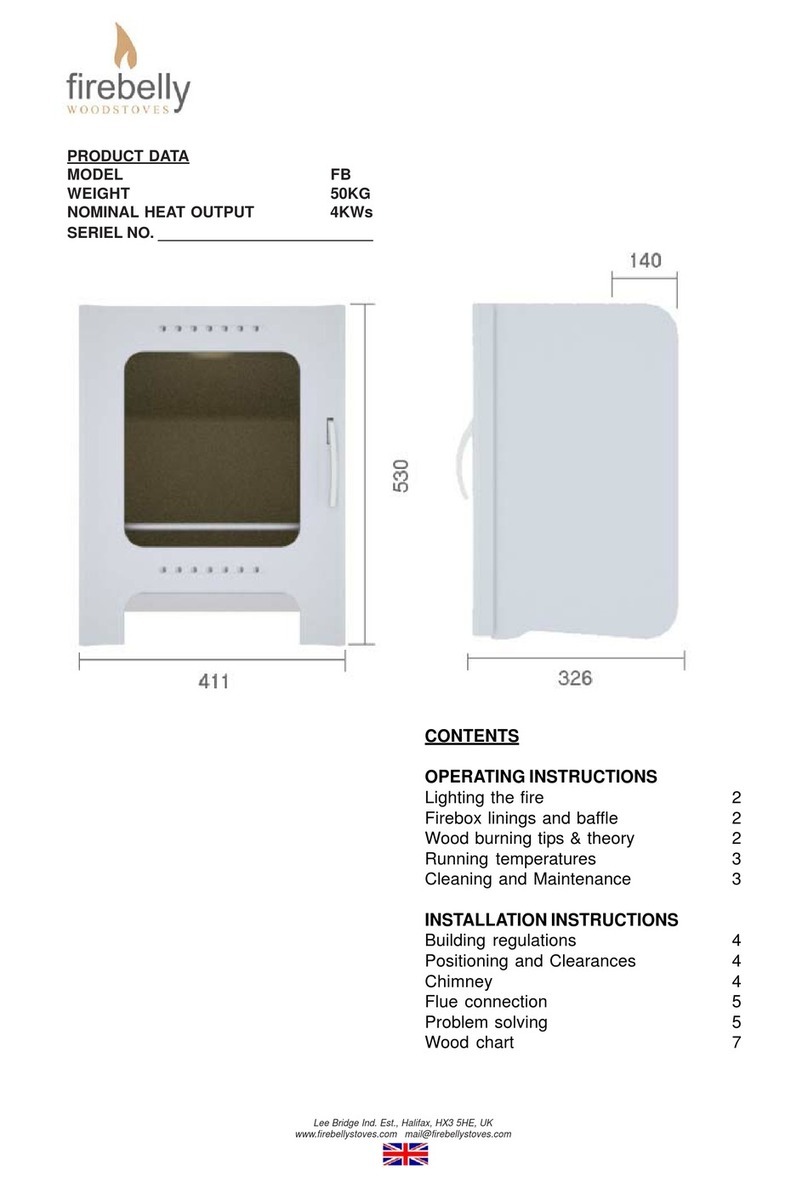

Before lighting check the rebricks and other internal components are in position gure 1 and that all

packaging has been removed.

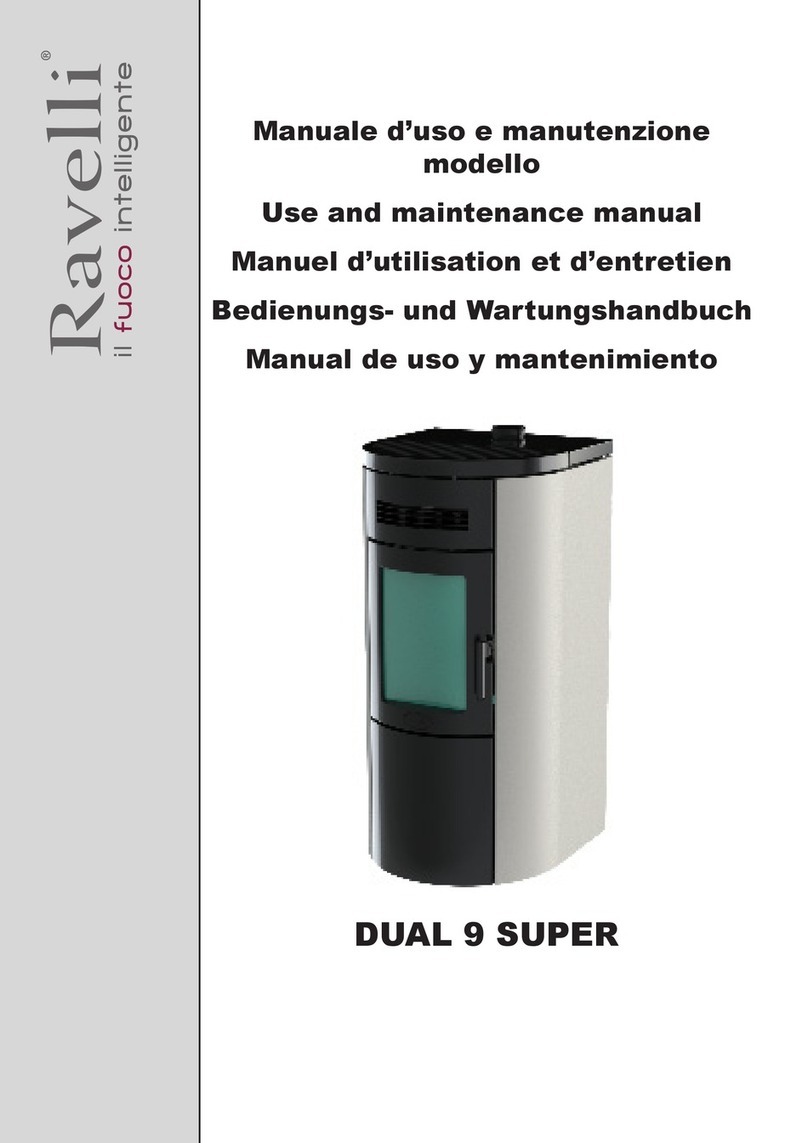

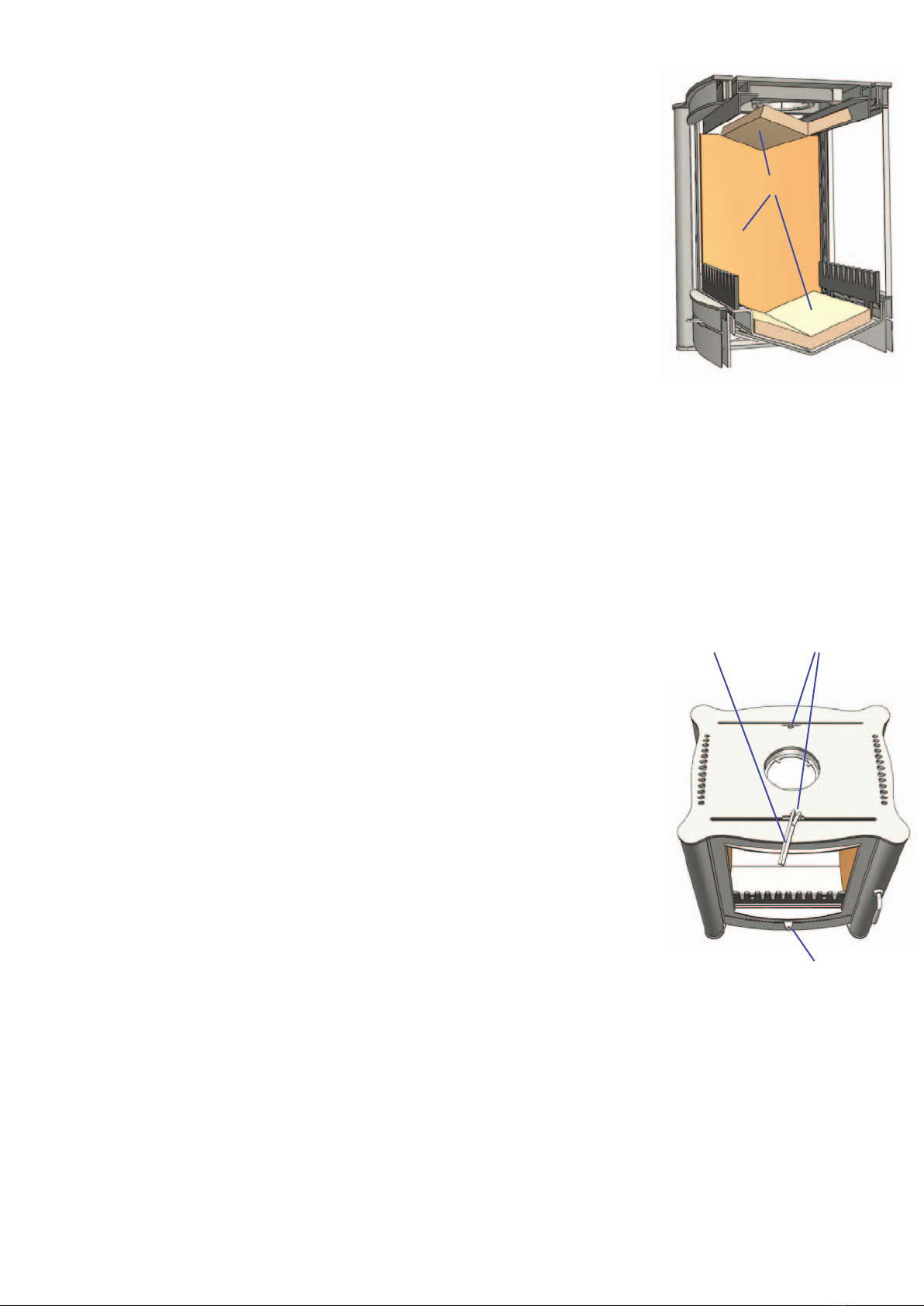

Step 1 Open both the top air controls and bottom air control fully. gure 2

To open the top air controls use the tool supplied to move back the two sliders . The top air control

becomes hot in use and so the supplied tool should always be used. To open the bottom air control

slide the tab fully to the right.

Step 2 Place rolled up and scrunched up newspaper at the back of the stove. Put small tinder on top

of the newspaper and then a few slightly larger pieces of wood on top of this, light the newspaper and

close the door.

Step 3 Let the re burn until all the pieces of wood are alight and burning. Then more and larger

pieces of wood/logs can be added.

Step 4 Once the re is established the bottom air control can be closed so that all the air for the re

comes via the top air controls. The burning rate of the re can now be controlled by adjusting the top

air controls and by regulating the amount of wood added. The bottom air control should normally

remain closed once the stove is running. If the re has been allowed to die too low then the bottom air

control can be opened to allow air to the base of the re in an attempt to revive it.

Do not run the stove with the door open

Warning. The external surfaces of the stove become hot during operation. Use the supplied tool

to operate the air controls when the stove is running.

Tips

• The rst stage of the re, just after lighting, is usually the smokiest because the cold wood

and cold stove take heat away from the ames. During this stage, ensure both air inlets of the

stove are fully open to get a hot ame. It might appear that this initial hot burn lets too much

heat go up the chimney, but it is a necessary part of an efcient re. The extra heat “primes”

the chimney to produce a strong draft, and helps keep the ue clean by loosening creosote that

might have been deposited by the previous re. The hot initial burn also drives moisture out of

the rewood and gives an ignition source for the smoke that is released from the wood.

• Make small changes. Do not try to add too much fuel at once, the fuel should not be stacked

higher than the top of the back re brick. Adding fuel gradually will help maintain a steady

temerature and burning rate so that the stove burns efciently and cleanly. Adding a large

amount of fuel all at once will dramatically reduce the temperature inside the stove. After

adding a large piece of wood/log it is a good idea to increase the top air opening slightly more

until the new fuel begins to burn and the stove returns to temperature.

• This also applies to the air controls. Adjusting them gradually will help maintain a steady

combustion rate.

• Do not run the stove with the top air controls fully closed. The top air controls supply air for the

glass ‘air shield’ system. The further open the top air control the more effective the air shield

system.

• Use a piece of newspaper to wipe the inside of the windows before lighting the stove each time

to prevent the gradual build up of deposits.

• Small, hot res are more efcient than large slumbering res. Most of the energy in burning

wood is released as a bright ame. The turbulence in the ames creates good mixing between

the combustion air and the gases that are released from the wood as it heats up. The heat of

the re ignites and burns these gases. In contrast, the dense smoke from a slow, smouldering

re is potential heat energy that escapes up the chimney and either clings to the chimney ue

as creosote or pollutes the outdoor air. Therefore, to gain the most heat from each load of

rewood, the wood should be aming throughout the burn cycle until it is reduced to ash.

• If you do a fair bit of slow woodburning, it is good practice to burn a good, hot stove at regular

intervals to keep your chimney dry and prevent the build up of tar.

• When refueling try to place logs length ways so that any spitting from the end grain does not go

onto the glass window.

gure 1

re bricks

gure 2 Primary air control.

Slide right to open.

2

Secondary air controls.

Slide back to open.

Tool for adjusting

top and bottom air

controls