FireClass Prescient III User manual

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12 APPROVED BY:JBJ

PAGE 1 of 43

PRESCIENT III

FIRE ALARM & GAS EXTINGUISHING CONTROL PANEL

Application, Installation, Operation & Maintenance

Manual

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 2 of 43

CONTENTS

1. INTRODUCTION ..................................................3

2. GENERAL DESCRIPTION.....................................3

3. FUNCTIONAL DESCRIPTION ................................8

3.9.1. REMOTE CONTROLS.....................................9

3.9.2. REMOTE SOUND ALARMS: ............................9

3.9.3. REMOTE SILENCE ALARMS:...........................9

3.9.4. REMOTE RESET:..........................................9

3.9.5. GAS TRAPPED.............................................9

3.9.6. AUTO/MANUAL LOCK-OFF SWITCH

(AUTO/MANUAL)......................................9

3.9.7. LOW PRESSURE FAULT (GAS LOW) ............9

3.9.8. EXTINGUISHING ISOLATION VALVE STATUS

(ISO. VALVE)..........................................10

3.9.9. GAS RELEASED PRESSURE SWITCH (GAS

REL.) ......................................................10

3.9.10. EMERGENCY HOLD (HOLD) .......................10

3.9.11. EMERGENCY ABORT INPUT (ABORT)..........10

3.10.1. FIRST STAGE SHUTDOWN (1STSTAGE)....11

3.10.2. SECOND STAGE SHUTDOWN (2ND STAGE)11

3.10.3. THIRD STAGE SHUTDOWN (3RD STAGE)...11

3.10.4. GAS DISCHARGED (GAS REL SIG)............11

3.10.5. FIRE SIGNAL (FIRESIG) ...........................11

3.10.6. FAULT SIGNAL (FAULT SIG)......................11

3.10.7. AUXILIARY RESET (RESET).......................11

3.12.1. FUNCTION SELECT SWITCH ........................12

3.12.2. LINK FOR EARTH FAULT MONITORING..........14

3.16.1. FIRE .......................................................15

3.16.2. FIRE SIGNAL..........................................15

3.16.3. ZONE 1...................................................15

3.16.4. ZONE 2...................................................15

3.16.5. AUX ZONE..............................................15

3.16.6. REMOTE SOUND ALARMS ...................16

3.16.7. FIRE SOUNDERFAULT/DISABLED......16

3.17.1. POWER SUPPLYON.............................16

3.17.2. GENERAL FAULT...................................16

3.17.3. POWER SUPPLYFAULT.......................16

3.17.4. SYSTEMFAULT.....................................16

3.17.5. EARTH FAULT........................................16

3.17.6. FUSE FAILED.........................................16

3.17.7. FAULT SIGNAL FAULT/DISABLED........16

3.17.8. SOUNDER TEST....................................16

3.18.1. AUTO&MANUAL...................................16

3.18.2. MANUAL ONLY ......................................16

3.18.3. MANUAL RELEASE ACTIVE..................16

3.18.4. SYSTEMACTIVATED ............................16

3.18.5. GAS RELEASED ....................................16

3.18.6. GAS RELEASED SIGNAL ACTIVE.........16

3.18.7. EMERGENCYABORT ACTIVE..............16

3.18.8. EMERGENCYHOLD ACTIVE ................17

3.18.9. CIRCUIT FAULT.....................................17

3.18.10. GAS LOW...............................................17

3.18.11. GAS TRAPPEDIN MANIFOLD...............17

3.18.12. ISOLATION VALVE ABNORMAL............17

3.18.13. ISOLATION VALVE CLOSED.................17

3.18.14. MANUAL RELEASE FAULT/DISABLED.17

3.18.15. EXTINGUISHINGDISABLED.................17

3.18.16. GAS RELEASED SIGNAL DISABLED....17

3.18.17. SHUTDOWN OUTPUTS DISABLED ......17

3.18.18. SECONDS TO DISCHARGE ..................17

3.19.1. SILENCE ALARMS.................................17

3.19.2. RESOUND ALARMS ..............................17

3.19.3. FIRE RESET...........................................17

3.19.4. EXTINGUISHINGRESET.......................17

3.19.5. SILENCE BUZZER .................................18

3.19.6. AUTO&MANUAL /MANUAL ONLY .......18

3.19.7. SELECT ON/OFF....................................18

3.19.8. ENABLE..................................................18

3.19.9. DISABLE.................................................18

3.19.10. TEST.......................................................18

3.19.11. SCROLL..................................................18

4. PANEL OPERATION ......................................... 18

4.2.1. DISABLE,RE-ENABLE,TEST ........................19

4.2.2. CONFIGURE I.S. ZONES..............................19

4.2.3. CONFIGURE SLU (STATUS LAMP UNITS)......19

4.5.1. MANUAL ONLYMODE ...........................20

4.5.2. AUTOMATIC &MANUAL MODE.............20

4.6.1. MANUAL ONLYMODE ...........................20

4.6.2. AUTOMATIC &MANUAL MODE.............20

4.8.1. EMERGENCY HOLD OPERATION ...................21

4.8.2. EMERGENCY ABORT OPERATION .................21

5. TECHNICAL SPECIFICATION ............................. 21

6. STANDBY BATTERY REQUIREMENTS ................ 22

7. DETECTOR COMPATIBILITY.............................. 24

8. PANEL INSTALLATION...................................... 28

9. SYSTEM MAINTENANCE................................... 34

10. PCB LAYOUT DIAGRAM .................................. 35

11. PANEL EXPLODED VIEW.................................. 36

12. CONNECTION DIAGRAMS ................................. 37

13. MECHANICAL,ELECTRICAL &ENVIRONMENTAL

SPECIFICATION ............................................... 42

14. CONSTRUCTION PRODUCTS DIRECTIVE............ 43

Figures

FIGURE 1–ENCLOSURE DIMENSIONS........................ 4

FIGURE 2–MOTHERBOARD TERMINAL IDENTIFICATION

PART 1................................................... 5

FIGURE 3–MOTHERBOARD TERMINAL IDENTIFICATION

PART 2................................................... 6

FIGURE 4–PRESCIENT III BLOCK SCHEMATIC DIAGRAM

.............................................................. 7

FIGURE 5–DISPLAY............................................... 15

FIGURE 6–POWER SUPPLY CONNECTION DETAILS . 23

Tables

TABLE 1–RESET INHIBIT SETTINGS........................ 13

TABLE 2–CIRCUIT MODES ..................................... 18

TABLE 3–FLOAT CHARGE VOLTAGES FOR

POWERSONIC VRLA BATTERIES............ 23

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 3 of 43

1. Introduction

The FIRECLASS Prescient III Gas Extinguishing

Control Panel is a stand-alone panel intended for

use with gas extinguishing systems. It has been

designed and approved to the European Standard

EN 12094-1:2003, as well as the relevant parts of

EN54-2:1997 & EN54-4:1997. The Prescient III also

incorporates the relevant recommendations of the

British Code of Practice BS7273-1:2000.

The Prescient III is fully compliant with the

mandatory requirements of EN54 parts 2 and 4

along with the following options with requirements:

1. EN54-2:1997 Clause 7.8 Outputs to fire alarm

devices (sounders).

2. EN54-2:1997 Clause 7.9 Outputs to fire alarm

routing equipment.

3. EN54-2:1997 Clause 8.9 Output to fault

warning routing equipment.

4. EN54-2:1997 Clause 10 Test condition.

The Prescient III provides the following compulsory

functions of BSEN 12094-1:2003 as listed in clause

4.3.2:

1. a) Reception & processing of at least one input

triggering signal from an f.d.a.s. (Fire detection

Zones 1 & 2) and an input triggering signal

from manual triggering device(s) connected

directly to the e.c.d. (Manual Release input).

2. b) Transmission of the extinguishing signal

(Actuator circuits 1 & 2)

3. c) Activation of Alarm devices (Extinguishing

Sounder circuit)

4. d) Indication of each condition unambiguously

(LEDs & internal buzzer).

5. e) Transmission of the information of the

incorrect status of components and of the

information of the fault warning condition (Fault

Signal Output).

6. f) Transmission of the information of the

released condition (Gas Released Output)

The Prescient III provides the following optional

functions of BSEN 12094-1:2003 as listed in clause

4.3.2:

1. g) Extinguishing system delay.

2. h) Reception of a signal representing the flow

of extinguishing agent (Discharged).

3. i) Monitoring of status of components:

a. Low pressure/low weight

4. j) Reception of signal from an emergency hold

device.

5. k) Separate monitoring of the status of non-

electrical disable device(s) (Isolation valve).

6. n) Input from auto/manual selector switches.

7. o) Transmission of a triggering signal to

equipment within the fire extinguishing system:

b. Optical warning devices (Status

indicators).

8. q) Transmission of signals to equipment

outside the fire extinguishing system (Shut

downs).

9. r) Reception of signal from an emergency

abort device.

10.u) Activation of alarm devices with different

signals. (2-stage sounders).

The Environmental Class as defined by clause 4.2

is:

Class A: temperature range -5 to +40 Deg C.

The Prescient III is fully compliant with the relevant

recommendations of BS 7273-1:2000. The following

safety critical aspects have been addressed:

1. 6.1.2 Avoidance of accidental discharge.

2. 6.4.3 A single short circuit in connections shall

not cause an extinguishant release.

3. 6.4.4 Protection against over voltages which

could cause an extinguishant release.

The Prescient III integrates the functions of a fire

alarm system and a gas extinguishing system. The

Prescient III monitors one extinguishing area and

one non-extinguishing area for fire conditions and

gives an appropriate audible and visual indication.

Zones 1 & 2 are used for coincident detection in the

extinguishing area and can be used to automatically

release the extinguishing gas. The Auxiliary zone

only provides an alarm indication. The Prescient III

also provides a facility for initiating the release of

extinguishing gas manually.

The Prescient III incorporates a 5 Amp switch-mode

power supply with Power Factor correction.

2. General Description

The Prescient III is housed in a metal enclosure

with a Manual Release facility mounted on the door.

The following functions are available on the front of

the panel:

1) Visual Indication of panel status via LEDs:

2) Numerical Display for the Extinguishant

Release Timer.

3) Buttons for User Control.

4) Manually operated Extinguishant Release unit

The following functions are available inside the

panel:

1) Three fully monitored Detection circuits.

2) One fully monitored Manual Release circuit.

3) Two fully monitored General Sounder circuits.

4) One fully monitored Extinguishing Sounder

circuit.

5) Two fully monitored Actuator circuits.

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 4 of 43

6) Repeater outputs for:

(i) Zone 1 Fire Detected

(ii) Zone 2 Fire Detected

(iii) Auxiliary Zone Fire Detected

(iv) Manual Release Activated

(v) Extinguishing System Disabled

(vi) Isolation Valve Closed

(vii) Isolation Valve Abnormal

(viii) Emergency Hold Activated (configurable for

auto & manual mode)

(ix) Emergency Abort Activated (configurable

for manual only mode)

7) Two Auxiliary 24VDC supply outputs.

8) RS485 communication link to drive external

Status Lamp Units.

9) Fully monitored inputs for:

(i) Gas Discharged Pressure Switch

(ii) Gas Low Pressure Switch

(iii) Gas Isolation Valve

(iv) Gas Trapped In Manifold

(v) Emergency Hold Switch

(vi) Emergency Abort Switch

(vii) Manual Only (Lock-Off) Switch

(viii) Remote Controls Switches (Sound alarms,

Silence Alarms, Reset)

10) Fully Monitored Outputs (Configurable for

Volt-Free operation) for:

(i) First Stage Shutdown

(ii) Second Stage Shutdown

(iii) Third Stage Shutdown

(iv) Auxiliary Fire Signal

(v) Auxiliary Fault Signal

(vi) Gas Released Signal

11) Volt-Free Relay Contacts for Auxiliary

Equipment Reset

12) Terminals for Internal Standby Batteries

13) Site Configuration DIL Switches

14) Fault indication LEDs

15) Internal Buzzer

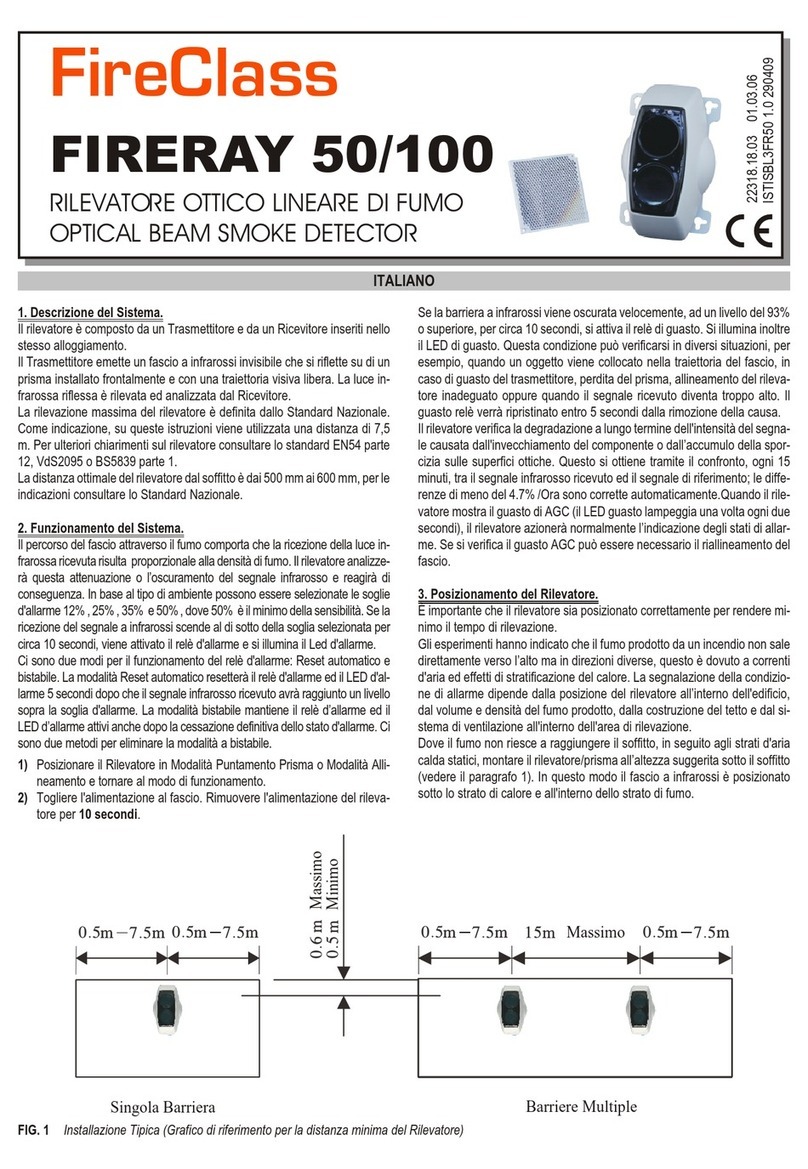

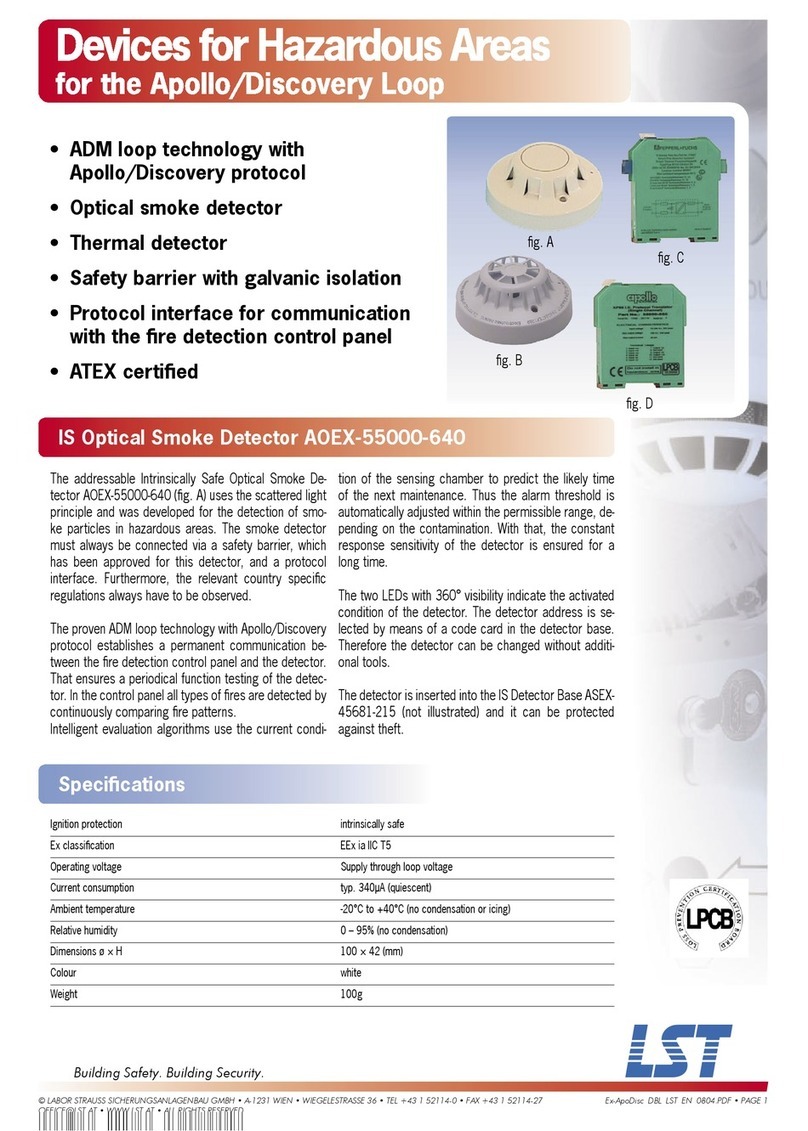

Figure 1 –Enclosure Dimensions

370.00 mm

325.00 mm 126.00 mm

4.00 mm

FIRE STATUS

COMMON STATUS

USER CONTROLS EXTINGUISHING STATUS

FIRE

FIRE SIGNAL

ZONE 1

ZONE 2

AUX ZONE

REMOTE SOUND ALARMS

REMOTE CONTROLS FAULT

FIRE SOUNDER FAULT/DISABLED

POWER SUPPLY ON

GENERAL FAULT

POWER SUPPLY FAULT

SYSTEM FAULT

EARTH FAULT

FUSE FAILED

FAULTSIGNAL FAULT/DISABLED

SOUNDER TEST

AUTO & MANUAL

MANUAL ONLY

MANUAL RELEASE ACTIVE

SYSTEM ACTIVATED

GAS RELEASED

GAS RELEASED SIGNAL ACTIVE

EMERGENCY ABORT ACTIVE

EMERGENCY HOLD ACTIVE

CIRCUITFAULT

GAS LOW

GASTRAPPED IN MANIFOLD

ISOLATION VALVE ABNORMAL

ISOLATION VALVE CLOSED

MANUAL RELEASE FAULT/DISABLED

EXTINGUISHING DISABLED

GAS RELEASED SIGNAL DISABLED

SHUTDOWN OUTPUTS DISABLED

SECONDS

TO

DISCHARGE

SILENCE

ALARMS

FIRE

RESET

SILENCE

BUZZER

SELECT

ON/OFF

SCROLL

OFF

ACCESS

CONTROLS

ON

TEST

DISABLE

ENABLE

AUTO &MAN/

MANUAL ONLY

EXTINGUISHING

SYSTEM RESET

(INHIBITED)

RESOUND

ALARMS

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 5 of 43

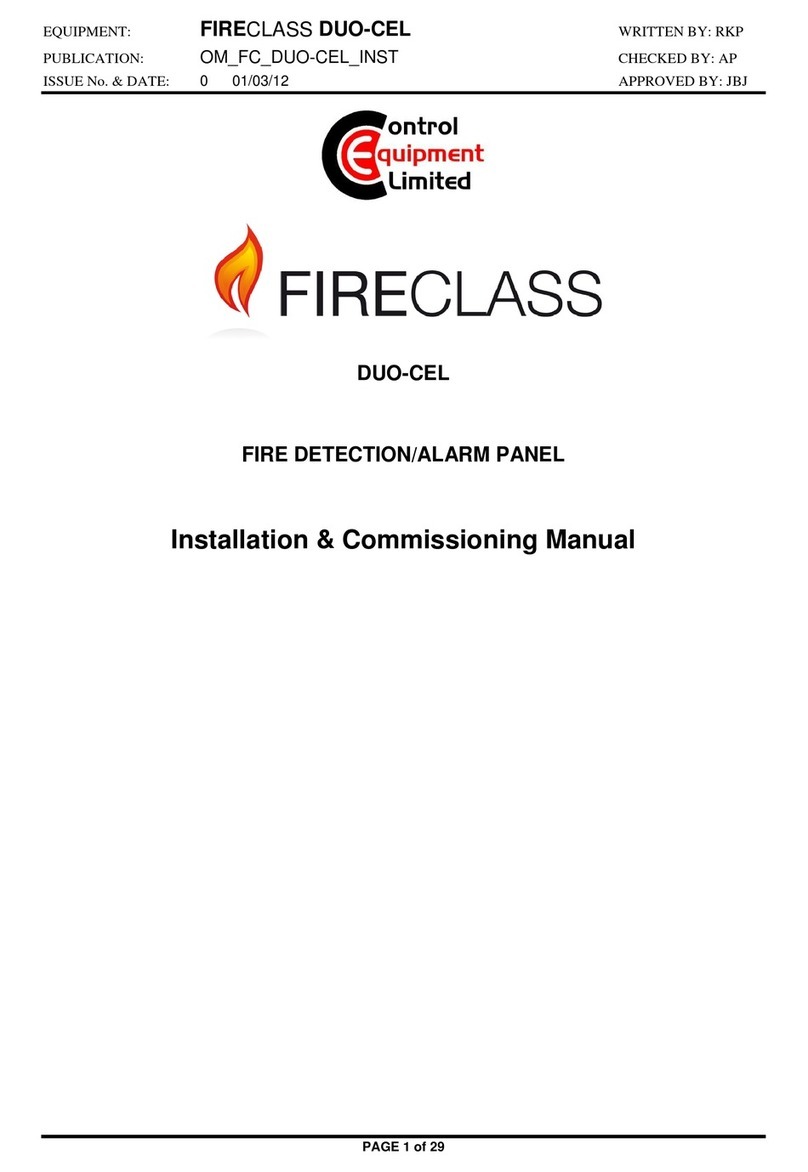

Figure 2 –Motherboard Terminal Identification Part 1

ZONE CIRCUITS

+-+-+-+-

1 2 AUX MR GAS

REL. GAS

LOW ISO.

VALVE GAS

TRAPPED Z1 Z2 AUX MR 1 2 3 4 5

OUTPUTS

HOLD ABORT REMOTE

CTRLS AUTO/

MANUAL

Repeat Output –Isolation Valve Abnormal

Repeat Output –Isolation Valve Closed

Repeat Output –Actuators Disabled

Repeat Output –Emergency Abort Activated

(Panel in Manual –DIL SW Selectable)

Repeat Output –Emergency Hold Activated

(Panel in Auto –DIL SW Selectable)

Repeat Output –Manual Release Activated

Repeat Output –Auxiliary Zone Fire

Repeat Output –Zone 2 Fire

Repeat Output –Zone 1 Fire

Status Input –Gas Trapped in Manifold

10K EOL, 680R Activation

Status Input –Isolation Valve Status

10K Abnormal, 2K2 = Open, 680R = Closed

Status Input –Gas Low

10K EOL, 680R = Gas Low

(DIL SW configurable for Normally closed

operation)

Status Input –Gas Released Pressure Switch

10K EOL, 680R = Activated

Manual Release Input

21VDC, 10K EOL, 680R = Activated

(DIL SW configurable for 3K9 EOL)

Auziliary Zone Input

21VDC, 22uF EOL, 680R = Activated

Detectors & Call-points allowed

(DIL SW configurable for 3K9 EOL)

Detector Zone 2 Input –Protected Area Zone

21VDC, 22uF EOL, 680R = Activated

Fire Detectors only

(DIL SW configurable for 3K9 EOL)

Detector Zone 1 Input –Protected Area Zone

21VDC, 22uF EOL, 680R = Activated

Fire Detectors only

(DIL SW configurable for 3K9 EOL)

Input –Emergency Hold Switch

10K EOL, 680R = Activated

Input –Emergency Hold Switch

10K EOL, 680R = Activated

Input

Auto/Manual Mode Select Switch

10K EOL, 4K7 = Manual Only Mode

Remote Control Input

10K EOL, 4K7 = Sound Alarms

1K8 = Silence Alarms

560R = Reset System

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 6 of 43

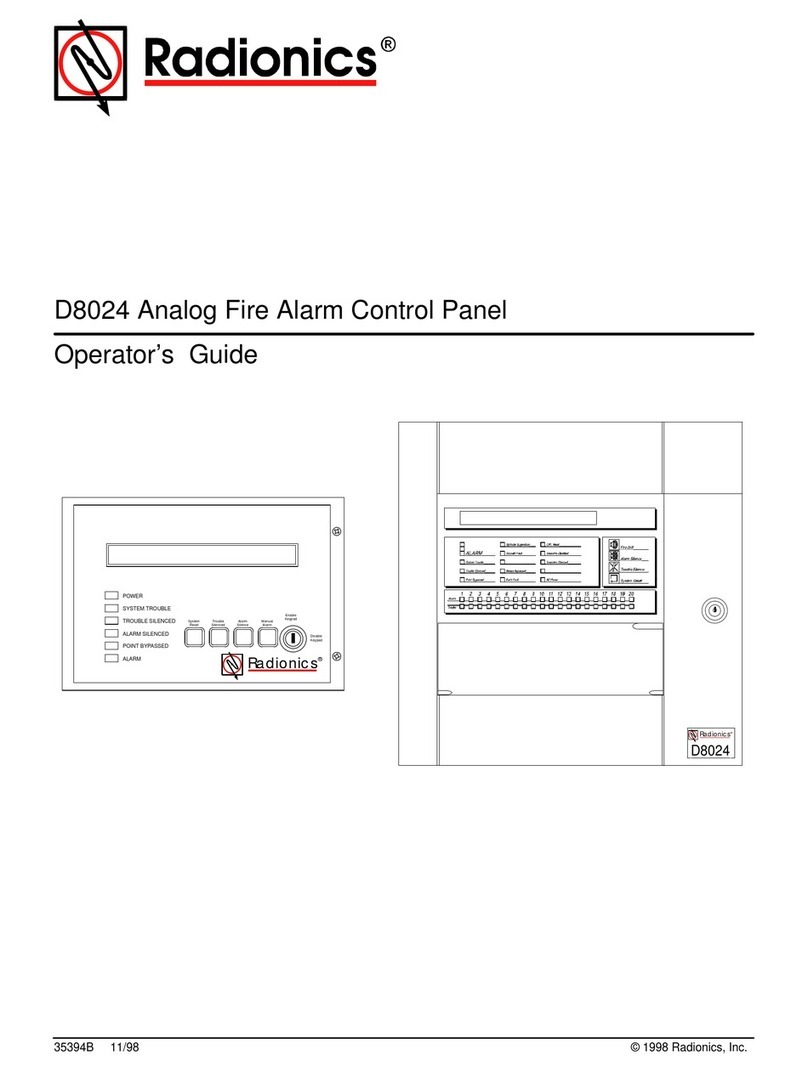

Figure 3 –Motherboard Terminal Identification Part 2

24V 0V

AUX

250mA

A B

S.L.U.

+ - + - + - + - + -

SNDR1 SNDR2 EXT.

SNDR ACT1 ACT2 C/+ P O/-C/+ P O/-O/+ P C/-

C/+ P O/-C/+ P O/-C/+ P O/-

GAS REL SIG FIRE SIG FAULT SIG

C P O

RESET

3RD STAGE2ND STAGE1ST STAGE

Reset Relay - Volt-FreeTerminals:

C = Normally Closed

P = Pole

O = Normally Open

Fault Relay - Volt-Free or Powered

Terminals:

C/+ = Normally Closed or 24V out

P = Pole

O/- = Normally Open or 0V out

Fire Relay - Volt-Free or Powered

Terminals:

C/+ = Normally Closed or 24V out

P = Pole

O/- = Normally Open or 0V out

Gas Released Relay - Volt-Free or Powered

Terminals:

C/+ = Normally Closed or 24V out

P = Pole

O/- = Normally Open or 0V out

Actuator Circuit 2

+ = 1.2V in quiescent, 24V when activated

- = 3.8V in quiescent, 0V when activated

Actuator Circuit 1

+ = 1.2V in quiescent, 24V when activated

- = 3.8V in quiescent, 0V when activated

Extinguishing Sounder Circuit

+ = 1.2V in quiescent, 24V when activated

- = 3.8V in quiescent, 0V when activated

Fire Sounder Circuit 2

+ = 1.2V in quiescent, 24V when activated

- = 3.8V in quiescent, 0V when activated

Fire Sounder Circuit 1

+ = 1.2V in quiescent, 24V when activated

- = 3.8V in quiescent, 0V when activated

SLU 2-Wire RS485 Data Connection

Connect A at panel to A at SLU

Connect B at panel to B at SLU

1 Amp 24V DC Power Supply Output

Primarily for use with SLUs

250mA 24V DC Power Supply Output

Primarily for use with Repeat Outputs

Third Stage Relay

Volt-Free or Powered Terminals:

C/+ = Normally Closed or 24V out

P = Pole

O/- = Normally Open or 0V out

Second Stage Relay

Volt-Free or Powered Terminals:

C/+ = Normally Closed or 24V out

P = Pole

O/- = Normally Open or 0V out

First Stage Relay

Volt-Free or Powered Terminals:

C/+ = Normally Closed or 24V out

P = Pole

O/- = Normally Open or 0V out

24V 0V

AUX

1A

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 7 of 43

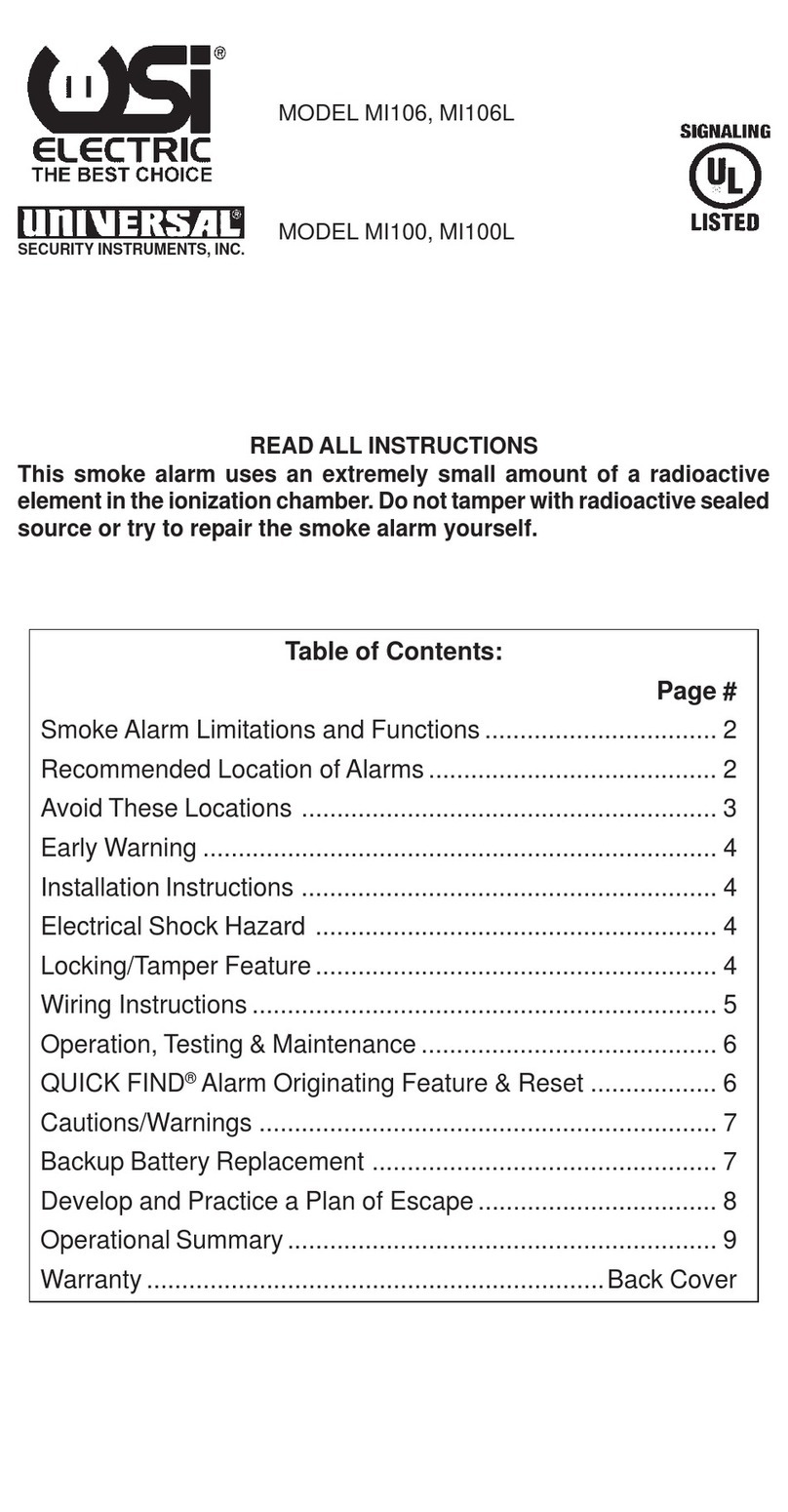

Figure 4 –Prescient III Block Schematic Diagram

Zone 1

Zone 2

Aux Zone

Gas

Released

Gas

Low

Isol Valve

Abnormal

Isol Valve

Closed

Act 1**

Act 2**

Gen Sndr 1**

Gen Sndr 2**

Ext Sndr**

Gas Released

[Routing]**

Gas Released [SLU]

Gas Manual [SLU]

Gas Auto [SLU]

1st stage Plant

Shutdown **

Fire Sig

[Routing]**

Fault Sig

[Routing]**

Timer Hold [SLU]

Release Aborted [SLU]

+24V AUX 1A Output

2nd stage Plant

Shutdown **

Aux Reset

Coincidence

detection

zones

Auxiliary

detection zone

Panel

Manual

Release

Gas discharged

pressure switch.

Gas Low

[Low pressure

switch/low weight]

[Valve Closed]

[See valve

wiring diag]

Gas isolation

valve.

[Valve Stuck]

Fire

Z1

Fault/

Disabled

Z1

Fire

Z2

Fault/

Disabled

Z2

Fire

Aux

Fault/

Disabled

Aux

Gas

Released Fault

Gas Low

* = Open & short cct flt

monitored input*

*

*

Open & short cct flt monitored

I/P. 680 Ohm = Ext Low

Open & short cct flt

monitored I/P.

680Ohms = V/Closed

2K2 = V/Abnormal

General

Fire

Sounder

Test

General

Fire

Sounder

Fault/

Disabled

Sndr 1

flt Sndr 2

flt

Internal

Act 1 flt Act 2 flt

Internal Extinguishing

Disabled

Aux DC Supply Max O/P

1A Fused

Active on any fire Z1 or

Z2 in auto, Man Rel or

Gas Released P/S signal

Pulsed when Z1 & Z2 in alarm

in auto, or Man Release active.

Continuous on actuator

activation or discharge

Pressure SW I/P signal active

Max O/P: 0.5A

** = Open & short circuit

monitored output

Active on coincidence

fire on Z1 and Z2 in

auto, Man Rel or Gas

Released P/S signal

Fire Sig

[Routing]

Active Fault/

Disabled

Fault Sig

[Routing] Fault/

Disabled

S/D Outputs

Disabled

Gas Rel

Signal

[Routing]

Active Disabled

Operates on any fire

Z1,Z2,Aux Zone

Link configurable O/Ps:

Link ON:

Open/short cct fault

monitored, powered at

24 VDC when active.

Link OFF:

1 x Volt-Free Change-

over relay contact

[Rated 1 Amp @ 24VDC] Operates [de-energises]

on any fault including

Valve Abnormal but not

Valve Closed

Operates on Gas P/S

active I/P or Actuator

operated when in "No

Discharge P/S" mode

Open collector O/Ps

each rated 50 mA

1 x V/F C/O relay contact

[Rated 1 Amp @ 24VDC] Operating for 10

seconds after

operation of Fire

Reset switch

*

*

*

3rd stage Plant

Shutdown ** Active on Actuators

operated (if no

Discharged Pressure

Switch) or Gas

Released P/S signal

Each Plant Shutdown O/P has:

1 x OP, link configurable as fault

monitored/powered when active [as per fire

routing O/P] or 1 x V/F C/O relay contact

rated 1 Amp @ 24 VDC.

S/D

O/P

1 flt

Internal

S/D

O/P

2 flt

S/D

O/P

3 flt

Gas Trapped

Pressure

Switch

Gas Trapped

in Manifold

+24V AUX 250mA Output

Max O/P 0.25A [Fused]

Internal

Ext Sndr Fault

Release Disabled [SLU]

RP- E/Hold Active

orPanelinAuto

RP- E/AbortActive

orPanelinManual

RP - Isol Valve Closed

RP - Isol Valve Abnormal

RP –Actuators (Extinguishing)

Disabled

Internal

Fault

Internal

Auto

&

Manual Manual

Only Fault

Internal

E Abort

Active Fault

Internal

E Hold

Active Fault

Internal

Isolation

Valve

Abnormal

Isolation

Valve

Closed Fault

Internal

Gas

Trapped in

Manifold Fault

Internal

0V AUX 1A Output

Release Count Down[SLU]

RS485 serial

data [SLU]

To Status

Indicator/

Controller

SLU

Fault

Internal

Man

Rel

Active

Man

Rel

Fault/

Disabled

Internal

Gas Rel Sig

[Routing] Fault

Conventional

Manual Release

Zone

Manual

Release

Conventional

E Hold input Emergency

Hold

Conventional

Abort input

Emergency

Abort

*

*

*

*

Conventional

Auto/Manual

switch input

Auto/Manual

Lock Off *

RCI

Remote Controls Input:

4K7 = Sound Alarms

1K8 = Silence Alarms

560R = Reset Panel

Remote

Sound

Alarms

Active RCI

Fault

*

RP - Fire Z1

RP - Fire Z2

RP - Fire Aux Zone

RP –Manual Release Operated

DILSwitch

Selectable

Continuousforfireon

Z1,Z2,AuxZone.

AlsoforRemoteSoundAlarm

MaxO/P:0.5A

Operate on Pre-discharge

Timer Ended or Man Release

in Immediate mode

Max O/P:1 Amp

Internal

Fault

Panel

MR

Internal

Fault

External

MR

Extinguishing

Reset

Inhibit

ActiveIlluminates steady

while Extinguishing

Reset is Inhibited

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 8 of 43

3. Functional Description

Note: Please refer to Section 10 for PCB Layout

Diagram and Section 12 for Connection

Diagrams.

3.1 Detection Zones (Zone 1, Zone 2 &

Aux Zone)

Three detection zone circuits are provided. They are

monitored for Open Circuit Fault, Short Circuit Fault

and Alarm (Fire). The End-Of-Line device is

normally a 22uF capacitor (or 10k resistor if set to

Intrinsically Safe mode) but can be configured for

3k9 resistor via a DIL switch on the motherboard.

A maximum of 32 devices may be connected on

each zone (the actual number is dependent on the

type of detector used, see section 7).

Manual Call Points may only be connected to the

aux. zone.

In Automatic mode, zones 1 and 2 are normally

used together to produce First Stage (pre-activated)

and Second Stage (activated) fire alarms, resulting

in automatic extinguishant discharge („Double

Knock‟ or „Coincidence‟ Zones).

The auxiliary detection zone only provides a general

fire indication.

Operation of Fire Reset causes the power supply to

all three zones to be disconnected for 4 seconds to

reset any activated detectors.

The Display Board has Fire and Fault LEDs for

each of the zones.

The Display Board also provides User Controls for

disabling the monitoring of individual zones.

3.2 Manual Release Facility (MR &

Panel Mounted Call Point)

Two circuits are provided for operating the Manual

Release facility.

1. The fourth detection zone is used as a Manual

Release zone. It is monitored for Open Circuit

Fault, Short Circuit Fault and Alarm. The End-

Of-Line device is usually a 10k resistor but can

be configured for 3k9 resistor via a DIL switch

on the motherboard.

It gives a Second Stage alarm in both

automatic and manual modes, and initiates the

Extinguishant release sequence when

activated.

This zone must only have manually operated

devices connected to it e.g. Manual Call Points.

The power supply to this zone is not switched

off during panel Reset.

2. A Manual Release Call Point is mounted on the

door of the panel and is monitored by a

separate circuit for open & short circuit faults.

The connection for the call point is on the rear

of the display board.

The Display Board has Activated and Fault LEDs for

the Manual Release facility, common to both

circuits. Individual fault LEDs are provided on the

motherboard inside the panel.

The Manual Release facility can be disabled,

resulting in both circuits being disabled.

3.3 General Alarm Circuits (SNDR1 &

SNDR2)

Two fully monitored general alarm circuits are

provided. They are monitored for Open Circuit and

Short Circuit faults. They are rated at 0.5A

(electronically fused), 28VDC each. The End-Of-

Line device is a 10k resistor (3k9 can also be used).

The Fire Sounder Fault/Disabled LED on the display

flashes for any fault conditions on the General

Alarm Circuits. Individual fault LEDs are provided on

the motherboard inside the panel. Both circuits can

be disabled as a group.

Note: The circuits are reverse-polarity monitored.

The PCB terminals are marked for the active

polarity. Ensure that all connected devices are

polarised.

3.4 Extinguishing Alarm Circuit (EXT

SNDR)

One fully monitored extinguishing alarm circuit is

provided, monitored for Open Circuit and Short

Circuit faults. It is rated at 0.5A (electronically

fused), 28VDC. The End-Of-Line device is a 10k

resistor (3k9 can also be used).

The Circuit Fault LED on the display flashes for any

fault condition on the Extinguishing Alarm Circuit,

with an individual fault LED on the motherboard

inside the panel. The circuit can be disabled by

disabling the extinguishing system (the Actuators

are also disabled at the same time).

Note: The circuit is reverse-polarity monitored. The

PCB terminals are marked for the active polarity.

Ensure that all connected devices are polarised.

3.5 Actuator Circuits (ACT1 & ACT2)

Two fully monitored actuator circuits are provided.

They are monitored for Open Circuit and Short

Circuit faults (short circuit fault indication can be

disabled). They are rated at 1A (fused), 28VDC

each. The End-Of-Line device is a 10k resistor (3k9

can also be used).

The Circuit Fault LED on the display flashes for any

fault condition on either Actuator Circuit, with

individual fault LEDs on the motherboard inside the

panel. Both circuits can be disabled by disabling the

extinguishing system (the Extinguishing Alarm

circuit is also disabled at the same time).

Note: The circuits are reverse-polarity monitored.

The PCB terminals are marked for the active

polarity. Ensure that all connected devices are

polarised.

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 9 of 43

3.6 Repeater Outputs (Z1, Z2, AUX,

MR, OUTPUTS 1, 2, 3, 4, 5)

Each repeater output consists of an Open Collector

transistor driver capable of sinking up to 50mA. The

following outputs are provided:

Z1 –Zone 1 Fire

Z2 –Zone 2 Fire

AUX –Auxiliary Zone Fire

MR –Manual Release Activated

OUTPUT 1–Emergency Hold Activated

(configurable for auto & manual mode)

OUTPUT 2–Emergency Abort Activated

(configurable for manual only mode)

OUTPUT 3–Actuators (Extinguishing) Disabled

OUTPUT 4–Isolation Valve Closed

OUTPUT 5–Isolation Valve Abnormal

3.7 Auxiliary 24VDC Supply

The panel provides two auxiliary 24Vdc power

supply outputs for connection to ancillary

equipment:

1. (AUX 250mA: 24V, 0V) –This output is rated

at 250mA (electronically fused), 24 Volts D.C.

2. (AUX 1A: 24V, 0V) –This output is rated at 1A

(electronically fused), 24 Volts D.C.

3.8 Status Lamp Unit

The panel communicates with the Status Lamp

Units (SLU) via two-wire RS485 serial data. The

following indications can be provided, dependent on

SLU type:

1. Emergency Abort Activated

2. Emergency Hold Activated

3. Gas Released

4. Auto & Manual

5. Manual Only

6. Extinguishing Disabled

7. Local Fault

8. Seconds Remaining to Discharge (fully

functional SLU only)

The SLU can provide the following controls,

dependent on SLU type:

1. Manual Release

2. Emergency Abort

3. Emergency Hold

4. Auto & Manual / Manual Only

The controls on the SLU can be transmitted via the

serial data link or hard-wired via conventional

circuits on the panel (see 3.9 below).

3.9 Remote Inputs

3.9.1. Remote Controls

This is a fully monitored input, providing: open &

short circuit fault monitoring, Silence Alarms, Re-

sound Alarms and Panel Reset. The EOL device

is a 10k resistor.

3.9.2. Remote Sound Alarms:

Non-latching.

4k7 = activate general sounders.

When activated –steady „Remote Sound

Alarms‟indication and continuous operation of

general sounders.

When deactivated –„Remote Sound Alarms‟

indication clears and general sounders stop.

3.9.3. Remote Silence Alarms:

Single Operation.

1k8 = silence active sounders (silencing of

extinguishing sounders is inhibited until the

Discharged condition is active)

When activated –same operation as pressing

the Silence Alarms button.

When deactivated –no action

3.9.4. Remote Reset:

Single Operation.

560R = Reset Fire System & Extinguishing

System (reset of the extinguishing system can

be inhibited until the inhibit timer ends or Abort

is operated)

When activated –Resets all indications on the

Fire Alarm section of the panel. Only resets the

indications on the Extinguishing section of the

panel if the Reset Inhibit is inactive.

When deactivated –no action

3.9.5. Gas Trapped

This is a fully monitored input, providing open &

short circuit fault monitoring. The EOL device is a

10k resistor, activated by a 680R resistor.

Activation illuminates the GAS TRAPPED IN

MANIFOLD LED and raises the general fault

condition.

3.9.6. Auto/Manual Lock-Off Switch

(AUTO/MANUAL)

The Auto/Manual input is fully monitored for open

& short circuit faults. The End-Of-Line device is a

10k resistor, activated by a 4k7 resistor. In the

active state the panel is placed in Manual Only

mode and the yellow Manual Only LED on the

display board pulses. Operation of the

Auto/Manual button on the display board has no

effect while the input is active. The input allows for

the connection of Auto/Manual Lock-Off switches

on SLUs. Door Lock switches may also be

connected via terminals on the SLUs. The total

number of Auto/Manual switches & Door Lock

switches that can be connected is 14. This allows

for 7 SLUs, each with an auto/manual Keyswitch

and a door lock switch fitted. See the SLU

installation manual for more details.

3.9.7. Low Pressure Fault (GAS LOW)

This is a fully monitored input, providing open &

short circuit fault monitoring. The EOL device is a

10k resistor, activated by a 680R resistor.

Activation illuminates the GAS LOW LED and

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 10 of 43

raises the general fault condition. An open or short

circuit fault is indicated by the Circuit Fault LED on

the display and a Gas Low Fault LED on the

motherboard. The input is configurable for

normally open or normally closed operation via a

DIL switch on the motherboard.

3.9.8. Extinguishing Isolation Valve Status

(ISO. VALVE)

This is a fully monitored input, providing open &

short circuit fault monitoring. The EOL device is a

10k resistor, giving an „ISOLATION VALVE

ABNORMAL‟ indication. An open or short circuit

fault is indicated by the Circuit Fault LED on the

display and a Isolation Valve Fault LED on the

motherboard. Three states are possible on the

input:

1. Valve Closed:

Activated by a 680R resistor; flashing the

Valve Closed LED on the display board &

pulsing the internal buzzer.

2. Valve Open:

Activated by a 2k2 resistor; no indication is

given on the panel as this is the healthy state

for the input.

3. Valve Abnormal:

Activated by the 10k EOL resistor; flashing

the Valve Abnormal LED on the display board

& raising a general fault indication. A 2-

second delay is applied to the abnormal

condition to avoid momentary activation

during normal movement of the valve

between open and closed positions.

See Connection Diagram in section 12.3 for

details.

NOTE: The healthy state for the input is

VALVE OPEN and therefore, if the input is not

used, the input should have a 2k2 resistor

fitted.

3.9.9. Gas Released Pressure Switch (GAS

REL.)

This is a fully monitored input, providing open &

short circuit fault monitoring. The EOL device is a

10k resistor. An open or short circuit fault is

indicated by the Circuit Fault LED on the display

and a Gas Released Fault LED on the

motherboard. The input is activated by a 680R

resistor, illuminating the Gas Released LED on the

display, the Extinguishing sounder circuit, the Gas

Released Signal & all three shutdown outputs.

3.9.10. Emergency Hold (HOLD)

This is a fully monitored input, providing open &

short circuit fault monitoring. The EOL device is a

10k resistor. An open or short circuit fault is

indicated by the Circuit Fault LED on the display

and a Hold Fault LED on the motherboard. If a

fault occurs on the input during the Activated or

Discharged condition then the fault indication is

still given but the Hold Active LED is illuminated

steady and the Hold condition is established until

the fault is removed. This fault condition

prevents the Extinguishant release.

The input is activated by a 680R resistor,

illuminating the Emergency Hold Active LED on

the display and resetting & holding the pre-

discharge delay timer.

NOTE: If more than three Emergency Hold

switches connected to the Hold input are

operated simultaneously then a short circuit

fault will be detected. If this occurs while the

Pre-discharge timer is running, then the Timer

will still be reset and held until all switches are

released. Use only non-latching switches

which return to open contacts when the switch

is released.

NOTE: If a SLU with a Hold switch is

configured to transmit the Hold signal via the

serial communications path, a communication

fault on this path will initiate the Hold

condition, as described above, and the release

of extinguishant will be inhibited.

3.9.11. Emergency Abort Input (ABORT)

This is a fully monitored input, providing open &

short circuit fault monitoring. The EOL device is a

10k resistor. An open or short circuit fault is

indicated by the Circuit Fault LED on the display

and an Abort Fault LED on the motherboard. In

addition, the Abort Active LED will pulse if the

system is not in the Activated or Discharged

condition, clearing when the fault is cleared. If a

fault occurs on the input during the Activated or

Discharged condition then the fault indication is

still given but the Abort Active LED is illuminated

steady and the Abort condition is latched until

reset. This fault condition prevents the

Extinguishant release.

The input is activated by a 680R resistor,

illuminating the Emergency Abort Active LED on

the display and stopping the Extinguishant

release. The active abort condition is latched until

the input is cleared and the Extinguishing Reset

button is pressed.

NOTE: Use only LATCHING switches which

need to be manually returned to the OFF

position (this is a requirement of EN 12094-

1:2003 clause 4.27.2)

NOTE: If a SLU with an Abort switch is

configured to transmit the Abort signal via the

serial communications path, a communication

fault on this path will initiate the Abort

condition, as described above, and the release

of extinguishant will be aborted.

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 11 of 43

3.10 Relay Contacts

Other than the Auxiliary Reset Relay, all Relay

outputs can be configured as either powered and

monitored outputs or Volt-free relay contacts. The

factory default is powered and monitored outputs as

required by EN54-2:1997 & EN12094-1:2003.

3.10.1. First Stage Shutdown (1ST STAGE)

The First Stage Shutdown Relay is energised

when the panel enters the pre-activated condition.

This occurs when the panel is in the AUTOMATIC

& MANUAL mode and a fire occurs on zone 1 or

zone 2. The relay is also energised if the panel

enters the 2nd Stage or 3rd Stage condition (see

3.10.2 and 3.10.3).

A triple jumper link allows the output to be

powered and monitored (Link ON) or Volt-Free

(Link OFF).

In the Monitored mode, an open or short circuit

fault on the field wiring illuminates the Circuit Fault

LED on the display and the 1st Stage Shutdown

Fault LED on the motherboard.

In the Volt-free mode, clean contacts for Pole,

Normally Open & Normally Closed are available,

rated at 1A, 30VDC.

3.10.2. Second Stage Shutdown (2ND

STAGE)

The Second Stage Shutdown Relay is energised

when the panel enters the activated condition.

This occurs when the panel is in the AUTOMATIC

& MANUAL mode and a fire occurs on zone 1 and

zone 2, or the Manual Release is operated (in

Auto or Manual mode). The relay is also energised

if the panel enters the 3rd Stage condition (see

3.10.3).

A triple jumper link allows the output to be

powered and monitored (Link ON) or Volt-Free

(Link OFF).

In the Monitored mode, an open or short circuit

fault on the field wiring illuminates the Circuit Fault

LED on the display and the 2nd Stage Shutdown

Fault LED on the motherboard.

In the Volt-free mode, clean contacts for Pole,

Normally Open & Normally Closed are available,

rated at 1A, 30VDC.

3.10.3. Third Stage Shutdown (3RD STAGE)

The Third Stage Shutdown Relay is energised

when the pre-discharge delay timer ends & the

actuator circuits are operated. The relay is also

energised if the panel enters the discharged

condition due to operation of the Gas Released

Pressure Switch input (see 3.10.4).

A triple jumper link allows the output to be

powered and monitored (Link ON) or Volt-Free

(Link OFF).

In the Monitored mode, an open or short circuit

fault on the field wiring illuminates the Circuit Fault

LED on the display and the 3rd Stage Shutdown

Fault LED on the motherboard.

In the Volt-free mode, clean contacts for Pole,

Normally Open & Normally Closed are available,

rated at 1A, 30VDC.

3.10.4. Gas Discharged (GAS REL SIG)

The Gas Discharged Relay is energised when the

Gas Released Pressure Switch input is activated,

or when the actuator circuits are operated if the

panel is configured for NO PRESSURE SWITCH.

A triple jumper link allows the output to be

powered and monitored (Link ON) or Volt-Free

(Link OFF).

In the Monitored mode, an open or short circuit

fault on the field wiring illuminates the Circuit Fault

LED on the display and the Gas Released signal

Fault LED on the motherboard.

In the Volt-free mode, clean contacts for Pole,

Normally Open & Normally Closed are available,

rated at 1A, 30VDC.

3.10.5. Fire Signal (FIRE SIG)

The Fire Signal Relay is energised when zones 1,

2 or Aux zone detect a fire condition.

A triple jumper link allows the output to be

powered and monitored (Link ON) or Volt-Free

(Link OFF).

In the Monitored mode, an open or short circuit

fault on the field wiring illuminates the Fire Signal

Fault LED on the display.

In the Volt-free mode, clean contacts for Pole,

Normally Open & Normally Closed are available,

rated at 1A, 30VDC.

3.10.6. Fault Signal (FAULT SIG)

The Fault Signal Relay is a fail-safe relay and is

normally energised. It is de-energised for any fault

condition on the panel.

A triple jumper link allows the output to be

powered and monitored (Link ON) or Volt-Free

(Link OFF).

In the Monitored mode, an open or short circuit

fault on the field wiring illuminates the Fault Signal

Fault LED on the display.

In the Volt-free mode, clean contacts for Pole,

Normally Open & Normally Closed are available,

rated at 1A, 30VDC.

3.10.7. Auxiliary Reset (RESET)

The Auxiliary Reset Relay is a single pole change-

over relay and is energised briefly when the panel

is in Fire Reset mode. The relay is energised for

10 seconds. This is to allow ancillary equipment

such as Beam Detectors to be reset. The relay

has no powered and monitored mode and only

volt-free contacts for Pole, Normally Open &

Normally Closed are available, rated at 1A,

30VDC.

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 12 of 43

3.11 Internal Standby Batteries

Terminals are provided to allow connection of one

set of internal standby batteries. The Charger

Circuit is monitored for the following:

Battery or associated wiring disconnected.

Battery fuse blown

Low battery voltage (<15.7V ±0.4V)

Battery and interconnection resistance is 0.35Ω

or higher.

3.12 Function Enable/Disable

Switches

Two sets of DIL switches and one jumper link are

available on the motherboard to allow the panel to

be configured for additional site-specific functions:

3.12.1. Function Select Switch

12 3 4 5

ON

CONFIG I/S INPUTS

PRE-DISCHARGE DELAY 5S

PRE-DISCHARGE DELAY 10S

SW1

7 8 9 10 11 126

PRE-DISCHARGE DELAY 20S

PRE-DISCHARGE DELAY 40S

SILENT ZONE TEST

BUZZER DISABLE

LATCHED FAULTS

INSTANT MANUAL RELEASE

BUZZER PULSES AT END OF DELAY

ZONES 1 & 2 SINGLE KNOCK

NO DISCHARGE PRESSURE SWITCH

SW2

12 3 4 5

ON

ACTUATOR S/C DISABLE

1 MIN

2 MIN

7 8 9 10 11 126

4 MIN

8 MIN

16 MIN

CLEAR ACTUATORS AFTER 1 MIN

SILENCE ALARMS BEFORE RESET

OUTPUT 1-AUTO, 2-MANUAL

CONFIG SLU

3K9 EOL

N/C GAS LOW I/P

RESET

INHIBIT

PERIOD

This consists of two sets of 12-way DIL switches,

providing the following options:

3.12.1.1. CONFIG I/S INPUTS

When in the ON position, enables zones 1, 2,

Aux zone and Manual Release input to be

individually configured for standard or

intrinsically safe monitoring. The circuits need to

be configured for I/S monitoring if Galvanic

Isolators or Zener Barriers are connected. I/S

zones will then be monitored for a 10k EOL

resistor and different monitoring limits due to the

I/S barrier/isolator series load. See section 4.2.2

for configuration details.

3.12.1.2. PRE-DISCHARGE DELAY (5S, 10S,

20S, 40S)

These four switches allow the Pre-discharge

delay timer to be configured from 0 to 60

seconds in 5-second increments. Any of the four

switches in the ON position adds to the delay

value, up to a maximum of 60 seconds.

Delay

Length

(Seconds)

SW1-2

(5S)

SW1-3

(10S)

SW1-4

(20S)

SW1-5

(40S)

0

OFF

OFF

OFF

OFF

5

ON

OFF

OFF

OFF

10

OFF

ON

OFF

OFF

15

ON

ON

OFF

OFF

20

OFF

OFF

ON

OFF

25

ON

OFF

ON

OFF

30

OFF

ON

ON

OFF

35

ON

ON

ON

OFF

40

OFF

OFF

OFF

ON

45

ON

OFF

OFF

ON

50

OFF

ON

OFF

ON

55

ON

ON

OFF

ON

60

N/A

N/A

ON

ON

3.12.1.3. SILENT ZONE TEST

Switch OFF:- A fire alarm on any zone in Test

Mode will operate the appropriate zonal fire

indicator and the general sounder circuits for

four seconds.

Switch ON:- A fire alarm on any zone in Test

Mode will operate the appropriate zonal fire

indicator but will NOT operate the general

sounder circuits.

3.12.1.4. BUZZER DISABLE

Switch OFF:- The internal buzzer operates for

any fire, fault or display button operation.

Switch ON:- The internal buzzer only operates

on operation of any display button.

Note: This is not compliant with EN54-2 or

EN12094-1. Provided for commissioning

purposes only.

3.12.1.5. LATCHED FAULTS

Switch OFF:- All fault indications are non-

latching and clear once the fault clears.

Switch ON:- All fault indications are latching and

require a manual reset via the FIRE RESET

and/or EXTINGUISHING SYSTYEM RESET

buttons.

3.12.1.6. INSTANT MANUAL RELEASE

Switch OFF:- Operation of Manual Release

starts the Pre-discharge delay timer.

Switch ON:- Operation of Manual Release

bypasses the Pre-discharge delay timer &

operates the actuator circuits immediately.

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 13 of 43

3.12.1.7. BUZZER PULSES AT END OF

DELAY

Switch OFF:- No change in the state of the

internal buzzer during the last five seconds of

the Pre-discharge delay timer.

Switch ON:- The internal buzzer pulses during

the last five seconds of the Pre-discharge

delay timer.

3.12.1.8. ZONES 1 & 2 SINGLE KNOCK

Switch OFF:- If the system is set to Auto &

Manual mode, a fire condition on both zones

1 & 2 is required to start the pre-discharge

delay timer.

Switch ON:- If the system is set to Auto &

Manual mode, a fire condition on either zone

1 or zone 2 will start the pre-discharge delay

timer.

3.12.1.9. NO DISCHARGE PRESSURE

SWITCH

Switch OFF:- The Panel only indicates SYSTEM

DISCHARGED when the GAS REL. input is

activated (via a Discharge Pressure switch).

Switch ON:- The panel indicates SYSTEM

DISCHARGED as soon as the actuator

circuits are activated.

3.12.1.10. ACTUATOR S/C DISABLE

Switch OFF:- The actuator circuits are monitored

for open & short circuit faults.

Switch ON:- The actuator circuits are only

monitored for open circuit faults. Used for

open-circuit fault monitoring of the solenoid

coil without a series end-of-line resistor.

3.12.1.11. RESET INHIBIT PERIOD

Five switches allow the Extinguishing System

Reset Inhibit timer to be configured from 0 to 30

minutes in 1-minute increments. Any of the five

switches in the ON position adds to the timer

value, up to a maximum of 30 minutes. See

Table 1.

3.12.1.12. CLEAR ACTUATORS AFTER 1 MIN

Switch OFF:- The actuator circuits are energised

until the Extinguishing System is reset.

Switch ON:- The actuator circuits are only

energised for 1 minute and then are de-

energised.

NOTE:

This facility is only to be used where the

actuators connected to the actuator circuits

remain activated when the power is

removed and require manual resetting. This

facility is not intended to control the gas

discharge period. It is only provided as a

means to reduce current consumption

during gas discharge.

Table 1 –Reset Inhibit Settings

Reset

Inhibit

Length

(minutes)

SW2-2

(1min)

SW2-3

(2min)

SW2-4

(4min)

SW2-5

(8min)

SW2-6

(16min)

0

OFF

OFF

OFF

OFF

OFF

1

ON

OFF

OFF

OFF

OFF

2

OFF

ON

OFF

OFF

OFF

3

ON

ON

OFF

OFF

OFF

4

OFF

OFF

ON

OFF

OFF

5

ON

OFF

ON

OFF

OFF

6

OFF

ON

ON

OFF

OFF

7

ON

ON

ON

OFF

OFF

8

OFF

OFF

OFF

ON

OFF

9

ON

OFF

OFF

ON

OFF

10

OFF

ON

OFF

ON

OFF

11

ON

ON

OFF

ON

OFF

12

OFF

OFF

ON

ON

OFF

13

ON

OFF

ON

ON

OFF

14

OFF

ON

ON

ON

OFF

15

ON

ON

ON

ON

OFF

16

OFF

OFF

OFF

OFF

ON

17

ON

OFF

OFF

OFF

ON

18

OFF

ON

OFF

OFF

ON

19

ON

ON

OFF

OFF

ON

20

OFF

OFF

ON

OFF

ON

21

ON

OFF

ON

OFF

ON

22

OFF

ON

ON

OFF

ON

23

ON

ON

ON

OFF

ON

24

OFF

OFF

OFF

ON

ON

25

ON

OFF

OFF

ON

ON

26

OFF

ON

OFF

ON

ON

27

ON

ON

OFF

ON

ON

28

OFF

OFF

ON

ON

ON

29

ON

OFF

ON

ON

ON

30

OFF

ON

ON

ON

ON

30

ON

ON

ON

ON

ON

3.12.1.13. SILENCE ALARMS BEFORE

RESET

Switch OFF:- The panel can be reset from the

alarm condition without first silencing the

alarms. (A requirement of EN54-2)

Switch ON:- The panel cannot be reset from the

alarm condition until the alarms have been

silenced. (A recommendation of BS5839).

3.12.1.14. AUTO/MANUAL OUTPUTS

Switch OFF:- Open Collector Output 1 operates

on Emergency Hold Active. Open Collector

Output 2 operates on Emergency Abort

Active.

Switch ON:- Open Collector Output 1 operates

when panel is in AUTO & MANUAL mode.

Open Collector Output 2 operates when

panel is in MANUAL ONLY mode.

3.12.1.15. CONFIG SLU

When in the ON position, allows the type code of

any connected SLUs to be configured on the

panel. See section 4.2.3 for configuration details.

3.12.1.16. 3k9 EOL

When in the ON position, zones 1, 2, Aux Zone

& Manual Release are monitored for a 3k9 End-

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 14 of 43

Of-Line device. Allows backward compatibility

when replacing older systems with this panel.

3.12.1.17. N/C LOW PRESSURE I/P

Switch OFF:- The Gas Low input monitors a

normally open switch, i.e. activated by a 680R

resistor.

Switch ON:- The Gas Low input monitors a

normally closed switch i.e. activated by

disconnection of the 680R resistor.

3.12.2. Link For Earth Fault Monitoring

This is a single jumper link located at the bottom

right of the control board (J22). When present, it

allows the panel to monitor for earth faults on the

cables coming into the panel. If this link is

REMOVED, it physically isolates the internal

control board from earth, thus disabling the

external earth fault monitoring facility.

3.13 Fault LEDs

SHUTDOWN 3 FAULT

SHUTDOWN 2 FAULT

SHUTDOWN 1 FAULT

ACTUATOR 2 FAULT

ACTUATOR 1 FAULT

EXT SNDER FAULT

SNDER 2 FAULT

SNDER 1 FAULT

AUTO/MAN FAULT

FIELD MR FAULT

PANEL MR FAULT

SLU FAULT

ABORT FAULT

HOLD FAULT

GAS TRAPPED FLT

ISOLATION VALVE FLT

GAS LOW FAULT

GAS RELEASED FLT

CONFIG ON

GAS SIGNAL FLT

MAINS FAULT

BATT/CHARGE FAULT

Twenty-two yellow LEDs are mounted on the control

board to indicate the following faults:

SHUTDOWN 3

FAULT

Illuminates for an open or short

circuit fault on the 3rd Stage

monitored Output.

SHUTDOWN 2

FAULT

Illuminates for an open or short

circuit fault on the 2nd Stage

monitored Output.

SHUTDOWN 1

FAULT

Illuminates for an open or short

circuit fault on the 1st Stage

monitored Output.

ACTUATOR 2

FAULT

Illuminates for an open or short

circuit fault on the Actuator 2

Output.

ACTUATOR 1

FAULT

Illuminates for an open or short

circuit fault on the Actuator 1

Output.

EXT SNDER

FAULT

Illuminates for an open or short

circuit fault on the Extinguishing

Sounder Output.

SNDER 2

FAULT

Illuminates for an open or short

circuit fault on the General Sounder

2 Output.

SNDER 1

FAULT

Illuminates for an open or short

circuit fault on the General Sounder

1 Output.

AUTO/MAN

FAULT

Illuminates for any open or short

circuit fault on the Auto/Manual

Input.

FIELD MR

FAULT

Illuminates for any open or short

circuit fault on the Manual Release

Zone Input.

PANEL MR

FAULT

Illuminates for any open or short

circuit fault on the Panel Mounted

Manual Release.

ABORT FAULT

Illuminates for any open or short

circuit fault on the Emergency Abort

input.

HOLD FAULT

Illuminates for any open or short

circuit fault on the Emergency Hold

input.

GAS TRAPPED

FLT

Illuminates for any open or short

circuit fault on the Gas Trapped

input.

ISOLATION

VALVE FLT

Illuminates for any open or short

circuit fault on the Isolation Valve

input.

GAS LOW

FAULT

Illuminates for any open or short

circuit fault on the Gas Low input.

GAS

RELEASED FLT

Illuminates for any open or short

circuit fault on the Gas Released

input.

SLU FAULT

Illuminates for a fault on any Status

Lamp Unit.

CONFIG ON

Illuminates when either the CONFIG

I/S INPUTS or the CONFIG SLU

DIL switch is in the ON position. It

indicates that the EEPROM on

control board is write-enabled.

GAS SIGNAL

FLT

Illuminates for any open or short

circuit fault on the Gas Released

Signal output.

MAINS FAULT

Illuminates if the AC mains input

voltage to the power supply is lost

or is less than the required

minimum for correct operation of the

power supply.

BATT/CHARGE

FAULT

Illuminates for any of the faults

described in section 3.11.

The General Fault LED on the Display board also

pulses for any of the above faults.

3.14 Internal Buzzer

The internal buzzer provides an audible indication to

compliment the visual indications provided via the

LEDs on the panel. The buzzer has various modes

as follows:

1. Fault Indication - Pulse, 1 second On, 3

seconds OFF

The buzzer can be silenced.

2. Alarm Indication –Pulse, 1 second On, 1

second OFF

The buzzer can be silenced.

3. Buzzer Pulse End Of Delay - Pulse, ½

second On, ½ second OFF (Optional)

The buzzer cannot be silenced.

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 15 of 43

3.15 Display Board –General

The Display board is connected to the internal

control board via a 16-way ribbon cable and

polarised ribbon socket. A polarised 16-way header

is provided on the main control board at position J1.

The Display is divided into three windows for clarity.

User Controls are positioned in the central window,

with status LEDs in the left & right windows.

The left window displays the status of the Fire Alarm

section of the panel, as well as indications which

are common to both the Fire Alarm section and the

Extinguishing section. The right window is dedicated

to displaying the status of the Extinguishing section

of the panel. See Figure 5 for details.

Figure 5 –Display

FIRE STATUS

COMMON STATUS

USER CONTROLS EXTINGUISHING STATUS

FIRE

FIRE SIGNAL

ZONE 1

ZONE 2

AUX ZONE

REMOTE SOUND ALARMS

REMOTE CONTROLS FAULT

FIRE SOUNDER FAULT/DISABLED

POWER SUPPLY ON

GENERAL FAULT

POWER SUPPLY FAULT

SYSTEM FAULT

EARTH FAULT

FUSE FAILED

FAULT SIGNAL FAULT/DISABLED

SOUNDER TEST

AUTO & MANUAL

MANUAL ONLY

MANUAL RELEASE ACTIVE

SYSTEM ACTIVATED

GAS RELEASED

GAS RELEASED SIGNAL ACTIVE

EMERGENCY ABORT ACTIVE

EMERGENCY HOLD ACTIVE

CIRCUIT FAULT

GAS LOW

GAS TRAPPED IN MANIFOLD

ISOLATION VALVE ABNORMAL

ISOLATION VALVE CLOSED

MANUAL RELEASE FAULT/DISABLED

EXTINGUISHING DISABLED

GAS RELEASED SIGNAL DISABLED

SHUTDOWN OUTPUTS DISABLED

SECONDS

TO

DISCHARGE

SILENCE

ALARMS

FIRE

RESET

SILENCE

BUZZER

SELECT

ON/OFF

SCROLL

OFF

ACCESS

CONTROLS

ON

TEST

DISABLE

ENABLE

AUTO & MAN/

MANUAL ONLY

EXTINGUISHING

SYSTEM RESET

(INHIBITED)

RESOUND

ALARMS

3.16 Display Board –Fire Status

Indications

3.16.1. FIRE

These two red LEDs are normally off, pulsing for a

fire alarm on zones 1, 2, or aux zone. The LEDs

are illuminated steady if the general sounders are

silenced during the fire alarm.

3.16.2. FIRE SIGNAL

The Fire Signal output status is displayed by two

LEDs.

The red LED is normally off, illuminating steady

when the Fire Signal output is active.

The yellow LED is normally off, pulsing for an

open or short circuit fault on the Fire Signal

output. The LED is illuminated steady if the Fire

Signal output is disabled.

3.16.3. ZONE 1

The Zone 1 input status is displayed by two LEDs.

The red LED is normally off, pulsing if a fire

condition is detected on zone 1, illuminating

steady when the alarm is accepted (by operation

of the Silence Alarms button).

The yellow LED is normally off, pulsing for an

open or short circuit fault on the Zone 1 input.

The LED is illuminated steady if the Zone 1 input

is disabled or selected to the Test mode.

3.16.4. ZONE 2

The Zone 2 input status is displayed by two LEDs.

The red LED is normally off, pulsing if a fire

condition is detected on zone 2, illuminating

steady when the alarm is accepted (by operation

of the Silence Alarms button).

The yellow LED is normally off, pulsing for an

open or short circuit fault on the Zone 2 input.

The LED is illuminated steady if the Zone 2 input

is disabled or selected to the Test mode.

3.16.5. AUX ZONE

The Aux Zone input status is displayed by two

LEDs.

The red LED is normally off, pulsing if a fire

condition is detected on the aux zone,

illuminating steady when the alarm is accepted

(by operation of the Silence Alarms button).

The yellow LED is normally off, pulsing for an

open or short circuit fault on the aux zone input.

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 16 of 43

The LED is illuminated steady if the aux zone

input is disabled or selected to the Test mode.

3.16.6. REMOTE SOUND ALARMS

The REMOTE CONTROLS input status is

displayed by two LEDs.

The red LED is normally off, illuminating steady

when the input registers a Sound Alarms.

The yellow LED is normally off, pulsing for an

open or short circuit fault on the Remote

Controls input.

3.16.7. FIRE SOUNDER FAULT/DISABLED

This is a yellow LED which is normally off, pulsing

for an open or short circuit on either of the general

sounder circuits, illuminating steady when the

general sounder circuits are disabled. A separate

fault LED for each sounder circuit is also provided

on the control board inside the panel.

3.17 Display Board –Common Status

Indications

3.17.1. POWER SUPPLY ON

This is a green LED which is illuminated steady as

long as there is a supply of power to the panel.

3.17.2. GENERAL FAULT

This is a yellow LED that is normally OFF. The

LED pulses for any fault on the panel.

3.17.3. POWER SUPPLY FAULT

This is a yellow LED that is normally OFF. The

LED pulses if there is a mains or battery failure.

3.17.4. SYSTEM FAULT

This is a yellow LED that is normally OFF. The

LED pulses if the CONFIG I/S INPUTS or

CONFIG SLU DIL switch is in the ON position.

The LED is steady if the microprocessor fails to

execute the software correctly or an internal

memory corruption is detected.

Note: The system is completely non-

functional and alternative fire detection

measures should be implemented.

3.17.5. EARTH FAULT

This is a yellow LED that is normally OFF. The

LED pulses if there is a low resistance to earth on

any of the field cables.

3.17.6. FUSE FAILED

This is a yellow LED that is normally OFF. The

LED pulses if either of the electronic fuses on the

two auxiliary 24V supply outputs are activated due

to excessive loading.

3.17.7. FAULT SIGNAL FAULT/DISABLED

The is a yellow LED which is normally off, pulsing

for an open or short circuit fault on the Fault Signal

output. The LED is illuminated steady if the Fault

Signal output is disabled.

3.17.8. SOUNDER TEST

This is a yellow LED which is normally off,

illuminating steady when the three sounder circuits

are in the TEST mode.

3.18 Display Board –Extinguishing

Status Indications

3.18.1. AUTO & MANUAL

This is a yellow LED that is illuminated steady if

the actuators can be operated both automatically

(via a fire alarm on zones 1 & 2) and manually (via

manual release).

3.18.2. MANUAL ONLY

This is a yellow LED that is illuminated steady if

the actuators can only be operated manually (via

manual release). The LED pulses if an

AUTO/MANUAL switch in the field is set to Manual

3.18.3. MANUAL RELEASE ACTIVE

This is a red LED that is normally off, pulsing if

manual release is activated either by operation of

the Manual Release Call Point on the front of the

panel or via the operation of a manual release unit

connected to the Manual Release Zone input. The

indication becomes steady when the panel is in

the Alarm Silenced condition.

3.18.4. SYSTEM ACTIVATED

This is a red LED that is normally OFF, pulsing

during the pre-activated condition (1st Stage),

illuminating steady during the activated condition

(2nd Stage). The LED remains illuminated until the

Extinguishing System is reset.

3.18.5. GAS RELEASED

This is a red LED that is normally OFF. It is

illuminated steady when the panel is in the Gas

Released condition. This normally occurs when

the GAS RELEASED input is activated, but can be

configured to occur as soon as the actuator

circuits are energised (via the NO DISCHARGE

PRESSURE SWITCH DIL switch). The LED

remains illuminated until the Extinguishing System

is reset.

3.18.6. GAS RELEASED SIGNAL ACTIVE

This is a red LED which is normally off. It is

illuminated steady when the Gas Released output

is active.

3.18.7. EMERGENCY ABORT ACTIVE

This is a yellow LED that is normally OFF. It

indicates that the release of extinguishing gas has

been aborted. The LED pulses if a fault occurs on

the Abort input when the Extinguishing System is

not in the pre-activated or activated conditions (a

separate fault LED is also provided on the control

board). The pulsed indication is non-latching and

clears when the fault clears. The LED is

illuminated steady If the Abort input is activated (at

any time), or a fault occurs on the input during the

pre-activated or activated conditions. The

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 17 of 43

indication is latching and must be manually reset

via the Extinguishing Reset button.

3.18.8. EMERGENCY HOLD ACTIVE

This is a yellow LED that is normally OFF. It

indicates that the pre-discharge delay timer has

been reset & held (therefore the release of the

extinguishing gas has been suspended). The LED

pulses if the Hold input is active when the pre-

discharge delay timer is not running. The LED is

illuminated steady if the Hold input is activated or

a fault occurs on the input during the pre-

discharge delay timer running. The pulsed &

steady indications are non-latching and clear when

the input clears.

3.18.9. CIRCUIT FAULT

This is a yellow LED that is normally OFF. It

pulses to indicate that one of the circuits related to

the Extinguishing system has an open or short

circuit fault. A separate LED on the control board

inside the panel will indicate which circuit is in

fault.

3.18.10. GAS LOW

This is a yellow LED which is normally OFF. It

pulses while the Gas Low input is active, clearing

when the input is cleared.

3.18.11. GAS TRAPPED IN MANIFOLD

This is a yellow LED which is normally OFF. It

pulses while the Gas Trapped input is active,

clearing when the input is cleared.

3.18.12. ISOLATION VALVE ABNORMAL

This is a yellow LED which is normally OFF. It

pulses while the Isolation Valve monitors an

abnormal value (nominally 10k load), to indicate

valve stuck between open & closed, clearing when

the input is cleared.

3.18.13. ISOLATION VALVE CLOSED

This is a yellow LED which is normally OFF. It

pulses while the Isolation Valve monitors a Closed

value (nominally 680R load), clearing when the

input is cleared.

3.18.14. MANUAL RELEASE

FAULT/DISABLED

This is a yellow LED which is normally OFF. It

pulses if the Manual Release zone input is in fault

or the internal circuit to the door mounted Manual

Release is in fault, clearing when the fault is

cleared. A separate fault LED for each circuit is

also illuminated on the internal control board. The

Manual Release Fault/Disabled LED is illuminated

steady when the Manual Release facility is

disabled.

3.18.15. EXTINGUISHING DISABLED

This is a yellow LED which is normally OFF. It is

illuminated steady when the Actuators are

disabled. [Note: When the actuators are disabled

the Extinguishing Sounder circuit is automatically

disabled].

3.18.16. GAS RELEASED SIGNAL DISABLED

This is a yellow LED which is normally OFF. It is

illuminated steady when the Gas Released Signal

output is disabled.

3.18.17. SHUTDOWN OUTPUTS DISABLED

This is a yellow LED which is normally OFF. It is

illuminated steady when the shutdown outputs are

disabled. [All three 1st Stage, 2nd Stage & 3rd Stage

shutdown outputs are disabled together].

3.18.18. SECONDS TO DISCHARGE

This is a 2-digit numeric display. It is normally

blank. When the pre-discharge timer is running,

the remaining seconds left to discharge are

displayed.

In CONFIG SLU mode, the 2-digit display allows

the SLU type codes to be programmed into the

panel (see section 4.2.3).

3.19 Display Board - User Controls

The Display Board provides user controls via

buttons behind the membrane of the display board.

All buttons except for TEST (for Test Display) are

disabled until the ACCESS CONTROLS key-switch

is rotated to the ON position.

The panel acknowledges a button press by

sounding the internal buzzer briefly.

The following controls are available:

3.19.1. SILENCE ALARMS

This button silences the general sounder circuits

and/or silences the extinguishing sounder circuit

when possible. Silencing of the extinguishing

sounder circuit is inhibited until the panel enters

the Gas Released condition or the Abort input is

activated.

The attached yellow LED is normally OFF. It

pulses when it is possible to silence any of the

sounder circuits and is illuminated steady to

indicate silenceable sounder circuits have been

silenced.

3.19.2. RESOUND ALARMS

This button allows previously silenced alarm

circuits to be resounded.

3.19.3. FIRE RESET

This button controls the resetting of fault and fire

conditions on the Fire Alarm section of the panel.

Faults common to the Fire section & the

Extinguishing section can also be reset with this

button.

3.19.4. EXTINGUISHING RESET

This button controls the resetting of fault and

active conditions on the Extinguishing section of

the panel. Faults common to the Fire section & the

Extinguishing section can also be reset with this

button. The resetting of the Extinguishing system

can be inhibited up to 30 minutes once the

extinguishing system has been activated and the

accompanying yellow LED is illuminated steady to

EQUIPMENT: FIRECLASS Prescient III WRITTEN BY: RKP

PUBLICATION: OMFCPRES3IN CHECKED BY: AP

ISSUE No. & DATE: 0 02/02/12

PAGE 18 of 43

indicate that the Extinguishing System Reset is

inhibited.

3.19.5. SILENCE BUZZER

This button silences the internal buzzer during any

fault or alarm condition. The accompanying yellow

LED is illuminated steady to indicate that the

buzzer has been silenced. Any new fault or alarm

will restart the buzzer and clear the LED.

3.19.6. AUTO & MANUAL / MANUAL ONLY

This button toggles the panel status between

(Automatic & Manual) and (Manual Only) modes.

If any Field Auto/Manual switch is in the Manual

Only position, then this button has no effect (the

Manual Only LED will be flashing).

3.19.7. SELECT ON/OFF

This button toggles the Circuit Select Cursor On

and OFF. See section 4.2 for more details.

3.19.8. ENABLE

This button has no function unless the Circuit

Select Cursor is ON. Depending on the current

mode, operation of the button can re-enable a

previously disabled circuit, set a zone for

intrinsically safe operation or move the cursor

between SLU number and SLU type code digits.

See section 4.2 for details.

3.19.9. DISABLE

This button has no function unless the Circuit

Select Cursor is ON. Depending on the current

mode, operation of the button can disable a circuit

or clear a zone from intrinsically safe operation.

See section 4.2 for details.

3.19.10. TEST

When the Circuit Select Cursor is OFF this button

operates the Test Display feature, sounding the

internal buzzer and illuminating all the LEDs on

the Display and internal control board for five

seconds. When the Circuit Select Cursor is ON,

depending on the current mode, operation of the

button can place the selected circuit into test

mode. See section 4.2 for details.

NOTE: Important safety feature:

When either zone 1 or zone 2 is placed into the

Test mode, the panel will automatically set both

zone 1 & zone 2 into test mode (see Table 2).

The panel display will show that BOTH zone 1 &

2 are in the Test mode. The Test mode for

zones 1 & 2 is linked because the zones are

usually used as coincidence detection zones

covering the same area. Testing detectors on

either zone 1 or zone 2 could inadvertently

activate detectors on the other zone.

The clearing of the Test mode is not linked, i.e.

each zone is individually removed from the

TEST mode. This allows the engineer to test

each zone individually if desired (as required by

EN54-2:1997 clause 10.1 (c)).

3.19.11. SCROLL

This button has no function unless the Circuit