Page 3 of 6

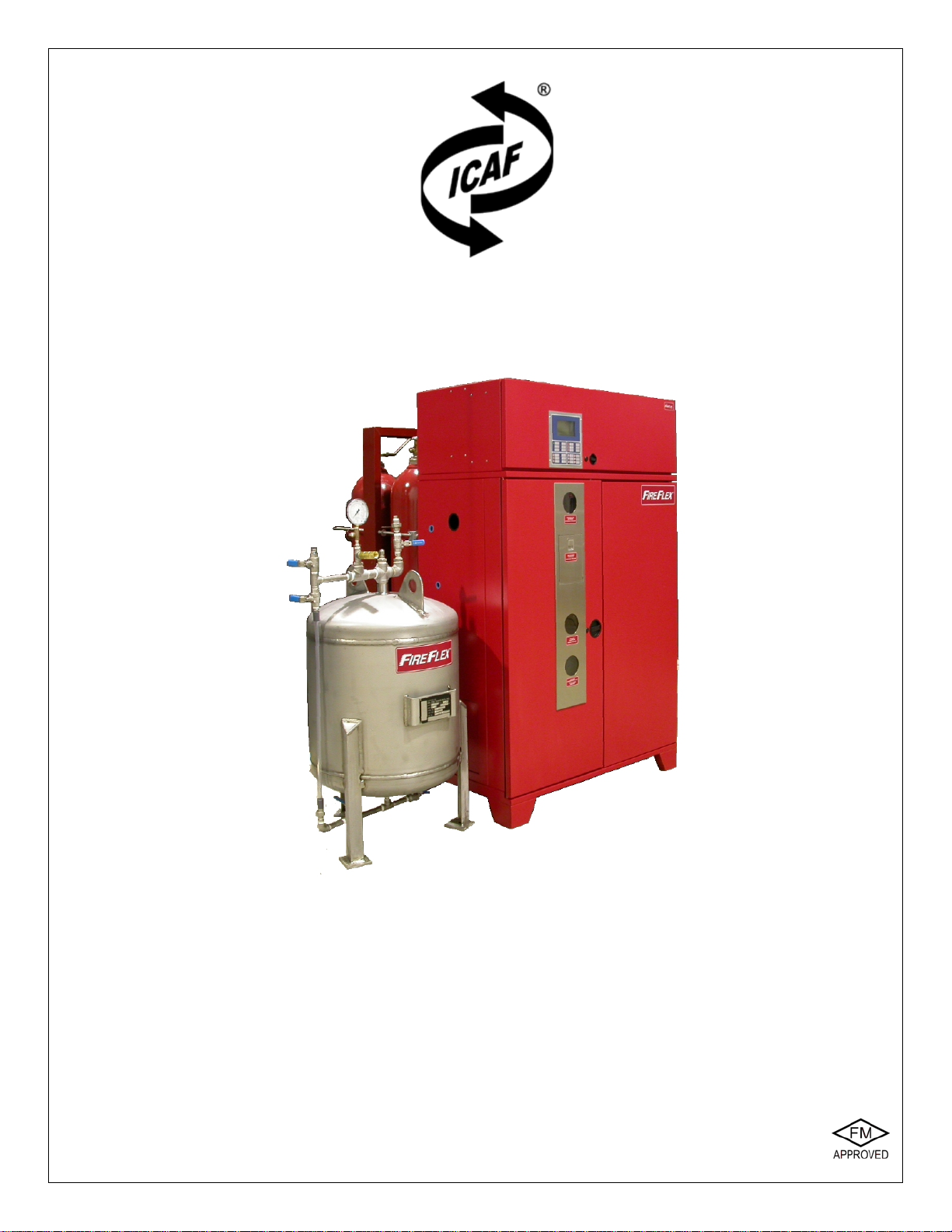

Integrated Compressed Air Foam System

A

General Section

FM-0723-0-7H

Foam Supply

Foam concentrate is stored inside a stainless steel pressure

vessel type tank as described in the FOAM SUPPLY

SECTION G .

There are two interconnection lines provided on all foam

storage tanks. One connection is used to pressurize the

foam storage tank with compressed air

3

on alarm

condition, the other to provide foam concentrate to the mixing

chamber

2

. Piping between the foam storage tank and the

ICAF system is factory prepared according to the installation

arrangement and is supplied with the system.

System Supervision

Refer to MECHANICAL OPERATION SECTION E TRIM SCHEMATIC

and AIR SUPPLY SECTION F .

The release control panel supervises the air and water

supplies to insure system's reliability at all times.

A high pressure sensor (V7) is provided to supervise cylinder

bank pressure. The intent of this device is to provide a

supervisory signal if the cylinder bank pressure goes under

the minimum pressure required to provide air supply for the

specified discharge time. A cylinder bank pressure under

2200 psi (15,168 kPa) will cause the control panel to go into

supervisory condition.

An alarm pressure switch (B10) is provided with an alarm test

valve (B5). The alarm pressure switch is operated through

the system's water alarm line when the system is discharged.

System actuation, manual or automatic, will cause the control

panel to go into alarm and water flow conditions.

The main control valve (B1) is supervised from abnormal

position by an integrated supervisory switch. The

supervisory switch supervises the valve in an open position

and will cause the control panel to go into supervisory

condition in case the main control valve is not at fully open

position.

Release Systems

Refer to MECHANICAL OPERATION SECTION E TRIM SCHEMATIC.

The system can be activated manually, electrically using

solenoid valve or pneumatically using a pilot line. When

electrically activated, the release solenoid valve is controlled

by a release control panel listed for releasing and compatible

with the solenoid valve.

អ

អអ

អElectric Failsafe Release

Electrically controlled ICAF system is equipped with a

three-way solenoid valve (R2) controlled by the release

control panel, and requires external detection devices

(refer to INSTALLATION AND OPERATION MANUAL of the

release control panel for list of compatible devices).

In fire condition, when the detection condition is satisfied,

the release control panel energizes the three-way

solenoid valve (R2). The pneumatic control line is then

pressurized, causing the pneumatically activated control

valves for water (B7), air (A1) and foam (F1) to open

simultaneously, generating CAF through a piping system

into the discharge devices covering the protected area.

The CAF discharge is maintained if the AC power fails

and the battery backup expires while the system is

operating, and continue flowing until AC power is restored

or the system is manually shut-off.

អ

អអ

អElectric Release

Electrically controlled ICAF system is equipped with a

three-way solenoid valve (R2) controlled by the release

control panel and requires external detection devices

(refer to INSTALLATION AND OPERATION MANUAL of the

release control panel for list of compatible devices).

In fire condition, when the detection condition is satisfied,

the release control panel energizes the three-way

solenoid valve (R2). The pneumatic control line is then

pressurized, causing the pneumatically activated control

valves for water (B7), air (A1) and foam (F1) to open

simultaneously, generating CAF through a piping system

into the discharge devices covering the protected area.

អ

អអ

អPneumatic Release

Pneumatically controlled ICAF system requires a

pneumatic release system, equipped with fixed

temperature releases, and/or pilot heads.

Release trim, for pneumatically controlled ICAF system

utilizes a pneumatic actuator (R5) normally held closed by

pressure maintained in the pneumatic release system.

The air supply for the pneumatic release piping system

could be provided by the cylinders bank installed as part

of the ICAF system unit or by external air supply. It is

recommended to provide Inspectors Test Connections on

the release system.

In fire condition, the low pressure resulting from the

operation of the pneumatic pilot line release system

causes the pneumatic actuator (R5) to open. The

pneumatic control line is then pressurized, causing the

pneumatically activated control valves for water (B7),

air (A1) and foam (F1) to open simultaneously, generating

CAF through a piping system into the discharge devices

covering the protected area.

អ

អអ

អManual Release

For each release system type, in case of malfunction of

the release control panel or the release line, an

emergency release valve (R1) is provided for manual

override by the user.

Manual ICAF system actuation is accomplished by turning

the manual release valve (R1) to EMERGENCY RELEASE

position (as identified on the front of the unit).

In fire condition, once the manual release valve (R1) is in

EMERGENCY RELEASE position, the pneumatic control line

is then pressurized, causing the pneumatically activated

control valves for water (B7), air (A1) and foam (F1) to

open simultaneously, generating CAF through a piping

system into the discharge devices covering the protected

area.

The discharge continues after the manual release

valve (R1) is returned to its NORMAL position.