4

Building regulations

Installation of your stove must comply with all local regulations, including those referring to national and

European Standards.

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of the authority to be a

smoke control area. It is an offence to emit smoke from a chimney of a building, from a furnace or from any

fixed boiler if located in a designated smoke control area. It is also an offence to acquire an “unauthorised

fuel” for use within a smoke control area unless it is used in an “exempt” appliance (“exempted” from the

controls which generally apply in the smoke control area). In England appliances are exempted by

publication on a list by the Secretary of State in accordance with changes made to sections 20 and 21 of the

Clean Air Act 1993 by section 15 of the Deregulation Act 2015. Similarly, in Scotland appliances are

exempted by publication on a list by Scottish Ministers under section 50 of the Regulatory Reform (Scotland)

Act 2014. In Wales and Northern Ireland these are authorised by regulations made by Welsh Ministers and

by the Department of the Environment respectively. Further information on the requirements of the Clean

Air Act can be found here at: https://www.gov.uk/smoke-control-area-rules Your local authority is

responsible for implementing the Clean Air Act 1993 including designation and supervision of smoke control

areas and you can contact them for details of Clean Air Act requirements.

The FireBob 69 has been recommended as suitable for use in smoke control areas when burning wood logs.

The appliance must be fitted with a permanent stop to prevent closure of the secondary air control beyond

10% open.

Installation

In the UK installation can be carried out by any competent person, provided the installation is carried out to

Building Regulations and checked and signed-off by a local council building inspector. Alternatively, you can

use a member of a certified installation body, such as HETAS, which will negate the involvement of the local

council building inspector.

Ventilation

The stove requires an air supply for combustion. This can be supplied by an airbrick with a permanently open

area. Any airbricks or grilles fitted should be positioned so that they are not liable to blockage. If other

appliances requiring ventilation operate within the vicinity of the stove there must be adequate ventilation

provided for both appliances running simultaneously.

Note: Extractor fans when operating in the same room or space as the stove may cause problems.

Hearth

The stove should be installed above a non-combustible hearth. The hearth should extend to 225mm in front

of the stove and 150mm to each side. A 12mm thick non-constructional hearth can be used.

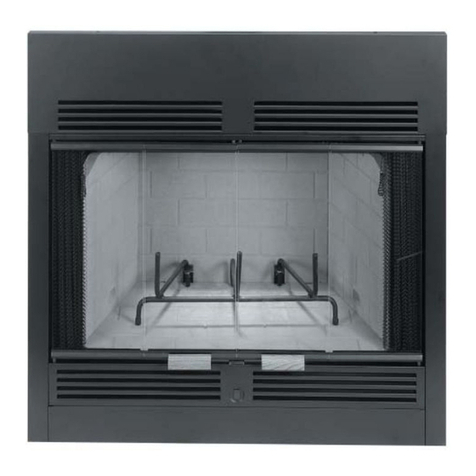

Positioning & clearances

The minimum clearance between the stove and combustible materials is:

Rear 150mm (400mm for the flat back version)

Sides 300mm

Front 1000mm

The minimum clearance between the flue and combustible materials is 450mm.

A minimum clearance of 50mm should be left between the stove and non-combustible materials.

Carbon monoxide alarm

An approved carbon monoxide alarm with a seven-year life sealed battery must be installed when any solid

fuel appliance is installed. Carbon monoxide alarms need to meet European safety standards and must be

audible. They must be fitted in accordance with the manufacturer’s instructions. An alarm is not a substitute

for regular maintenance and chimney sweeping.