6.

6. 6.

6. FREESTANDING FLUE SYSTEM

FREESTANDING FLUE SYSTEMFREESTANDING FLUE SYSTEM

FREESTANDING FLUE SYSTEM

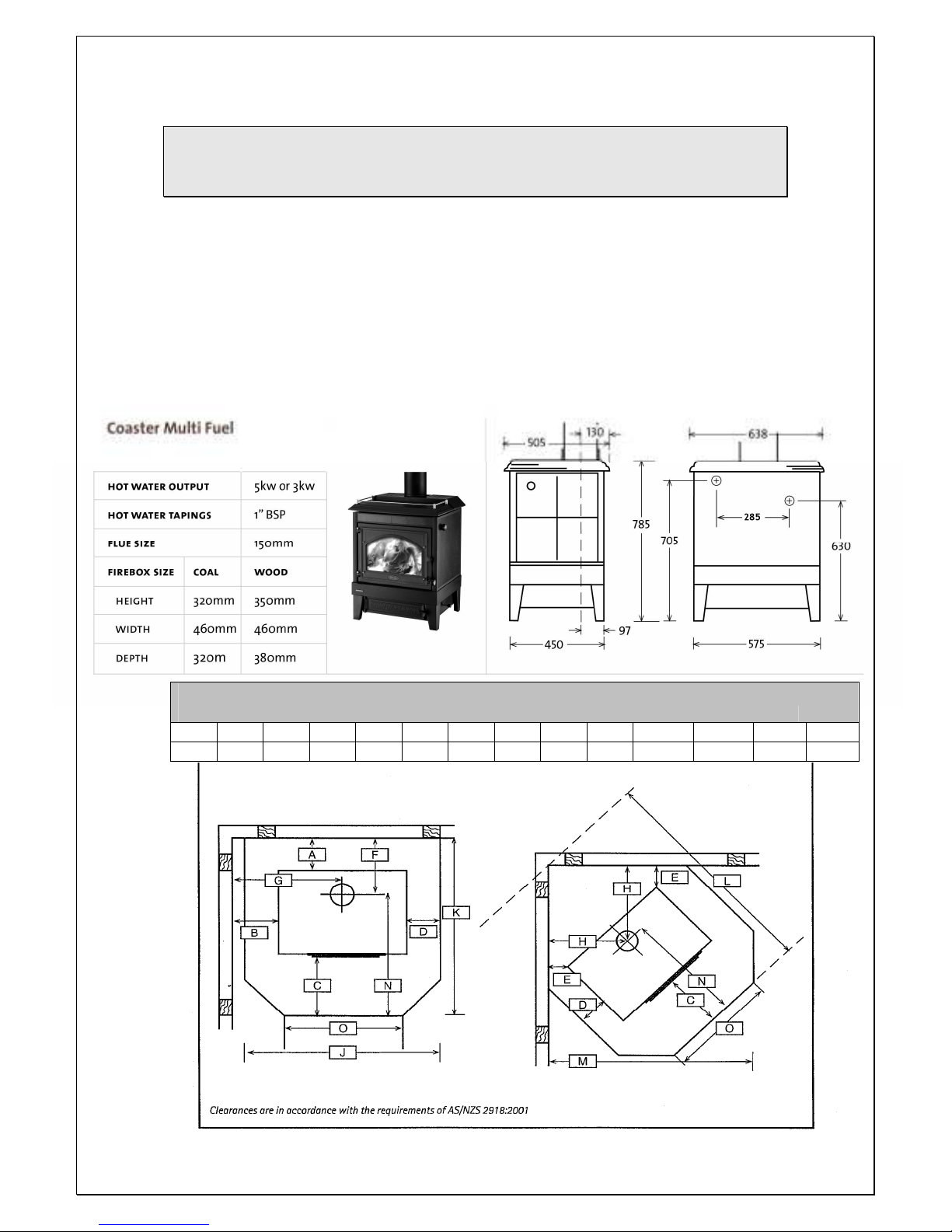

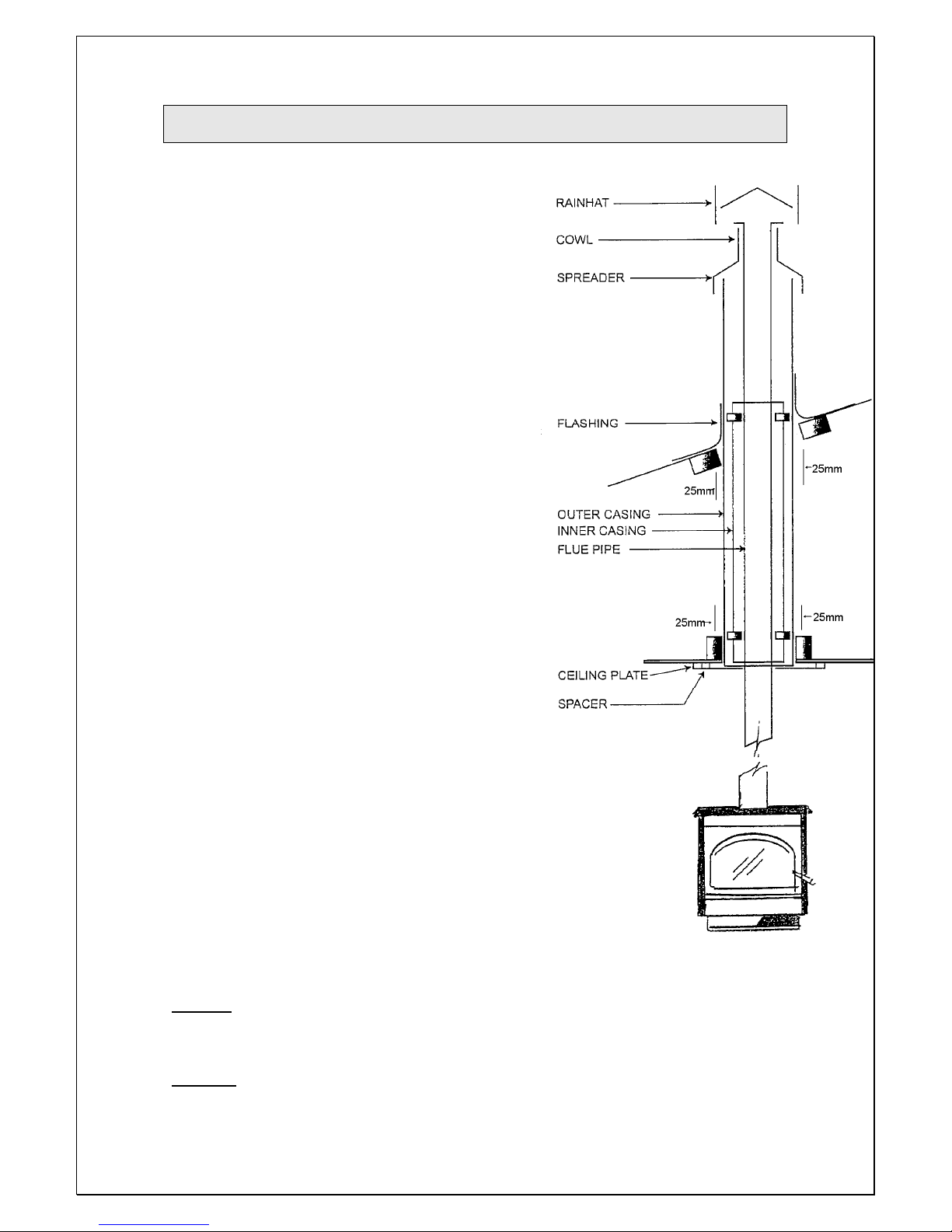

1. Position heater on floor protector ensuring all heater

clearances are correct as per clearances on page 5.

2. Once the location is confirmed, the appliance and floor

protector shall be fixed to the floor itself (refer to

page 6 & 7 .

3. Extend a plumb line from the centre of the fire flue pipe

spigot to the ceiling. Mark position on ceiling and roof.

4. Trim hole and nog as required ensuring that a 25mm

safe clearance between combustible materials and flue

components is maintained. Fix with non combustible

spacers and screws or clouts on all four sides.

5. Cut and frame (when required an opening in the roof,

position the outer casing through the roof until it is flush

with the under side of the ceiling, making sure as with

the ceiling there is a 25mm safe clearance between

non-combustible materials and the flue components.

Fix as in step 4.

6. Fix appropriate flashing around outer casing to the

roof to ensure a weatherproof seal.

7. Assemble flue pipe sections ensuring all seams are in

line, the assembly is straight and crimped. Ends are

pointing downwards. Fix each joint with three stainless

rivets or self-tapping screws.

8. Place ceiling plate with folded edges upwards over

heater spigot.

9. Position the flue pipe into the heater spigot. The flue

pipe can either lowered from the top as a single unit or

fed up from the room a length at a time, ensuring that

all joints are fixed properly.

10. Slide the inner casing into place, between the outer casing

and the flue pipe.

11. The flue pipe must extend 200mm above the outer casing.

Note: Extra lengths of flue pipe, inner and outer casing

may be required to achieve the minimum clearance from

the roof.

12. Slide top spreader over flue pipe down into outer and inner

casing and tighten.

13. Slide cowl over flue pipe until it rests on spreader. Secure

with rivets or self-tapping screws.

14. Fit rainhat. Do not fasten as it must be removable for flue

pipe cleaning.

15. Fix ceiling plate to ceiling maintaining an even gap all around the flue pipe.

Note: Ensure ceiling plate is spaced off from the ceiling with ceramic spacers supplied.

16. Fit flue shield.

CAUTION: Mixing of appliance or flue system components from different sources or modifying the

dimensional specifications of components may result in hazardous conditions. Where such action is

considered the manufacturer should be consulted in the first instance.

WARNING: The appliance and flue system shall be installed in accordance with AS/NZS 2918:2001

and the appropriate requirements of the relevant building code or codes.