Fireye SP-48-NG-FD-S User manual

SF-600

Aug.3rd, 2018

SureFire IITM Pilot

Forced Draught

Gas Pilot type

SP-48-NG/PG-FD-S/M/L

Instruction Manual

1.

INTRODUCTION

This Instruction Manual contains a description of the type SP-48-NG/PG-FD gas pilot construction,

operation principle and the instructions for installation, start-up and service, including the industrial

health & safety recommendations.

The SP-48-NG/PG-FD-S/M/L (48 mm outer diameter, NG - Natural Gas or PG - Propane Gas, FD -

Forced Draught, S– Small, M– Medium, L– Large capacity range) gas pilot is a reliable and

effective source of ignition for oil and gas burners (see Appendix 1 – the pilot capacity vs. gas

pressure graphs).

S/M/Lcapacity ranges: Natural Gas: 20 ÷ 46 / 63 ÷ 132 / 84 ÷ 217 kW at 20 ÷ 80 kPa;

Propane Gas: 35 ÷ 74 / 98 ÷ 203 / 154 ÷ 305 kW at 20 ÷ 80 kPa

A sample of Pilot Part Number for Natural gas and Medium capacity is “SP-48-NG-FD-M-xxx”, for

Propane gas and Large capacity range is “SP-48-PG-FD-L-xxx” (other Fuel gas on request) where

“-xxx” is the insertion length “L” from 0.5 to 3.0 metres.

The pilot is constructed of high quality materials and each unit is checked and tested before dispatch.

Acquaintance with the following instructions and strict attention to the indications reduce the

possibility of equipment failure to a minimum and ensure safety during normal operation.

2.

OPERATION PRINCIPLE AND TECHNICAL

SPECIFICATION

Unit construction provides a stable flame, ignition repeatability with low demand for combustion

and cooling air. No moving parts ensure long, trouble-free operation with low maintenance costs.

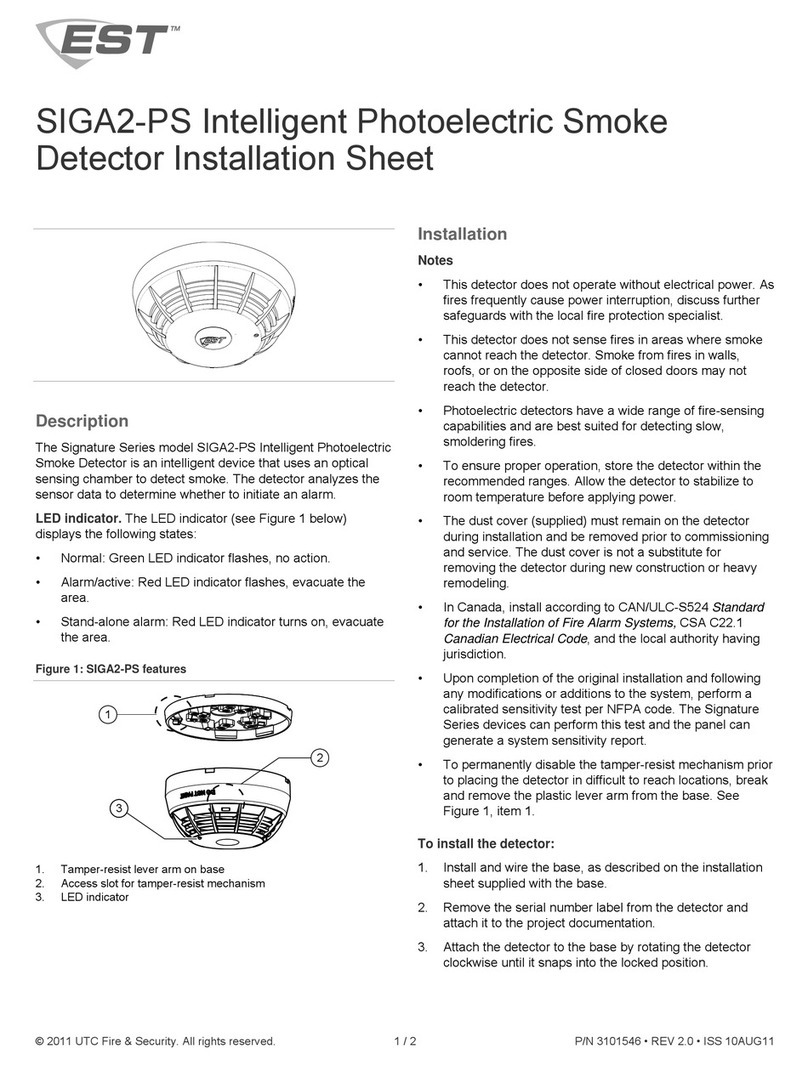

FIGURE 1.

Gas pilot type SP-48-NG/PG-FD-S/M/L.

®

SP-48-NG/PG-FD-S/M/L can operate as an intermittent (light-off), or as a continuous pilot.

Main parts of SP-48-NG/PG-FD-S/M/L pilot are: air tube (pos. 4 on Fig. 1) with air inlet (3/4”BSP) and gas part

assembly including gas head (pos. 3) with gas inlet (1/2” BSP), ignition rod hole (1/2”BSP) with igniter rod

holding gland (pos. 5) and sight port hole (1/2” BSP) with stop plug mounted. It includes also the fixed gas tube

(pos. 2). The orifice-stabilizer assembly (pos. 1) is fixed at the end of gas tube. It consist of a gas divider with

main and bleed orifices, gas tube and swirler-stabilizer. Gas part assembly is mounted in the air tube by means of

the thread joint with mounting ring equipped with the small locking screw.

In many applications SP-48 is mounted on the main burner using the mounting tube (see p. 3).

The source of ignition is an electric high energy spark igniter (HESI) or high tension arc igniter (HTI) for safe or

hazardous area (depending on the application) equipped with the ignition rods of outer diameter of 16 mm and

coaxial electrode arrangement – see Fig. 3.

The ignition rod is mounted in the gas head and goes through air tube to the orifice-stabilizer assembly. The rod

tip end should be placed as on drawing Fig. 1, to provide a successful ignition of air-gas mixture.

Gas pilot SP-48 can be supplied together with electric ignition device selected depending on the application.

Ignition device is not in gas pilot scope of supply and should be ordered separately.

SP-48-NG/PG-FD-S/M/L pilot principle of use: gas is supplied through the inlet 1/2“BSP to the gas head and to

the gas tube and further to the orifice-stabilizer assembly. A small amount of gas leaves through the bleed orifice

mounted in the gas divider, into the zone before the swirler-stabilizer plate, where it mixes with air to form a

combustible mixture. It is ignited in that zone by a spark or an electric arc generated at the tip of the electrical

igniter rod. Further it ignites the main stream of gas which exits the main nozzle at the outlet of the air tube. The

main flame then stabilizes in the primary combustion zone in front of the swirler-stabilizer which provides an

adequate shape and stability of the flame.

The orifice-stabilizer assembly is optimized for Natural gas or Propane gas. In case of other Fuel gases contact

Fireye as this may need the orifice replacement or changes to the assembly.

Thanks to this principle of design, the pilot combustion zone is protected, the main combustion zone is outside

the pilot, hence the air tube does not overheat and there is no need for retraction of the ignition device rod.

The flame length is 0.6-1 m depending on the kind of gas,air and gas pressures versus the pressure in

combustion chamber.

In addition, using Fireye high tension igniter type HTSS in the Spark & Sense version, the center electrode of

igniter rod is also an ionization rod extended into the primary combustion zone and specially designed to work

with SureFire II Pilots. The HT igniter initially creates the electric arc to ignite the gas, and then the electric

circuit switches the operating mode for ionization detection, confirming the presence of the igniter flame.

3.

MOUNTING TUBES

FIGURE 2.

Pilot mounting tubes: for welding and flanged

For fixing the pilot burner to a burner plate there are two types of mounting tubes available (material: carbon

steel), offered as an optional accessory and to be ordered separately.

A flanged mounting tube allowing the fixing of a gas pilot without the use of welding (Fig. 2), to be fixed with bolts to

the burner plate. After inserting the pilot into the mounting tube its position is determined and secured with a clamping

ring located at the end of the tube assembly. This ring also provides the necessary sealing for the connection, pilot

mounting tube for the second option welded tube (Fig. 2), to be fixed to the burner plate by means of welding. Pilot

fixing inside the mounting tube is as in p. 7.1. There are two lengths A available: 150 and 600 mm.

4.

IGNITION SOURCES FOR GAS PILOT LIGHT-OFF. (SETTING METHOD)

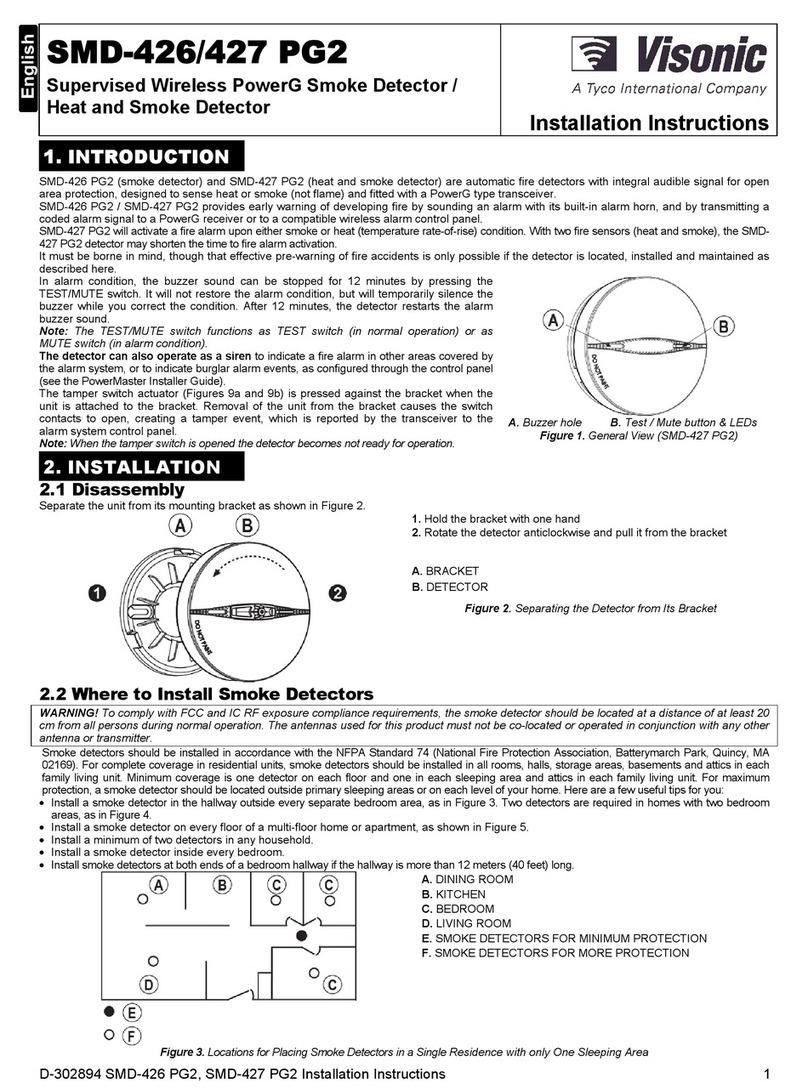

Sources of ignition of the gas in the gas pilot SP-48 are electrical high energy spark igniters (HESI) or high tension igniters

(HTI) equipped with the ignition rods of outer diameter up to 16 mm and coaxial electrode arrangement (see Fig. 3):

For the high energy spark igniter (HESI): this type of device creates single sparks of a high energy

of about 12 Joules. With frequency of 4 to 5 sparks per second it ensures reliable ignition of a gas/air mixture under all

conditions. The secondary circuit voltage is nominally 2,000 VDC at primary supply 230VAC or 110 VAC,

For the high tension igniter (HTI): this type of device creates an electrical arc of low energy which allows for ignition of a

gas/air mixture in clean environment and repeatable conditions. The secondary circuit voltage is 8,000 VAC at primary

supply 230VAC or 110 VAC.

Using the Fireye High Tension Igniter, the end of the rod tip should be placed at a distance of 10 mm back from the swirler-

stabilizer (see Fig.1). In case of the High Energy Spark Igniter, the rod tip should be placed further back ~ 50 mm back from

the swirler-stabilizer.

It should be noted that the rod tip positioning against the swirler-stabilizer plate in the pilot gas part assembly (pos. 3 on Fig.

1) should be done outside the air tube only (do not install the rod in the gas head already mounted in the air tube). Only after

proper rod positioning should the rod be fixed by tightening the rod holding gland and the whole gas assembly with igniter

rod inserted into the air tube pos. 4.

FIGURE 3.

Gas pilot type SP-48-NG/PG-FD-S/M/L with examples of electrical ignition devices

®

The rods of both types of devices are mounted in gas head by means of a holding gland 1/2"BSP.

The ignition control is not in gas igniter scope of supply. It is normally specified and ordered separately.

5.

TECHNICAL DATA

Fuel Natural Gas / Propane Gas - other fuel gases upon request

Outer diameter of the air tube 48.0 mm

Outer diameter of the mounting tube 55.0 mm

Outer diameter of the ignition rod ≤16.0 mm

Capacity range : Natural Gas S: 20 ÷ 46 kW, M: 63 ÷ 132 kW, L: 84 ÷ 217 kW at 20 ÷ 80 kPa

Propane Gas S: 35 ÷ 74 kW, M: 98 ÷ 203 kW, L: 154 ÷ 305 kWat 20 ÷ 80kPa

- other fuels and capacities upon request

Air flow max. ~ 30 m3/h – adjust to capacity as in p. 8.11

Air pressure range 0.5-1.0 (max. 1.2 kPa)

Air connection 3/4" BSP (inner thread)

Gas connection 1/2" BSP (inner thread)

Igniter rod reference length range “L” 0.5 ÷ 3.0 m - longer upon request

Material used for pilot construction all parts: 304/316 SS, heat-resistant steel 310/330

Notes: 1. If the above parameters are different than those required please contact Fireye

2. For Imperial Units please refer to the Appendix 3 Unit Conversion Table

3. Device complies with the requirements of the European Directive 2002/95/EC

(RoHS)

6.

OPERATIONAL SAFETY

When operating and handling the pilot burner please follow the rules below:

6.1 Use pilot only for its intended purpose.

6.2 At the time of installation, operation and maintenance follow the procedures described in the

instructions and documentation of the pilot, ignition device and the main burner.

6.3 Follow the warnings contained in the documentation.

6.4 Do not make any modifications or changes to the pilot construction.

6.5 Before starting, make sure that all parts of the pilot and electric ignition device are in good

condition.

6.6 Circuits of power packs as well as igniter rods, enclosures and junction boxes must be properly

grounded.

6.7 Before igniting, check the tightness of gas tube connections

6.8 During the observation of the pilot flame wear special goggles to protect the eyes from UV

radiation of the flame.

6.9 Do not remove the protective ground when the ignition device is energized.

6.10 Before working on the ignition device, ensure the power is disconnected.

6.11 Before maintenance or repair works check that the gas shut-off valve is closed.

6.12 During installation, start-up or maintenance works on the pilot or burner/ heater always wear

protective clothing and use protective gloves.

WARNING: ALL ACTIONS RELATED TO THE INSTALLATION, SERVICE AND

OPERATION OF GAS PILOT MAY ONLY BE CARRIED OUT BY A TRAINED AND

QUALIFIED PERSONNEL.

7.

INSTALLATION

During the installation, all components have to be protected from impact or bending.

Pilot SP-48-FD is designed such that it can be welded directly to the burner plate, or placed in the

mounting tube (see Fig. 2).

It should be noted that the distance from the gas head with mounting ring to the burner plate should be

not less than 150 mm and insertion depth cannot exceed the “L” value – see Fig. 1.

Pilot air tube is made of stainless steel, mounting tube is made of carbon steel which must be noted for

welding.

REMARK: IN CASE OF ANY DOUBTS REGARDING INSTALLATION OF THE

PILOT CONSULT WITH THE MANUFACTURER.

7.1 MOUNTING TUBE

The mounting tube, if used, should be attached to the burner plate using bolts or welding (see Fig. 2). If it

is not possible to use one of mounting tubes proposed above, a different type can be used, bearing in

mind that its inner diameter should be properly matched to the outer diameter of the pilot air tube to be

able to fit and fix the pilot in a tube with proper clearance.

In the case of application including a mounting tube proceed the following way:

a) Based on assembly drawings mark and cut a hole in the burner plate with a diameter slightly

larger than the diameter of the mounting tube.

b) The mounting tube for welding: slide the mounting tube in the hole and set it in the correct position

(insertion depth and proper angle relative to the main burner nozzle position).

c) The mounting tube for welding: weld using the electrode appropriate for the material.

d) If the flanged mounting tube is used, bolt it to the burner plate after drilling the correct sized holes.

e) For both types of mounting tube the clamp assembly with screws and gasket provides a fast and

reliable mounting and dismounting of the pilot.

7.2 GAS ASSEMBLY AND AIR TUBE

a) The position of the electric igniter rod tip in relation with the orifice-stabilizer assembly of pilot

should be checked following information in p. 4. The correct position for different types of

electrical igniter rods should be taken into consideration (see Fig. 1).

It should be remembered that the rod tip positioning against the swirler-stabilizer plate in the pilot

gas part assembly (pos. 3 on Fig.1) should be done outside the air tube only.

Only after proper rod positioning should the rod can be fixed by tightening the gland and the whole

gas assembly with rod inserted into the air tube.

b) In case of necessary adjustments loosen the rod holding gland and set the appropriate position.

If the rod of the electric igniter is supplied separately, insert the rod in the rod holding gland and

then in gas part assembly mounting bracket and set the appropriate tip position following the above

instructions. If there are problems sliding the rod through rings of fixing gland apply a small

amount of high temperature resistant grease or grind slightly the gland ring inner surface.

After setting the correct rod position, fasten the rod fixing gland in the gas head. Then the complete

gas part assembly can be slid into the air tube.

Do not remove the rod from fixing gland if it is not necessary, as the gland rings once clamped on

rod do not allow easy rod movement.

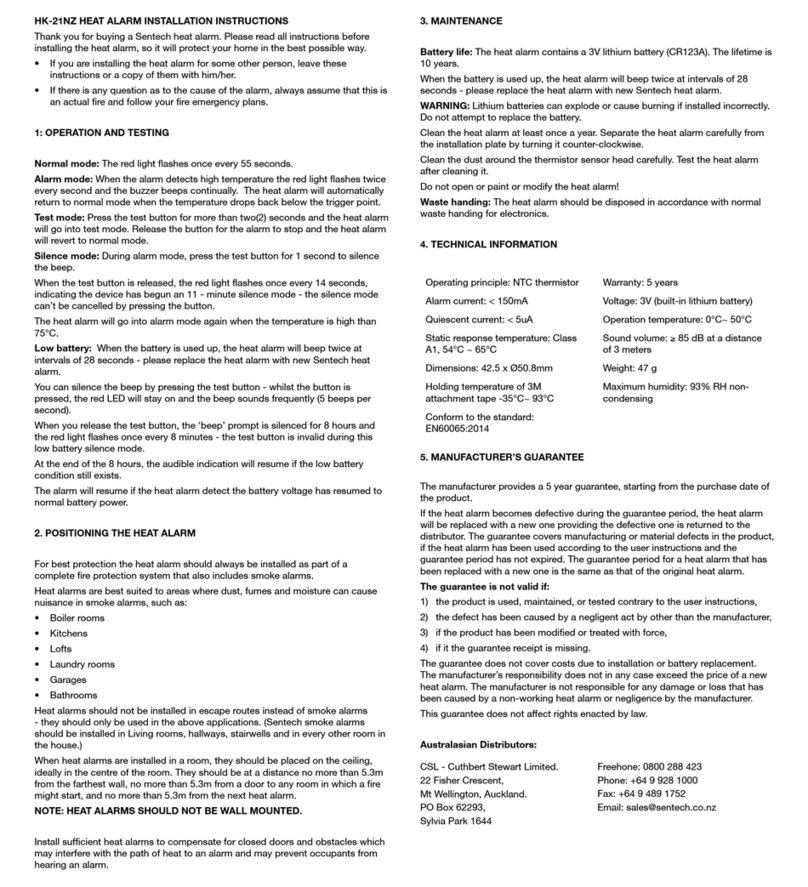

c) Gas part assembly and air tube should be fastened by the mounting ring thread joint. Ensure that the

ring gasket is correctly fitted in the gas head seat (see Fig. 4). The mounting ring small locking

screw (pos. 6 on Fig. 1) should be tightened to prevent the ring from accidentally unfastening.

d) The complete pilot (air tube) can be inserted into the mounting tube. In order to make the air tube

slide-in easier, apply a small amount of high temperature resistant grease.

e) The insertion depth of SP-48-FD pilot is determined by the design of the main burner. If an existing

pilot has to be replaced, the insertion length and pilot tip position should be the same.

®

In case of any doubts, the position of the pilot should be confirmed with the pilot and burner

manufacturer.

f) After determining the position of the complete pilot relative to the mounting tube, the mounting

tube clamping screws should be tightened to prevent the device from moving.

FIGURE 4.

Gas head with ring gasket and swirler-stabilizer assembly with bleed and main gas orifices

7.3 GAS AND AIR SUPPLY INSTALLATION

a) The pilot must be set in the mounting tube such that the air and gas connections are in the

desired positions.

b) Connect the air and gas hoses to the appropriate pilot inputs. Hoses cannot be tangled

or twisted. If necessary, additional connectors may be used.

c) To ensure a long and trouble-free operation of the pilot it should be kept clean. Take care

of the air,gas tube and orifice-stabilizer assembly patency. Hoses should be dry and not

cracked.

d) During maintenance or service works, secure the disconnected ends of the hoses by closing

the ends with a plug or a tape.

e) Use the automatic shutoff valves of the appropriate size and the respective closing rate and pilot

gas pressure measurement with safety interlocks (compliant with the requirements of relevant

standards concerning the shut-off safety fuel valves and burner safety) to be sure that the gas

delivered to the pilot is of an adequate pressure and can be quickly and effectively shut off.

f) Use manual shut-off valves on air and gas lines for each pilot in case of maintenance or

replacement and for adjustment of pressure and flow on each pilot separately.

REMARK: AT THE DESIGN STAGE DETERMINE LENGTH OF CABLES AND

FLEXIBLE AIR AND GAS CONNECTIONS TO ACCOMMODATE ANY EXPECTED

HEATER OR BOILER CONSTRUCTION MOVEMENT

7.4 CABLING

Wiring and electrical connections design and layout should be in accordance with the requirements

for burner installation devices specified in their instructions and the relevant regulations.

8.

PILOT START-UP, OPERATIONAL TESTS

Before proceeding with the start-up and operational tests of SP-48-NG/PG-FD-S/M/L pilot check

the following:

8.1 Gas and air installations are correctly mounted, tight and functionally checked, including: valves,

flaps, strainers, fittings and joints (flanged and screwed), control and interlock devices.

8.2 Gas and air connections to the pilot are made in accordance with the above instructions and the

assembly drawing.

8.3 Electrical components and circuitsare properly connected, grounded and tested.

Ring gasket

Swirler- stabilizer plate

Main gas orifice and gas tube

Bleed gas orifice

Bracket

Gas divider

HTI rod tip

8.4 Power supply to the electrical circuit of the ignition device and spark or arc release should be

allowed only after assembly of the device, and when installed in the operating position on the

burner or outside the burner only to validate the operation strictly according to the device

instructions e.g. on special test stand.

Then perform next steps:

8.5 Select one pilot as a representative for tests.

8.6 Prepare the burner control system to enable manual trials in a safe way.

8.7 Install for the trial period appropriate gauge and manual valve on the igniter gas supply line. This

will allow for fine adjustment of the gas pressure.

8.8 After verification of ignition device mounting and wiring, the electric igniter can be powered up.

Check for the spark or arc presence.

8.9 At presence of a spark or an electric arc from ignition device, slowly open the pilot manual

shut-off gas valve without opening the air manual shut-off valve (it should be closed). At certain

degree of opening the pilot flame should establish.

8.10 Adjust the gas pressure slowly up to the working pressure. Pilot flame may be yellow and bushy due

to too little combustion air.

8.11 Slowly open the air valve manually until the flame stabilizes at the end of the air tube and

reaches a blue-yellow color. If the airflow is too low the end of the air tube may start to glow as the

main flame burns inside the igniter. Further opening of the air valve should stabilize the flame

outside the air tube. This will stop the overheating of the air tube. Flame should be as stable as

possible.

Notes: 1. Pilot flame should be blue near the igniter tip and yellow at his end. With some kind of

gases the flame color may stay yellow.

2 In some applications e.g. on up-fired burners, when the draught of the furnace is

significant, it may be necessary to limit the amount of air by closing the air valve

accordingly in order to keep stable pilot flame.

3. Gas pilot works usually with preset, constant air/fuel ratio (turn-down ratio 1:1), after

proper adjustment as above. However it should ignite repetitively and burn with a

stable flame in each gas pressure point throughout the whole range after proper

adjustments.

8.12 In case of insufficient pilot capacity, the amount of gas and air can be further adjusted bearing in

mind the above principles.

8.13 In multiple burner and pilot applications on one heater/boiler with a similar gas and air supply

installation and similar layout on the main burner, set the other pilots gas and air valves to be in the

same position.

8.14 Then carry out light-off tests. In case of differences in the quality of combustion adjust manual

valves so that the flame is similar to that on the test pilot. In some cases the main burner air should

be adjusted.

8.15 Repeat the light-off tests several times on each pilot to confirm the repeatability of ignition. Flame

should be stable, in proper position and of desired shape.

If the SP-48-NG/PG-FD-S/M/L gas pilot has been correctly commissioned and the settings were

optimized, with correct maintenance, the igniter will operate trouble free.

9.

OPERATION

After installing and completion of pilot start up and tests SP-48-NG/PG-FD-S/M/L is ready for

operation.

General description of activities performed by the burner/boiler control system or manually

by the operator:

9.1 Preparation of the furnace/boiler for firing up.

9.2 Opening of air to the burner and pilot.

9.3 Preparation of gas installation for operation.

®

9.4 Setting the gas pressure at the correct level.

9.5 Starting of pilot trial for ignition sequence performed by the controller or in some cases

by the operator:

a) The correct setting of the main burner combustion air.

b) Checking the interlock conditions before firing up.

c) Providing power to the ignition source.

d) Optionally, carrying out the gas line leakage test.

e) Closing the purge valves and opening of gas shut off valves.

f) The ignition should take place within the time specified by the standards, which should

be confirmed by the relay output of the flame detector.

g) Electrical igniter power off after confirming the presence of the pilot flame, closing

the pilot shut off valves (in case of continuous pilot operation they stay open).

h) In case of the absence of the flame after trial for ignition - the valves are closed and

electrical igniter is switched off.

i) Eventual repeating of trial for ignition sequence (depends on the application). Details

of sequence, timings are dependent on application and applicable standards.

In the case of a manually controlled gas pilot, the operator has to close the gas supply to the pilot

himself at the right time if the flame is not detected.

10.

SERVICE, MAINTENANCE AND REPAIRS

To remove the igniter for inspection or repair the gas and electrical supply must be shut off first.

Checks that the gas and air manual shut off valves are closed and that the power for ignition device

is disconnected.

WARNING: DO NOT PERFORM ANY MODIFICATION OF THIS PRODUCT ON

YOUR OWN AND DO NOT USE OTHER PARTS THAN ORIGINAL. DANGER TO LIFE

AND HEALTH!

WARNING: WHEN THE HEATER/BOILER IS IN OPERATION, DURING SERVICE

WORKS ON BURNER INSTALLATION ALWAYS USE PROTECTIVE PPE CLOTHING,

GLOVES AND GOGGLES!

REMARK: EVERY 12 MONTHS MAKE AN INSPECTION OF AIR TUBE. IF YOU SEE

ANY TRACES OF EXCESSIVE TEMPERATURE DURING OPERATION INCREASE

THE COOLING-COMBUSTION AIR FLOW OR RETRACT THE GAS PILOT A LITTLE

FROM THE COMBUSTION CHAMBER. IF INCREASING THE AMOUNT OF AIR

REMEMBER THAT IT MAY IMPACT FLAME QUALITY.

10.1 INSPECTION AND MAINTENANCE

SP-48-FD pilot because of its simple design does not require complicated maintenance procedures.

Checking and cleaning of gas tube and orifice-stabilizer assembly:

a) Close the manual gas valve and disconnect the pilot gas line.

b) Disconnect the ignition rod electric supply cable.

c) Unscrew the locking screw and the mounting ring.

d) Carefully slide out the gas part assembly from the air tube.

9

e) Pull out the electrical igniter rod by loosening the ignition rod holding gland, only if it is

absolutely necessary e.g. when rod is worn or damaged.

f) Check and clean the bleed orifice and main nozzle. For cleaning use a soft copper wire.

g) To remove heavy dirt use a soft wire brush e.g. copper wire brush.

h) Blow compressed air through the whole gas part assembly.

i) To check the air tube condition loosen the mounting tube clamp assembly screws and pull out

air tube. Check for overheating traces and clean it. If it is damaged – repair or replace it.

j) Assemble all the elements back to obtain the original configuration.

Checking of ignition device:

k) Check the ignition rod at least every 12 months. Follow the instructions in the ignition device

User's Manual.

10.2 TROUBLESHOOTING

If the gas pilot does not operate correctly check the following:

a) All manual gas valves ongas supply line were open and there is gas available.

b) All valves in the supply line are functioning properly.

c) The preset gas pressure is correct.

d) The correct pilot air pressure is maintained.

e) Gas and air supply lines are clear - check strainers.

f) Bleed orifice and the main orifice in orifice-stabilizer assembly are clear.

g) Electric ignition device is working correctly and its rod is correctly positioned in gas part

assembly. If it is not working properly - follow the ignition device manual.

h) The power parameters for ignition device are correct.

If the gas lights but the flame is unstable or goes out when main burner goes into operation,

check that:

i) The gas pressure does not drop during pilot light-off (trial for ignition).

j) The air pressure is always at the correct level.

k) The air from the main burner does not blow out the pilot flame or does not move it out of the

field of view of the flame scanner (if applied).

l) Flame safeguard system works correctly and the flame is not obscured.

Improper operation of the whole installation requires detailed checking of the power line and all

components, including any temporary use of override switches or jumpers.

Be aware of all connections to be later restored to normal state, to allow safe operation.

10.3 SPARE PARTS

For start-up and warranty period it’s recommended to order following spare parts in quantity as below:

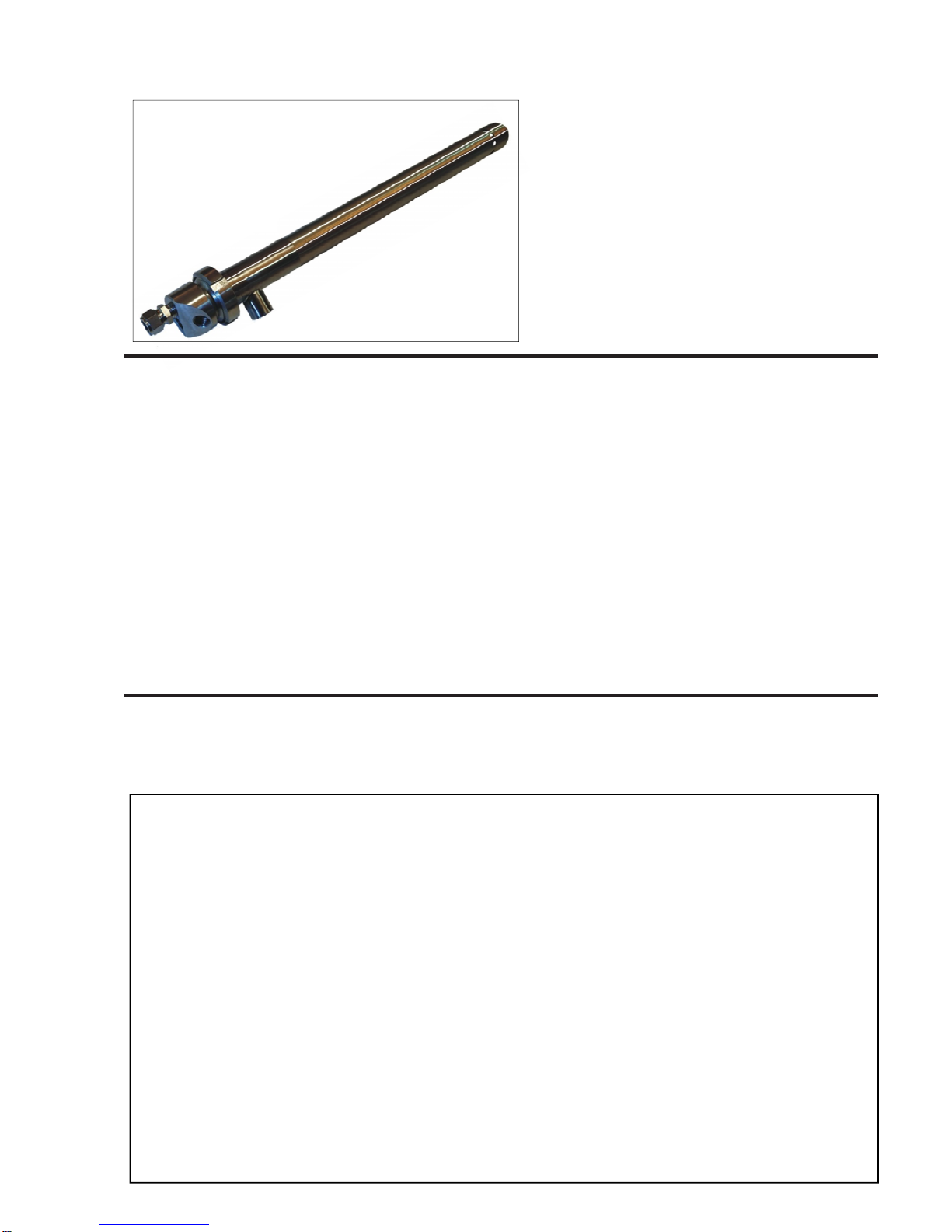

- a set of loose parts used on both sizes on pilots: SP-32 and SP-48 (see Fig. 5) - one for 4 pilots,

- complete orifice-stabilizer assembly for SP-48-FD pilot, including: main orifice nipple with gas

tube, bleed orifice, swirler-stablizer, divider – choose a proper capacity range S, M or L - one for 4

pilots,

In case of air tube wear or damage:

- if air tube or mounting ring has to be replaced - order a replacement air tube with mounting ring of

length “L” – prices on request only,

- if just the end of air tube is eroded - cut 200 mm of the tube tip, order and weld spare part

P/N SP-48-ND-END - replacement air tube end, length 200 mm, SS310/330.

List of pilot spare parts Part Numbers is in Table 2.

10

®

FIGURE 5.

Loose Spare Parts set for SP-32 and SP-48 pilots

Loose Spare Parts set includes:

1 - rod gland ½” NPT – 1 pc

2 - locking screw M4 hex – 3 pcs,

3 - hex key 2mm – 1 pc

4 - gasket OD 25x5 (for SP-32) – 1 pc

5 - O ring 46x3 (for SP-48) – 1 pc

6 - thumb screw M4 with two washers

(for SP-32-ND and SP-48-ND) – 1 pc

11.

STORAGE

SP-48 gas pilot should be stored in a clean, dry environment and in its original packaging if possible.

In case of long length pilots, always keep them in a horizontal position by supporting both ends and

in the middle. It should also be protected from contamination using caps on gas and air inlet and pilot

outlet and covering with foil.

Storage over 30 days: relative humidity of no more than 85%, temperature below 50°C.

12.

ORDERING INFORMATION

Before ordering, please provide the data as in Appendix 2.

Table 1 below shows examples of the Part Numbers of length “L” every 0.5 metre, the fuel options of

Natural Gas or Propane Gas and Small, Medium or Large capacity ranges.

Pilots can be ordered in size increments of 0.1 metre lengths, from 0.5 to 3.0 metres.

Part Number coding samples:

SP-48-NG-FD-S-1.5 or SP-48-PG-FD-S-1.5

Which means: SureFire II Pilot - 48 mm OD - Natural Gas (NG) or Propane Gas (PG) - Forced

Draught (FD) - Small capacity (S) - 1.5 metre insertion length

Table 1:

SureFire II Forced Draught Pilot selection Table, showing only the 0.5 metre intervals, 0.1 metre

intervals may be ordered (See Price List).

REMARKS:

1. Select required kind of fuel – choose NG for natural Gas or PG for Propane Gas.

2. Select required pilot capacity range – choose S for small, M for medium, L for large capacity range

– see p. 5 Technical Data

3. Select Electric Igniter rod and power pack separately

Part No

Description

SP-48-NG/PG-FD-S/M/L-0.5

SureFire II Pilot, 48 mm OD, Nat. or Prop. Gas, Forced Draught, S M or L capacity, 0.5 m ins. length

SP-48-NG/PG-FD-S/M/L-1.0

SureFire II Pilot, 48 mm OD, Nat. or Prop. Gas, Forced Draught, S M or L capacity, 1.0 m ins.

length

SP-48-NG/PG-FD-S/M/L-1.5

SureFire II Pilot, 48 mm OD, Nat. or Prop. Gas, Forced Draught, S M or L capacity, 1.5 m ins.

length

SP-48-NG/PG-FD-S/M/L-2.0

SureFire II Pilot, 48 mm OD, Nat. or Prop. Gas, Forced Draught, S M or L capacity, 2.0 m ins.

length

SP-48-NG/PG-FD-S/M/L-2.5

SureFire II Pilot, 48 mm OD, Nat. or Prop. Gas, Forced Draught, S M or L capacity, 2.5 m ins.

length

SP-48-NG/PG-FD-S/M/L-3.0

SureFire II Pilot, 32 mm OD, Nat. or Prop. Gas, Forced Draught, S M or L capacity, 3.0 m ins.

length

2

1

3

4

5

6

11

Table 2 below shows Part Numbers of gas igniter mounting tubes and spare parts.

Table 2:

SureFire II Pilot Mounting Tubes & Spare Parts

Part No

Description

SP-48-MTF Mounting Tube Flanged, flange OD 80, length 120mm

SP-48-MTW-150 Mounting Tube for Welding, length 150 mm

SP-48-MTW-600 Mounting Tube for Welding, length 600 mm

SP-32/48-LS-SET Loose Spare Part set for SP32 and SP-48 pilots *

SP-48-FD-STOR-S Stabilizer assy: swirler-stabilizer, divider, main & bleed orifice for SP-48-FD-S of Small capacity range

SP-48-FD-STOR-M Stabilizer assy: swirler-stabilizer, divider, main & bleed orifice for SP-48-FD-M of Medium capacity range

SP-48-FD-STOR-L Stabilizer assy: swirler-stabilizer, divider, main & bleed orifice for SP-48-FD-L of Large capacity range

SP-48-ND-END Air tube end with inlets, 200 mm long, SS310, for SP-48-ND / SP-48-FD

* Loose Spare Part set includes items as on Fig. 5

12

®

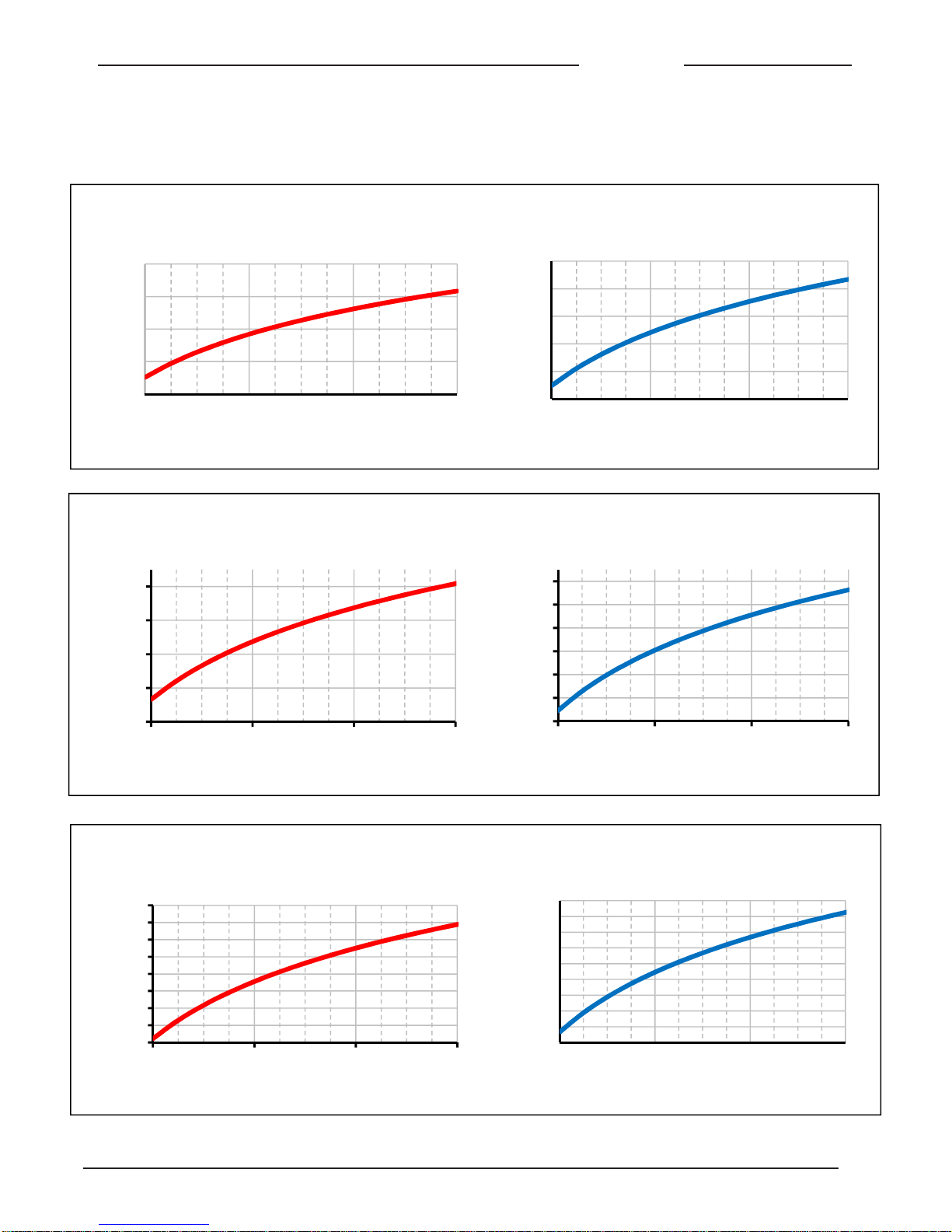

APPENDIX No 1

Pilot capacity vs. gas pressure graphs for S, M, L capacity range

15

25

35

45

55

20 40 60 80

CAPACITY [kW]

PRESSURE [kPa]

GAS PILOT type SP-48-NG-FD-S-xxx

NATURAL GAS ( 35,73 MJ/Nm3) -(1,15;1,7)

30

40

50

60

70

80

20 40 60 80

CAPACITY [kW]

PRESSURE [kPa]

GAS PILOT type SP-48-PG-FD-S-xxx

PROPANE GAS (91,26 MJ/Nm3) -(1,15;1,7)

50

70

90

110

130

20 40 60 80

CAPACITY [kW]

PRESSURE [kPa]

GAS PILOT type SP-48-NG-FD-M-xxx

NATURAL GAS (35,73 MJ/Nm3) -(3,2;1,7)

90

110

130

150

170

190

210

20 40 60 80

CAPACITY [kW]

PRESSURE [kPa]

GAS PILOT type SP-48-PG-FD-M-xxx

PROPANE GAS (91,26 MJ/Nm3) -(3,2;1,7)

80

100

120

140

160

180

200

220

240

20 40 60 80

CAPACITY [kW]

PRESSURE [kPa]

GAS PILOT type SP-48-NG-FD-L-xxx

NATURAL GAS (35,73 MJ/Nm3) -(4,5;2,0)

140

160

180

200

220

240

260

280

300

320

20 40 60 80

CAPACITY [kW]

PRESSURE [kPa]

GAS PILOT type SP-48-PG-FD-L-xxx

PROPANE GAS (91,26 MJ/Nm3) -(4,5;2,0)

13

APPENDIX No 2

Proposal Data Sheet

SureFire IITM Pilot - Forced Draught Gas Pilot

Type SP-48-NG/PG-FD-S/M/L-xxx

Please provide the following data before placing the Order for gas pilot:

1. Information about End User

—Plant Name:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

—Owner:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

—Country:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

—Localization (address):

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Gas pilot mode of operation: —intermittent light-off

—continuous pilot

3. Insertion length “L”:

(see Fig. 1)

. . . . . . . . . . . . .

[m]

4. Fuel gas for pilot:

—Natural Gas, Propane Gas, other Fuel Gas: NG PG FG

—if other Fuel Gas – specify the type of gas:

enclose gas composition sheet

. . . . . . . . . . . . . . . . . . . . . . . . .

5. Gas net calorific value:

. . . . . . . . . . . . .

[MJ/Nm

3

]

6. Required pilot heat input (capacity):

. . . . . . . . . . . . .

[kW]

7. Gas pressure range available for pilot:

. . . . . . . . . . . . .

[kPa]

8. Main burner nominal (or max.) capacity:

capacity of burner to be lit

. . . . . . . . . . . . .

[kW]

9. Air for pilot

cooling and combustion air

—air pressure:

. . . . . . . . . . . . .

[kPa]

—air flow:

. . . . . . . . . . . . .

[m

3

/min]

14

®

APPENDIX No 3

UNIT CONVERSION TABLE

Quantity Metric Units Imperial Units

Length 1 millimetre [mm] x 0.003281 = foot [ft.; ’] x 0.03937 = inch [in; ”]

1 metre [m] x 3.281 = foot [ft; ’] x 39.370 = inch [in; ”]

Volume 1 cubic metre [m3] x 35.315 = cubic foot [ft3]

Air flow rate 1 cubic metre/hour [m3/h] x 0.589 = standard cubic foot/min [SCFM]

Weight 1 kilogram [kg] x 2.2046 = pound [lb.]

Pressure 1 kilopascal [kPa] x 6.895 = pound square inch gauge [psig] x 4.015 = inch H2O

Power

(capacity) 1 kilowatt [kW] x 293.1 = million BTU/hr. [mmBTU/Hr]

Calorific

value 1 mega joule/cubic metre

[MJ/m3] x 26.839 = BTU/ cubic foot [BTU/ft3]

Temperature Deg. Celsius [°C] Formula: °C x1.8 + 32 = Deg. Fahrenheit [°F]

15

- This page intentionally left blank -

16

®

NOTICE

When Fireye products are combined with equipment manufactured by others and/or integrated into

systems designed or manufactured by others, the Fireye warranty, as stated in its General Terms and

Conditions of Sale, pertains only to the Fireye products and not to any other equipment or to the

combined system or its overall performance.

WARRANTIES

FIREYE guarantees for one year from the date of installation or 18 months from date of

manufacture of its products to replace, or, at its option, to repair any product or part thereof (except

lamps, electronic tubes and photocells) which is found defective in material or workmanship or

which otherwise fails to conform to the description of the product on the face of its sales order.

THE FOREGOING IS IN LIEU OF ALL OTHER WARRANTIES AND FIREYE MAKES

NO WARRANTY OF MERCHANTABILITY OR ANY OTHER WARRANTY, EXPRESS

OR IMPLIED. Except as specifically stated in these general terms and conditions of sale, remedies

with respect to any product or part number manufactured or sold by Fireye shall be limited

exclusively to the right to replacement or repair as above provided. In no event shall Fireye be

liable for consequential or special damages of any nature that may arise in connection with such

product or part.

FIREYE

SF-600

3 Manchester Road

Aug.3rd, 2018

Derry, New Hampshire 03038 USA

www.fireye.com

®

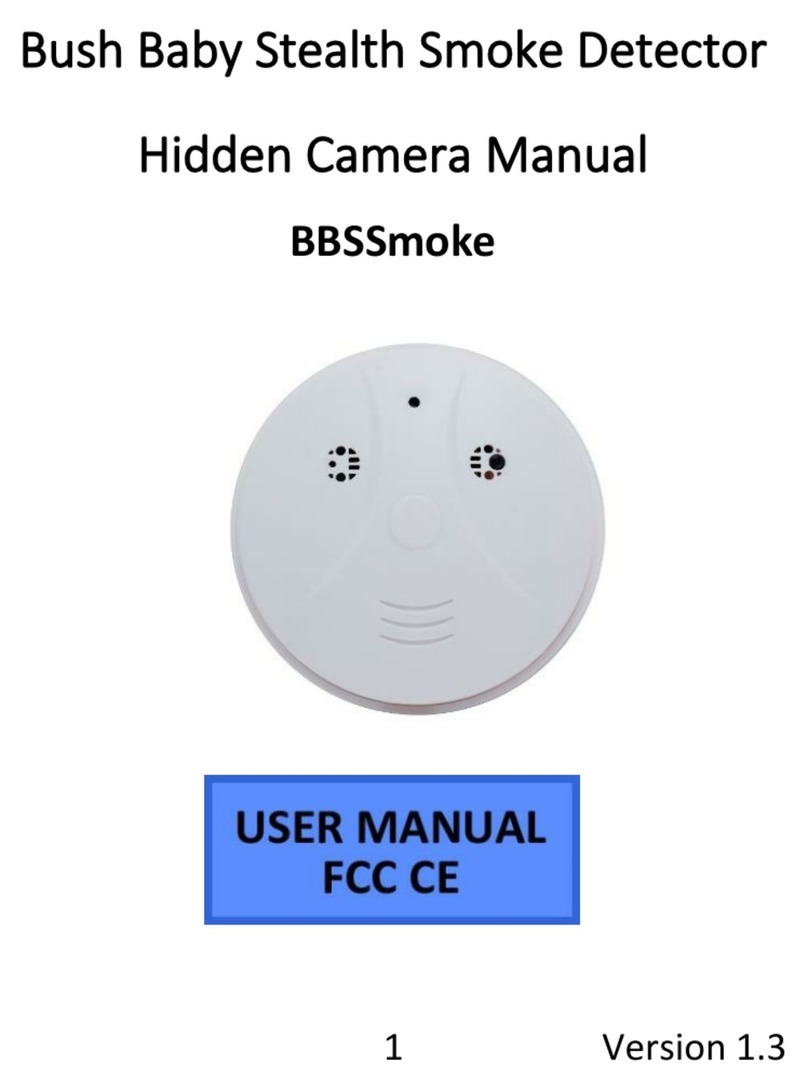

This manual suits for next models

6

Table of contents

Popular Smoke Alarm manuals by other brands

BRK electronic

BRK electronic SA340B quick start guide

Mini Gadgets

Mini Gadgets BBSSmoke user manual

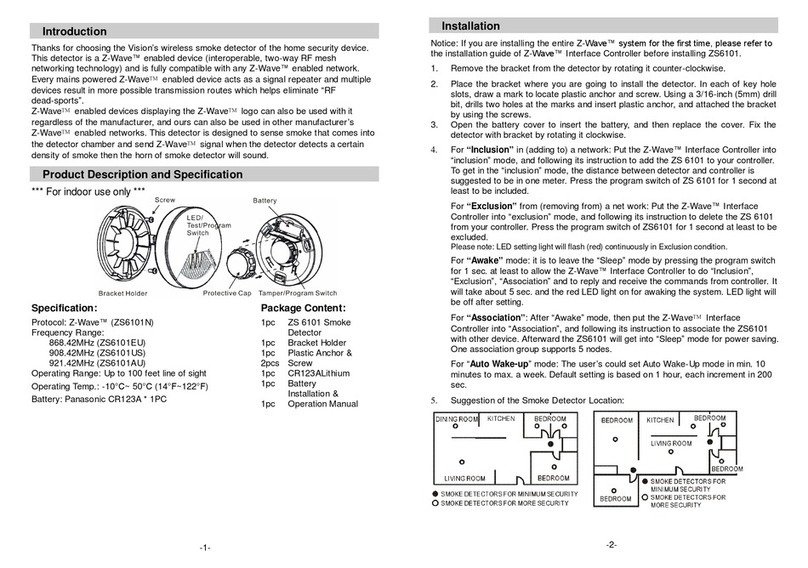

Vision

Vision ZS 6101 EU Installation & operation manual

Kidde

Kidde 945 user guide

System Sensor

System Sensor Innovair Flex D2E Installation and maintenance instructions

EST

EST Signature Series Installation sheet