First Choice WaveTruck User manual

www.FirstChoicePool.com

INSTALLATION MANUAL

•Programmed movement for better cleaning

•Ecient, quiet operation

•Engineered for enhanced durability

•Simple installation, no additional tools required

•Easy grip roll bar handle

FULL KIT INCLUDES CLEANER, NINE CONNECTOR HOSES, ONE

LEADER HOSE, FLOW GAUGE, REGULATOR VALVE,SKIMMER

CONE,AND OWNER’S MANUAL.

THE WAVETRUCK AUTOMATIC SUCTION SIDE POOL CLEANER FEATURES:

See pages 15-17 for a complete list of replacement parts and kits

REMEMBER THESE IMPORTANT FACTS!

Before installing the WaveTruck automatic pool cleaner:

• Manuallyclean/vacuumthepoolandcleanallskimmer,pumpanddebrisbaskets.

• Cleanorbackwashthelter.

• Checkthatthewaterisatitsproperlevel.

• Checkwaterchemistry.Makesurethepoolisfreefromexcessalgaetoensureproper

operation of the WaveTruck automatic pool cleaner.

NeverusetheWaveTruckautomaticpoolcleanertoremoveplaster/pebbledebrisin

new or remodeled pools.

Always remove the WaveTruck automatic pool cleaner before backwashing or

chemically shocking the pool.

1

Thank you for purchasing the WaveTruck automatic pool cleaner.

The WaveTruck automatic pool cleaner works from the suction side ofyourpoollter

system and is subject to the GPM (gallons per minute) of the suction line. It is designed

to operate and install simply with most swimming pools. Occasionally, additional hoses

and/orpartsareneededtocompleteyourspecialsituation.Fortechnicalassistance

and parts availability, call your local First Choice dealer.

Keepthisinstallationmanualonle–withyourreceipt,purchasedateandserialnumber.

Always remove the WaveTruck automatic pool cleaner and hoses before swimmers

enter the pool. It is not a toy and is not intended for children to play with.

When removed from the pool, keep the WaveTruck automatic pool cleaner

disconnectedandstoredinashadedsafeplace–awayfromallchewing

animals!

The hoses must be stored straight. DO NOT COIL!

Carry the WaveTruck automatic pool cleaner by the handle only.

Always install a USPC-approved safety vacuum lock with sidewall connections. When

the WaveTruck automatic pool cleaner is removed, make sure the safety vacuum lock

wallttingcapissecurelycoveringthesidewallsuctionportandsnappedshut.SAFETY

FIRST!

THE WAVETRUCK AUTOMATIC POOL CLEANER

2

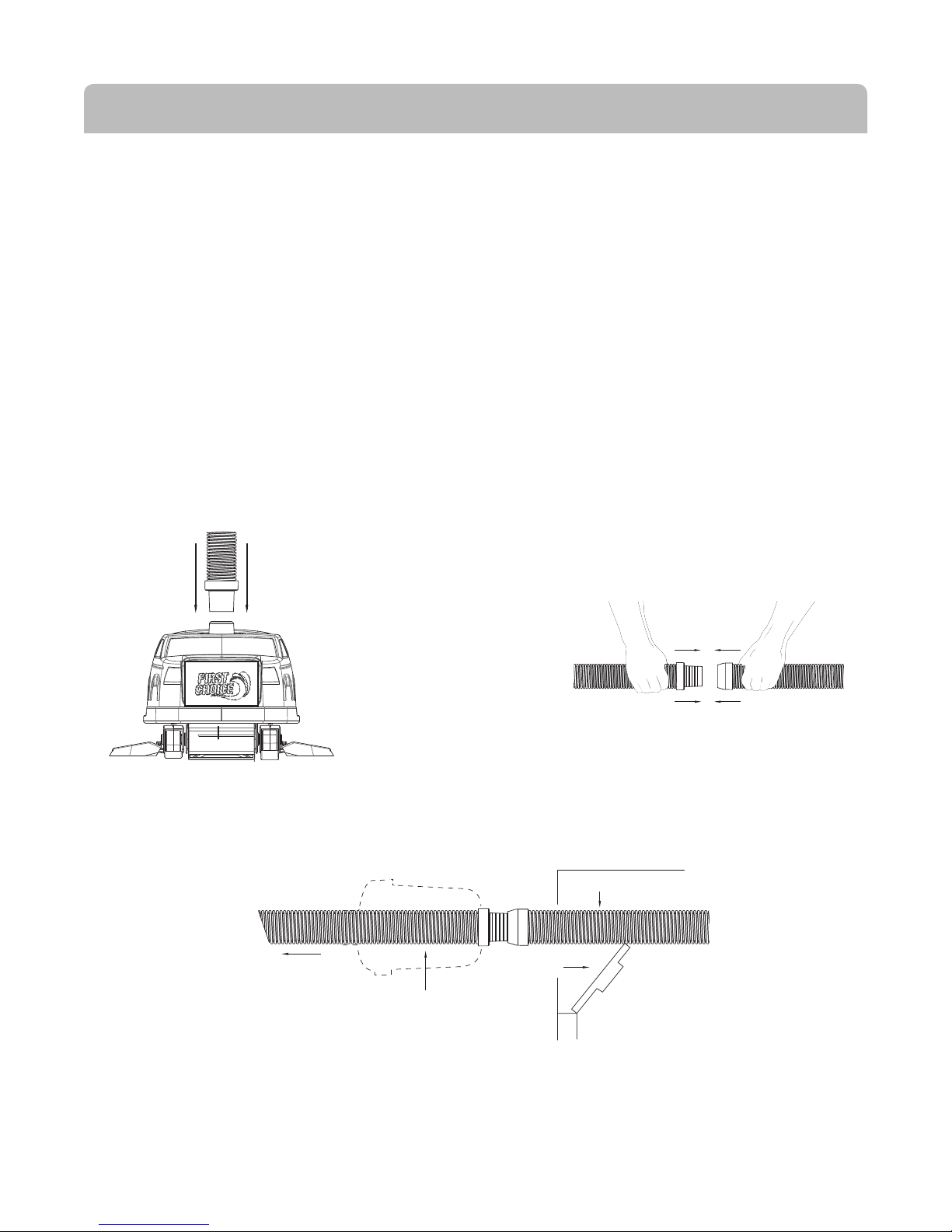

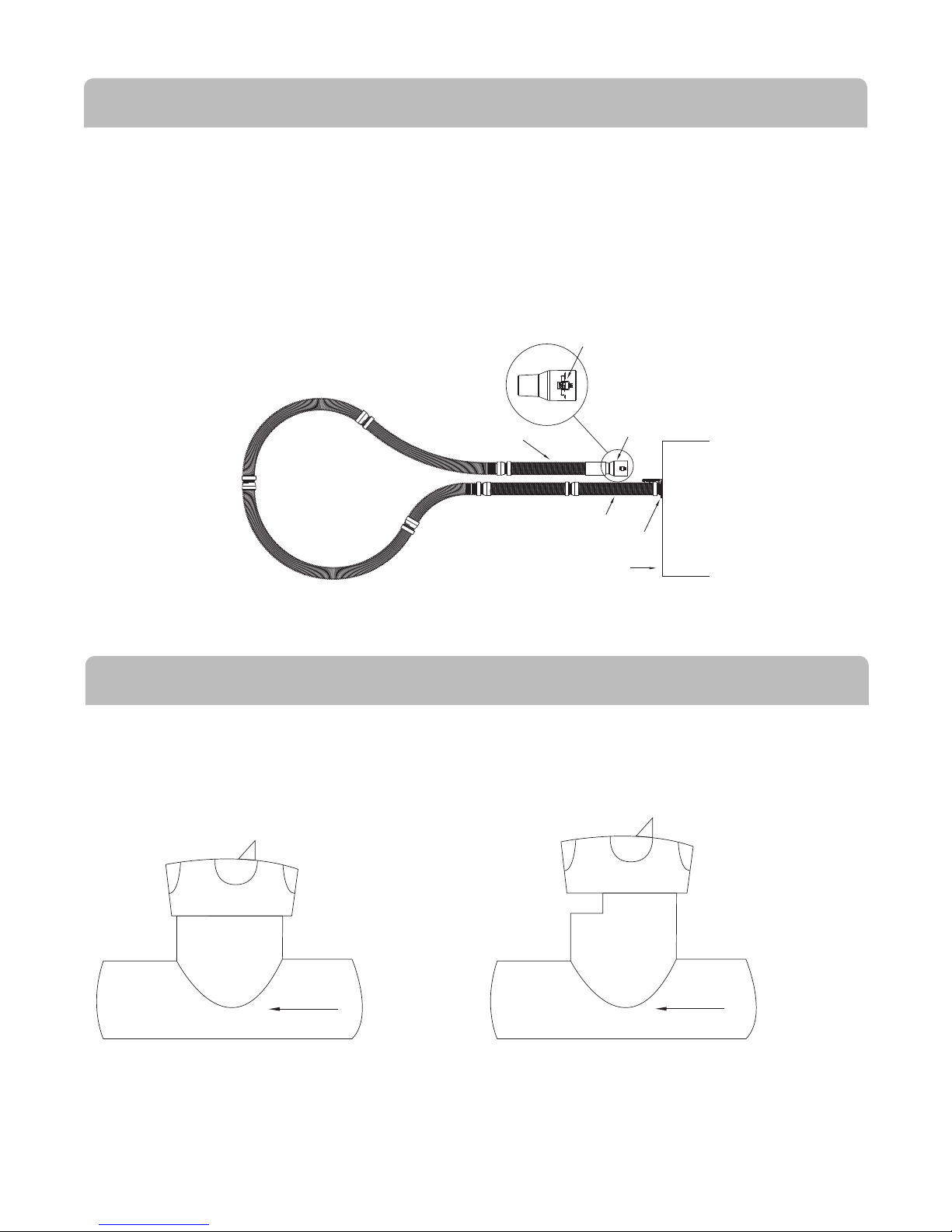

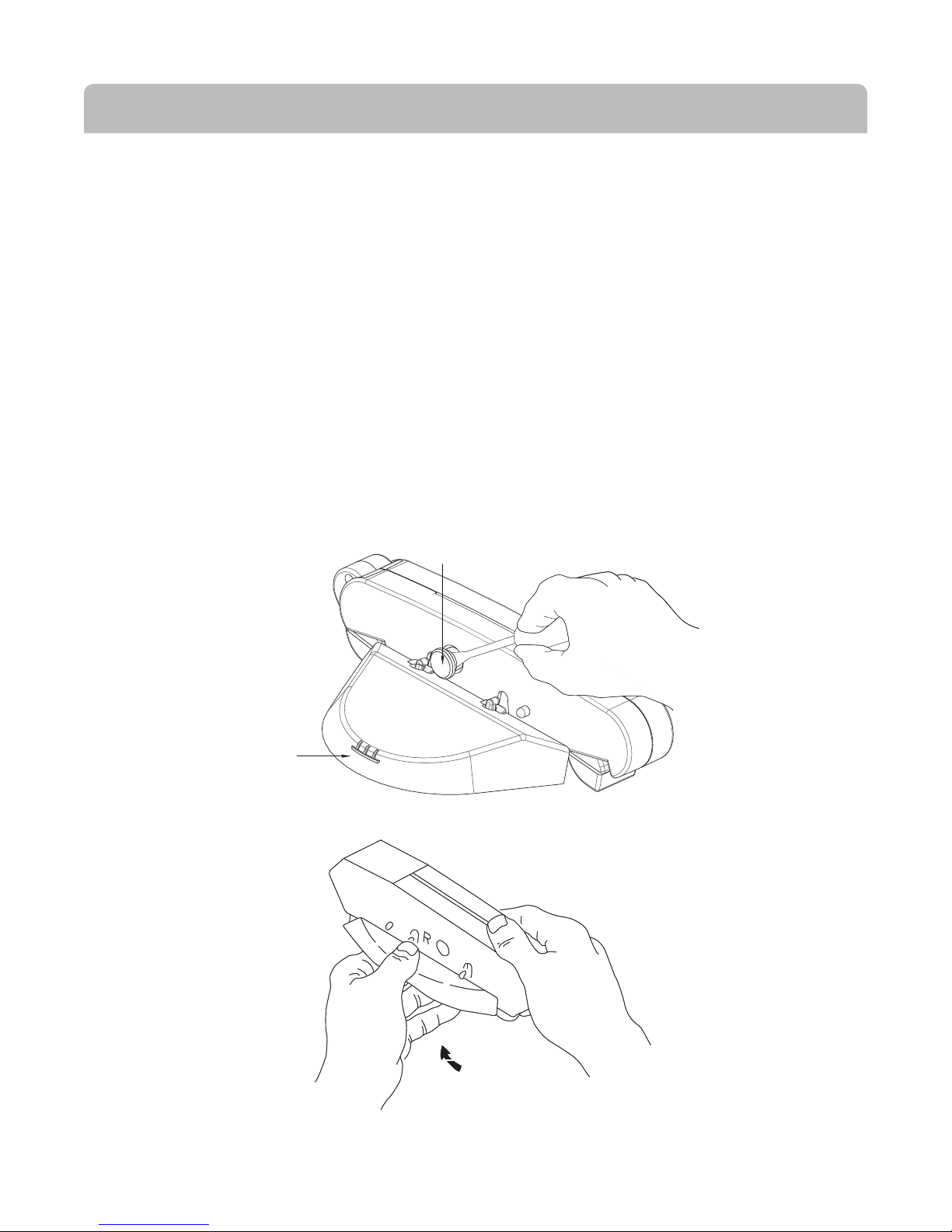

STEP 1: CONNECTING AND SUBMERGING THE HOSES AND CLEANER

Fig. 2

Fig. 1

There are nine connector hoses and one leader hose with a gray hose cu. The hose cu connects

to the top of the WaveTruck automatic pool cleaner (see Fig. 1).

Connect the WaveTruck automatic pool cleaner hose sections together by pushing and twisting

thetaperedmaleconnectorendofeachhosermlyintotheopenfemaleendoftheadjacenthose

section (see Fig. 2). Depending on the size and shape of your pool, all hose sections might not be

used.Thehoseshouldreachfromtheskimmerorsafetyvacuumlockwallttingtothefurthest

pointinthepoolplusoneextrahosesection.Ifthehoseisnotlongenough,itwillbenecessaryto

purchase additional hose sections from your pool dealer. After the correct hose length has been

assembled,llthehosecompletelywithwaterbyloweringtheattachedWaveTruckautomaticpool

cleaner and then vertically pushing the hose down, allowing all the air to escape. If optional leaf

canisterispurchased,installbetweenrstandsecondhosesections(seeFig.3).

Fig. 4

To StarzTruck Skimmer

First hose section

Second hose section

(showing leaf canister)

Fig. 7

VLK15Txxx safety

vacuum lock wall fitting

Pool deck / coping

First hose section

To skimmer or vac-lock

Leader hose

Flow Gauge

HWN163

Flow indicator

(desired position)

Fig. 3

3

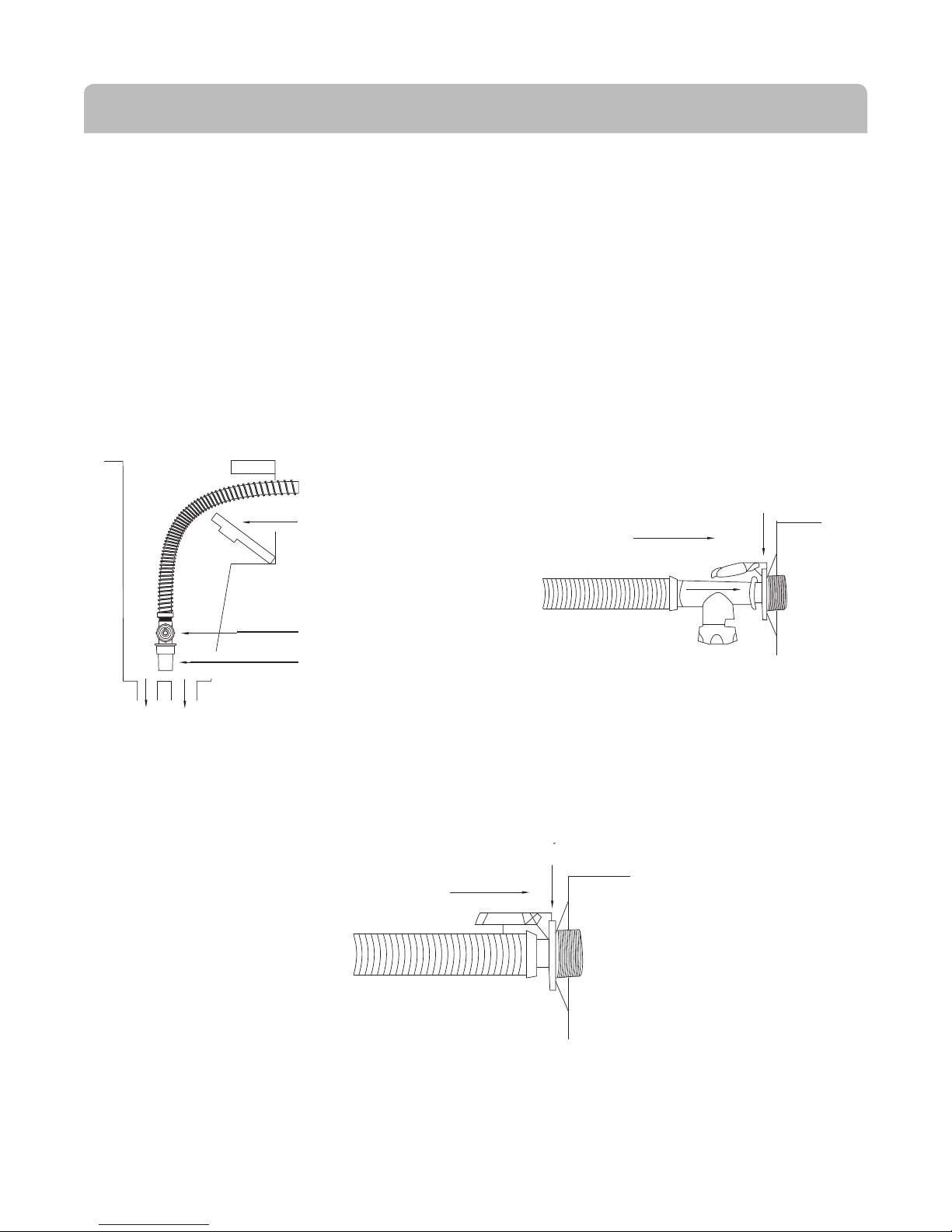

STEP 2: CONNECTING TO SUCTION

Fig. 5

HWN161 regulator valve

HWN152cone adapter

To pump

To StarzTruck

Hose

To main drain (if applicable)

Skimmer

Fig. 6

VLK15Txxx safety

vacuum lock wall fitting

Fig. 7

VLK15Txxx safety

vacuum lock wall fitting

Connect the skimmer cone adapter to the regulator valve and then insert the skimmer cone into:

A. The suction port of the skimmer (see Fig. 4) or

B. The wall port safety vacuum lock without a three-way or ball valve (see Fig. 5)

Without the skimmer cone and regulator valve, insert the male end of the hose directly into the

safetyvacuumlockwallttingportwithathree-wayorballvalve(seeFig.6)

Fig. 6

VLK15Txxx safety

vacuum lock wall fitting

Fig. 7

VLK15Txxx safety

vacuum lock wall fitting

Fig. 4

To StarzTruck Skimmer

First hose section

Second hose section

(showing leaf canister)

Fig. 5

HWN161 regulator valve

HWN152cone adapter

To pump

To StarzTruck

Hose

To main drain (if applicable)

Skimmer

Fig. 6

VLK15Txxx safety

vacuum lock wall fitting

4

Pool deck / coping

First hose section

To skimmer or vac-lock

Leader hose

Flow Gauge

HWN163

Flow indicator

(desired position)

Fig. 3

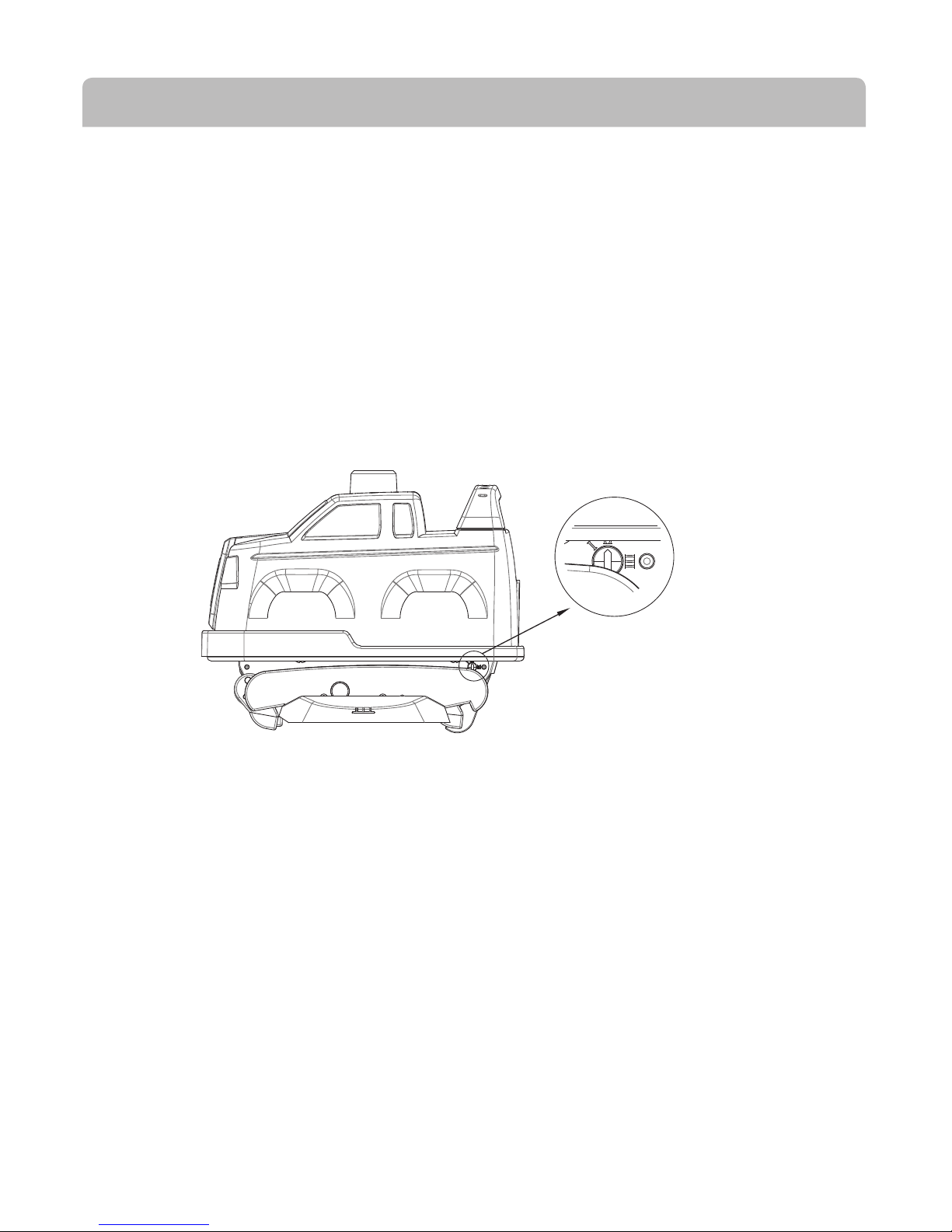

STEP 3: TESTING THE FLOW

Ensure that the hose is full of water and that your pump is running. Remove the WaveTruck auto-

matic pool cleaner from the hose, then insert the ow gauge into the leader hose. Make sure the ow

gauge is underwater (see Fig. 7), and with the opposite end of the hose attached to a dedicated suc-

tion or skimmer port observe the ow gauge. The optimal level is inbetween the MAX and MIN lines

of the ow gauge. If the setting is higher than the MAX marking, it will be necessary to reduce the

ow using the regulator valve described in Step 4.

STEP 4: ADJUSTING WATER FLOW

Observe your WaveTruck automatic pool cleaner in operation at higher speed with dual or variable speed

pumps. Adjust the regulator, three-way or ball valve to speed up or slow down the cleaner (see Fig. 8).

Fig. 9

Screw top in.

Bypass less water.

Speed cleaner up.

Unscrew top.

Bypassmore water.

Slow cleaner down.

MaxMax

Min

To slow cleaner down

screwtop outward.

(Bypass more water)

To speed cleaner up

screwtop inward.

(Bypass less water)

Fig. 7

VLK15Txxx safety

vacuum lock wall fitting

Fig. 8

5

The rear ap tension adjuster is preset to II. When the WaveTruck automatic pool cleaner seems to be spending

too much time against steps, vertical walls and other obstructions, turn the rear ap tension adjuster to position

I (see Fig. 9). Sometimes adjusting your ow valve up or down will also help. Custom pools with interior bar

stools, fountains, planters, etc., will require someone to physically free the cleaner in the case that its becomes

trapped.TheWaveTruckautomaticpoolcleanerwillclimbverticalwallsinconcreteandberglasspools(not

vinyl) if there is at least a 12-inch radius where the oor meets the walls. The cleaner will not climb or go all

thewayupthewalleverytimeduetotheprogrammedgearbox.IftheWaveTruckautomaticpoolcleaneris

not sticking to the wall, set the rear ap tension adjuster to position III (see Fig. 9)and/oradjustyourregulator

valve(s). If the cleaner climbs above the waterline and sucks in air, set the rear ap tension adjuster to position I

(see Fig. 9)and/oradjustyourregulatorvalve(s).

STEP 5: ADJUSTING YOUR WAVETRUCK AUTOMATIC POOL CLEANER

Fig. 10

Rear flap tension adjuster

Fig. 9

Screw top in.

Bypass less water.

Speed cleaner up.

Unscrew top.

Bypassmore water.

Slow cleaner down.

MaxMax

Min

6

WAVETRUCK AUTOMATIC POOL CLEANER SERVICE TIPS

Bottom of cleaner (concrete)

Fig. 17

Slots

Captive

screwFixed access

cover

Bottomof cleaner (vinyl)

Fig. 18

Captive

screwFixed access

cover

Slots

Turbine/vacuum chamber

Fig. 19

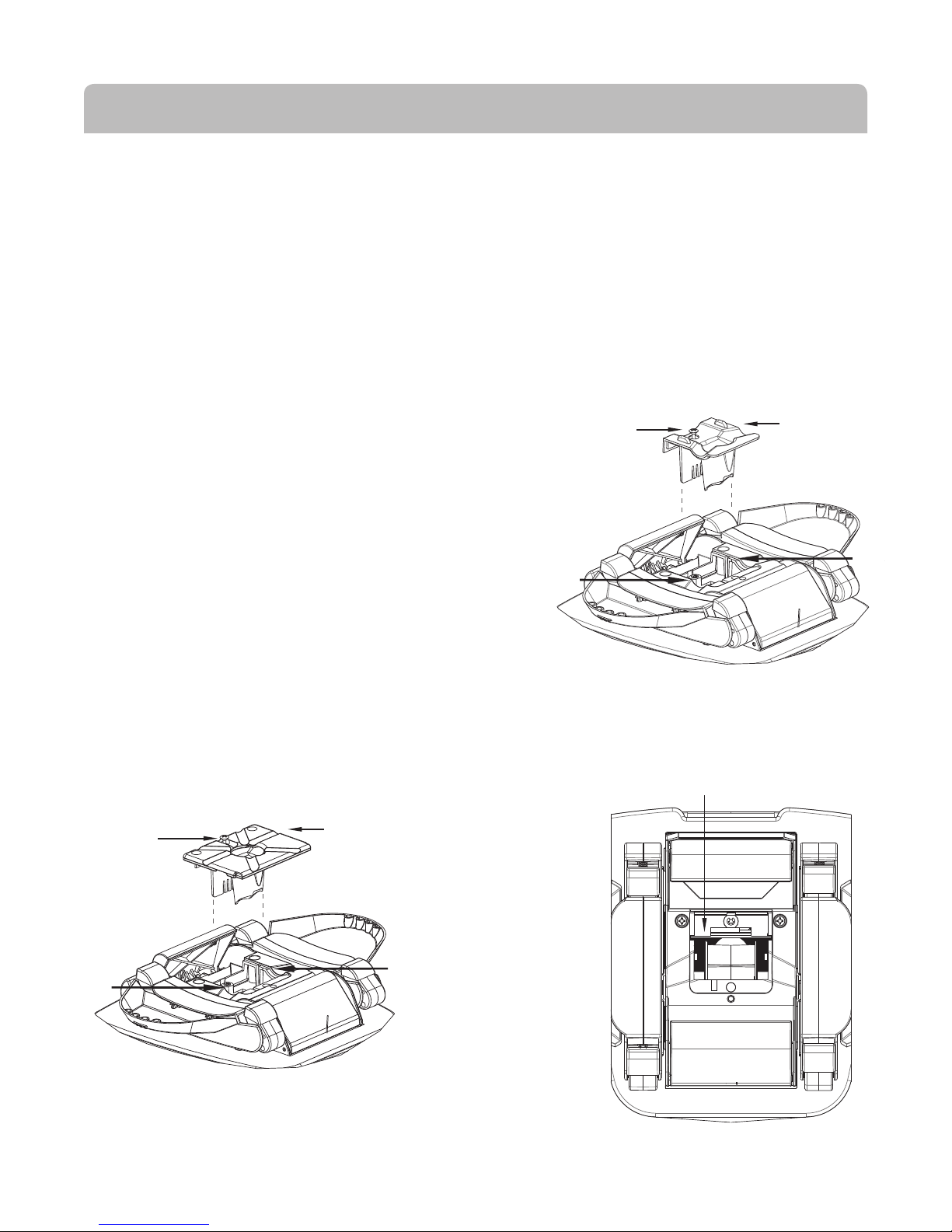

BOTTOM OPENING REMOVAL AND CLEANING INSTRUCTIONS

REMOVING THE BOTTOM OPENING

Should the WaveTruck automatic pool cleaner stop moving or become sluggish due to debris trapped in the

throatorinsidetheunit,theturbine/vacuumchamberisaccessiblefollowingtheseinstructions.

1. Turn o pump.

2. Remove WaveTruck automatic pool cleaner from pool.

3.DisconnectWaveTruckautomaticpoolcleanerfromleaderhose.

4. Turn WaveTruck automatic pool cleaner upside down.

5. Locate and loosen the captive screw behind the

throat in the center of the bottom (see Figs. 10 & 11).

6.Liftxedaccesscover(seeFigs.10&11).

7.Cleanturbine/vacuumchamber(seeFig.12).

8. Check turbine for free movement.

9.Reinstallthexedaccesscoverbyliningitupwiththe

two slots as shown in Figs. 10 & 11.

Slide the cover in place and tighten the captive screw.

10. Reinstall WaveTruck automatic pool cleaner in pool per

installation instructions.

Bottom of cleaner (concrete)

Fig. 17

Slots

Captive

screwFixed access

cover

Fig. 10

Rear flap tension adjuster

Worn

Shoe

Good shoe

Wear

Mark

Fig. 11

Wear mark

Fig. 12

Pod plug

7

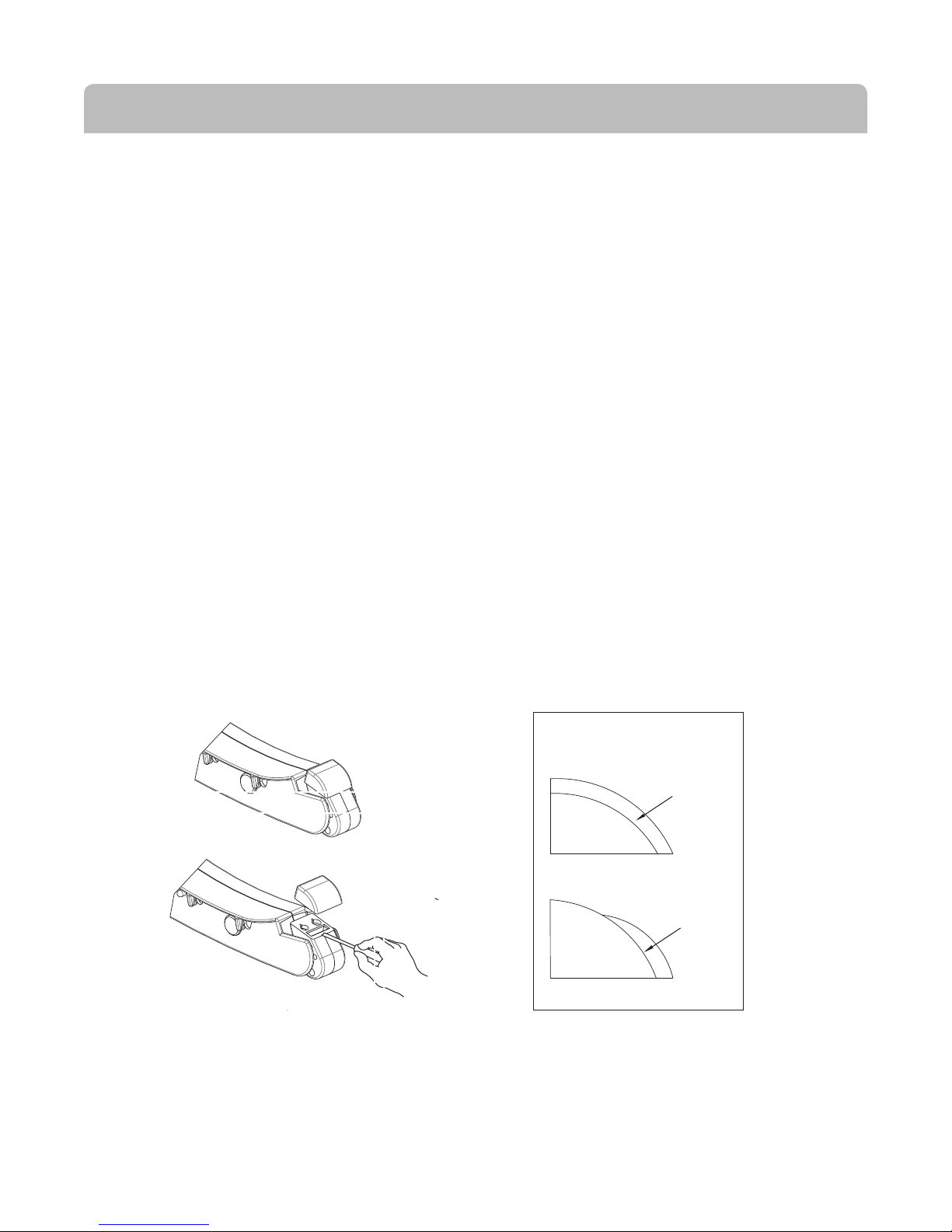

CHECK THE CONDITION OF THE SHOES, WINGS AND FLAPS PERIODICALLY

The pod shoes and wings have wear indicators on their sides and should be checked occasionally to determine

if replacement is needed. The shoe wear indicator is a line on the side of the pod shoe that appears as a

dierenceintexture.Whenthistexturedierenceisnolongervisibleatthebottomoftheshoewhenviewed

from either side, the shoes must be changed (see Fig. 13). The wing wear indicator is located on the side and

is a horizontal line which has three vertical lines above it. When you can no longer see the horizontal line, the

wings must be replaced (see Fig. 14 on page 8 ).

POD SHOE REPLACEMENT

A. Turn unit upside down.

B. Insert screwdriver between foot and shoe on one of the pods (see Fig. 13).

C. Using a lifting motion, remove the shoe from the foot.

D. Dip a new shoe in water and attach the shoe to the foot, making sure to put the small post into the small hole

and the large post into the large hole. These posts and holes are dierent sizes to prevent the shoes from being

improperly installed.

E. Repeat steps b, c and d for each shoe.

WAVETRUCK AUTOMATIC POOL CLEANER SERVICE TIPS

Worn

Shoe

Good shoe

Wear

Mark

Fig. 11

Worn

Shoe

Good shoe

Wear

Mark

Fig. 11

Worn

Shoe

Good shoe

Wear

Mark

Fig. 11

Fig. 13

8

WAVETRUCK AUTOMATIC POOL CLEANER SERVICE TIPS

Wear mark

Fig. 12

Pod plug

Fig. 13

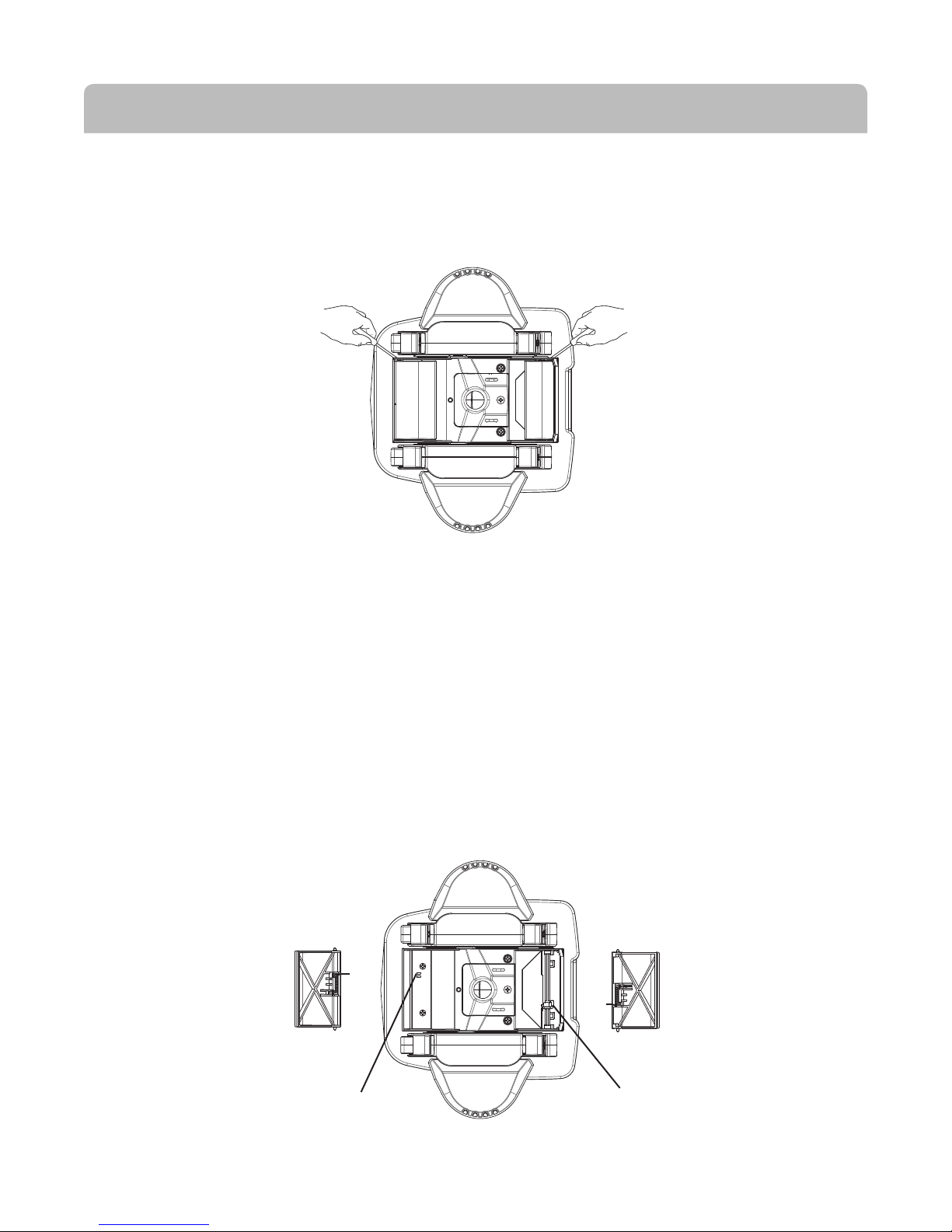

WING REPLACEMENT

A. Using a screwdriver, remove the plugs from both pods (see Fig. 14).

B. Remove the old wings by bending the wings up toward the sides of the cleaner, and lift them o their hooks

(see Fig. 12). If any of the wing hooks are broken, take the WaveTruck automatic pool cleaner to your dealer

for pod replacement as the cleaner will not function properly if the wings are not properly attached.

C. Attach new wings, making sure that you match the “L”(left) and “R” (right) wings to the corresponding pods.

D. Replace the pod plugs and tap them into place

Bottom of cleaner

Fig.14

REARFRONT

Bottom of cleaner

Fig.15

POD REPLACEMENT

A. Using a screwdriver, remove the plugs from the pod (see Fig. 14).

B.Unscrewandremovethehexboltthatwascoveredbytheplug.

C. Remove pod by placing equal pressure on both ends of the pod until it releases from the cleaner body.

D.Installnewpodandreplaceandtightenhexbolt.Ensurethatthepodmoveseasilyandfreely.

9

Bottom of cleaner

Fig.14

WAVETRUCK AUTOMATIC POOL CLEANER SERVICE TIPS

REARFRONT

Bottom of cleaner

Fig.15

FLAP REPLACEMENT

A. Remove the front and rear aps from your WaveTruck automatic pool cleaner by inserting a small screwdriver

between the ap and the lower body near the pivot point of the aps (see Fig. 13).

. You will notice that your replacement aps look similar but are marked “Front” and “Rear” on the ap. It is absolutely

necessary to install the proper ap in the front and rear of the unit because the springs in the aps are dierent.

Failure to do so will result in unsatisfactory performance of the WaveTruck automatic pool cleaner.

Wheninstallingthefrontap,besurethattheextendedlegofthespringisinsertedintothenotchonthefront

ofthelowerbody.Securetheapbyrstplacingoneofthecornertabsintoitscorespondingholeandthen

carefullypushingtheotheredgeintosecurethenaltabinplace.Youwillfeelandhearasnapwhentheap

falls in place. Fold the ap in toward the bottom of the WaveTruck automatic pool cleaner. You will feel some

resistance at this point (that is normal). As the ap snaps into its normal position, you will feel the spring action and

notice that the front ap is now in its normal operating position.

Wheninstallingtherearap,theextendedlegofthespringmusttagainstoneoftheatsurfacesofthecam(see

CamNotch

Bottom of cleaner (concrete)

Fig. 17

Slots

Captive

screwFixed access

cover

Bumper

Front flap

Lower body assembly

Captive screw

“B” screws

“C” screws

“A” screws

Fig. 16

10

WAVETRUCK AUTOMATIC POOL CLEANER SERVICE TIPS

Bumper

Front flap

Lower body assembly

Captive screw

“B” screws

“C” screws

“A” screws

Fig. 16

WAVETRUCK AUTOMATIC POOL CLEANER BUMPER REPLACEMENT

Replacement of the WaveTruck automatic pool cleaner bumper is not recommended as a“do it yourself” repair,

because there is a slight possibility that the replacement might cause a problem in the propulsion system. We

strongly suggest that you consult your dealer for this repair.

A #2 phillips screwdriver is necessary for this repair.

1. TurnWaveTruckautomaticpoolcleanerupsidedownandplaceitinapositionthatissteady/rm.

2. Locateandloosenthecaptivescrewbehindthethroatinthecenterofthebottom(Figs.10,11,12,onPg6).

3. Liftthexedaccesscover(seeFigs.11&12,Pg6).

4. Remove four “A” screws (see Fig. 10,Pg6).

5. Lift the lower body assembly o the WaveTruck automatic pool cleaner (see Fig. 10,Pg6).

6. Remove four“B”screws (see Fig. 18).

7. Remove bumper carefully, do not tamper with any other cleaner parts.

9. Replace with new bumper, do not tamper with any other cleaner parts

10. Reinstallscrewsandparts,followingstepsinreverse–6,5,4,3,2.

11. Reinstall WaveTruck automatic pool cleaner in pool per installation instructions.

Bottomof cleaner (vinyl)

Fig. 18

Captive

screwFixed access

cover

Slots

11

PROBLEM:SLOW/NOFORWARDMOVEMENT

CAUSES SOLUTIONS

Lackof/improperwaterowthroughcleaner Check and adjust water ow, Pg 4

Partial blockage of WaveTruck throat Clearblockage,Pg6

Worn shoes Replace shoes, Pg 7

Worn wings Replace wings, Pg 8

PROBLEM:CLEANERFAILSTOCLIMBVERTICALWALLSGUNITE/CONCRETEPOOL

CAUSES SOLUTIONS

Improper shoes for application Contact your local First Choice dealer

Lackof/improperwaterowthroughcleaner Adjust water ow, Pg 4

Partial blockage of WaveTruck throat Clearblockage,Pg6

Worn shoes Replace shoes, Pg 7

Worn wings Replace wings, Pg 8

Hose too short Install additional hose sections, Pg 2

Improper tension on rear ap Turn rear ap adjuster to III, Pg 5

WAVETRUCK AUTOMATIC POOL CLEANER TROUBLESHOOTING GUIDE

12

PROBLEM: CLEANER CLIMBS TO SURFACE AND SUCKS AIR

CAUSES SOLUTIONS

Toomuch/improperwaterowthroughcleaner Adjust water ow, Pg 4

Improper tension on rear ap Turn rear ap adjuster to I

If still climbing too much, reduce water ow

until proper operation is achieved, Pg 4, 5

Steering failure 1. Check and clean rear screen

2. Check to see that cone gear is free and

rotates smoothly in both directions

3.Checkmediumturbineandspindlegear

assemblies for malfunction. This will require the unit

be disassembled, if you are not comfortable with the

cleaner’s assembly please seek professional help.

PROBLEM: CLEANER HEAD FLOATS

CAUSES SOLUTIONS

Cleaner head or return line has air in it Remove all air from cleaner head

Stop all air from entering the pool through

the return lines

Ifcleanerheadandhosearecoveredwithne

bubbles, give the hose a good tug. This will release

the air bubbles and allow the cleaner head to settle

to the bottom of the pool until the hose is covered

with bubbles again

The cleaner head is being pulled or lifted o

the bottom of the pool by the cleaner hose

orreturnlineow–eitheratthesurfaceorat

thebottomofthepool–orboth

Readjust return lines to prevent water ow from

interferingwithcleanerheadand/orhose

WAVETRUCK AUTOMATIC POOL CLEANER TROUBLESHOOTING GUIDE

13

A. Pool plaster is aected by age, water chemistry, etc.

B. Pool plaster can deteriorate over a period of time.

C. The integrity of “good” pool plaster is such that a pool

vacuumcleaner–automaticormanual–cannotremove

that plaster.

D. The integrity of “good” pool plaster is such that the plaster

will cause wear on the WaveTruck automatic pool cleaner

–notviceversa.

E. Vinylandberglassareaectedbyage,sunlightand

water chemistry.

F. Vinyl can become brittle and weak.

G. Vinyl can also be aected by the installation and the pool’s

surroundings.

H. When installing the WaveTruck automatic pool cleaner,

you assume all responsibility for the condition of the pool

and the pool’s surroundings.

To better serve you, please have the following information

available if you contact your local First Choice dealer.

1. The purchase date and purchase location of your

WaveTruck automatic pool cleaner.

2. The serial number of your WaveTruck automatic pool

cleaner.

3. Thenumberofhosesectionsused.

WAVETRUCK AUTOMATIC POOL CLEANER TROUBLESHOOTING GUIDE

WAVETRUCK AUTOMATIC POOL CLEANER DISCLAIMER

PROBLEM: CLEANER STICKS AT STEPS, CORNERS, ETC.

CAUSES SOLUTIONS

Improper water ow Check and adjust water ow, Pg 4

Worn shoes Replace shoes, Pg 7

Worn wings Replace wings, Pg 8

Hose too short Install additional hose, Pg 2

Steering failure 1. Check and clean rear screen

2. Check to see that cone gear is free and rotates

smoothly in both directions

3.Checksteeringprogramandtroubleshoot–then:

A.Clean,repairorreplacegearbox

B. Checkpod/A-frameconnectionandreplace

ifnecessary–donotattempttoretighten

loose pods

C. Check medium turbine and spindle gear

assemblies- This will require the unit be

disassembled, if you are not comfortable with the

cleaner’s assembly please seek professional help.

14

Thislimitedwarrantyisextendedtotheoriginalpurchaser

(consumer) from the manufacturer of the WaveTruck Automatic

Pool Cleaner.

First Choice warrants this cleaner to be free from defects in

materials and workmanship for a period of one year from the

original date of purchase subject to all the following conditions

andexclusions.

1. Should the cleaner fail to be in good working order in

accordance with the above schedule, First Choice will at its

option repair or replace the cleaner or any defective parts

atnoadditionalchargeexceptassetforthbelow.Repair

parts and replacement products will be furnished on an

exchangebasisandwillbeneworfunctionallyequivalent.

All parts removed as a result of replacement shall become

the property of First Choice. Liability of First Choice and

the sole remedy of the purchaser whether in contract

under any warranty, in tort (including negligence), in

strict liability or otherwise, shall be limited to the repair

or replacement of defective parts only and shall in no

eventexceedreturnoftheamountofthepurchaseprice

paid by the purchaser.

2. This limited warranty is for the replacement of alleged

defective parts during the term of the warranty. First

Choice, upon determination and at our option, will repair

and return to the owner all defective parts that are covered

by this warranty. Any parts not covered by this limited

warranty will be returned to owner freight collect.

3. Thislimitedwarrantyisonlyextendedtotheoriginal

purchaser (consumer) and only during the time in which

the original purchaser occupies the premises where the

cleaner was originally installed. It does not apply to any

subsequent purchasers or recipients of the cleaner.

4. This limited liability warranty includes thereplacement

of parts due to normal wear but does not include cosmetic

situations including but not limited to: discoloration or

fading due to sunlight or chemicals, scratches, scus, etc.

5. This limited warranty does not cover any loss, damage,

injury, or malfunction of the equipment due to the failure

to properly maintain and or operate the cleaner, or

alteration of the equipment, tampering, and act of God,

abuse, misuse, negligence, omissions.

6. Thiscleanerisintendedforaproperlydesignedand

maintained swimming pool. This limited warranty

does not cover pools that have a defective design, are

improperly maintained, and are inappropriate for the

WaveTruck automatic pool cleaner’s operation.

7. This limited warranty does not cover damage or injury

from improper installation, pump running dry, damage

due to loss of prime or plugged pipes.

8. This limited warranty does not cover any change in

appearance, damage, malfunction due to chemical

reactions, etc.

9. First Choice is not responsible for any loss of time,

inconvenienceoranyconsequentialexpensessuchas

telephone calls, labor, etc., unless required by law.

10. Deterioration, discoloration or brittleness of pool plaster

and vinyl liners can be caused over time separately by

or in combination with, age and an imbalance in pool

water chemistry, improper installation and other factors.

First Choice hereby disclaims any and all claims, and

purchaser releases First Choice from any and all claims for

damages to any pool plaster or vinyl liner in purchaser’s

poolbyreasonoftheuseand/oroperationofthecleaner.

11. This limited warranty is only valid in the USA and Canada.

12. This limited warranty is in lieu of any other warranties

expressorimplied,includingthewarrantiesof

merchantabilityortness.Anysuchimpliedwarranty

imposed by state consumer law is limited in duration

to one year from date of purchase.

No distributor, dealer or representative has any authority to

makeanywarrantiesexpressorimpliedconcerningWaveTruck

automaticpoolcleanerexceptascontainedherein.Unless

warranty card has been received by First Choice, First Choice

reserves the right to refuse repair service or to honor warranty.

STARZTRUCK AUTOMATIC POOL CLEANER LIMITED WARRANTY

www.FirstChoicePool.com

15

Discover the quality, price and

selection of these dependable

First Choice replacement parts. Each

one is made to last in the USA, and

engineeredforaperfectt.

www.FirstChoicePool.com

1.

TopShellFCH420036

2.

Cone Gear FCH420041

3. IntermediateFCH420043

4. Intermediate Gear Shaft FCH420045

5. Spindle Gear Screw FCH420047

6. SpindleGearFCH420049

7. SpindleGearBushingFCH420053

8. ConeGearBushingFCH420053

9. Upper Middle Body FCH420055

10. UpperBodyScrewKit(6Pack)

FCH420057

11. Medium Turbine Drive Gear

FCH420059

12. MediumTurbineFCH420061

13. MediumTurbineCasewithAxle

FCH420063

14. GearBoxAssemblyFCH420065

15. RearScreen(White)FCH420067

16. FloatKit(2Pack)FCH420073

17. Lower Middle Body FCH420075

18. Bumper (White) FCH420077

19. MiddleBodyScrew(6Pack)

FCH420083

20. Lower Body Screw (4 Pack)

FCH420085

21. Flap Adjuster FCH420087

22. Lower Body (White) FCH420089

23. FlapKitFCH420095

24. Pod Screw Kit FCH420001

25. PodPlugs(6Pack)FCH420003

26. WingKit:LeftandRightWings

FCH420021

27a. Pod Shoes (4 Pack) for Vinyl

FCH420009

27b. Pod Shoes (4 Pack) for Concrete

FCH420011

28. CaptiveScrew/RetainingClip

FCH420101

29a. FixedAccessCoverAssembly

forConcreteModels(White)FCH420103

29b. FixedAccessCoverAssembly

for Vinyl Models FCH420109

30. PodKit(White)FCH420013

31. TurbineBearingsFCH420005

32. SkimmerConeFCH420111

33. MediumTurbine/SpindleGearKit

FCH420115 (not shown)

34. UniversalA-FrameKitFCH420029

35. TurbineKitFCH420007

36. A-FrameandTurbineKitFCH420029

(not shown)

37. A-Frame/Bushing/SaddleKit

FCH420033(notshown)

38. LeafCanister(SeeLocalDealer)

39. RegulatorValveFCH420125

40. Safety Vacuum Lock Wall Fitting

(See Local Dealer)

41. Propulsion/ConversionKit

(White)FCH320119(notshown)

42. FlowGaugeFCH320113

43. HoseConnectorFCH420117

32

33 37 38

FIRST CHOICEALLAMERICAN REPLACEMENT PARTS

FOR THE WAVETRUCK™AUTOMATIC POOL CLEANER

3938 40 41 42

43

4

3

2

9

6

5

15

16

19

17

20

11

12

14

13

18

8

35

31

34

30

21

25

24

37

23

22

7

1

29

10

28

27

26

16

HWN119 -A-FRAME& TURBINE KIT

(REPLACES AXV621DAT)

HWN118 -UNIVERSAL A-FRAME KIT

(REPLACES AXV621D)

HWN11601 -POD KIT (WHITE)

(REPLACES AXV417WHP)

37

35

30a

30b HWN11602 -POD KIT (BLACK)

(REPLACES AXV417BKP)

HWN112 -TURBINE BEARINGS: (2 PACK)

(REPLACES AXV055P)

31 HWN113 -TURBINE KIT

(REPLACES AXV602P / AXV112P)

36

HWN120 - A-FRAME/BUSHING/SADDLE KIT

(REPLACES AXV621D)

41

HWN119 -A-FRAME& TURBINE KIT

(REPLACES AXV621DAT)

HWN118 -UNIVERSAL A-FRAME KIT

(REPLACES AXV621D)

HWN11601 -POD KIT (WHITE)

(REPLACES AXV417WHP)

37

35

30a

30b HWN11602 -POD KIT (BLACK)

(REPLACES AXV417BKP)

HWN112 -TURBINE BEARINGS: (2 PACK)

(REPLACES AXV055P)

31 HWN113 -TURBINE KIT

(REPLACES AXV602P / AXV112P)

36

HWN120 - A-FRAME/BUSHING/SADDLE KIT

(REPLACES AXV621D)

41

HWN160 - PROPULSION/CONVERSION KIT

(REPLACES AXV622DPK)

40

HWN154 - MED. TURBINE/SPINDLE GEAR KIT

(REPLACES AXV079VP)

34

MediumTurbine/SpindleGearKit

FCH420115

Turbine Kit: Turbine and

Two Turbine Bearings

FCH420007

A-Frame/Bushing/SaddleKit

FCH420033

Universal A-Frame Kit

FCH420029

FIRST CHOICE REPLACEMENT KITS

We’ve made your pool equipment service and repair a lot easier with these convenient replacement kits. Each one is a

complete grouping that contains everything you need for that particular repair. For more information or to stock up on

individual replacement parts, visit FirstChoicePool.com.

17

HWN119 -A-FRAME& TURBINE KIT

(REPLACES AXV621DAT)

HWN118 -UNIVERSAL A-FRAME KIT

(REPLACES AXV621D)

HWN11601 -POD KIT (WHITE)

(REPLACES AXV417WHP)

37

35

30a

30b HWN11602 -POD KIT (BLACK)

(REPLACES AXV417BKP)

HWN112 -TURBINE BEARINGS: (2 PACK)

(REPLACES AXV055P)

31 HWN113 -TURBINE KIT

(REPLACES AXV602P / AXV112P)

36

HWN120 - A-FRAME/BUSHING/SADDLE KIT

(REPLACES AXV621D)

41

A-Frame and Turbine Kit

FCH420031

Propulsion/ConversionKit

FCH420119

HWN160 - PROPULSION/CONVERSION KIT

(REPLACES AXV622DPK)

40

HWN154 - MED. TURBINE/SPINDLE GEAR KIT

(REPLACES AXV079VP)

34

FIRST CHOICE REPLACEMENT KITS

Rev01/17

P/NFCTM

www.FirstChoicePool.com

Table of contents