Superabrasive UserManual OriginalLanguageLavina®25LM‐S‐E 12/2014

5

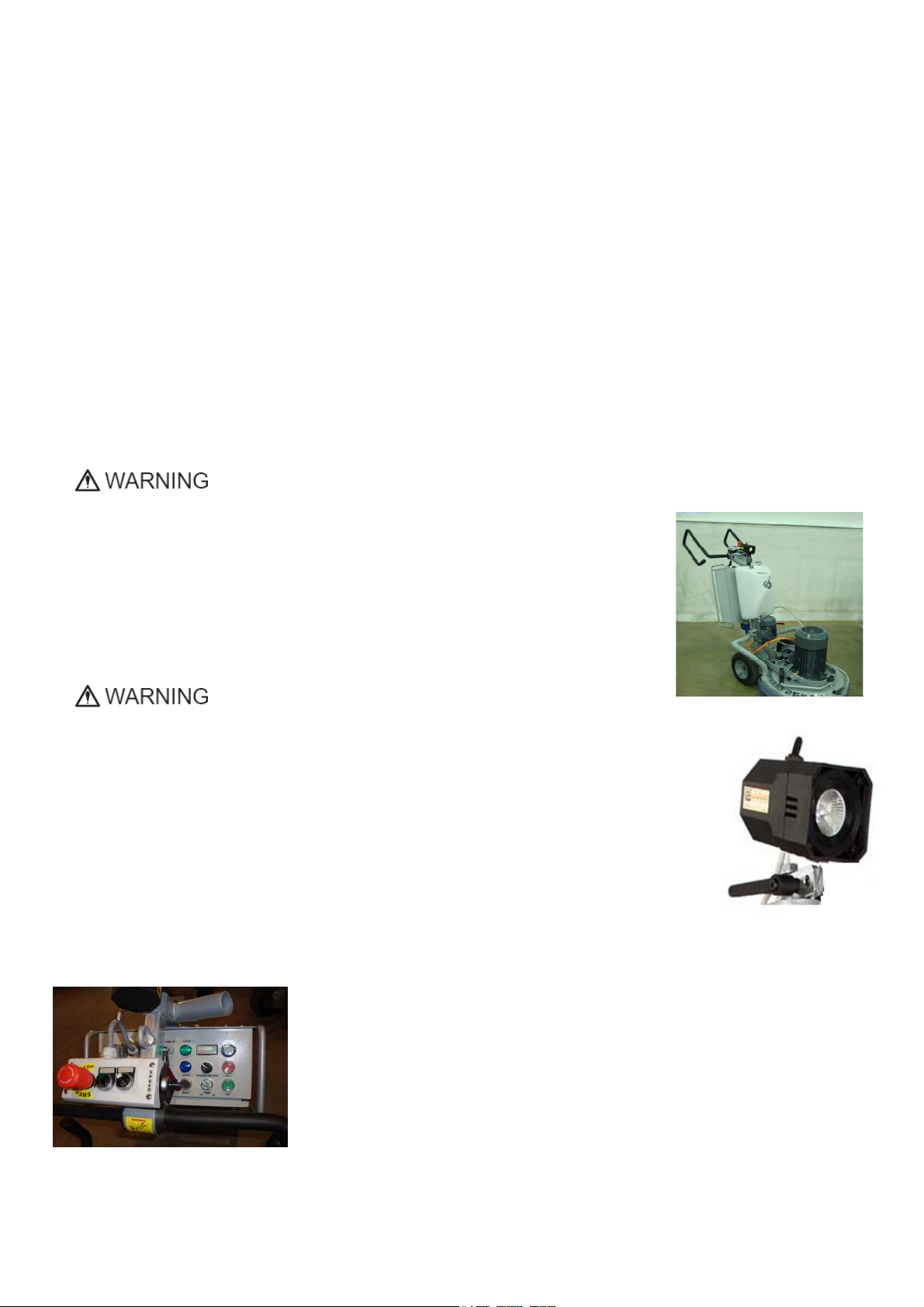

PREPARATIONFORWORK

Makesurethat:Youhaveclosed

theworkarea,sothatnopersonsunfamiliarwithoperatingthe

machinecanenterthearea.Thetoolplateandtoolsare

adjustedtothemachineproperly.Therearenomissingpartsof

themachine.Themachineisinuprightworkingposition.The

protectiondevicesareworkingproperly.Theelectricalcableis

freetomoveandfollowthemachineeasily.Inordertokeepthe

electricalcablefrombeingdamaged,novehicleshouldcrossthe

zonewhereelectricalcablesaresituated.

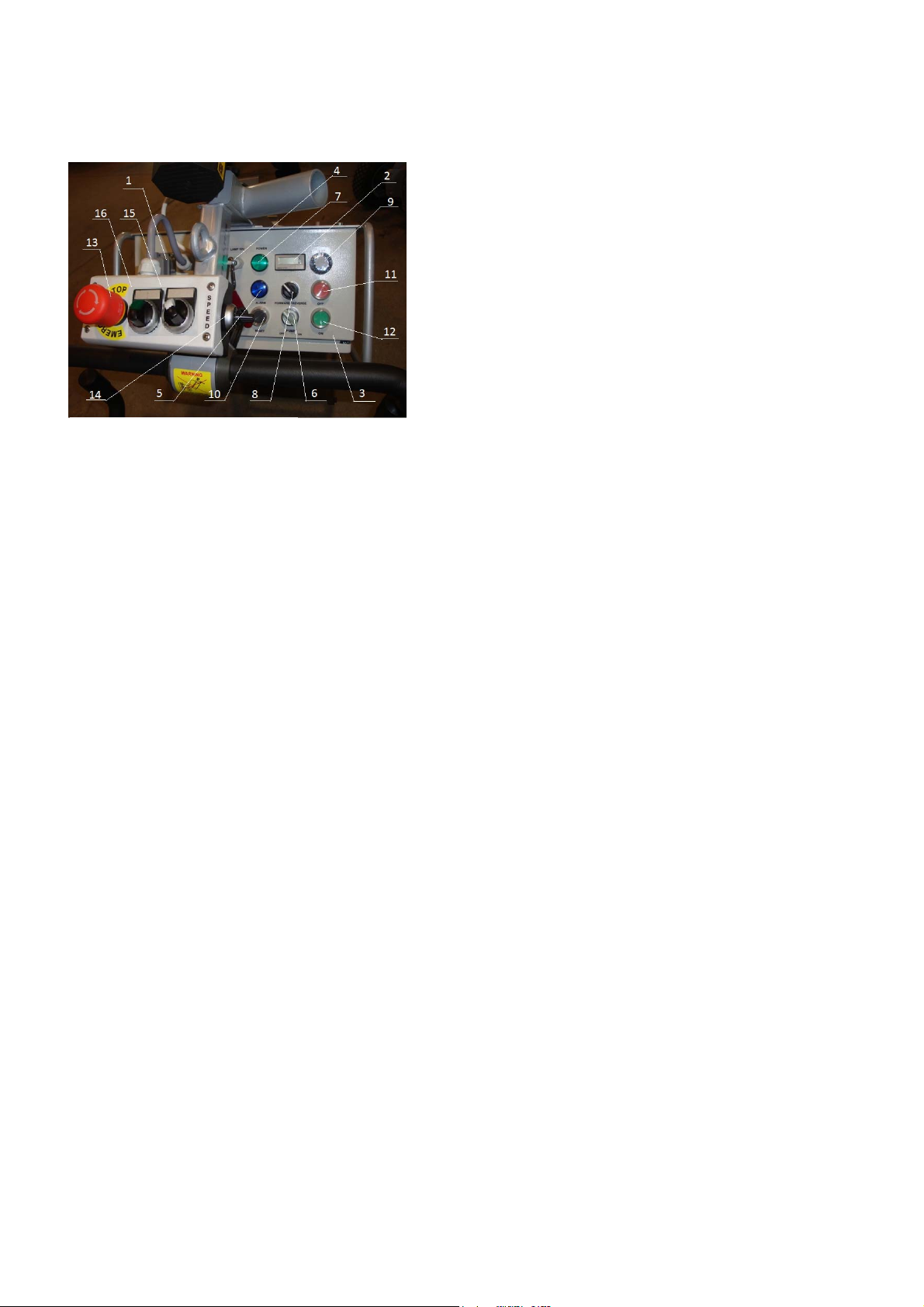

PROTECTIONDEVICES

Themachineisequippedwithseveralprotectiondevices

includingthefollowing:

Anemergencystopbutton

Aprotectionskirtandahoodforprotectingthetool

plates.

Thesedevicesprotecttheoperatorand/orotherpersonsfrom

potentialinjuries.Donotremovethem.Oncontrary,before

usingthemachine,pleaseensurethatallprotectivedevicesare

mountedandfunctionproperly.Thesecurityplatepreventsthe

QuickChangepadsfromlooseningduringwork.

ARRESTFUNCTIONS

Functionsofarrestingofthemachinearefollowing:

Buttontostopthemotor(category1)

Emergencybutton(category1)

SAFEUSE

TheLavina®25LM‐S‐Eisdesignedtoeliminateallriskscorrelated

withitsuse.However,itisnotpossibletoeliminatetherisksof

eventualaccidentwiththemachine.Unskilledoruninstructed

operatormaycausecorrelatedresidualrisks.

Suchrisksare:

PositionRisksduetooperator’sincorrectworkingposition

TanglingupRisksduetowearinginappropriateworkingclothes

TrainingRisksduetolackofoperationaltraining

NOTE:Inordertoreduceallconsequencesoftheabove‐

mentionedrisks,weadvisethatmachineoperator’sfollowthe

instructionsinthemanualatalltimes.

RESIDUALRISKS

Duringthenormaloperatingandmaintenancecycles,the

operatorisexposedtofewresidualrisks,whichcannotbe

eliminatedduetothenatureoftheoperations.

BEFOREYOUBEGIN

Workingareamustbeclearfromanydebrisorobjects.

Afirst‐timeoperatormustalwaysreadthemanualandpay

attentiontoallsafetyinstructions.

Allelectricconnectionsandcablesmustbeinspectedfor

potentialdamages.

Groundwiresystemofthepowersupplymustalsobeinspected.

Performgeneraldailyinspectionsofthemachineandinspectthe

machinebeforeeachuse.

Alwaysinspectthesafetydevices:Mountthesecurityplateand

theQuickChangepads

Theemergencybreakmustbeclearandworking.

Thetoolprotectormustbeworking

Themachinemustbeclean

Neveroperatethemachineintherain!

Confirmthattherearenomissingpartsespeciallyafter

transportation,repair,ormaintenance.

Beforefillingthewatertankwithwatermakesurethatthe

machineisnotworkingandthemainswitchisturnedoff.

Beforeturningonthemachinemakesurethatthebaseis

Placedonthefloor,themachineMUSTNOTbeinanupright

positionwhenturnedon!

OPERATINGMACHINE

WhenoperatingtheLavina®25LM‐S‐E,makecertainthatthere

isno

one,butyouaroundthemachine.

Neverleavethemachineunattendedwhileworking.

Theelectricalcablemustmovefreelyandmustbedamage‐

free.

Thewaterhosemustmovefreelyandmustbedamage‐free.

Checkifthefloor,youwillworkon,isnottoouneven.Ifthisis

the

case,itmaycausedamagetothemachine.

AfterWorkiscompleted

Cleanthemachineanditssurroundingsproperly

Emptyandcleanthewatertank

Unplugthemachineandwinduptheelectricalcable

Storethemachineinasafeplace

THEWORKAREA

Makecertainthatpeopleorvehiclesdonotenterthework

area.

Avoidcablesandhosesbeingintheway.

Alwayscheckthefloorfordebris.

PERSONALPROTECTIVE

EQUIPMENT(PPE)

Alwayswearsafetyshoeswhenworkingwiththemachine.

Alwayswearprotectorswhenworkingwiththemachine.

Allpersonnelintheimmediateworkareamustwearsafety

glasseswithsideshields.

Alwayswearsafetygloveswhenchangingthetools.

Alwayswearclothessuitablefortheworkenvironment.

OPERATOR

TheLavina®25LM‐S‐Emachine.

Theoperatormustknowthemachine’sworkenvironment.

Onlyoneoperatoratatimecanworkwiththemachine.The

operatormustbeproperlytrainedandwellinstructedprior

tooperatingthemachine.

Theoperatormustunderstandalltheinstructionsinthis

manual.

Theoperatormustunderstandandinterpretallthedrawingsand

designsinthemanual.

Theoperatormustknowallsanitationandsafetyregulations

pertainingtotheoperationoftheLavina25LM‐S.

Theoperatormusthavefloorgrindingexperience.

Theoperatormustknowwhattodoincaseofanemergency.

Theoperatormusthaveanadequatetechnicalknowledgeand

preparation.