3

7. A fused isolator control which isolates all poles and has a

minimum contact clearance of 3mm, must be fitted in the

electrical supply close to each unit for use in emergency

and to facilitate servicing.

8. If the electrical supply cable is damaged, it must be

replaced by a qualified electrician using 3 core, 2.5mm2

cable to the HO5-RNF specification or higher.

9. The normal leakage current for this appliance is not

greater than 5mA.

10.It is recommended that a residual current device to

BS4293 standard is used on each power supply.

11.In the event of a fault developing, it is essential that the

appliance is isolated from the mains electricity supply and

a competent person informed.

12.In the interest of safety and performance, regular

maintenance and servicing of the appliance is important.

To ensure that the appliance is in optimum condition,

periodical service and maintenance contracts can be

undertaken by the supplier. Equipment is inspected and

serviced by our engineers and, where necessary, faults are

rectified. Any replacement parts are quickly obtained and

fitted to bring the appliance into good working condition.

INSTALLATION

GENERAL

NOTE! It is necessary to employ a qualified electrical

engineer to install and service this appliance.

1. Remove all packaging from the applicance. Any

protective film on the stainless steel panels may be left on

until installation is completed. HOWEVER all protective

film MUST BE REMOVED before the appliance is

commissioned and used.

2. This appliance must be supported clear of any bench top

or shelf upon which it is to stand. A minimum of 50mm

(2”) is recommended. The use of the optional Bench

Stand is strongly urged.

3. Ensure that the area where the appliance is to stand is

leveled, and is capable to support the weight of the

appliance. If the support, or its surround, is made of

combustible material it is recommended that they shall be

clad with a suitable non-combustible heat insulating

material, and the local fire regulations must be observed.

4. Ensure that there is enough room at the front of the

appliance to accommodate the Toast Grid Handles and

the Brander Plate Drip Trough when fitted, and the Toast

Grid might be removed and handled safely.

5. This appliance should preferably be installed below the

hood of an extraction system incorporating filters.

Should the installation be required without a ventilation

hood then a minimum distance of 1000mm (3 feet) must

be allowed between the top of the appliance and any over

head shelf or ceiling. This

appliance may be fitted close to side walls if they are

made of a fire-proof material. A distance of 150mm must

be allowed between the rear of the appliance and a back

6. wall to enable the electrical cable entry. Where the walls

are made of a combustible material, then a minimum

distance of 150mm MUST be maintained between the

appliance and adjacent walls.

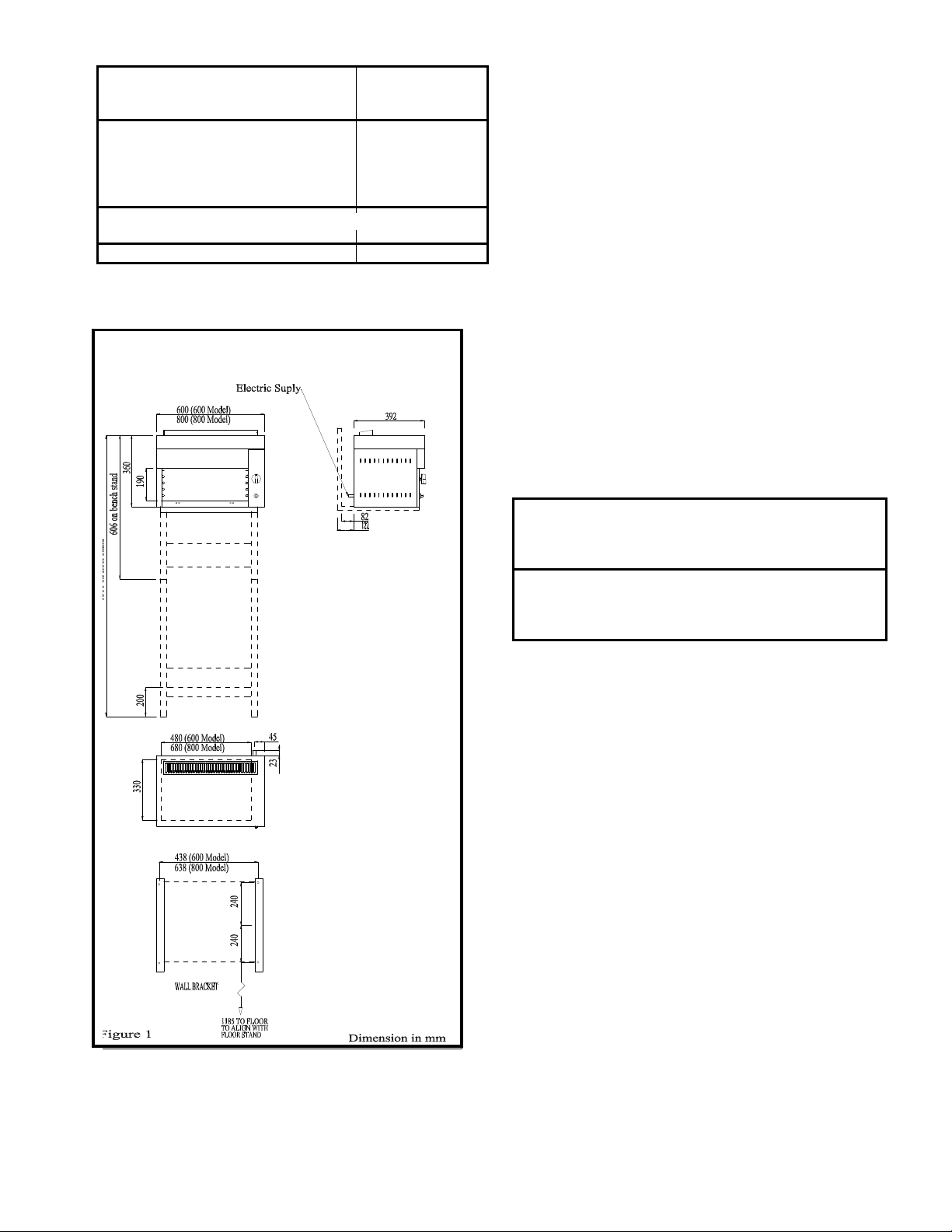

7. When installation is to be made using Wall Brackets,

refer to the enclosed diagram. Ensure that the wall is

capable of supporting and holding the Wall Bracket’s

fixings and the combined weight of the Brackets and

Grill. Measure and mark upon the wall the position of the

Bracket fixings. Drill suitable holes and apply the

selected fixings. Securely screw the Brackets in position.

Place the Grill in position upon the Brackets, aligning the

front of the appliance with the front edge of the projecting

Brackets. Fix the Grill

into position using the four screws provided by screwing

them into the four fixed nuts in the bottom front and rear

flanges of the appliance base.

ELECTRICAL CONNECTION

ENSURE THAT THE MAINS ISOLATING SWITCH

IN THE OFF POSITION.

TURN THE APPLIANCE CONTROL KNOB TO THE

OFF POSITION.

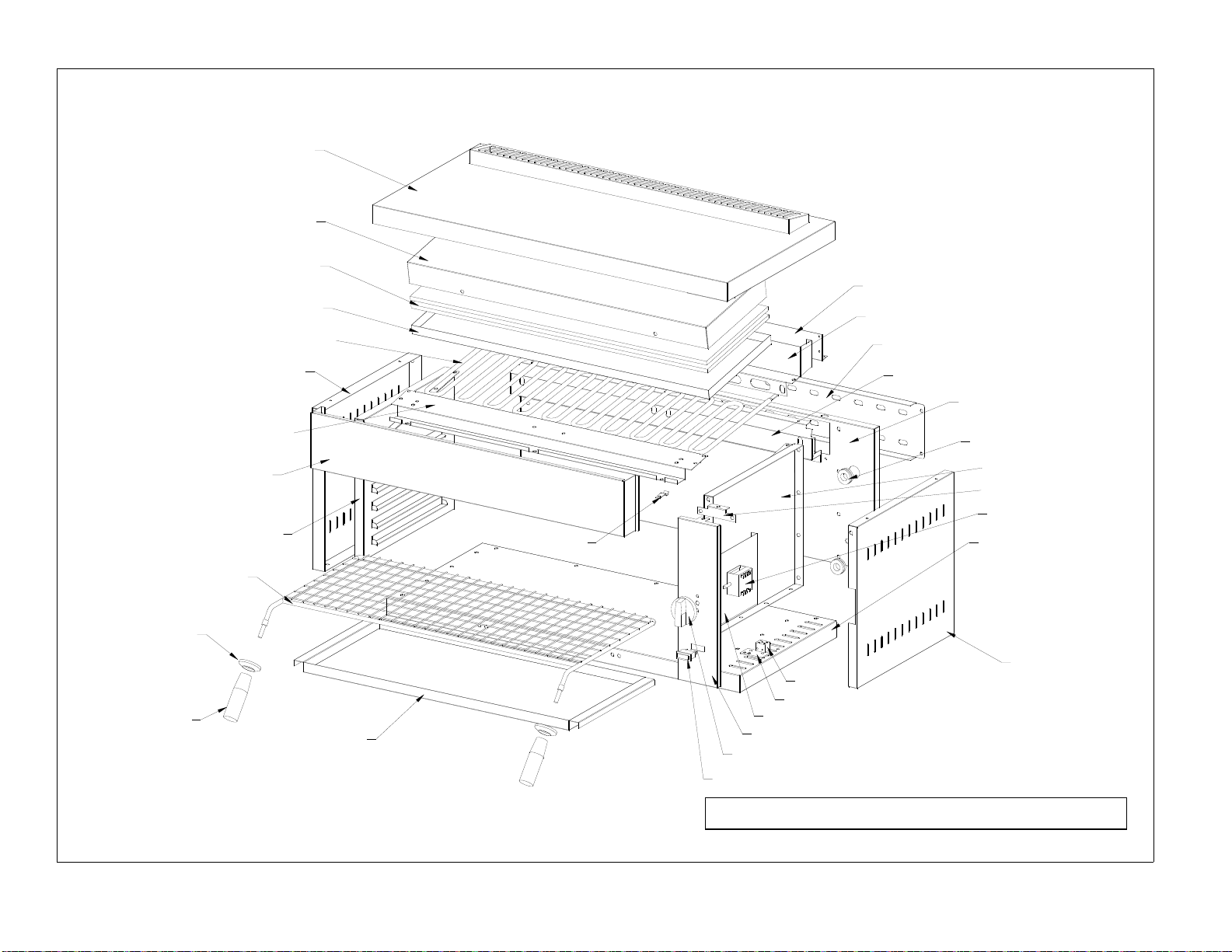

1. Remove the Outer Top Panel by sliding it towards the

front, and then lift it clear of the appliance.

2. Pull off the appliance Control Knob.

3. Remove the Control’s Fascia Panel by removing two

slotted head screws from below the lower front of the

Fascia and one slotted screw from the top of the fascia.

CAREFULLY place the Control’s Fascia aside so that no

undue strain is placed upon the Switch Wiring.

4. Remove the RH Outer Side Panel by unscrewing slotted

head screws from the rear (2), from the upper front (1),

and from below the lower side flanges (3). The Outer Side

may now be pulled clear of the appliance.

5. The appliance’s Mains Terminal Block is now exposed.

Pass the prepared mains cable through the strain relief

grommet in the lower Back Panel of the appliance and

route it through the eyelet fixed in the Terminal Block

Bracket. Make the connections.

LIVE = RED

EUTRAL = BLUE

EARTH = GREEN/YELLOW

With only a minimum “sag” on the Mains Cable within

the appliance, tighten up the Strain Relief Grommet in the

Rear Panel.

6. Refit the RH Outer Side Panel and the Control´s Fascia

Panel.

7. Refit the RH Outer Top Panel by positioning the keyhole

slots in the underside of the Outer Top above the four

pegs projecting from the Outer Side Panels. Fimly press

the Outer Top down, and then slide it towards the rear of

the appliance until the backs line up.