First Products ND-120 Installation and operation manual

OPERATOR’S

MANUAL & PARTS LIST

MULTI-drill

MODEL ND-120

FIRST PRODUCTS INC.

164 Oakridge Church Road

Tifton, Georgia 31794 U.S.A.

Phone (229) 382-4768

1-800-363-8780

Fax (229) 382-0506

Web: www.1stproducts.com Email: Sales@1stproducts.com

ND-120 SER. 1004 thru ___

Printed in U.S.A.

PBREV 0623

1

INTRODUCTION

Thank you for purchasing a First Products Multi-Drill. This piece of equipment has been carefully

engineered and manufactured to provide years of reliable service.

The Multi-Drill is one of the most unique and versatile pieces of equipment on the market today.

It is designed for primary seeding in various soil conditions.

We recommend that you carefully read the operators manual prior to operation. Also ensure that

all future operators read this manual and become fully trained before allowing them to use or

maintain this equipment. Time spent becoming acquainted with the safe operation, performance,

and maintenance of the Multi-Drill will add longer life and greater satisfaction to your new

purchase.

This machine is designed with safety in mind. However, if the machine is handled carelessly and

not as instructed, it can be a dangerous piece of equipment. Observe all safety information in this

manual and decals on the equipment.

The illustrations and data used in the manual were current at the time of printing. The manufacturer

reserves the right to make changes or add improvements to its products at any time without

incurring any obligation to make such changes to products manufactured previously.

For service questions, First Products has trained personnel, genuine First Products parts, and the

necessary tools/equipment to handle all your needs.

Use only genuine First Products parts. Substituting parts will void warranty and may not meet

standards required for safe and satisfactory operation. Record the model number and serial number

of your equipment in the spaces provided below:

MODEL: __________________________________

SERIAL NUMBER: _________________________

DATE OF PURCHASE: _____________________

Read and understand the instructions and warnings carefully before using

this machine.

Read the warranty located on page 18. Fill in the required information on

the warranty registration provided and return to the address on the front of

this manual. The warranty registration must be returned to validate

warranty.

REMEMBER SAFETY IS ALWAYS FIRST!

2

TABLE OF CONTENTS

INTRODUCTION ...................................... 1

TABLE OF CONTENTS ............................ 2

GENERAL INFORMATION ..................... 3

SPECIFICATIONS for ND-144 ................. 3

SAFETY SYMBOLS.................................. 4

SAFETY RULES ........................................ 5

Training ................................................... 5

Preparation .............................................. 5

Operation ................................................. 5

Transportation ......................................... 6

Maintenance ............................................ 6

Storage ..................................................... 7

SAFETY DECALS ..................................... 7

OPERATION .............................................. 9

Front Coulter Disc Shaft ....................... 10

Seed Disc Assembly .............................. 10

Seeders .................................................. 10

Attaching Multi-Drill ............................ 11

1. Standard Cat. II/III 3-point hitch: 11

2. Standard Cat. II Quick hitch: ....... 11

3. Tow hitch with hydraulics: ........... 11

Seeder Setup .......................................... 12

Seeder Controls ................................. 12

Setting Seed Depth ............................. 13

Seeder Calibration ............................. 14

CLEANING .............................................. 17

After Each Use ...................................... 17

Periodic or Before Extended Storage .... 17

WARRANTY INFORMATION .............. 18

Parts Book ................................................. 23

Row Unit Group .................................... 23

Spring Rod Group ................................. 27

Press Wheel Arm Group ....................... 28

Frame Group ......................................... 29

Coulter Shaft Group .............................. 33

Frame to Seeder Group ......................... 34

Primary Hopper Group .......................... 37

Primary Hopper (Rt) Group .................. 41

Agitator Group ...................................... 45

Spout Tray Group ................................ 467

Hydraulic Idler Group ......................... 478

Hydraulic Motor Group ....................... 489

Hopper Hydraulics Group ..................... 50

Auxiliary Hopper Group ....................... 52

Auxiliary Hopper (Rt) Group ................ 56

Auxiliary to Primary Hopper Group ..... 59

Chain Cover Group ............................... 60

Auxiliary Chain Cover Group ............... 61

Electrical Group .................................... 62

Tow Hitch Group .................................. 64

3

GENERAL INFORMATION

The purpose of this manual is to assist you in operating and maintaining your Multi-Drill. Read

it carefully. It furnishes information and istructions that will help you achieve years of

dependable performance. These instructions have been compiled from extensive field

experience and engineering data. Some information may be general in nature due to unknown

and variying operating conditions. However, through experience and these instructions, you

should be able to develp procedures suitable to your particular situation.

The illustrations and data used in this manual were current at the time of printing, but due to

possible inline production changes, your machine may vary slightly in detail. We reserve the

right to redesign and change the machines as may be necessary without notification.

Throughout this manual, references are made to right and left locations. These are determined

by standing behind the equipment facing the direction of forward travel.

SPECIFICATIONS for ND-144

Working Width 126”

Overall Width 162”

Disc Diamete

r

Coulter disc: 16” / Seed disc: 13.5”

Disc Spacing 9”

Hitch Cate

g

or

y

CAT II/III

Quick Hitch Compatible Yes

Hydraulic Lift Compatible No

Towin

g

Hitch Compatible Yes

Gua

g

e Wheels 32 X 11 X 15 (Implement Tire – 20 mph max)

Wei

g

ht w/ all options 4600 Lbs

Primar

y

Seedbox Capacit

y

16 Bushels

Auxiliary Seedbox Capcity 6 Bushels

Primar

y

Seed Distribution Metho

d

Gravit

y

metered into rows

Seed Depth Gau

g

e Metho

d

Gua

g

e Wheels

–

Turnbuckle

Warning

Multi-Drill should never be operated with any safety shielding removed.

4

SAFETY SYMBOLS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

This is a standard safety alert symbol meaning

CAUTION

Indicates hazardous situation, injury may

occur, used to alert against carelessness.

WARNING

Indicates potentially hazardous situation. Death

or serious injury may occur if proper

procedures are not followed.

DANGER

Indicates most hazardous situation. Death or

serious injury will occur if proper procedures

are not followed.

5

SAFETY RULES

Safety is a primary concern in the design and manufacturing of our products. However, our

efforts to provide safe equipment can be avoided by an operator’s careless act. Accident

prevention ultimately is dependent upon the awareness, concern, judgement, and proper training

of the personnel involved in the operation, transport, maintenance, and storage of the equipment.

It is incumbent upon every operator to practice proper safety protocol to avoid life-threatening

situations.

Training

Safety instructions are important! Read all

attachment and power unit manuals; follow

all safety rules and safety decal information.

Failure to follow instructions or safety rules

can result in serious injury or death.

If you do not understand any part of this

manual and need assistance, call First

Products.

Know your controls and how to stop engine

and attachment quickly in an emergency.

Operators must be instructed in and be

capable of the safe operation of the

equipment, its attachments, and all controls.

Do not allow anyone to operate this

equipment without proper instructions.

Never allow children or untrained persons to

operate equipment.

Preparation

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Always wear relatively tight and belted

clothing to avoid getting caught in moving

parts. Wear proper personal protective

equipment for eyes, hair, hands, hearing, and

head.

Make sure all safety decals are installed.

Replace if damaged. See Safety Decals

section for location and part numbers for

ordering replacements.

A minimum 20% of tractor and equipment

weight must be on the tractor’s front wheels

when attachments are in transport position.

Without this weight, front tractor wheels

could raise up and result in loss of steering.

Operation

Keep bystanders away from equipment.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Operate only in daylight or good artificial

light.

Keep hands, feet, hair, and clothing away

from equipment while engine is running.

Stay clear of all moving parts.

Always comply with all state and local

lighting and marking requirements.

Never allow riders on power unit or

attachment.

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt

securely fastened. Falling off power unit

can result in death from being run over or

crushed. Keep foldable ROPS system in

“locked up” position at all times.

Always sit in power unit seat when

operating controls or starting engine.

6

Securely fasten seat belt, place transmission

in neutral, engage brake, and ensure all other

controls are disengaged before starting

power unit engine.

Look down and to the rear and make sure

area is clear before traveling in reverse.

Do not operate seeder in reverse.

Use extreme care when working close to

fences, ditches, other obstructions, or on

hillsides.

Do not operate or transport on steep slopes.

Do not start, stop, or change directions

suddenly on slopes.

Use extreme care and reduce ground speed

on slopes and rough terrain.

Watch for hidden hazards on the terrain

during operation.

Stop power unit and equipment immediately

upon striking an obstruction. Turn off

engine, remove key, inspect, and repair any

damage before resuming operation.

Transportation

Use additional caution and reduce speed

when under adverse surface conditions,

turning, or on inclines.

A minimum 20% of tractor and equipment

weight must be on the tractor’s front wheels

when attachments are in transport position.

Without this weight, front tractor wheels

could raise up and result in loss of steering.

The weight may be attained with front wheel

weights, ballast in tires, front tractor

weights, or front loader. Weigh the tractor

and equipment. Do not estimate.

Do not operate or transport on steep slopes.

Always raise unit and install transport lock

before transporting. Leak down or failure of

mechanical or hydraulic systems can cause

equipment to drop.

When utilizing a pull-type hitch, always

attach safety chain to tractor drawbar when

transporting unit.

Never exceed 20 mph (32.2 hm/h) during

transport.

Maintenance

Before dismounting power unit or

performing any service or maintenance,

follow these steps: 1) disengage power to

equipment 2) lower unit to ground 3)

operate valve levers to release any hydraulic

pressure 4) set parking brake 5) stop engine

6) remove key 7) unfasten seat belt.

NEVER GO UNDERNEATH

EQUIPMENT. Never place any part of the

body underneath equipment or between

moveable parts even when the engine has

been turned off. Hydraulic system leak-

down, hydraulic system failures, mechanical

failures, or movement of control levers can

cause equipment to drop or rotate

unexpectedly resulting in severe injury or

death. (Service work does not require going

underneath).

Read Operator’s Manual for service

instructions or have service performed by

qualified personnel.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Keep all persons away from operator control

area while performing adjustment, service,

or maintenance.

Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter

7

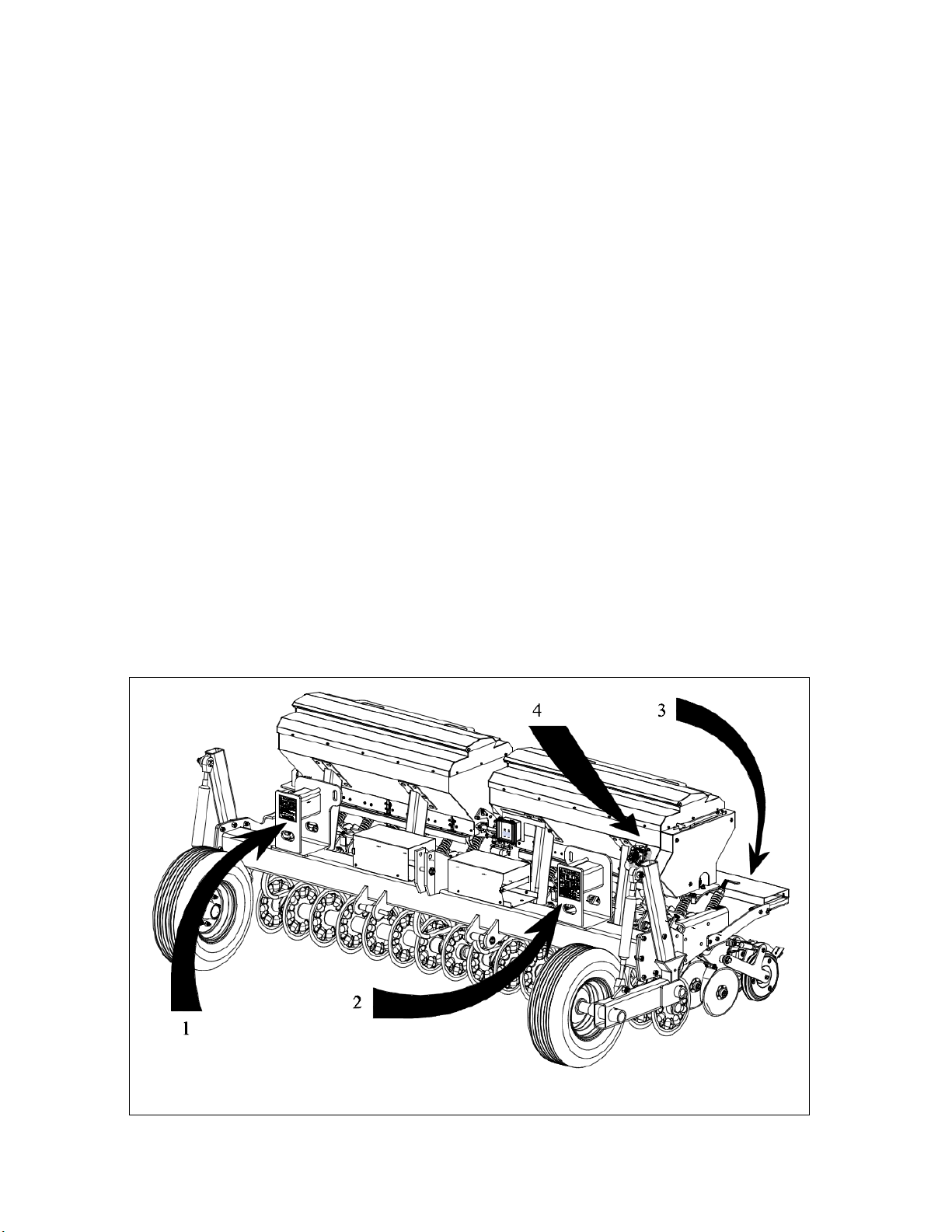

Figure 1. Safety Decal placement on Multi-Drill

pins are installed securely to ensure

equipment is in a safe condition before

putting unit into service.

Make sure all safety decals are installed.

Replace if damaged. See Safety Decals

section for location and corresponding part

numbers.

Storage

Block equipment securely for storage.

Cover with tarp included with seeder.

Keep children and bystanders away from

storage area.

SAFETY DECALS

Your implement comes equipped with all safety labels in place. They were designed to help you

safely operate your implement.

1. Read and follow decal directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals.

4. Refer to this section for proper decal placement.

Avoid spraying too close to decals when using a pressure washer; high pressure water can enter

through very small scratches or under edges of decals causing them to peel or come off.

To install new decals:

Clean the area the decal is to be placed. Peel backing from decal. Press firmly on surface being

careful not to cause air bubbles under label.

8

2 – Operator Warning (DS50-068)

3 – No Riders (AG50-089)

4 – Hydraulic Pressure (AE50-194)

1 – General Warning (DS50-067)

9

OPERATION

The operator is responsible for the safe operation of this seeder. The operator must be properly

trained. Operators should be familiar with the equipment, the tractor, and all safety practices

before starting operation. Read the safety rules and safety decals provided in this operator’s

manual.

The Multi-Drill is an excellent primary seeder, food plot seeder, and conservation seeder. Its

primary function is to deliver a variety of seed to the soil at the desired depth with minimal ground

disturbance. The Multi-Drill does this utilizing a series of discs to cut narrow slits in the ground

where seed is precisely positioned at the proper depth and packed down via closing wheels. The

Multi-Drill is capable of planting multiple seed varieties at once due to its optional second seed

box attachment. Seed plates are adjusted on the hoppers to achieve the desired seed rates while

electric actuators shuttle the hopper outlets open and closed. When the electric actuators open the

hopper outlets, a hydraulic motor powers an agitator shaft which stirs the seed over every outlet to

encourage the free flow of seed at the measured rate. The speed of the hydraulic motor can be

changed to finetune the seed rate.

WARNING

Power unit must be equipped with Roll Over Protection System (ROPS) or ROPS cab and

seat belt. Keep seat belt securely fastened. Falling off power unit can result in death from

being run over or crushed. Keep foldable ROPS system in” locked up” position at all times.

Never allow children or untrained persons to operate equipment.

Keep bystanders away from equipment.

Keep hands, feet, hair, and clothing away from equipment while engine is running. Stay clear

of all moving parts.

CAUTION

Stop power unit and equipment immediately upon striking an obstruction. Turn off engine,

set parking brake, remove key, inspect, and repair any damage before resuming operation.

Always wear relatively tight and belted clothing to avoid getting caught in moving parts.

Wear proper personal protective equipment for eyes, hair, hands, hearing, and head.

10

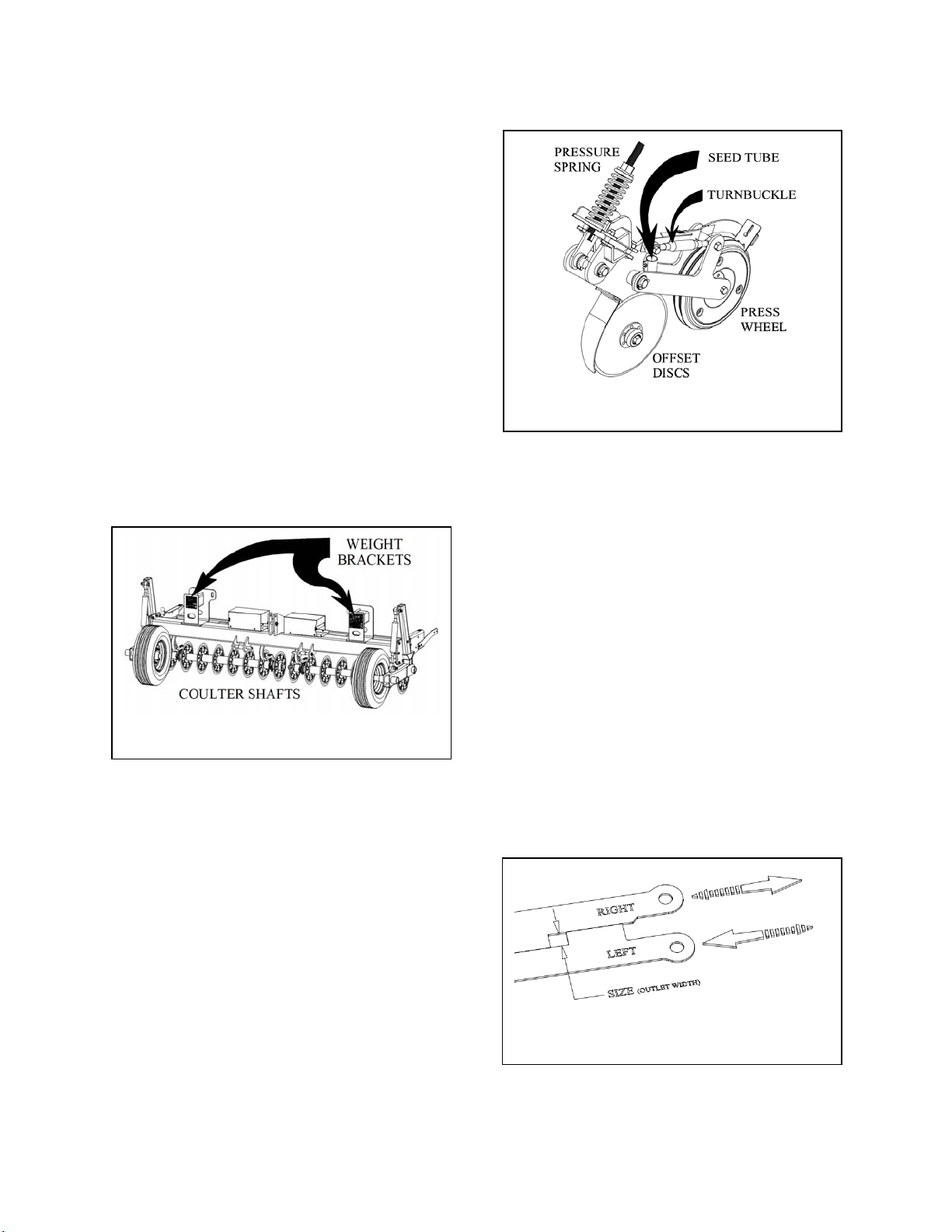

Front Coulter Disc Shaft

The Multi-Drill is equipped with a coulter

disc shaft mounted to the front of the frame.

The function of this shaft is to cut a narrow

slit in the ground in preparation for the seed

delivery to follow. The cutting depth of the

shaft is manipulated using the gauge wheels

on the sides of the frame. Whatever the

desired depth of the final seed delivery may

be, it is recommended that these coulter discs

be set to cut ¼” deeper to allow adequate

room for the seed to easily fall in and be

packed into place. If the ground is too hard

for the coulter shaft to reach its target depth,

weights can be added to the weight brackets

located on both sides of the frame above the

coulter disc shaft.

Seed Disc Assembly

Often referred to as double disc openers, the

Multi-drill sports offset discs which follow

directly behind each coulter disc and are

specifically designed to open the slit made by

the preceded coulter and drop seed from the

primary hopper in the trench made. Each

seed disc assembly is comprised of two

angled discs, pressure spring, turnbuckle,

seed tube, and press wheel. The seed depth

is adjusted utilizing the turnbuckle. The seed

tube receives the hose from the primary box

and drops the seed directly between the discs

at the measured depth created by the discs.

The press wheel utilizes the force from the

spring to firm up the soil over the seed.

Seeders

The Multi-drill is equipped with a standard

hopper, referred to as “primary”, while

having the capability of adding a smaller

hopper for simultaneous applications. The

seeders are comprised of a hopper, seed

plates, electric actuator, hydraulic motor, and

one handheld control harness. Each seeder

utilizes the same metering principle and

delivery system. The outlets on the bottom

of the seeders have their sizes adjusted

manually by sliding the seed plates past one

another, Figure 4. There are different sizes of

seed plates to account for the various seeds

Figure 2. Coulter Disc Shaft

Figure 3. Seed Disc Assembly

Figure 4. Seed plates

11

which are specified in the calibration

instructions. A handheld control harness

tethered to the seeders opens and closes the

seed openings using a cutoff plate. When the

seeder is energized, an electric actuator opens

the bottom of the seeder exposing the outlets

while a hydraulic motor powers an agitator

shaft which stirs the seed inside the hopper as

shown in Figure 5. The speed of the

hydraulic motor is adjusted using the flow

control valve (discussed further in Seeder

Controls section). Figure 6 shows the

location of the flow control valve, the

hydraulic motor, and the agitator shaft which

stirs the seed in the hopper.

Attaching Multi-Drill

Note: The ND-144 Model is designed to have

three ways of attaching to power unit:

1. Standard Cat. II/III 3-point hitch

2. Standard Cat. II Quick hitch

3. Tow hitch with hydraulics

1. Standard Cat. II/III 3-point hitch:

Attach the tractor’s lower lift arms to the

Multi-Drill’s frame and secure with indicated

hitch/lynch pins (Figure 7). Attach the

tractor’s top link to the mast plates of the

Multi-Drill.

2. Standard Cat. II Quick hitch:

For quick hitch use, install the bushings with

lower lift pins and appropriate top pin to

receive upper hook.

3. Tow hitch with hydraulics:

The tow hitch requires hydraulics cylinders

to act in place of the turnbuckles which adjust

the gauge wheels. Simply pin the tow hitch

tongue to the tractor’s drawbar and plumb the

hydraulics to the tractor’s remote ports

accordingly.

Figure 5. Seeder Actuator & Control Box

Figure 6. Hydraulics (hoses not shown)

Figure 7. Hitch Specifications

12

Figure 8. Quick Start Setting Guide - Step 3

Fi

g

ure 9. A

g

itator shaft location

Seeder Setup

The Multi-Drill is capable of planting a wide

variety of seeds over a wide range of seeding

rates. Several variables have to be taken into

account when planting: seed depth, ground

speed, and seed rate. These all have to come

together in order to achieve the optimum

stand desired.

The Multi-drill seeder utilizes a gravity feed

system combined with variable seed agitation

and adjustable outlets to achieve consistent

and precise seed rates. The size of the outlets

is primarily a function of what size seed plate

is used during calibration. The speed of the

seed agitator is manipulated toward the end

of the calibration process to finetune the

desired rate.

Seeder Controls

After hitching the Multi-drill to the tractor,

the electrical harness and hydraulic hoses

must be properly routed and connected.

The electrical connection starts at the

tractor’s battery where it is then routed to

the operator’s station and terminated on the

seeder’s control box seen in Figure 5. This

harness includes the lanyard tethering the

switch box to the operator. Ensure this

wiring harness is clear of any moving parts

or obstructions during operation and that the

operator can easily access the switch box at

all times.

The hydraulic lines are simply plumbed into

the tractor’s remote ports. If the tractor uses

a closed-center system, the shutoff valve

located by the flow control valve (Figure 6)

will need to be closed allowing the tractor to

sense the pressure needed to operate the

hydraulic motor. However, if the tractor has

an open-center hydraulic system the shutoff

valve needs to remain open. The flow

control valve is used to adjust the speed of

the agitator shaft (Figure 9)

13

Fi

g

ure 11. Seed disc ad

j

ustment

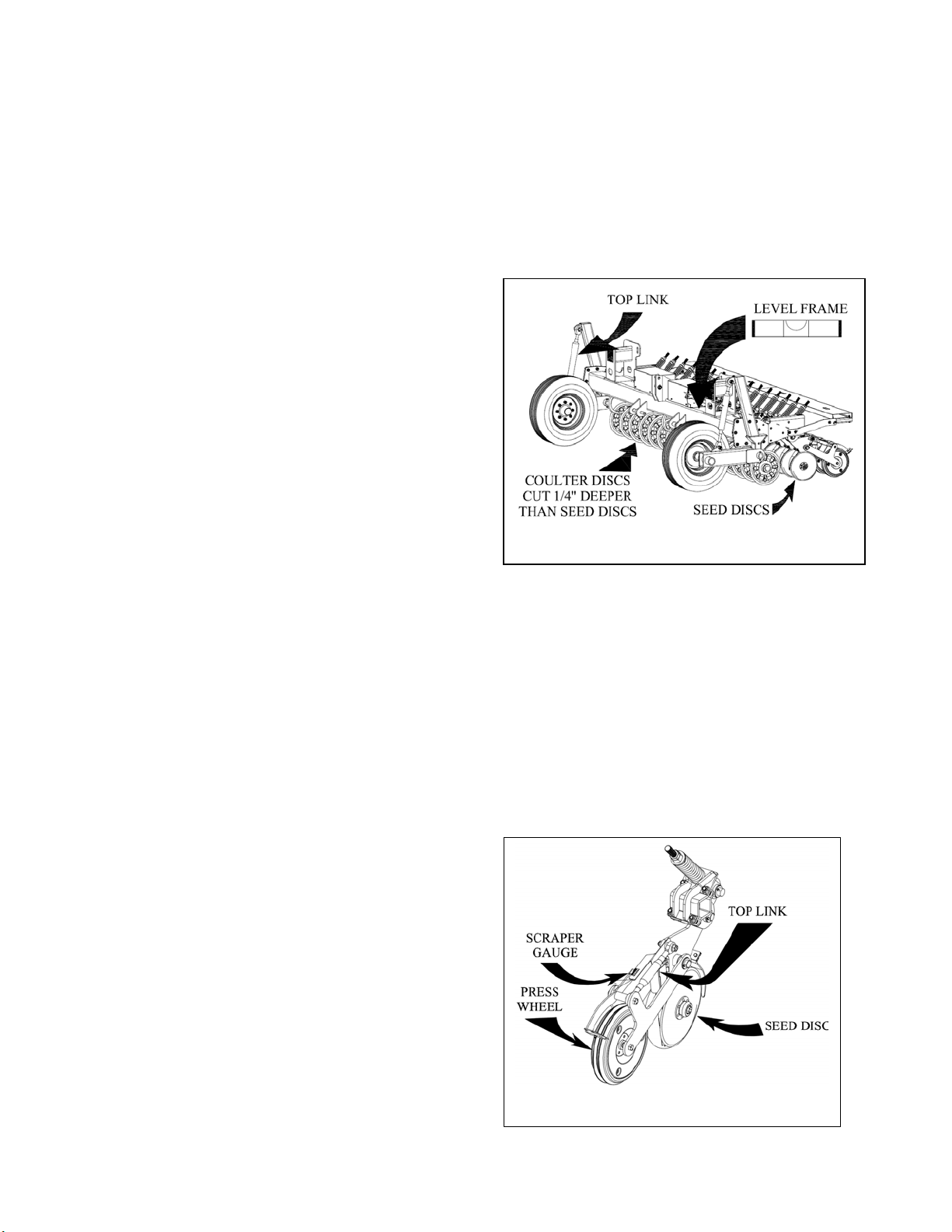

Setting Seed Depth

After hitching Multi-drill and making all

necessary connections (see previous

sections), the seed depth must be set before

seed calibration is addressed. The following

steps must be done in order to set the seed

depth:

1. Level Multi-drill frame

2. Set Coulter depth

3. Check seed depth and adjust

Each of these steps is detailed below:

1. Level Multi-drill Frame

Whether using the standard 3-point hitch or

the towing hitch, the procedure is the same.

Lower the Multi-drill to the ground. Pull

forward a short distance to allow the coulter

discs to settle into the ground. Place a level

on the main toolbar of the Multi-drill and

check for adjustments (Figure 10). Use the

top link to tilt the frame until its operation is

level.

2. Set Coulter depth

Using a scale, measure the depth of cut the

coulter discs made from the leveling

process. The coulter discs are designed to

cut ¼” deeper then the desired seed depth.

So, if the desired seed depth is ¾”, the

coulter discs are to cut 1” deep.

To adjust depth with a 3-point hitch, the

machine must be lifted in the air and have

each top link on both sides adjusted

accordingly, Figure 10. Use a tape measure

to ensure they are both the same.

To adjust the depth with a tow hitch,

hydraulic cylinder stops are used to limit the

stroke of the gauge wheels. With the

machine in the air, simply add/remove the

stops where the gauge wheel lowers the

coulter discs to desired depth (1/4” increments).

3. Check seed depth and adjust

Once the frame is level and the desired

depth of cut is obtained, a short pass can be

made operating the seeder at the desired

speed (wait until seeder calibration is done

before filling hoppers). This allows the

operator to check the seed depth.

After checking the depth of the seed in the

ground, changes can be made by adjusting

the pressure on the Press Wheel (Figure 11).

The seed can be slightly lowered or lifted

rotating the Top Link on the attached Row

Unit. Shorten the Top Link to lower the

seed deeper and lengthen the Top Link to

raise the seed closer to the surface. The

Scraper Gauge is used as a point of

reference for this final adjustment. Simply

repeat this step until the proper seed depth is

obtained.

Figure 10. Level Multi-drill frame

14

Seeder Calibration

Before operating the seeder, calibration has

to be done in order to take all variables into

account and maximize efficiency of the

seeder. The following steps must be done to

calibrate the seeder:

1. Determine ground speed.

2. Select seed rate.

3. Select seed plates.

4. Use calibration chart to find target

seed weight (Figure 13).

5. Position calibration trough to catch

seed.

6. Operate seeder in air for 1 minute.

7. Compare weight of seed caught to the

target weight in step 4.

8. Manipulate seed plates or electric

motor speed to reach target weight.

9. Repeat steps 5 thru 8 until target

weight is achieved.

10. Check for consistent seed metering.

Each of these steps is detailed below:

1. Determine ground speed

Determining ground speed usually depends on

the terrain in which the seeding is done. In order

to help set a ground speed, it is recommended the

operator make a test pass without operating the

seeder to determine a good starting point. If the

tractor isn’t equipped with a speedometer, a

smartphone app may prove useful.

2. Select seed rate

Most seed varieties have a set standard for what

rate works best. Investigate the seed and

determine what the recommended rate would be

for the particular application. The calibration

chart uses pounds per acre.

3. Set seed plates and hydraulic motor setting

Determine the seed plates needed to achieve the

desired seed rate. The seed plates come in four

different sizes identified with laser etching on one

end. Figure 8 displays a Quick Start Setting

Guide. This chart is used as a point of reference

to help select the proper seed plate, set their

starting position, and choosing the agitator shaft

speed.

If the Quick Start Setting Guide is not helpful for

selecting a seed plate, below is a list of common

seeds under the corresponding seed plates:

¼” Seed Plate: Clover, Grain, Sorghum, Canola

3/8” Seed Plate: Soybeans (low rates)

½” Seed Plate: Wheat and Rye Grass Peas,

Beans (under 60 lbs/acre),

Soybeans (moderate rates)

¾” Seed Plate: Wheat and Rye Grass, Oats,

Mixes, medium to large Grains,

Peas, Beans (over 60 lbs/acre),

Soybeans (high rates)

If the current plates inside the hopper are not the

desired set to use, refer to “Changing Seed Plates”

for step-by-step instructions.

To set the seed plates, the Multi-Drill is supplied

with a wrench, DS27-026, to help as shown in

Figure 12. Use the wrench to loosen the Setting

Bolt sporting the arrow; the wrench also adds

leverage for shifting the plates to the desired

setting. When the setting is adjusted, retighten

the Setting Bolt and store the wrench for future

use.

Figure 12. Seed Plate Setting/Adjustment

15

At this time, the agitator shaft speed should be set

to what the Quick Start Setting Guide

recommends. Figure 6 illustrates the location of

the motor and flow control valve while figure 9

shows the location of the agitator shaft. With

speed in mind, the operator must manually adjust

the flow to the hydraulic motor in order to achieve

the target agitator shaft in revolutions per minute.

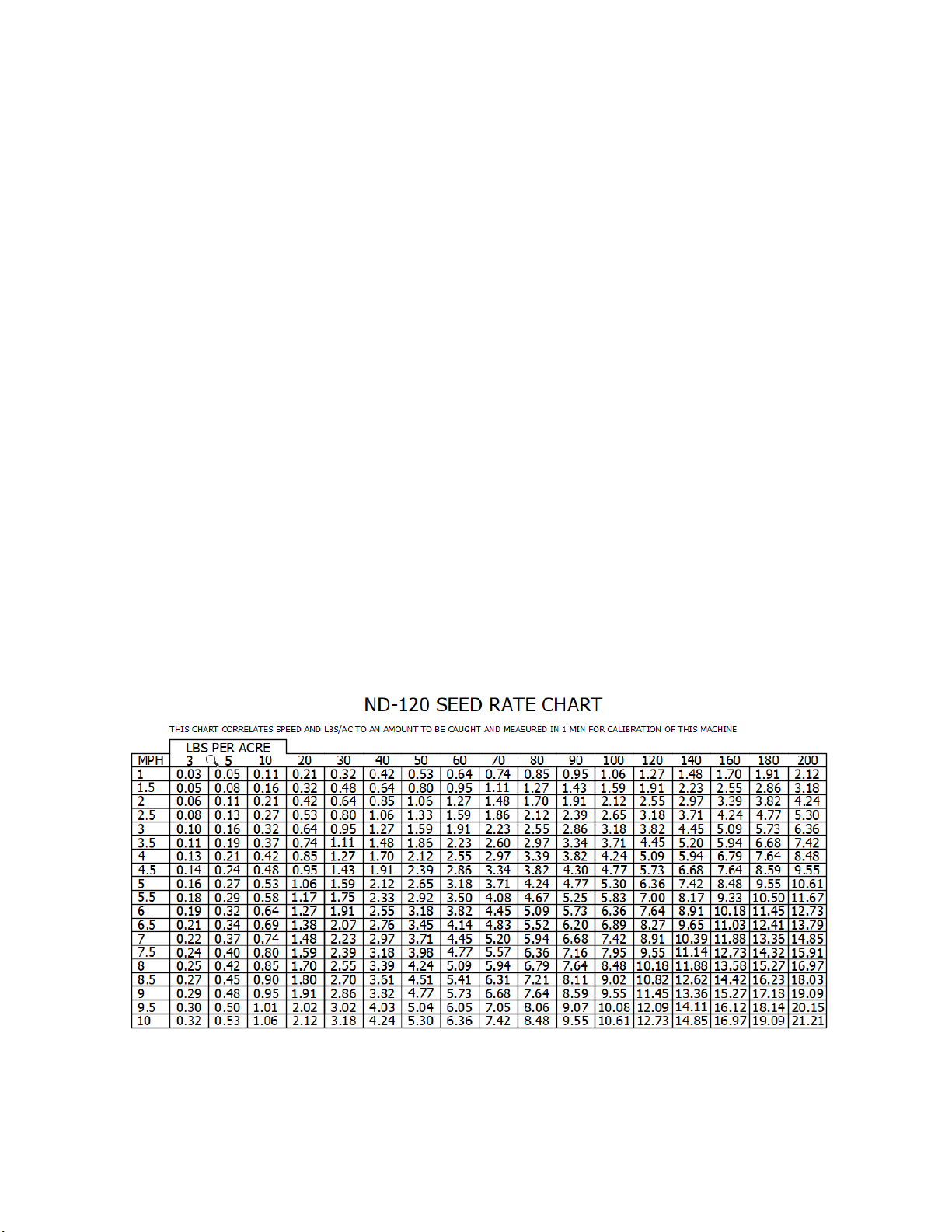

4. Find Target Seed Weight

Finding the Target weight is simply done using

the calibration chart seen in Figure 13. Knowing

the ground speed (left side of chart) and the

desired seed rate (top of chart), a target weight to

be caught can be selected.

5. Position Calibration Trough

Every Multi-Drill is equipped with calibration

trough which is used to catch the seed. In order

to do so, the trough should be positioned directly

under the seed discs while the machine is lifted.

6. Operate Seeder for One Minute

With seed loaded in Multi-Drill, use the handheld

control harness to open the seed plates and

energize the hydraulics while the machine in the

air for one minute. The seed should flow through

the seed discs and be captured by the calibration

trough.

7. Weigh and Compare Seed Weight

The seed caught in the calibration trough from

step 6 will need to be weighed on an accurate

digital scale capable of producing pounds (in

decimal form is preferred). If the scale displays

pounds and ounces, divide the ounces by 16 and

add the decimal to the pounds to get the complete

weight.

8. Manipulate Seed Plates/Hydraulic Motor

If the weight of seed is within 10% of the target,

the speed of the hydraulic motor can be modified

to finetune the rate. Otherwise, the seed plates

can be repositioned to dial the seed rate in closer

to the target using the same method outlined in

step 3. If the rate needs to increase, the setting

will be increased; and likewise, the setting will

decrease if the rate needs to be cut down.

9. Repeat Steps as Necessary

Until the target weight is achieved, steps 5

through 8 should be repeated. In some instances,

the seed plates may need to be changed during

this process. Don’t fill hopper until calibration is

complete.

Figure 13. ND-120 Calibration Chart used for Step 4

16

Changing Seed Plates

The seed plates are strategically positioned

between the hopper’s outlet holes (seen when

the hopper is empty) and the “cutoff plate”

which the linear actuator shuttles back and

forth to start and stop seed flow.

Each set of plates are labeled with laser

etching on one side: “left”, “right”, and their

respective sizes.

In order to change the seed plates, the hopper

must be vacuumed/blown clean. If the plates

are removed with seed in the hopper, the seed

can wedge between the “cutoff plate” and the

hopper outlets making it impossible to slide

the next set of plates into place.

The seed plates are changed using the

following steps:

1. To change plates you will need two

9/16” wrenchs and the Adjuster

Wrench, DS27-026. Using the small

end of the Adjuster Wrench, located

on top of chain cover as shown in

Figure 9. Loosen and remove the two

½” carriage head bolts connecting the

adjuster handle to the Adjuster mount

as shown Figure 14.

2. Pull straight out on the adjuster

handle and slide the seed plate

assembly out of the seed box as

shown in Figure 15.

3. Using the 9/16” wrenches, loosen and

remove the 3/8” bolts connecting both

seed plates to the adjuster linkages as

shown in Figure 15.

4. Slide the plates and bushings out of

linkages, set plates to the side, hold

onto the bushings.

5. Select plates you want in machine and

be sure to read etchings on plate

ensuring both plates have the same

size with corresponding sides.

6. Reassemble the desired seed plate

assembly; be sure the left and right

plates are oriented as shown in Figure

15.

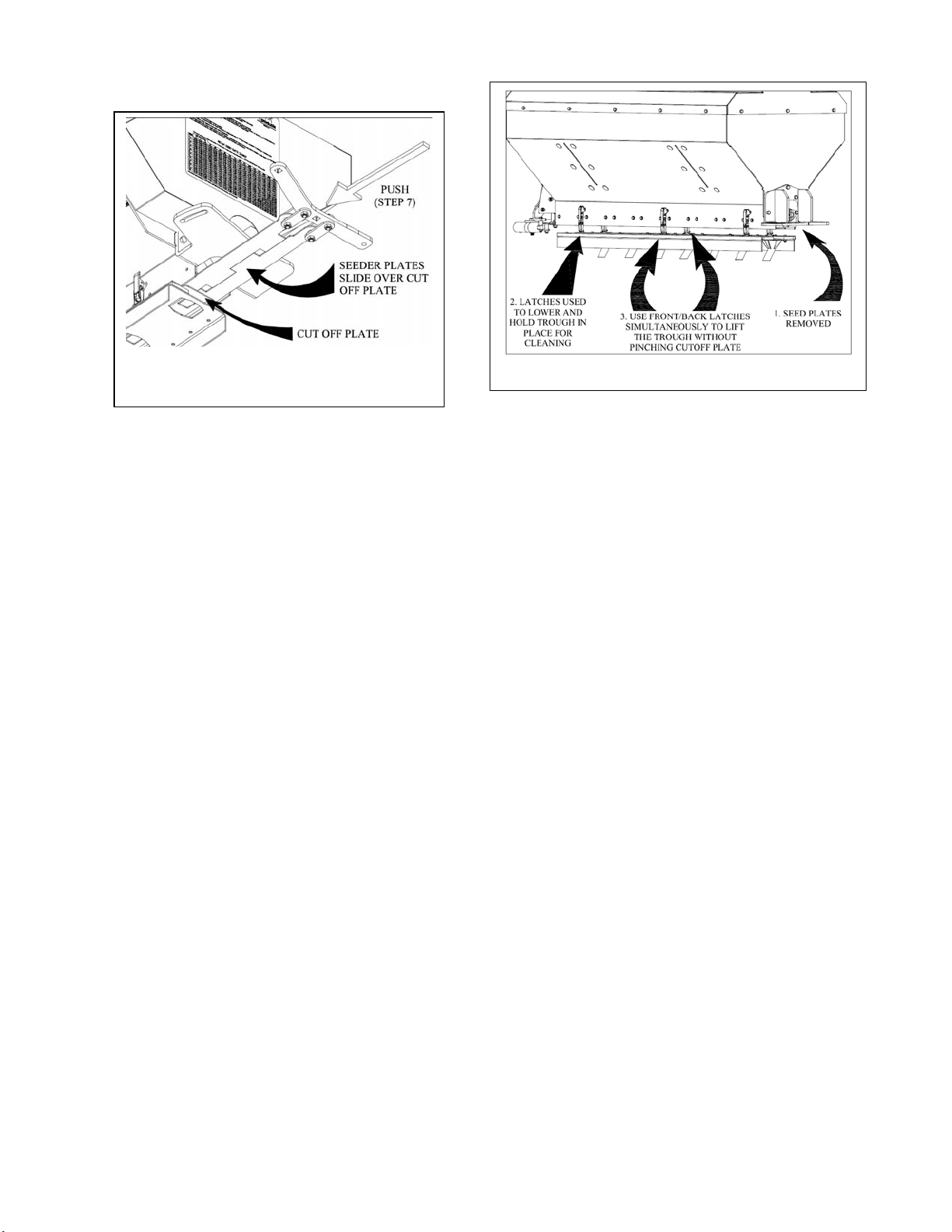

7. Take seed plate assembly and slide

back into machine; be sure to put seed

plates on top of cut off plate when

starting to push them into the machine

as shown in Figure 16.

8. Reattach the Adjuster Handle to the

Adjuster Mount as shown in Figure

14, and fasten bolts.

Fi

g

ure 14. Seed Plates – Step 1

Figure 15. Seed Plates – Steps 2,3 & 6

17

CLEANING

After Each Use

Remove large debris such as clumps of dirt,

grass, crop residue, etc. from machine.

Inspect machine and replace worn or damaged

parts.

Replace any safety decals that are damaged,

missing, or not legible.

Grease bearings located on Coulter Disc shaft.

Oil and tighten (if necessary) all chains driving

powered components.

Thoroughly clean hopper(s) vacuuming out all

seed and debris from previous use.

Periodic or Before Extended Storage

Remove large debris such as clumps of dirt,

grass, crop residue, etc. from machine.

Remove the remaining debris with a low-

pressure washer spray:

1. Be careful when spraying near scratched or

torn safety decals or near edges of decals as

water spray can peel decal off surface.

2. Be careful when spraying near chipped or

scratched paint as water spray may lift paint.

3. If a pressure washer is used, follow the

advice of the pressure washer manufacturer.

Inspect machine and replace worn or damaged

parts.

Check all hardware and ensure proper torque is

present.

Sand down scratches and the edges of area of

missing parts and coat with First Products spray

paint of matching color.

Replace any safety decals with that are missing

or not legible. See Safety Decals section for

location drawing.

Cover the seeder with supplied tarp when the

Multi-drill is being stored.

NOTE: Occasionally, it may be necessary to

lower the trough as illustrated in Figure 18 to

thoroughly clean all the moving components in

the hopper to promote easier calibration and

functionality in the future.

1. Remove Seed Plates as explained in

previous section.

2. Use the latches to lower and hold the trough

in place while using water or compressed air

to clean all moving parts and their

corresponding surfaces. If water is used, do

not reassemble until everything is

thoroughly dry.

3. It is best to use the latches on the front and

back to simultaneously lift the trough back

into place making sure not to pinch the Cut

Off Plate between the trough and the hopper.

4. Install desired Seed Plates for future use.

Figure 16. Seed Plates – Step 7 Figure 17. Trough lowered and cleaned

18

WARRANTY INFORMATION

ONE YEAR LIMITED WARRANTY

FIRST PRODUCTS INC. WARRANTS THIS PRODUCT TO BE FREE OF DEFECTS IN MATERIALS

AND WORKMANSHIP FOR A PERIOD OF TWELVE MONTHS FROM THE ORIGINAL DELIVERY

DATE. THIS WARRANTY DOES NOT COVER PARTS CAUSED TO BE DEFICIENT DUE TO

NORMAL WEAR, MISUSE, ACCIDENTS, OR LACK OF PROPER MAINTENANCE.

ANY PARTS THOUGHT TO BE DEFECTIVE MUST BE RETURNED TO THE FACTORY FOR

WARRANTY CONSIDERATION. A RETURN AUTHORIZATION NUMBER MUST BE OBTAINED

AND CLEARLY MARKED ON ALL PACKAGES OF PARTS REQUIRING RETURN TO THE

FACTORY.

THE OBLIGATION OF FIRST PRODUCTS INC. UNDER THIS WARRANTY SHALL BE

EXCLUSIVELY LIMITED TO REPLACEMENT OF PARTS DETERMINED TO BE DEFECTIVE BY

FIRST PRODUCTS INC. WITH FREIGHT PREPAID. IN NO EVENT SHALL FIRST PRODUCTS INC.

BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IN CONNECTION

WITH THE USE OF THIS PRODUCT.

FIRST PRODUCTS INC. RESERVES THE RIGHT TO MAKE CHANGES OR ADD IMPROVEMENTS

TO ITS PRODUCTS AT ANY TIME WITHOUT OBLIGATION TO MAKE SUCH CHANGES OR

IMPROVEMENTS ON PRODUCTS SOLD PREVIOUSLY.

WARRANTY CLAIMS ARE PAID USING A JOB STANDARD (AUTHORIZING MAN HOURS)

USING THE APPROPRIATE TIME FRAME ALLOWED FOR EACH PART REPLACED OR LABOR

FUNCTIONS PERFORMED. THIS JOB STANDARD LIMITS THE MAN HOURS AUTHORIZED BY

TASK. IT DOES NOT SET A SPECIFIC HOURLY RATE BUT LIMITS THE AUTHORIZED MAN

HOURS THAT WILL BE PAID BY EACH TASK. MILEAGE IS NOT PAID.

This manual suits for next models

1

Table of contents

Other First Products Drill manuals

Popular Drill manuals by other brands

Stanley

Stanley STDH7013 instruction manual

Universal Tool

Universal Tool UT8892 Series General Safety Information & Replacement Parts

Makita

Makita FD04 instruction manual

Cocraft

Cocraft JOZ-SP01-1020 instruction manual

Black & Decker

Black & Decker CRT129 instruction manual

Berner

Berner RS25e Use instruction