First SHW Series Manual

*SHW *SVW Direct Drive ECM

DIRECT DRIVE BLOWER COIL UNITS

0-10VDC input controlled

Installation, Operation, and

Maintenance Instructions

W

ARNING TO

I

NSTALLER

, S

ERVICE

P

ERSONNEL

,

AND

O

WNER

Altering the product, improper installation, or replacing parts with unauthorized parts voids

all warranty or implied warranty and may result in adverse operational performance or

possible hazardous conditions to service personnel and occupants. Company employees or

contractors are not authorized to waive this warning.

NOTES:

Read the entire installation instruction manual before starting the

installation.

These instructions are intended as a general guide and do not supersede

national, state, or local codes in any way.

These instructions must be left with the property owner.

S

AFETY

C

ONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion,

fire, electrical shock, or other conditions which may cause personal injury or property damage.

Consult a qualified licensed installer, service agency, or your distributor for information or

assistance. The qualified licensed installer or service agency must use factory-authorized kits or

accessories when modifying this product. Refer to the individual instructions packaged with kits or

accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloth for brazing

operations. Have fire extinguisher available. Read these instructions thoroughly and follow all

warnings or cautions attached to the unit. Consult local building codes and National Electrical Code

(NEC) for special requirements.

IOM8801 Rev. B 04/22 1

Safety Considerations

SHW/SVW

:

Installation, Operation, and Maintenance Instructions

2

Recognize safety information. This is the general safety-alert symbol . When you see this

symbol on the unit and in instruction manuals, be alert to the potential for personal injury or

damage to equipment. The lightning bolt symbol signifies an electrical shock hazard.

WARNING:

This WARNING

signifies general hazards which could result in personal injury or death.

WARNING:

This WARNING signifies electrical shock hazards which could result in personal injury or

death.

CAUTION:

CAUTION

is used to identify unsafe practices which would result in product and property

damage.

NOTE:

NOTE

is used to highlight suggestions which may result in enhanced

installation, reliability, or operation.

G

ENERAL

The manufacturer does not warrant equipment subjected to abuse. Metal chips, dust, drywall tape,

paint overspray, etc. can void warranties and liability for equipment failure, personal injury, and

property damage.

The manufacturer assumes no responsibility for equipment installed in violation of any code

requirement.

These instructions give information relative to the installation of blower coil units only. For other

related equipment refer to proper instructions.

WARNINGS:

•

Always wear eye protection when working on equipment.

•

Before servicing unit, always turn off all power to unit. There may be more than one

disconnect switch. Electrical shock can cause personal injury or death.

•

When blower coil is operating, some components are operating at high speeds. Personal

injury can result from touching these items with any object.

•

All electrical and service access panels must be secured in their proper place before

operating equipment.

•

Clear surrounding area of all tools, equipment and debris before operating unit.

CAUTION:

Unit must not be operated during building construction due to excessive airborne dust and

debris. Also, the unit must never run under any circumstances without an air filter in place.

Material in this shipment has been inspected at the factory and released to the transportation

agency in good condition. When received, a visual inspection of all cartons should be made

immediately. Any evidence of rough handling or apparent damage should be noted on the delivery

receipt and the material inspected in the presence of the carrier’s representative. If damage is

found, a claim should be filed against the carrier immediately.

Safety Considerations

SHW/SVW: Installation, Operation, and Maintenance Instructions

3

All models are designed for indoor installation only. The installation of this unit, field wiring, duct

system, and other related equipment must conform to the requirements the National Electric Code,

ANSI/NFPA No. 70 (latest edition) in the United States, as well as any state laws and local codes.

Local authorities having jurisdiction should be consulted before installation is made. Such

applicable regulations take precedence over the general instructions contained in this manual.

INSTALLATION PRECAUTIONS

WARNING:

Some units are very heavy. Use two or more people when moving and installing these units.

Failure to do so could result in personal injury or death. Contact with metal edges and

corners while applying excessive force can result in personal injury. Use gloves when

handling equipment. Use caution during installation or while servicing equipment.

Installation of this blower coil should be performed only by a licensed contractor to ensure proper

installation and the safety of the installer. Observe the following precautions for typical

installations:

1.

Always use proper tools and equipment.

2.

No wiring or other work should be attempted without first ensuring blower coil is

completely disconnected from the power source and locked out. Always verify that a good

permanent, uninterrupted ground connection exists prior to energizing any power

sources.

3.

Always review the nameplate and wiring diagram on each unit for proper voltage and control

configurations. This information is determined from the components and wiring of the unit and

may vary from unit to unit.

4.

When soldering or brazing to the unit, it is recommended to have a fire extinguisher readily

available. When soldering close to water valves or other components, heat shields or wet rags

are required to prevent damage.

5.

When the blower coil unit is in operation components are rotating at high speeds.

6.

Units must be installed level or angled toward the drain nipple to ensure proper drainage

and operation.

7.

Check unit prior to operation to ensure that the condensate water will drain toward the drain

connection. An overflow drain or an auxiliary drain pan under the blower coil may be required

as a back up to a clogged primary drain. Condensate overflow switches may be used as well,

under certain conditions

8.

Be sure that the drain pan is free from foreign material prior to start up.

9.

Check filter media installation to ensure that it is installed correctly. Use the directional

arrows or other information on the filter to determine the proper flow direction.

10.

Ensure air distribution system does not exceed the external static rating of the unit.

Safety Considerations

SHW/SVW

:

Installation, Operation, and Maintenance Instructions

4

BLOWER COIL UNIT

The installer must adhere strictly to all local and national code requirements pertaining to the

installation of this equipment.

The SHW blower coil units are designed to be installed in a horizontal position with discharge air in

a horizontal direction. The SVW blower coil units are designed for installation in a vertical direction

with discharge air in a vertical position. Both units include a positive slope drain pan with 3/4” NPT

nipple that exits the unit on the side of the coil header connections. All units need to be leveled

such that the positive slope of the drain pan is directed towards the condensate drain nipple.

NOTE:

Before mounting unit: Remove red headed shipping bolts and metal bushing

at blower base and blower outlet. If present, also remove the wire tie

securing motor to blower rail.

Sufficient clearance must be provided on the side of the blower coil to allow access to electrical

controls and to service the motor blower assembly. Standard unit configuration is right hand

looking with the direction of airflow. The unit can be field converted to left hand by repositioning

the coil, drain pan, and corresponding slope bracket.

Standard vertical blower configuration is counter-swirl, with the motor facing in the same direction

as the supply and return headers of a right hand coil configuration. Vertical blower configuration

can be field converted by reposition blower and corresponding mounting brackets.

NOTES:

A field-fabricated secondary drain pan, with a drain pipe routed to the

outside of the building, may be required in installations over a finished

living space or in any area that may be damaged by water overflow

from the main drain pan. In some localities local codes may require a

secondary drain pan for any horizontal installation.

If a condensate overflow shut off switch, that is designed to be installed

in the drain line, is used in place of a secondary drain line then place

it in the primary drain line between the blower coil and the P-trap

MOUNTING

It is important to ensure that the blower coil unit is securely mounted and the structure is sufficient

to support the weight of the equipment. SHW blower coil models 90-120 are intended to be

mounted with a support angle or channel located under the unit. There are 7/8" knockouts

located at all four corners top and bottom which permits field supplied hanging rods to extend

through the unit to secure to the field supplied angle or channel. (See figure 1). All anchors for

mounting the equipment must be placed and sized to ensure a safe and durable installation.

When necessary use shims to obtain the proper level. This will ensure that the condensate will drain

from the unit.

Support angle or channel

Safety Considerations

SHW/SVW: Installation, Operation, and Maintenance Instructions

5

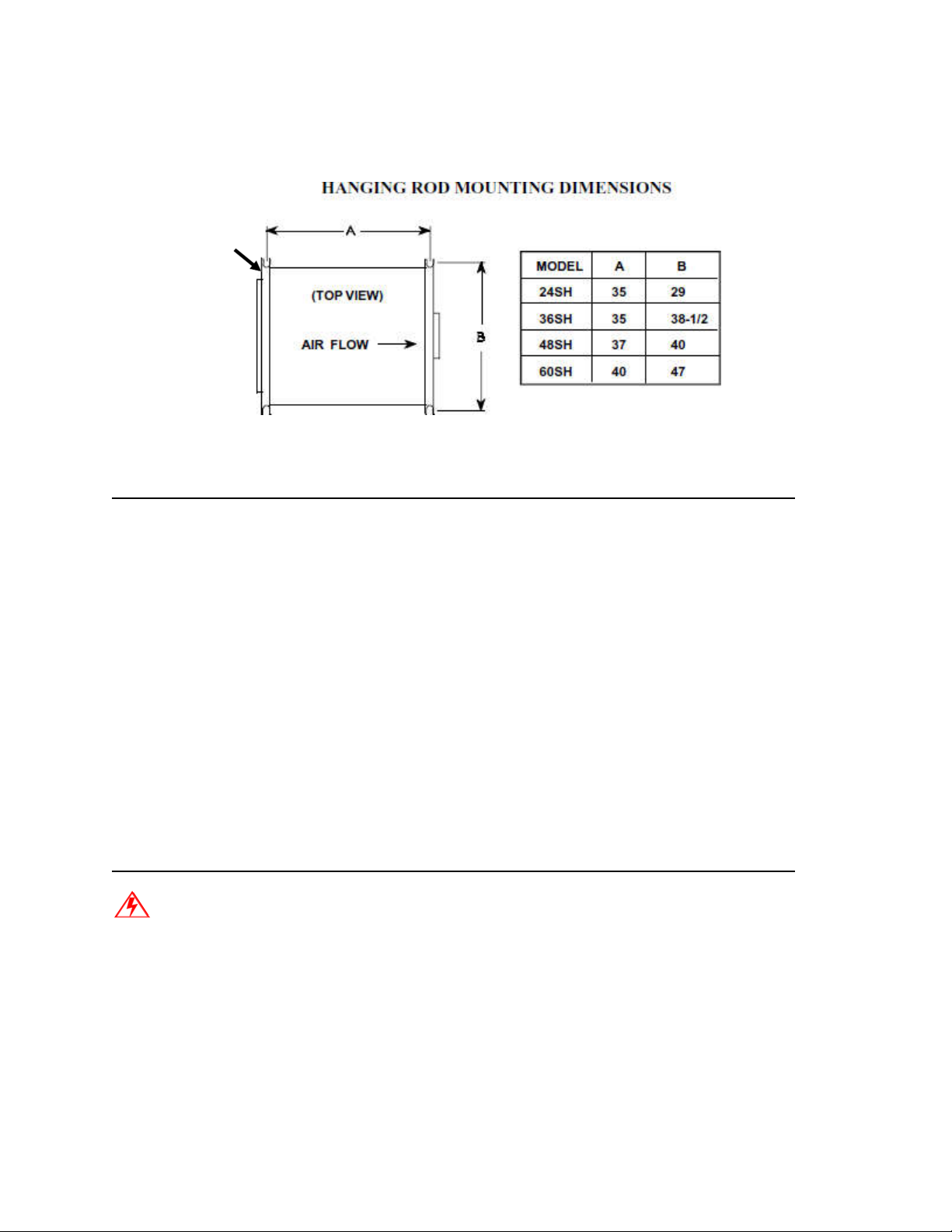

For models 24-60, two (2) mounting rails are supplied on the blower coil unit, as shown in Figure 2.

All anchors for mounting the equipment must be placed and sized to ensure a safe and durable

installation. When necessary use shims to obtain the proper level. This will ensure that the

condensate will drain from the unit.

Hanging rod

(For 24-60SHW)

Figure 2

AIR DISTRIBUTION DUCTS

All duct work must be installed in accordance with National Fire Protection Association Codes 90A

and 90B. Ducts should be adequately insulated to prevent condensation during the cooling cycle

and to minimize heat loss during the heating cycle. All return air must be filtered to prevent dirt

buildup on the coil surface. If there is no ducted return, applicable installation codes may limit the

unit to installation only in a single story residence. In many cases it is acceptable to use ducting of

the same size as the blower coil connections. However, unique arrangements or long duct runs

must be confirmed by a local professional. The manufacturer will not be responsible for misapplied

equipment.

Supply and return duct system must be adequately sized to meet the system’s air requirements and

static pressure capabilities. The duct system should be insulated sufficiently to avoid condensation

on the duct surface.

DUCTWORK

All duct work must be installed in accordance with industry accepted practices, and all applicable

national and local code requirements.

ELECTRICAL

WARNINGS:

Electric Shock Hazard

•

Disconnect all power supplies before servicing; lock out/tag out to prevent accidental

electrical shock. Note: there may be multiple power sources.

•

Use copper conductors only.

•

Install all parts and panels before operating.

•

Failure to follow these warnings can result in injury or death.

All wiring must comply with local and national code requirements. Units are provided with wiring

diagrams and nameplate data to provide information required for necessary field wiring.

Safety Considerations

SHW/SVW

:

Installation, Operation, and Maintenance Instructions

6

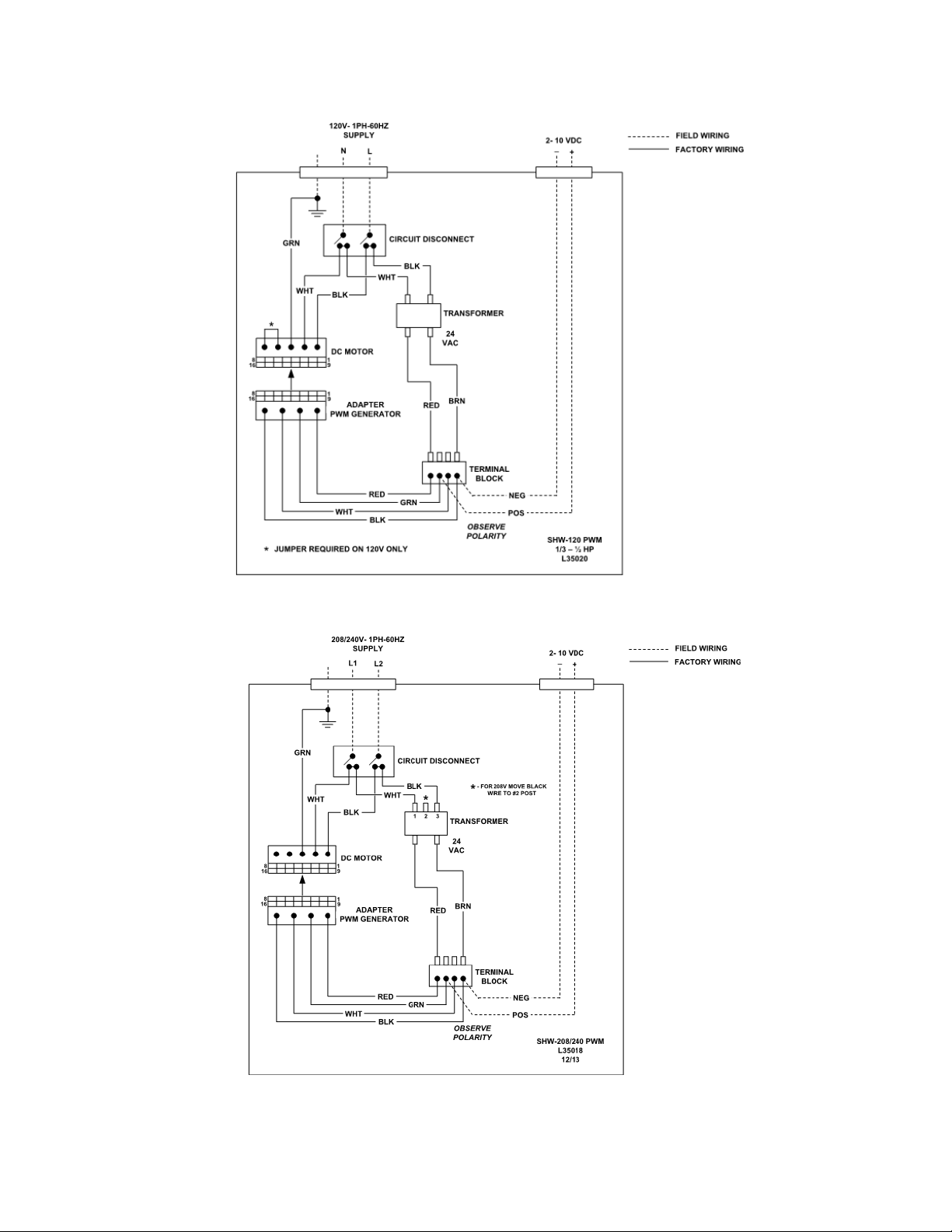

These direct drive blower coil units are provided with a control box with 0-10V low voltage terminal

connections, for in-field installation. ECM motor speed adjustments will be done through the field

installed 0-10V signal.

Reference Wiring Diagrams (Check product for applicable wiring diagram)

Figure 3: Standard wiring diagram, 3 phase

Safety Considerations

SHW/SVW: Installation, Operation, and Maintenance Instructions

7

Figure 4: Condensate switch option, 3 phase

Figure 5: Standard 120V, 1 phase

Figure 6: Standard 230V, 1 phase

Safety Considerations

SHW/SVW

:

Installation, Operation, and Maintenance Instructions

8

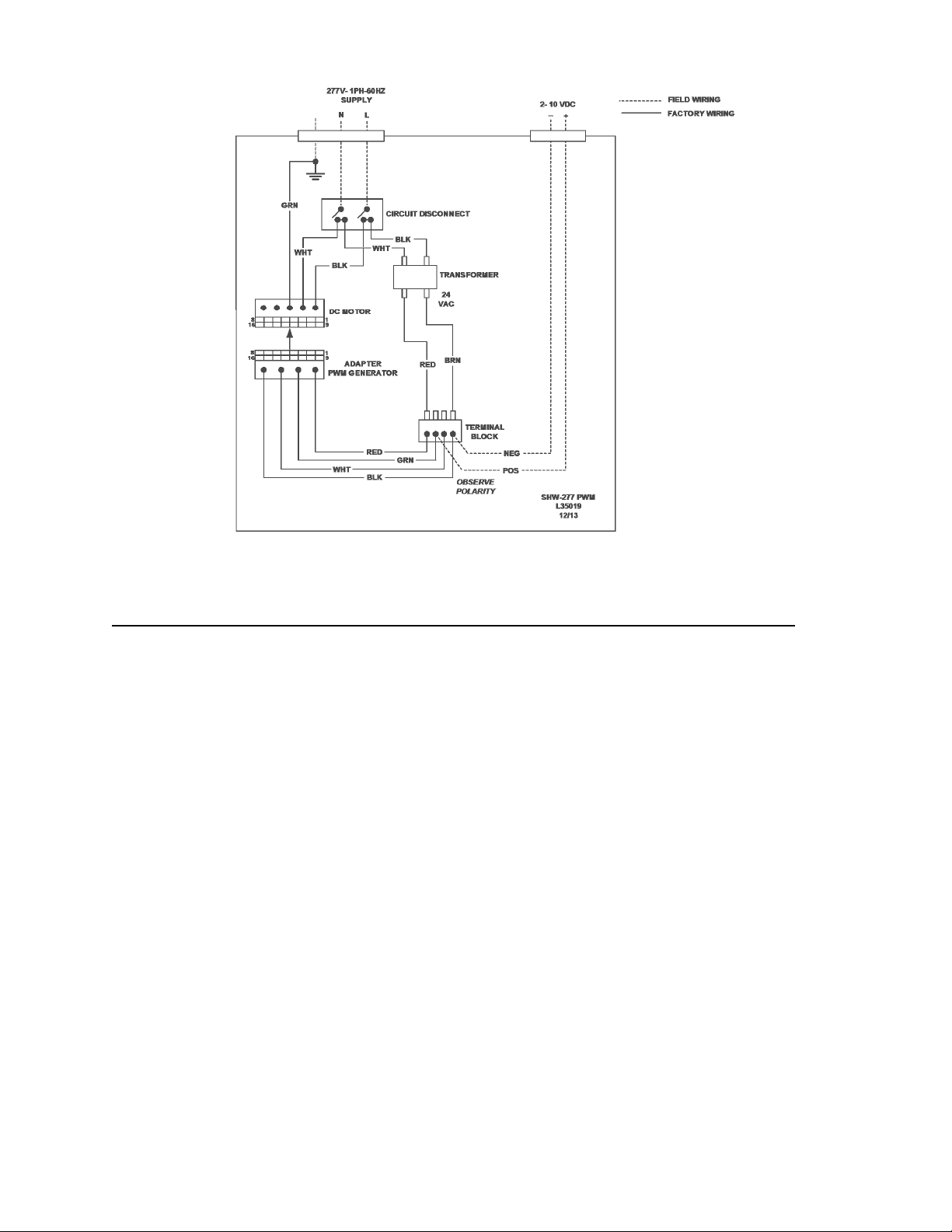

Figure 7: Standard 277V, 1 phase

PIPING

PIPING PRECAUTIONS

1.

Flush all field piping prior to connection to remove all debris.

2.

Use wet cotton rags to cool valve bodies when soldering.

3.

Open all valves (mid-way for hand valves, manually open on motorized valves) prior to soldering.

4.

When soldering to bronze or brass, heat the piping while in the socket/cup and begin

introducing the solder when the flux boils rapidly. Avoid direct flame into the solder joint.

5.

Heat can only be applied to the cup of the valve body for a minimal time before damage occurs

(even with the use of wet rags).

6.

Avoid rapid quenching of solder joints as this will produce joints of inferior quality.

7.

The valve package will not support the weight of the connecting pipes. All pipes connected to

the units must be completely supported prior to connection to the unit.

8.

Provisions must be made for expansion and contraction of piping systems. All horizontal and

vertical risers, including runouts, must be able to withstand significant movement with

temperature changes. Failure to do so will result in damage and failure of piping, fittings and

valves throughout the building.

9.

Never insulate the heads or motorized portion of control valves. Damage can occur in the form

of excessive heat build up and interference to the operation and moving parts will result.

10.

All piping made in the field should be installed with consideration of additional space for any

electrical routing that may be required.

11.

Connect all piping per accepted industry standards and observe all regulations governing

installation of piping systems.

Safety Considerations

SHW/SVW: Installation, Operation, and Maintenance Instructions

9

CAUTION:

Hydronic systems are not designed to hold pressurized air and should only be tested with

water. Pressurizing system with air could damage equipment.

12.

When all connections are complete, pressure test system. Repair any solder joint leaks and

gently tighten any leaking valve packing nuts and piping accessories, as required.

PIPING INSTALLATION

These units employ a hydronic coil designed for use with either hot or chilled water.

•

All piping must be adequately sized to meet the design water flow requirements as specified for

the specific installation. Piping must be installed in accordance with all applicable codes.

•

The piping connections on the equipment are not necessarily indicative of the proper supply and

return line sizes. To minimize restrictions, piping design should be kept as simple as possible.

Figure 8: Trap configuration comparison

CAUTIONS:

•

When connecting piping to blower coil units, do not bend or reposition the coil header

tubing for alignment purposes. This could cause a tubing fracture resulting in a water leak

when pressure is applied to the system.

•

Prior to connecting to the blower coil all external piping must be purged of debris.

•

All chilled water piping must be insulated to prevent property damage from condensation.

Condensate drain lines must be installed with adequate slope away from the unit to assure positive

drainage. Since the drain pan is located on the suction side of the blower, a negative pressure

exists at the drain pan and a minimum trap of 1-1/2 inches must be provided in the drain line to

assure proper drainage.

Figure 9: Recommended trap configuration

Safety Considerations

SHW/SVW

:

Installation, Operation, and Maintenance Instructions

1

0

Figure 10: Bad trap configuration

PIPING INSULATION

Installing Contractor - After the system has been proven leak free, all lines and valve control

packages must be insulated to prevent condensate drippage or insulated, as specified on the

building plans.

NOTE: Many valve packages will not physically allow all components to fit over an

auxiliary drain pan. It is the installer’s responsibility to insulate all piping to

ensure adequate condensation prevention.

NOISE

These blower coil units are designed for quiet operation, however, all air handling equipment will

transfer some amount of noise to the conditioned space. This should be taken into consideration

when planning the location of the equipment.

PRE-STARTUP CHECKS

WARNINGS:

•

Electrically ground blower coil. Connect ground wire to ground terminal marked “GND”.

Failure to do so can result in injury or death.

•

Do not touch any rotating component with any object. Damage to the equipment and

personal injury can occur.

CAUTION:

Any device such as a fan switch or thermostat that has been furnished by the factory for field

installation must be wired in strict accordance with the wiring diagram that is supplied with

the unit. Failure to do so could result in damage to components and will void all warranties.

Prior to starting the unit:

1.

Ensure supply voltage matches nameplate data.

2.

Ensure unit is properly grounded.

3.

With power off, check blower wheel set-screws for tightness and ensure blower wheels rotate

freely and quietly.

4.

Ensure blower coil is properly and securely installed.

5.

Ensure unit is sloped toward drain line.

6.

Ensure unit will be accessible for servicing.

7.

Ensure condensate line is properly sized, run, trapped, pitched and tested.

8.

Ensure all cabinet openings and wiring connections have been sealed.

9.

Ensure a clean filter is in place and of adequate size.

Safety Considerations

SHW/SVW: Installation, Operation, and Maintenance Instructions

11

10.

Ensure all access panels are in place and secured.

11.

Check that coil(s), valves and piping have been leak checked and insulated as required.

12.

Ensure that all air has been vented from the system.

13.

Ensure polarity is observed for 0-10V low voltage connections (see wiring diagram)

MAINTENANCE

INSPECTION AND CLEANING

Before start-up all of the components should be given a thorough check. Optimal operation of this

equipment requires cleanliness. Often after installation of this equipment additional construction

activities occur. Care must be taken to protect the equipment from debris during these

construction phases.

FAN

The fan should be inspected and cleaned annually, in conjunction with maintenance of the motor

and bearings. It is important to keep the wheels clean in order to avoid imbalance and vibration.

MOTOR

Check motor connections to ensure that they are secure and made in accordance with the wiring

diagram.

WARNING:

Units with ECM motors have line voltage power applied at all times. Make sure power is

disconnected before servicing.

FILTER

The air filter should be cleaned or replaced every 30 days or more frequently if severe conditions

exist. Always replace the filter with the same type as originally furnished.

COIL

Any dust or other contaminants which accumulate on the heat transfer surfaces interferes with the

air flow and impairs heat transfer. The coil must be kept clean by any of the following methods.

•

Cleaning with low-pressure compressed air.

•

Cleaning with steam

•

Flushing or rinsing with water (an approved coil cleaning detergent is advisable for greasy

surfaces).

•

Prior to the water system start-up and balancing, the chilled/hot water systems should be

flushed to clean out dirt and debris construction. All unit service valves are closed during this

process. Strainers are to be installed in the piping mains to prevent this material from entering

the units during normal operation.

CAUTION:

Be sure to return valves to their proper operating positions prior to start-up.

Safety Considerations

SHW/SVW

:

Installation, Operation, and Maintenance Instructions

1

2

DRAIN PIPING

The drain should always be:

•

Connected or piped to an acceptable disposal point sloped away from the unit at least 1/8-inch

per foot, and kept clean and free from obstructions.

•

Checked before summer operation.

•

Periodically checked during summer operation.

PREVENTATIVE MAINTENANCE

To achieve maximum performance and service life of each piece of equipment, a formal schedule of

regular maintenance should be established and maintained.

MAINTENANCE UPDATES

Contact Factory for current Maintenance Program Information.

P.O. BOX 270969, Dallas, TX 75227

www.firstco.com or www.ae-air.com

The manufacturer works to continually improve its products. It reserves the right to change design and specifications without notice.

©2022 First Co., Applied Environmental Air

This manual suits for next models

1

Table of contents