HEF7 series manual 3

Index

1. General description.............................................................................................................................4

1.1. Safety instructions........................................................................................................................5

2. HEF7 nomenclature............................................................................................................................7

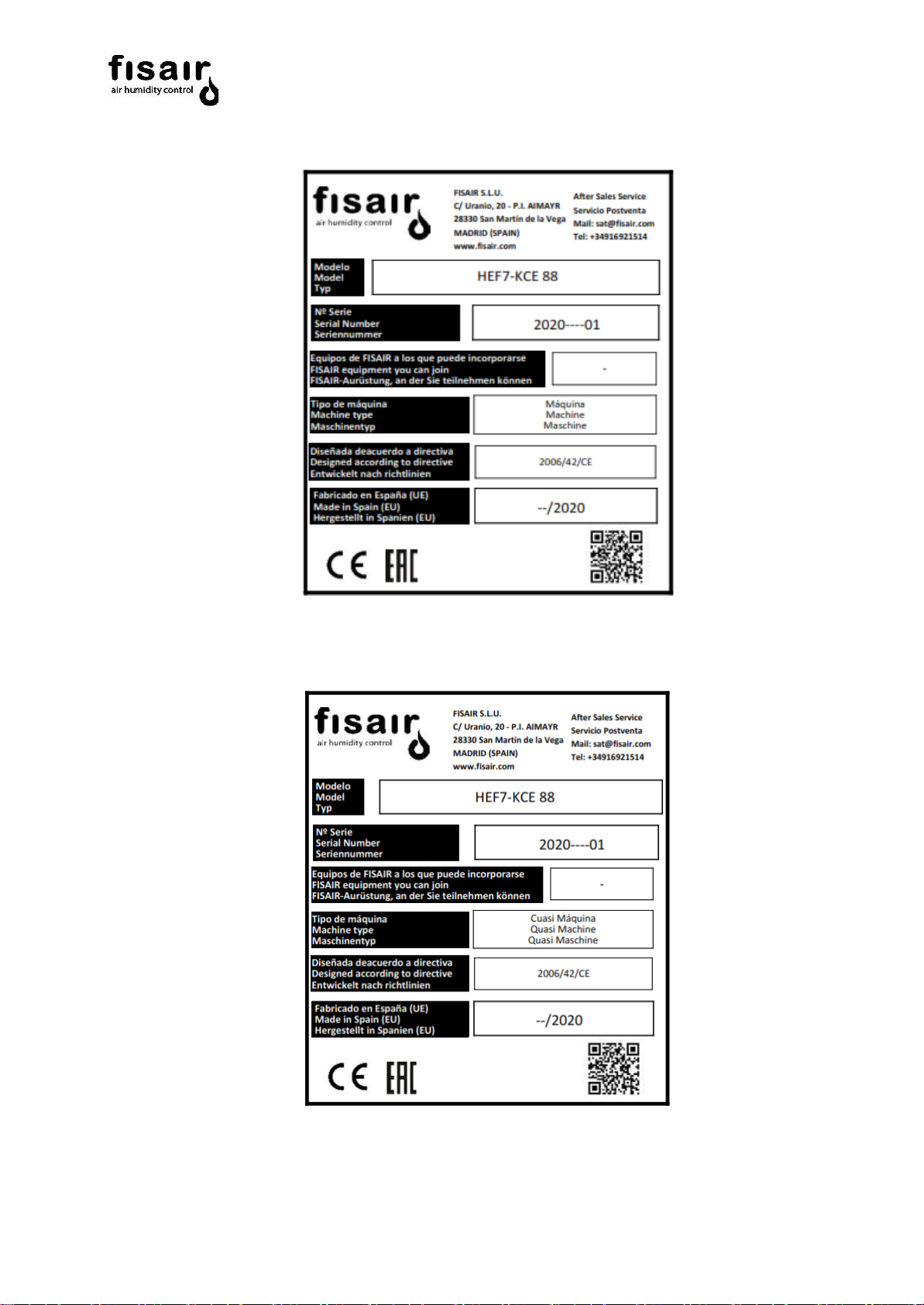

3. Rating plate and machine type............................................................................................................8

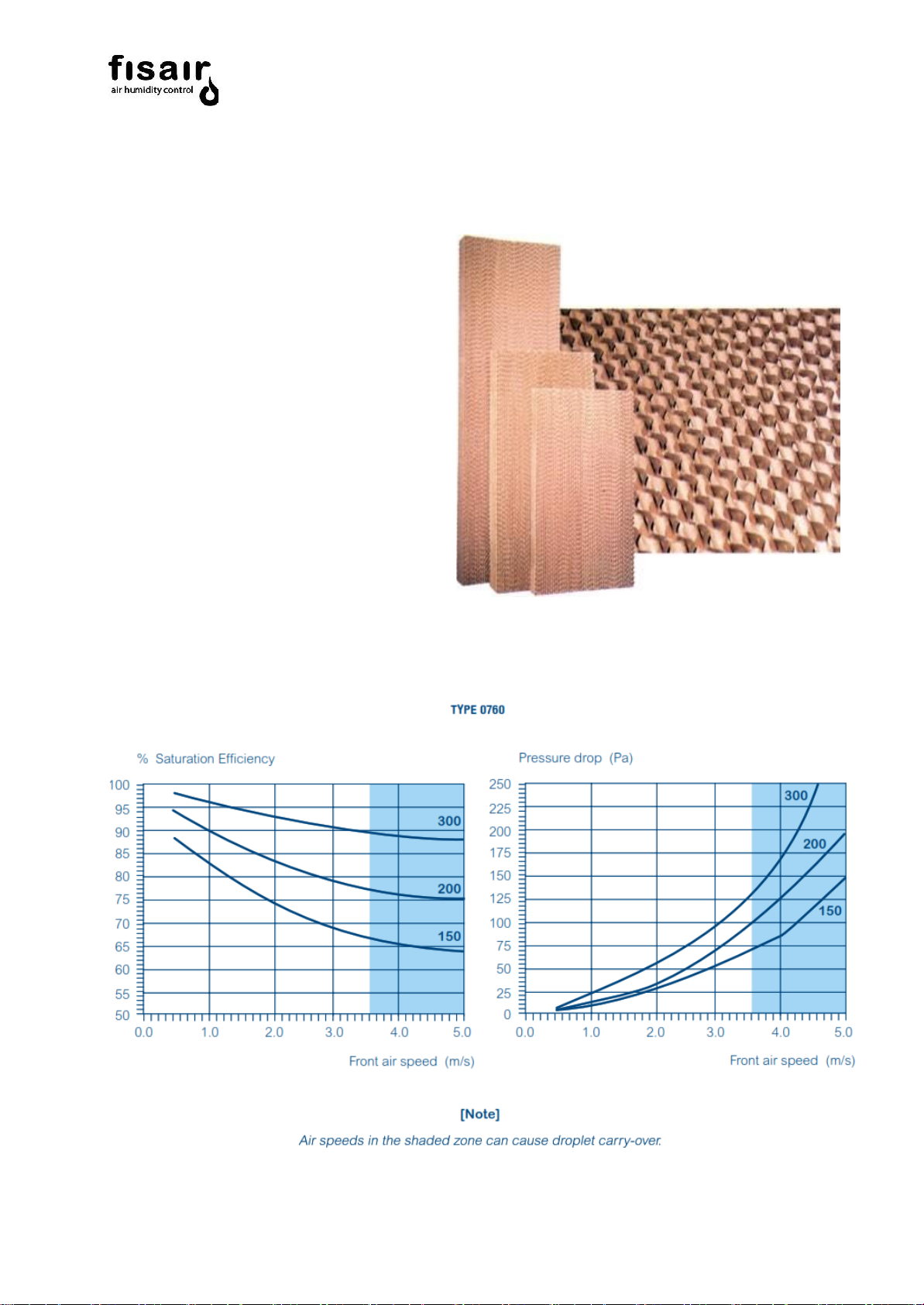

4. High efficiency HEF7 evaporative panel............................................................................................10

4.1. ORGANIC EVAPORATIVE PANEL............................................................................................10

4.2. INORGANIC EVAPORATIVE PANEL........................................................................................11

5. Unit components...............................................................................................................................12

6. Operating principle............................................................................................................................14

7. Installation requirements...................................................................................................................15

8. Connections and regulation...............................................................................................................17

9. Recirculation pump electricity connection..........................................................................................19

10. Level detector connection..............................................................................................................20

11. Solenoid valve electricity connection .............................................................................................22

12. Connection of the motor-zone valve N.C. for automatic emptying / draining .................................23

13. Setting the valve regulating irrigation flow......................................................................................26

14. Setting the valve regulating the bleed-off flow...............................................................................27

15. Start-up recommendations.............................................................................................................29

16. Maintenance and cleaning.............................................................................................................30

16.1. Evaporative humidification: a natural method that does not carry bacteria. ................................30

16.2. Cleaning.....................................................................................................................................30

16.2.1. General......................................................................................................................................30

16.2.2. Scale formation process.............................................................................................................31

16.2.3. Desinfection...............................................................................................................................31

17. Machine conformity declaration .....................................................................................................34

18. Cuasi machine conformity declaration ...........................................................................................35

19. WARRANTY..................................................................................................................................36