FISCHER NK10 Series User manual

Operating manual

NK10

Fill Level Limiter

09005111 • BA_EN_NK10 • Rev. ST4-E • 01/19

*09005111*

| Masthead FISCHER Mess- und Regeltechnik GmbH

2 / 28 BA_EN_NK10

Masthead

Manufacturer: FISCHER Mess- und Regeltechnik GmbH

Bielefelderstr. 37a

D-32107 Bad Salzuflen

Telephone: +49 5222 974 0

Telefax: +49 5222 7170

eMail: [email protected]

web: www.fischermesstechnik.de

Technical editorial team: Documentation representative: T. Malischewski

Technical editor: R. Kleemann

All rights, also those to the translation, reserved. No part of this document may

be reproduced or processed, duplicated or distributed using electronic systems

or any other form (print, photocopy, microfilm or another process) without the

written consent of the company FISCHER Mess- und Regeltechnik GmbH, Bad

Salzuflen.

Reproduction for internal use is expressly allowed.

Brand names and procedures are used for information purposes only and do

not take the respective patent situation into account. Great care was taken

when compiling the texts and illustrations; Nevertheless, errors cannot be ruled

out. The company FISCHER Mess- und Regeltechnik GmbH will not accept any

legal responsibility or liability for this.

Subject to technical amendments.

© FISCHER Mess- und Regeltechnik 2015

Version history

Rev. ST4-A 01/15 Version 1 (first edition)

Rev. ST4-B 06/16 Version 2 (Correction)

Rev. ST4-C 04/17 Version 4 (Dimensional drawings changed)

Rev. ST4-D 11/18 Version 5 (Dimensional drawing/DNV-GL/CE declaration

changed)

Rev. ST4-E 01/19 Version 6 (Order codes optional information (SIL))

FISCHER Mess- und Regeltechnik GmbH Table of Contents

BA_EN_NK10 3 / 28

Table of Contents

1 Safety guidelines ............................................................................................................................................4

1.1 General .....................................................................................................................................................4

1.2 Personnel Qualification.............................................................................................................................4

1.3 Risks due to Non-Observance of Safety Instructions ...............................................................................4

1.4 Safety Instructions for the Operating Company and the Operator............................................................4

1.5 Unauthorised Modification ........................................................................................................................4

1.6 Inadmissible Modes of Operation .............................................................................................................4

1.7 Safe working practices for maintenance and installation work .................................................................5

1.8 Pictogram explanation ..............................................................................................................................5

2 Product and functional description ..............................................................................................................6

2.1 Delivery scope ..........................................................................................................................................6

2.2 Use as intended........................................................................................................................................6

2.3 Function diagram ......................................................................................................................................6

2.4 Design and mode of operation..................................................................................................................7

3 Installation and assembly..............................................................................................................................8

3.1 Process connection ..................................................................................................................................8

3.2 Electrical connections ...............................................................................................................................8

4 Commissioning...............................................................................................................................................9

4.1 Generalities...............................................................................................................................................9

4.2 Function test .............................................................................................................................................9

5 Servicing .......................................................................................................................................................10

5.1 Maintenance ...........................................................................................................................................10

5.2 Transport ................................................................................................................................................10

5.3 Service....................................................................................................................................................10

5.4 Disposal ..................................................................................................................................................10

6 Technical data...............................................................................................................................................11

6.1 General ...................................................................................................................................................11

6.2 Application conditions .............................................................................................................................11

6.3 Switch contacts.......................................................................................................................................11

6.4 Measurement accuracy ..........................................................................................................................11

6.5 Directives and certificates.......................................................................................................................12

6.6 Construction design ................................................................................................................................12

7 Order Codes..................................................................................................................................................17

8 Attachments..................................................................................................................................................18

8.1 Declarations of conformity ......................................................................................................................18

8.2 Type testing certificates ..........................................................................................................................20

8.3 DIN CERTCO Certification DIN 4754-3 ..................................................................................................24

8.4 SIL Certificate .........................................................................................................................................26

8.5 EAC Declaration .....................................................................................................................................28

1 | Safety guidelines FISCHER Mess- und Regeltechnik GmbH

4 / 28 BA_EN_NK10

1 Safety guidelines

1.1 General

This operating manual is an integral part of the product and therefore needs to

be kept close to the instrument in a place that is accessible at all times to the re-

sponsible personnel.

The following sections, in particular instructions about the assembly, commis-

sioning and maintenance, contain important information, non-observance of

which could pose a threat to humans, animals, the environment and property.

The instrument described in these operating instructions is designed and manu-

factured in line with the state of the art and good engineering practice.

1.2 Personnel Qualification

The instrument may only be installed and commissioned by specialized person-

nel familiar with the installation, commissioning and operation of this product.

Specialized personnel are persons who can assess the work they have been

assigned and recognize potential dangers by virtue of their specialized training,

their skills and experience and their knowledge of the pertinent standards.

1.3 Risks due to Non-Observance of Safety Instructions

Non-observance of these safety instructions, the intended use of the device or

the limit values given in the technical specifications can be hazardous or cause

harm to persons, the environment or the plant itself.

The supplier of the equipment will not be liable for damage claims if this should

happen.

1.4 Safety Instructions for the Operating Company and the Operator

The safety instructions governing correct operation of theinstrument must be

observed. The operating company must make them available to the installation,

maintenance, inspection and operating personnel.

Dangers arising from electrical components, energy discharged by the medium,

escaping medium and incorrect installation of the device must be eliminated.

See the information in the applicable national and international regulations.

Please observe the information about certification and approvals in the Tech-

nical Data section.

1.5 Unauthorised Modification

Modifications of or other technical alterations to the instrument by the customer

are not permitted. This also applies to replacement parts. Only the manufacturer

is authorised to make any modifications or changes.

1.6 Inadmissible Modes of Operation

The operational safety of this instrument can only be guaranteed if it is used as

intended. The instrument model must be suitable for the medium used in the

system. The limit values given in the technical data may not be exceeded.

The manufacturer is not liable for damage resulting from improper or incorrect

use.

FISCHER Mess- und Regeltechnik GmbH Safety guidelines | 1

BA_EN_NK10 5 / 28

1.7 Safe working practices for maintenance and installation work

The safety instructions given in this operating manual, any nationally applicable

regulations on accident prevention and any of the operating company's internal

work, operating and safety guidelines must be observed.

The operating company is responsible for ensuring that all required mainten-

ance, inspection and installation work is carried out by qualified specialized per-

sonnel.

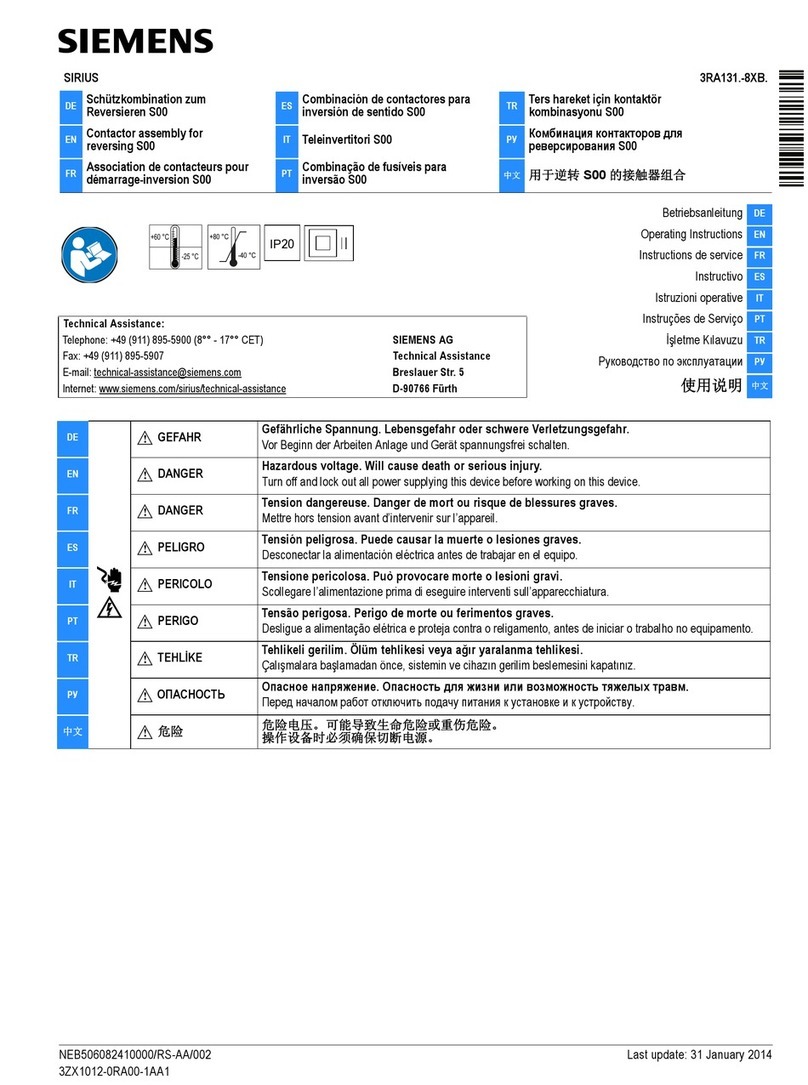

1.8 Pictogram explanation

DANGER

Type and source of danger

This indicates a direct dangerous situation that could lead to death or serious

injury (highest danger level).

a) Avoid danger by observing the valid safety regulations.

WARNING

Type and source of danger

This indicates a potentially dangerous situation that could lead to death or ser-

ious injury (medium danger level).

a) Avoid danger by observing the valid safety regulations.

CAUTION

Type and source of danger

This indicates a potentially dangerous situation that could lead to slight or seri-

ous injury, damage or environmental pollution (low danger level).

a) Avoid danger by observing the valid safety regulations.

NOTICE

Note / advice

This indicates useful information of advice for efficient and smooth operation.

2 | Product and functional description FISCHER Mess- und Regeltechnik GmbH

6 / 28 BA_EN_NK10

2 Product and functional description

2.1 Delivery scope

• NK10 according to specification (see order code)

• Operating Manual

• SIL safety manual for version NK10 … U0600

2.2 Use as intended

The NK10 fill level limiter is used in thermo-technical and process plants as a

safeguard against the fill level falling below the lowest permissible level. As a

limiter the device conforms to the requirements of DIN 4754.

The devices in this series are...

• type-tested in compliance with DIN 4754-3

• certified to DNVGL-CG-0339

• Functional safety as per IEC 61508/61511

• certified to directive 2014/68/EU

Copies of the certificates can be found in the appendix to the operating manual.

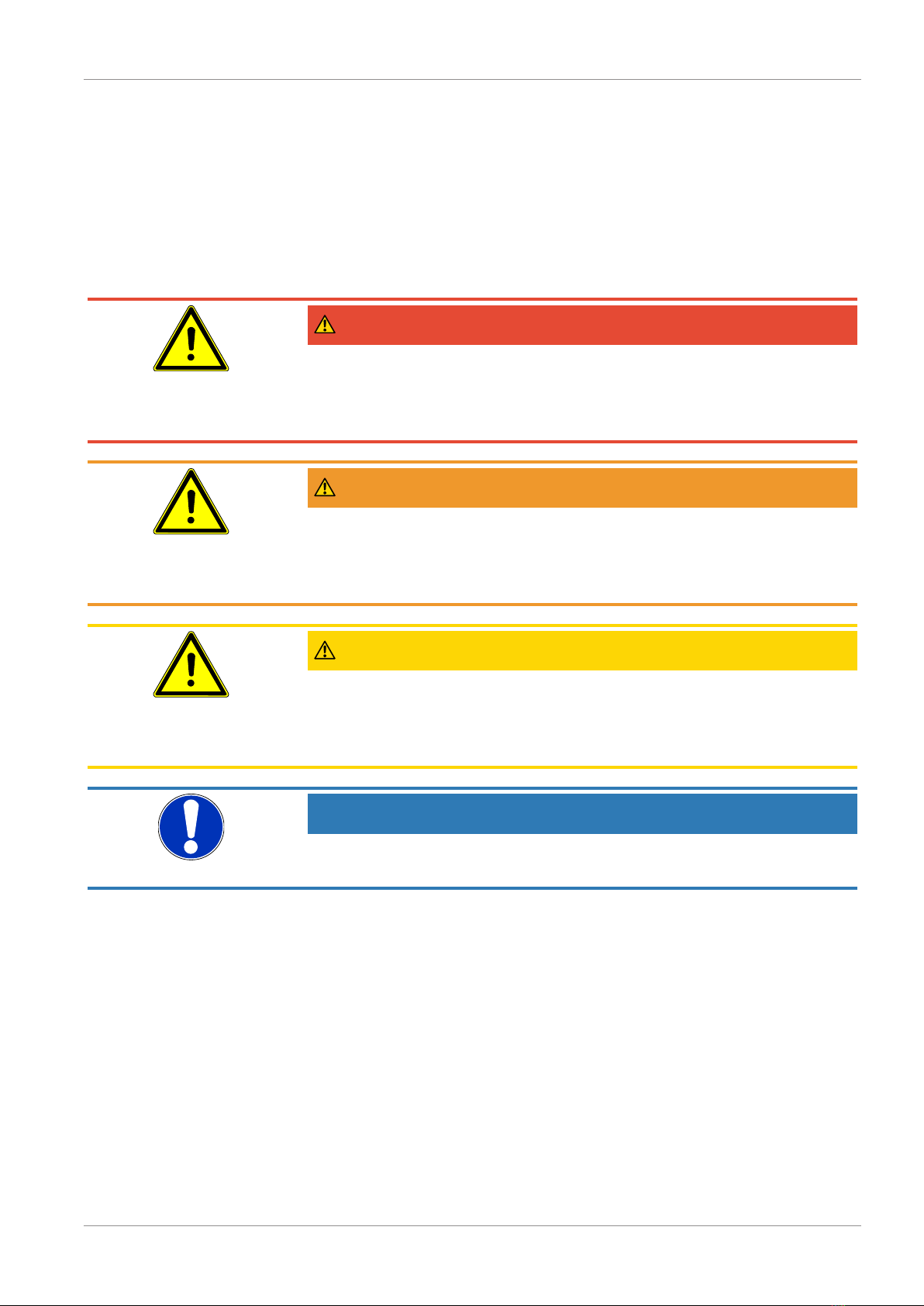

2.3 Function diagram

1

2 3

6

4

9

8 7

10

approx. 10 mm

approx. 60 mm

5

Fig.1: Function diagram

1 Swimmer 2 Swimmer rod

3 Metal bellows 4 Test button

5 Switch lever 6 Micro-switch S1

7 Cable screw connection 8 Flange and counter-flange

9 Welding socket 10 Tank

FISCHER Mess- und Regeltechnik GmbH Product and functional description | 2

BA_EN_NK10 7 / 28

2.4 Design and mode of operation

The swim system of the fill level limiter is contained in the fluid-filled reservoir

(expansion tank). The swimming motions generated by changes in the fill level

are transmitted directly to the micro-switch S1 by a swimmer rod sealed in a

stainless-steel bellows. The fulcrum of the swimmer rod is located outside of the

pressure chamber.

There is also a test button outside the pressure chamber with which a function

check as per DIN 4754-3 can be run without lowering the fill level. When

pressed, the body of the swimmer is moved against its buoyancy.

The factory default switching point of micro-switch S1 is set so that it switches

when the swimmer rod is horizontal. The optional warning switch S2 switches

approx. 2.5 mm before S1.

The fill level height at which switching is triggered depends on the density of the

heat carrier. The lowest density at which a secure function is guaranteed is 0.6

kg/dm³.

When the medium has a density of 1.0 kg/dm³, the switching level is approx.

60mm below the middle of the flange or socket.

3 | Installation and assembly FISCHER Mess- und Regeltechnik GmbH

8 / 28 BA_EN_NK10

3 Installation and assembly

NOTICE!The information in the safety manual must be observed in con-

nection with equipment with functional safety.

3.1 Process connection

The process connection may be realised by authorized and qualified specialized

personnel.

The unit is set ex-works for horizontal installation. Only this installation position

is allowed.

Dangers caused by pressure on the instrument are to be prevented with suit-

able measures.

The flange and/or process connections are designed for a working temperature

of max. 400 °C and a working pressure of max. 20 bar.

CAUTION

The data of the flange used may be lower.

Please check the actual data in the technical data section.

There are a range of flanges and welded hexagon nipples with which the device

can be installed on-site. Take care that the side of the device marked TOP

faces upwards when being installed.

NOTICE!Please check:

• The swimmer must be able to move freely in the vertical direction!

• Test the switching function using the test button.

3.2 Electrical connections

• By authorized and qualified specialized personnel only.

• When connecting the unit, the national and international electro-technical

regulations must be observed.

• Disconnect the system from the mains, before electrically connecting the

device.

• Install the consumer-adapted fuses.

• Do not connect the connector if strained.

When laying the electrical supply lines, ensure that no short circuit between the

electrical conductors and the surroundings can occur.

A locking and unlocking system as per DIN 4754-3 must be incorporated, if the

device is used as a fill level limiter. This safety system must conform to DIN

50156 / VDDE 0116.

3.2.1 Circuit diagram

123

Test button

123 456

1 Switch

(S1)

2 Switch

(S1 with warn switch S2)

PE PE PE

Fig.2: Circuit diagram

FISCHER Mess- und Regeltechnik GmbH Commissioning | 4

BA_EN_NK10 9 / 28

4 Commissioning

4.1 Generalities

All electrical supply, operating and measuring lines and the pressure connec-

tions must have been correctly installed before starting operation and the flange

connections must have been correctly made. All supply lines are arranged so

that there are no mechanical forces acting on the device.

NOTICE!Leak test

The leak tightness of the flange connection must be tested in the course of the

system leak tests.

4.2 Function test

There is a test button outside the pressure chamber with which a function check

as per DIN 4754-3 can be made without lowering the fill level. When pressed,

the body of the swimmer is moved against its buoyancy.

The factory default switching point of switch S1 (clamps 1, 2, 3) is set so that it

switches when the swimmer rod is horizontal. The optional warning switch S2

switches ca. 2.5 mm before S1.

Check the function of the unit:

• Check the switching function (with the aid of the test button) in combination

with the following components.

• Check the swimmer via the buoyancy behaviour after pressing the test but-

ton.

If the result of the function test is negative, the fill level limiter must be taken out

of operation and the process must be kept safe by other means.

5 | Servicing FISCHER Mess- und Regeltechnik GmbH

10 / 28 BA_EN_NK10

5 Servicing

5.1 Maintenance

CAUTION!Observe the system safety and operating regulations.

The instrument is maintenance-free. We recommend the following regular in-

spection to guarantee reliable operation and a long service life:

• Check the switching function (with the aid of the test button) in combination

with the following components.

• Check the seal tightness of the flange connection.

• Check the electrical connections (cable clamp connection).

The exact test cycles need to be adapted to the operating and environmental

conditions. If several components of the unit interact, all operating instructions

of the other units also need to be observed.

5.2 Transport

The measuring device must be protected against impacts. It should be transpor-

ted in the original packaging or a suitable transport container.

5.3 Service

All defective or faulty devices should be sent directly to our repair department.

Please coordinate all shipments with our sales department.

WARNING

Process media residues

Process media residues in and ondismantled devices can be a hazard to

people, animals and the environment. Take adequate preventive measures. If

required, the devices must be cleaned thoroughly.

Return the device in the original packaging or a suitable transport container.

5.4 Disposal

Please help to protect the environment by always disposing of the work pieces

and packaging materials in compliance with the valid national waste and recyc-

ling guidelines or reuse them.

FISCHER Mess- und Regeltechnik GmbH Technical data | 6

BA_EN_NK10 11 / 28

6 Technical data

6.1 General

Please also observe the order code here.

6.2 Application conditions

Ambient temperature -10 … +70 °C

Storage temperature -20 … +85 °C

Max. temperature of medium Depends on model

Specific minimum density of medium ρ = 0.6 kg/dm3

Installation position horizontal

Type of protection IP 55 acc. to DIN EN 60529

Variant Max. working pressure: Max. temperature of medium

NK10 1 … 20 bar 400°C

NK10 2 … 20 bar 400°C

NK10 3 … 10 bar 350°C

NK10 4 … 16 bar 400°C

NK10 5 … 16 bar 400°C

NK10 6 … 20 bar 400°C

NK10 7 … 20 bar 400°C

NK10 A … 10 bar 350°C

NK10 B … 20 bar 400°C

NK10 F … 20 bar 400°C

NK10 G … 20 bar 400°C

NK10 H … 20 bar 400°C

NK10 K … 150 lbs 400°C

NK10 M … 300 lbs 400°C

NK10 N … 300 lbs 400°C

NK10 P … 300 lbs 400°C

6.3 Switch contacts

Maximum load data at ohmic load.

250 V AC 6A

250 V DC 250 mA

6.4 Measurement accuracy

Switch hysteresis approx. 6 mm

Switching point differential between S1 and

S2 (+)

max. 30 mm

Switching point differential on the

medium surface

dependent on medium density

(+) only for two micro-switches

6 | Technical data FISCHER Mess- und Regeltechnik GmbH

12 / 28 BA_EN_NK10

6.5 Directives and certificates

Directives Applicable standards

Pressurised Vessel Directive 2014/35/

EU

DIN EN 13445-1:2013-12

DIN 4754-3:2015-03

Low-Voltage Directive 2014/35/EU DIN EN 61010-1:2011-07

examination Certificate no.

EC type testing in compli-

ance with Pressurised Ves-

sel Directive

Module

B

Cert. no. 07 202 1081 Z 9143/13/H

Module

D

Cert. no. 07/202/1081/Z/0095/18/D/001

DNV GL type testing Cert. no. TAA000020S

DIN CERTCO acc. to 4754-3 Cert. no. 10F001

Functional security

in compliance with EN 61508/61511 *)

Cert. no. Z10 11 04 27632 002

*) Only for devices with the order code for SIL (optional information).

6.6 Construction design

Swimmer system Stainless steel 1.4571

Metal bellows Stainless steel 1.4571

Flange / counter-flange (*) Stainless steel 1.0425 (P265GH) or 1.4571

Welding socket St.35.8 [1.0345 (P235GH)]

Screws / nuts (x) G 7258 / C35PbK

(*) Please note the material information in the dimensional drawings.

(x) Only for version with welding connection

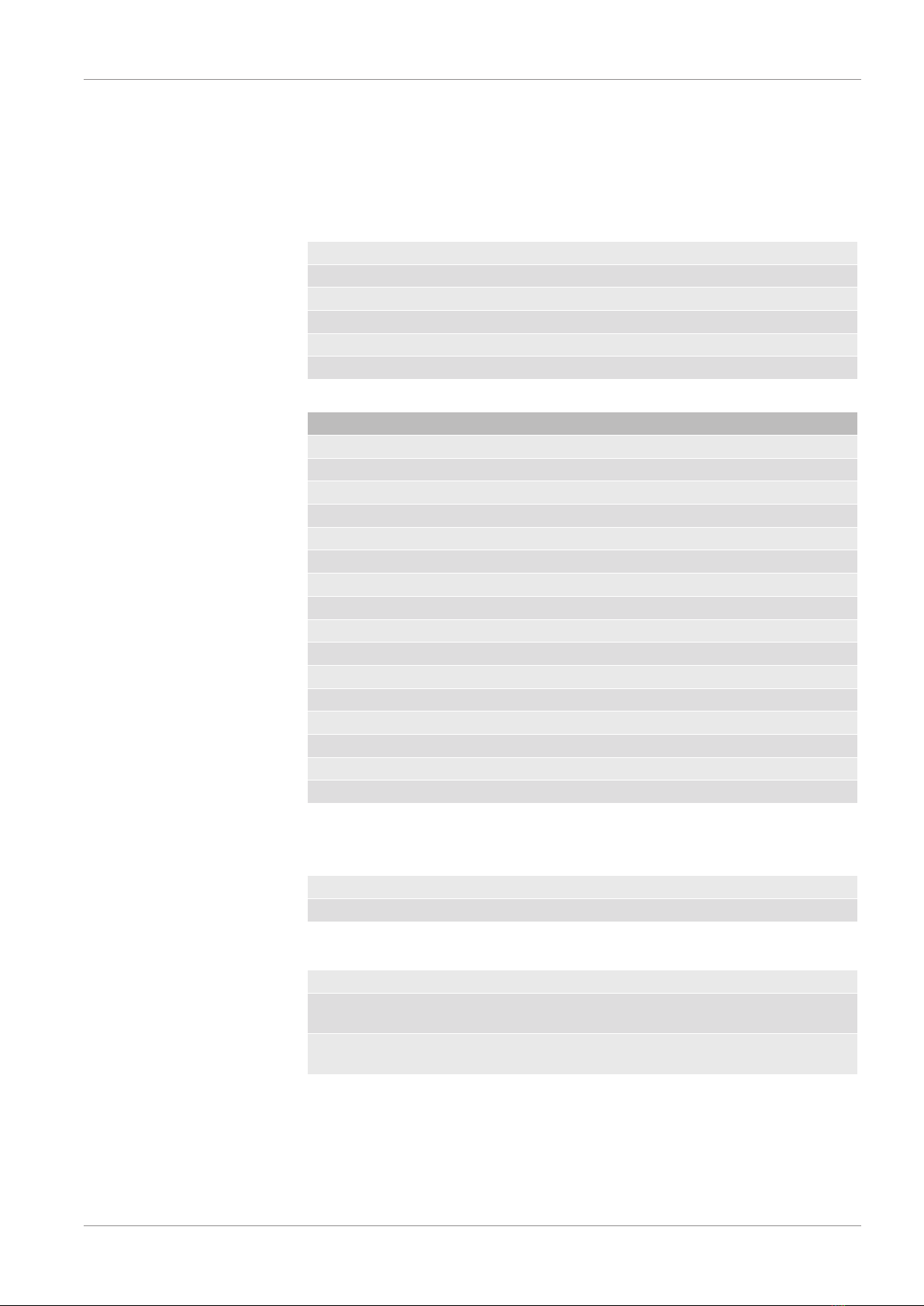

6.6.1 Dimensional drawings

All dimensions in mm unless otherwise stated

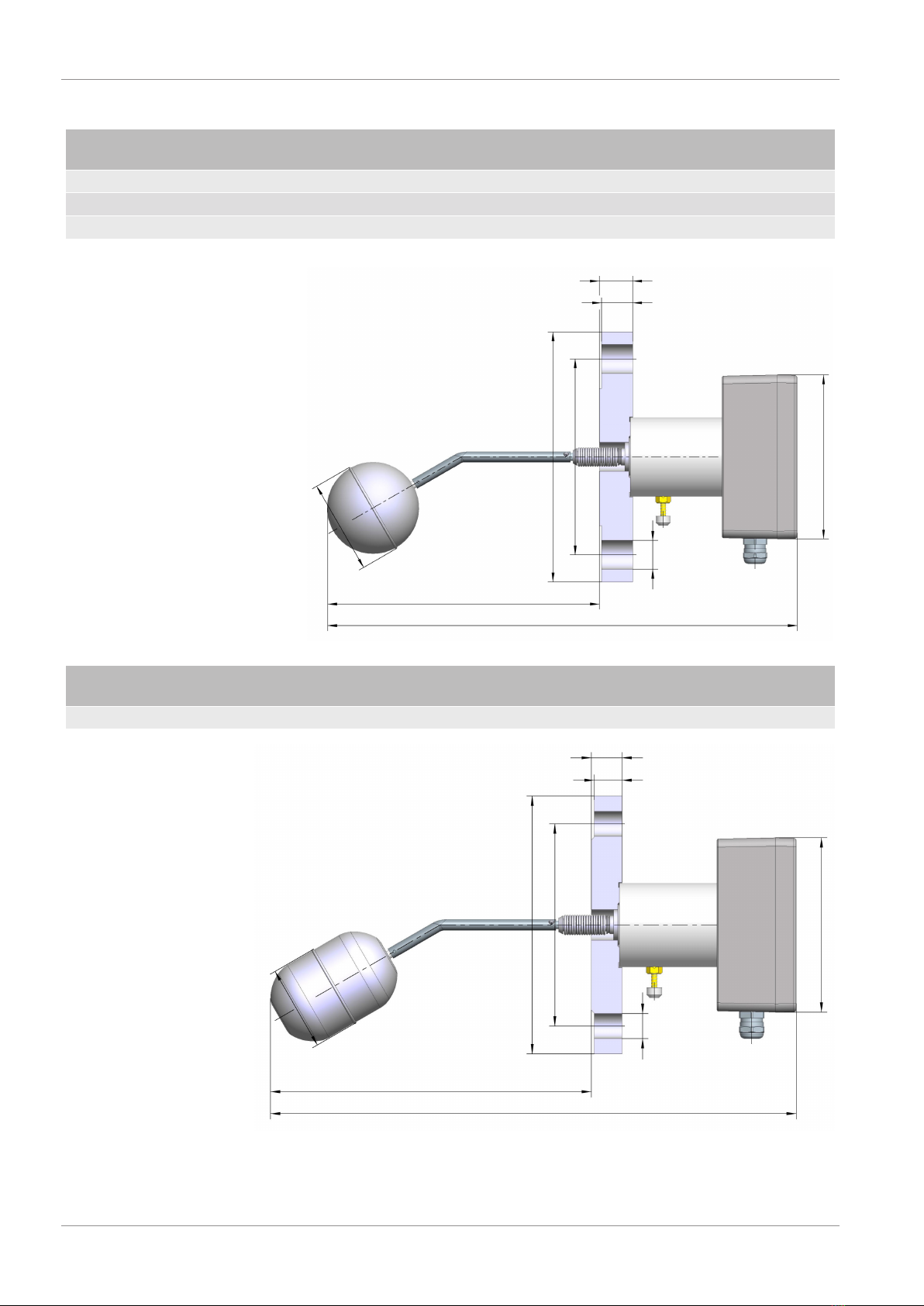

6.6.1.1 Version with welding connection

Version Flange

material

ABC

[Ø]

D

[square]

e

NK104 1.0425 P265GH 213 359 82.5 77.8 x 77.8 107

NK105 1.0425 P265GH 250 396 88.9 90.0 x 90.0 105

A

B

125

D

C

Ø72

E

Fig.3: Dimensional picture NK104 NK105

FISCHER Mess- und Regeltechnik GmbH Technical data | 6

BA_EN_NK10 13 / 28

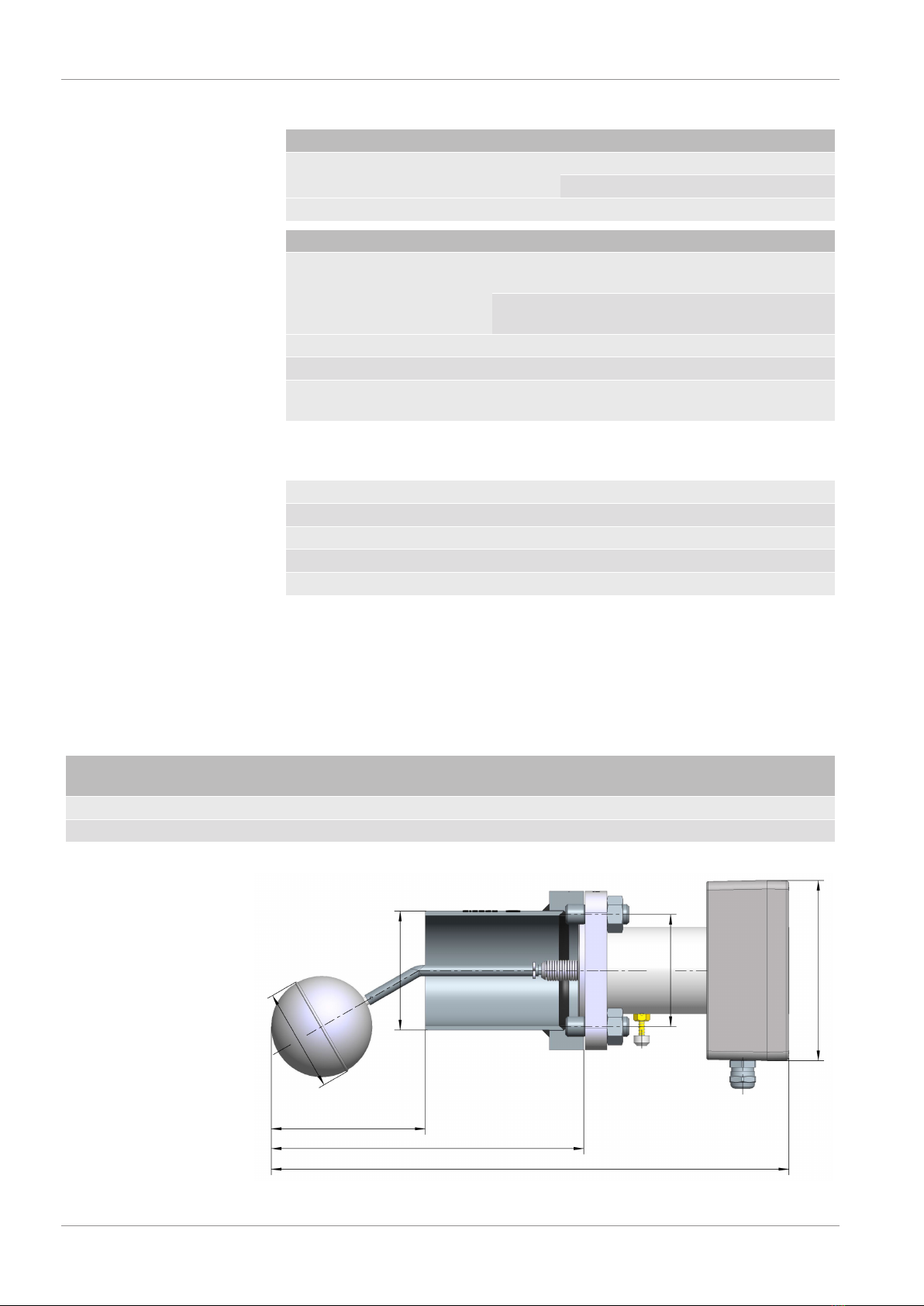

6.6.1.2 Flange DIN EN 1092-1 Type B1

Version Flange

material

Port D

[Ø]

LK

[Ø]

B b d

[Ø]

No. of

holes

NK102 1.0425 P265GH DN80 PN40 200 160 24 22 18 8

NK10G 1.4571 --- DN80 PN40 200 160 24 22 18 8

209

359

125

B

b

d

D

LK

Ø72

Fig.4: Dimensional picture NK102 NK10G

Version Flange

material

Port A D

[Ø]

LK

[Ø]

B b d

[Ø]

No. of

holes

NK101 1.0425 P265GH DN65 PN40 230 185 145 22 20 18 8

NK103 1.0425 P265GH DN65 PN16 234 185 145 18 16 18 4

NK107 1.4571 --- DN65 PN40 230 185 145 22 20 18 8

379

125

B

b

d

D

LK

Ø62

A

Fig.5: Dimensional picture NK101 NK103 NK107

6 | Technical data FISCHER Mess- und Regeltechnik GmbH

14 / 28 BA_EN_NK10

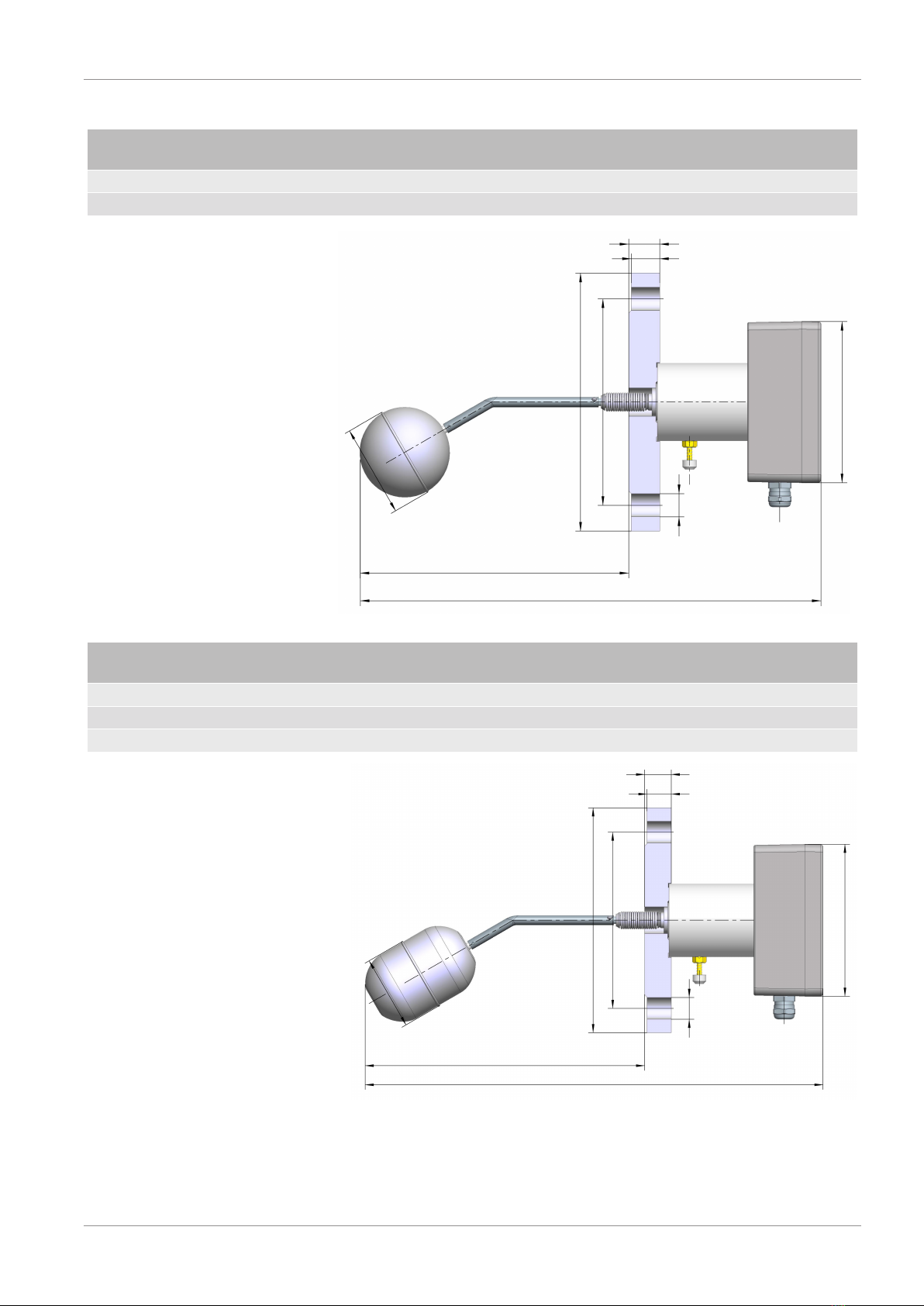

6.6.1.3 Flange DIN EN 1092-1 Type C

Version Flange

material

Port D

[Ø]

LK

[Ø]

B b d

[Ø]

No. of

holes

NK10F 1.0425 P265GH DN80 PN40 200 160 24 19.5 18 8

209

359

125

Ø72

D

LK

Ø120

Ø106

d

B

b

Fig.6: Dimensional picture NK10F

Version Flange

material

Port A D

[Ø]

LK

[Ø]

B b d

[Ø]

No. of

holes

NK106 1.0425 P265GH DN65 PN40 230 185 145 22 17.5 18 8

NK10A 1.0425 P265GH DN65 PN16 234 185 145 18 13.5 18 4

B

b

379

125

d

D

LK

Ø109

Ø95

Ø62

A

Fig.7: Dimensional picture NK106 NK10A

FISCHER Mess- und Regeltechnik GmbH Technical data | 6

BA_EN_NK10 15 / 28

6.6.1.4 Flange DIN EN 1092-1 Type G

Version Flange

material

Port D

[Ø]

LK

[Ø]

B b d

[Ø]

No. of

holes

NK10H 1.4571 --- DN80 PN40 200 160 24 22 18 8

B

b

209

359

d

D

LK

Ø106

125

Ø72

Fig.8: Dimensional picture NK10H

6.6.1.5 Flange DIN EN 1092-1 Type D

Version Flange

material

Port D

[Ø]

LK

[Ø]

B b d

[Ø]

No. of

holes

NK10B 1.0425 P265GH DN65 PN40 185 145 22 20 18 8

230

279

125

B

b

d

D

LK

Ø110

Ø94

Ø62

4

Fig.9: Dimensional picture NK10B

6 | Technical data FISCHER Mess- und Regeltechnik GmbH

16 / 28 BA_EN_NK10

6.6.1.6 Flange ANSI B16.5

Version Flange

material

Port A D

[Ø]

LK

[Ø]

B b d

[Ø]

No. of

holes

NK10K 1.0425 P265GH 3‘‘ 150 lbs 209 192.5 152.4 24 22.8 19.1 4

NK10N 1.0425 P265GH 3‘‘ 300 lbs 204 209.5 168.1 28.4 26.8 22.3 8

NK10P 1.0425 P265GH 4‘‘ 300 lbs 201 254 200.1 31.7 30.1 22.3 8

359

B

b

d

125

D

LK

Ø72

A

Fig.10: Dimensional picture NK10K NK10N NK10P

Version Flange

material

Port A D

[Ø]

LK

[Ø]

B b d

[Ø]

No. of

holes

NK10M 1.0425 P265GH 2.5‘‘ 300 lbs 227 190.5 149.3 25.4 23.8 22.3 8

B

b

359

d

D

LK

125

Ø62

A

Fig.11: Dimensional picture NK10M

FISCHER Mess- und Regeltechnik GmbH Order Codes | 7

BA_EN_NK10 17 / 28

7 Order Codes

0 0

Switching

elements

N K 1 0

Type

Flange

000 00000

1 2 5 6 7 8 9 10 11 123 4Code no. 13 14 15 16 17

Optional information

e.g. SIL

[1] Flange material

1DIN EN 1092-1 Form B1 DN 65 PN40 1.0425 P265GH

2DIN EN 1092-1 Form B1 DN 80 PN40 1.0425 P265GH

3DIN EN 1092-1 Form B1 DN 65 PN16 1.0425 P265GH

7DIN EN 1092-1 Form B1 DN 65 PN40 1.4571 ---

gDIN EN 1092-1 Form B1 DN 80 PN40 1.4571 ---

6DIN EN 1092-1 Form C DN 65 PN40 1.0425 P265GH

ADIN EN 1092-1 Form C DN 65 PN16 1.0425 P265GH

FDIN EN 1092-1 Form C DN 80 PN40 1.0425 P265GH

BDIN EN 1092-1 Form D DN 65 PN40 1.0425 P265GH

hDIN EN 1092-1 Form G DN 80 PN40 1.4571 ---

KANSI B16.5 3‘‘ 150 lbs 1.0425 P265GH

CANSI B16.5 2.5‘‘ 300 lbs 1.0425 P265GH

NANSI B16.5 3‘‘ 300 lbs 1.0425 P265GH

PANSI B16.5 4‘‘ 300 lbs 1.0425 P265GH

4Welding connection 82.5 mm (S80)

5Welding connection 88.9 mm (S90)

[8] Switching Elements

11 micro-switch

22 micro-switch

[13-17] Optional information

##### Code for special models e.g. SIL

The code is generated as agreed with our sales team.

8 | Attachments FISCHER Mess- und Regeltechnik GmbH

18 / 28 BA_EN_NK10

8 Attachments

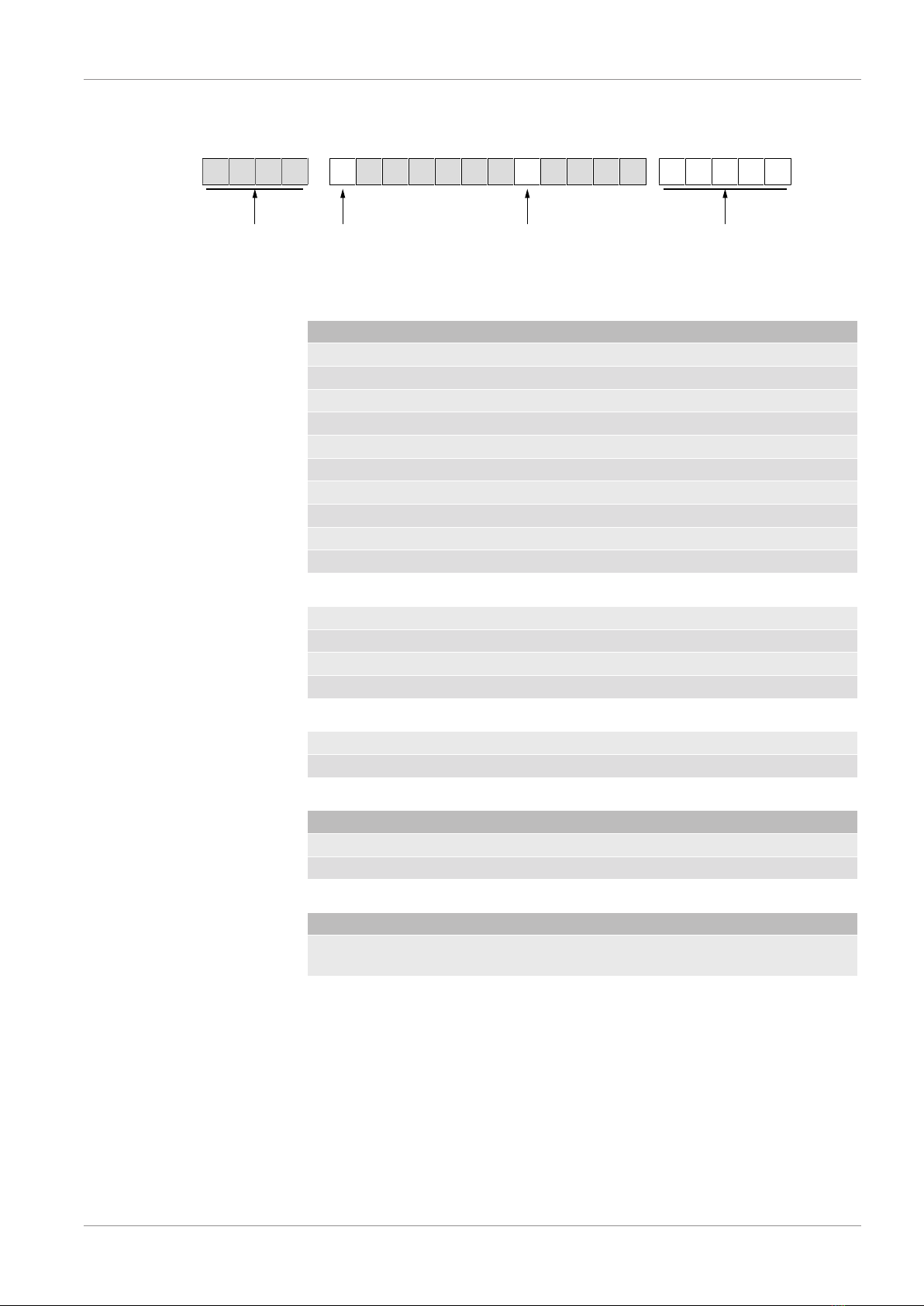

8.1 Declarations of conformity

Fig.12: CE_DE_NK10 part1

FISCHER Mess- und Regeltechnik GmbH Attachments | 8

BA_EN_NK10 19 / 28

Fig.13: CE_DE_NK10 part2

8 | Attachments FISCHER Mess- und Regeltechnik GmbH

20 / 28 BA_EN_NK10

8.2 Type testing certificates

8.2.1 Pressurised Vessel Directive 2014/68/EU

0

YNO

ZERTIFIKAT

CERTIFICATE

I )

I

I

B)

&

TÜV &

�

Fig.14: BMP_97-23-EG_DE_EN

This manual suits for next models

16

Table of contents

Other FISCHER Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

Pilz

Pilz PSS SB PASSIVE JUNCTION operating instructions

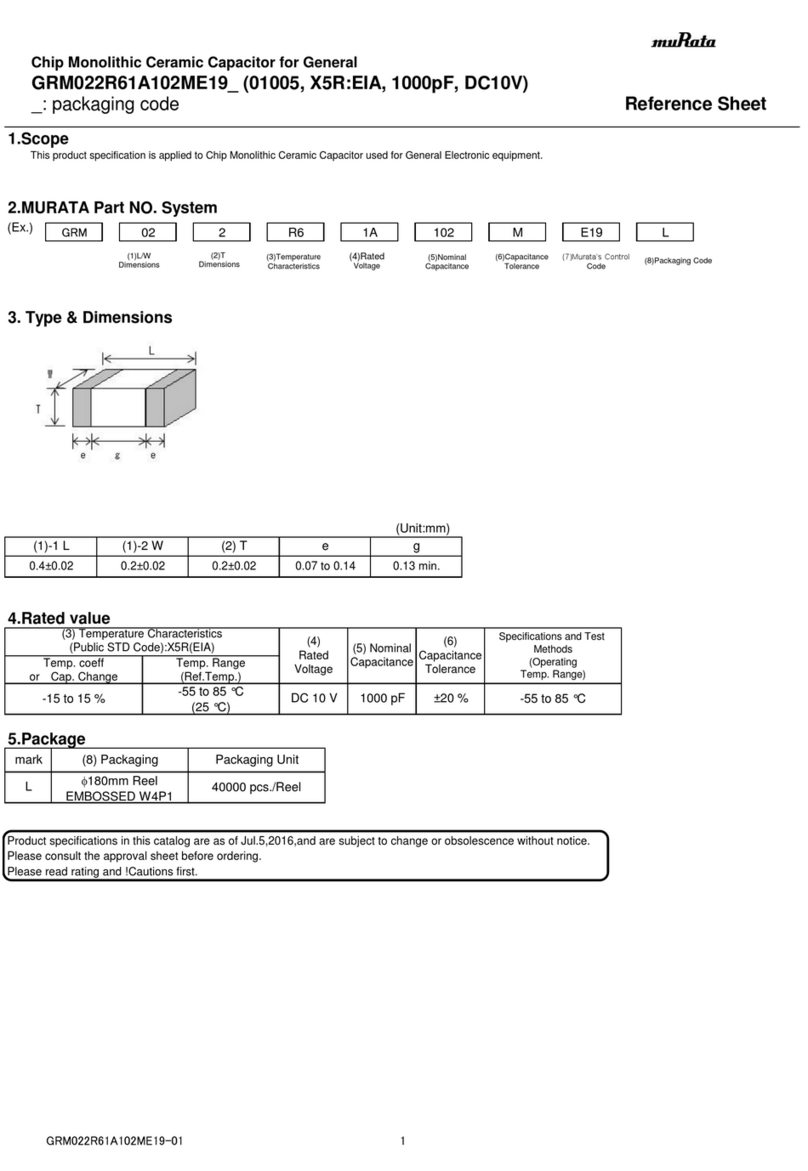

Murata

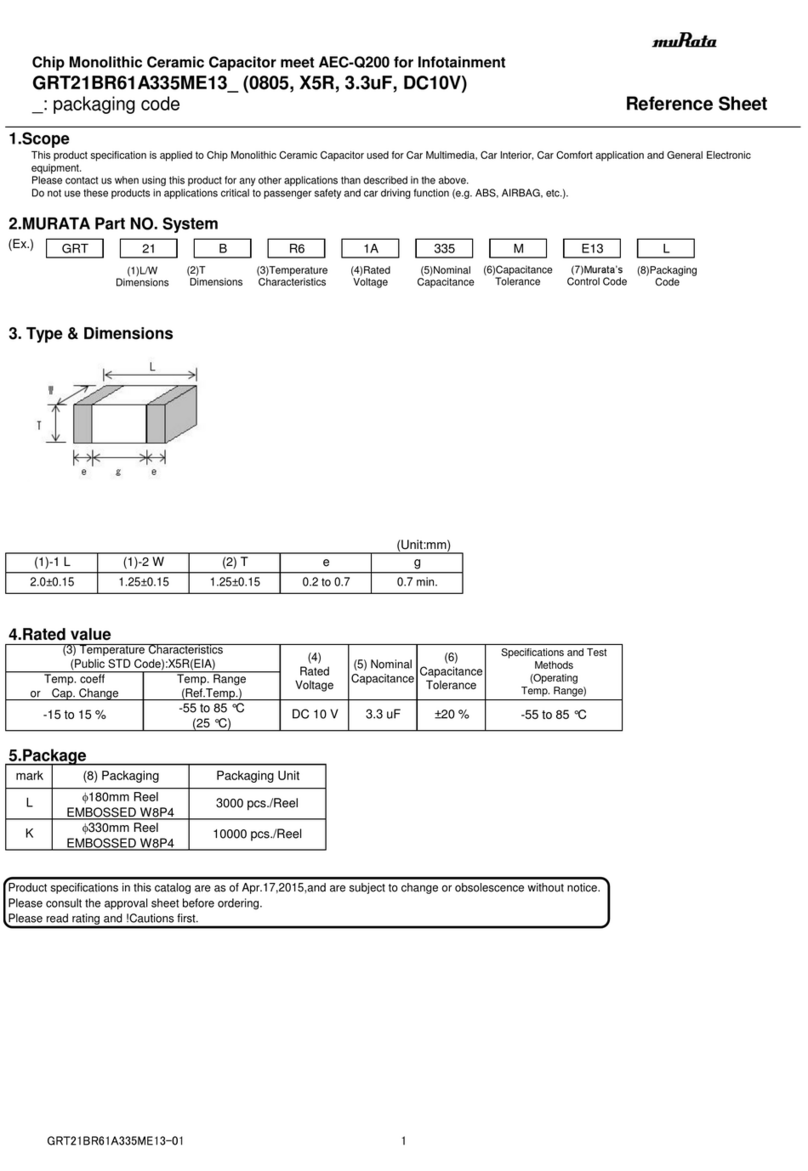

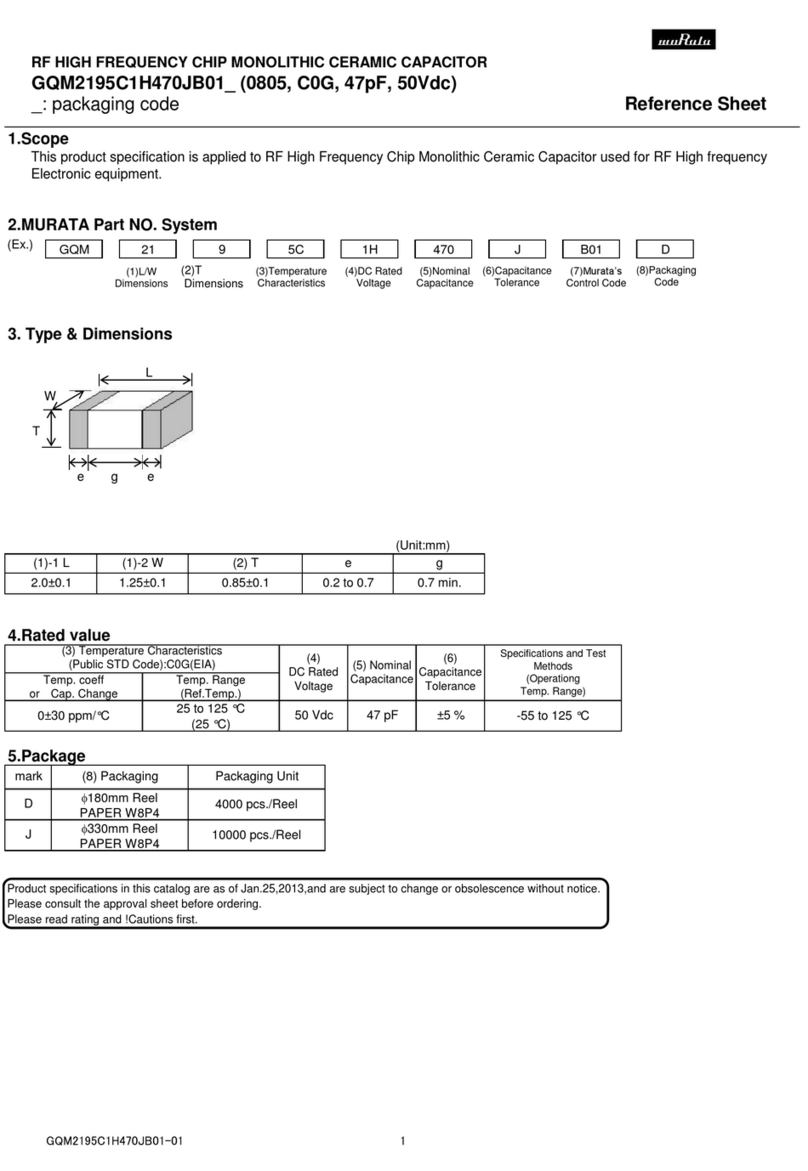

Murata GRM022R61A102ME19 Series Reference sheet

Moeller

Moeller NZM-XCM installation instructions

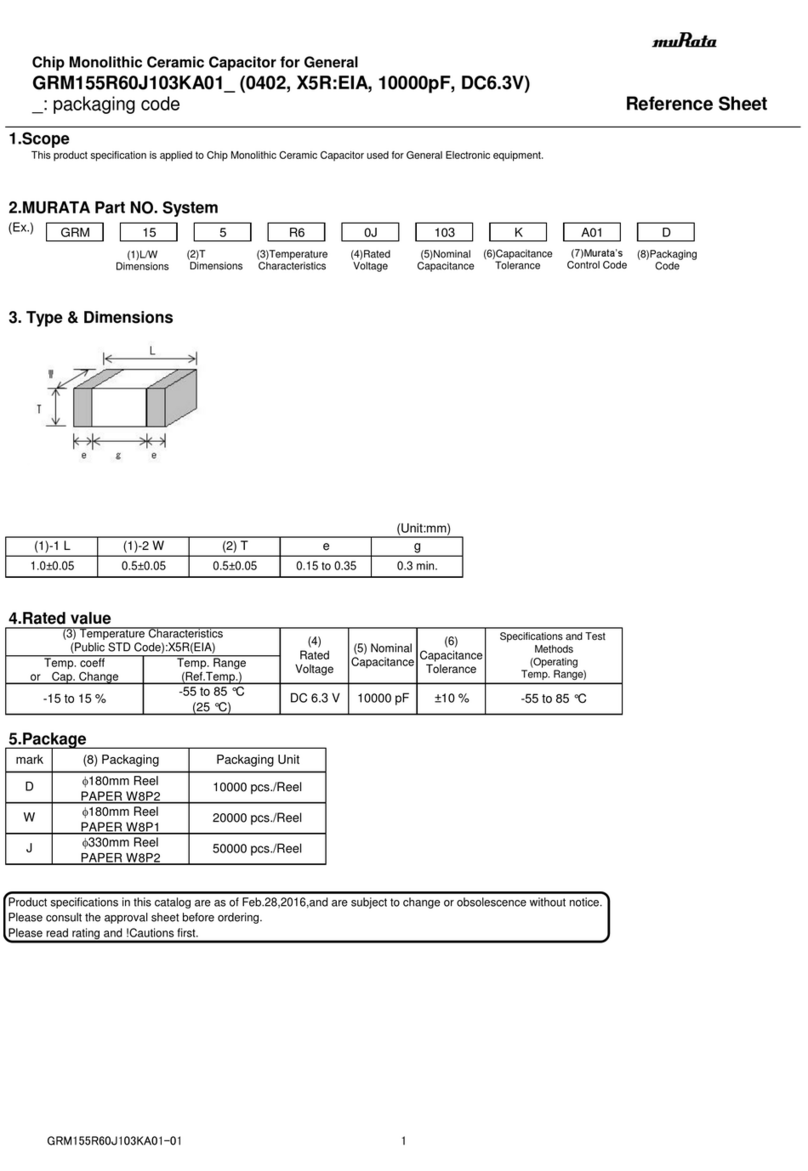

Murata

Murata GRM155R60J103KA01 Series Reference sheet

Moeller

Moeller NHI-NZM 14 Series installation instructions

ABB

ABB ACS880-604 Hardware manual