FISCHER Mess- und Regeltechnik GmbH Table of Contents

BA_EN_NK10_H_ST4-C iii

Table of Contents

1 Safety guidelines........................................................................................................................................... 4

1.1 General....................................................................................................................................................4

1.2 Personnel Qualification ...........................................................................................................................4

1.3 Risks due to Non-Observance of Safety Instructions..............................................................................4

1.4 Safety Instructions for the Operating Company and the Operator ..........................................................4

1.5 Unauthorised Modification.......................................................................................................................5

1.6 Inadmissible Modes of Operation............................................................................................................5

1.7 Safe working practices for maintenance and installation work................................................................5

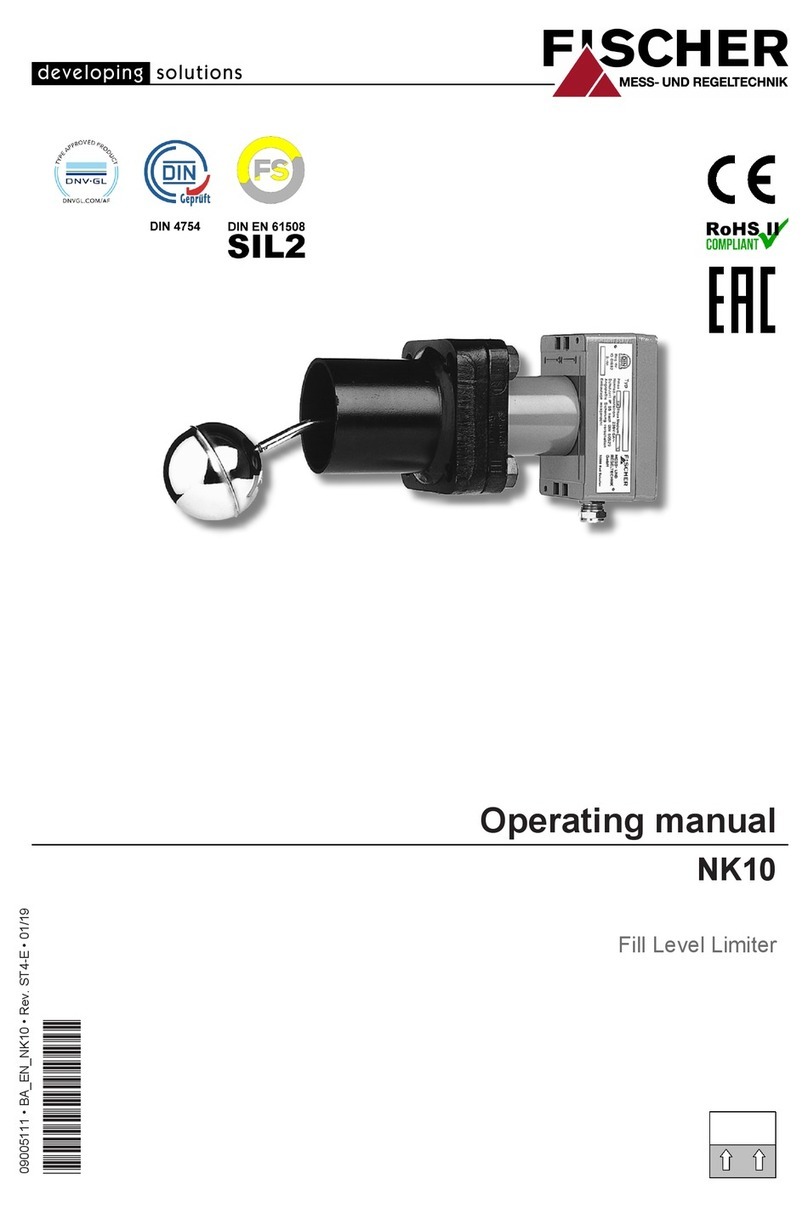

1.8 Pictogram explanation.............................................................................................................................5

2 Product and functional description............................................................................................................. 6

2.1 Delivery scope.........................................................................................................................................6

2.2 Explosion hazard area classification .......................................................................................................6

2.3 Function diagram.....................................................................................................................................6

2.4 Design and mode of operation ................................................................................................................7

3 Installation and assembly ............................................................................................................................ 8

3.1 Safety guidelines .....................................................................................................................................8

3.2 Valid range ..............................................................................................................................................8

3.3 Process connection .................................................................................................................................8

3.4 Electrical connections..............................................................................................................................9

4 Commissioning ........................................................................................................................................... 11

4.1 Safety guidelines ...................................................................................................................................11

4.2 Generalities ...........................................................................................................................................11

4.3 Function test..........................................................................................................................................11

5 Servicing ...................................................................................................................................................... 12

5.1 Maintenance..........................................................................................................................................12

5.2 Transport ...............................................................................................................................................12

5.3 Service ..................................................................................................................................................12

5.4 Disposal.................................................................................................................................................12

6 Technical data ............................................................................................................................................. 13

6.1 General..................................................................................................................................................13

6.2 Application conditions............................................................................................................................13

6.3 Switch contacts .....................................................................................................................................14

6.4 Measurement accuracy .........................................................................................................................14

6.5 Directives and certificates .....................................................................................................................14

6.6 Construction design...............................................................................................................................14

7 Order Codes ................................................................................................................................................ 20

8 Attachments ................................................................................................................................................ 21

8.1 Declaration of Conformity......................................................................................................................21

8.2 Type testing certificates.........................................................................................................................23

8.3 DIN CERTCO Certification DIN 4754-3.................................................................................................31

8.4 EAC Declaration....................................................................................................................................33