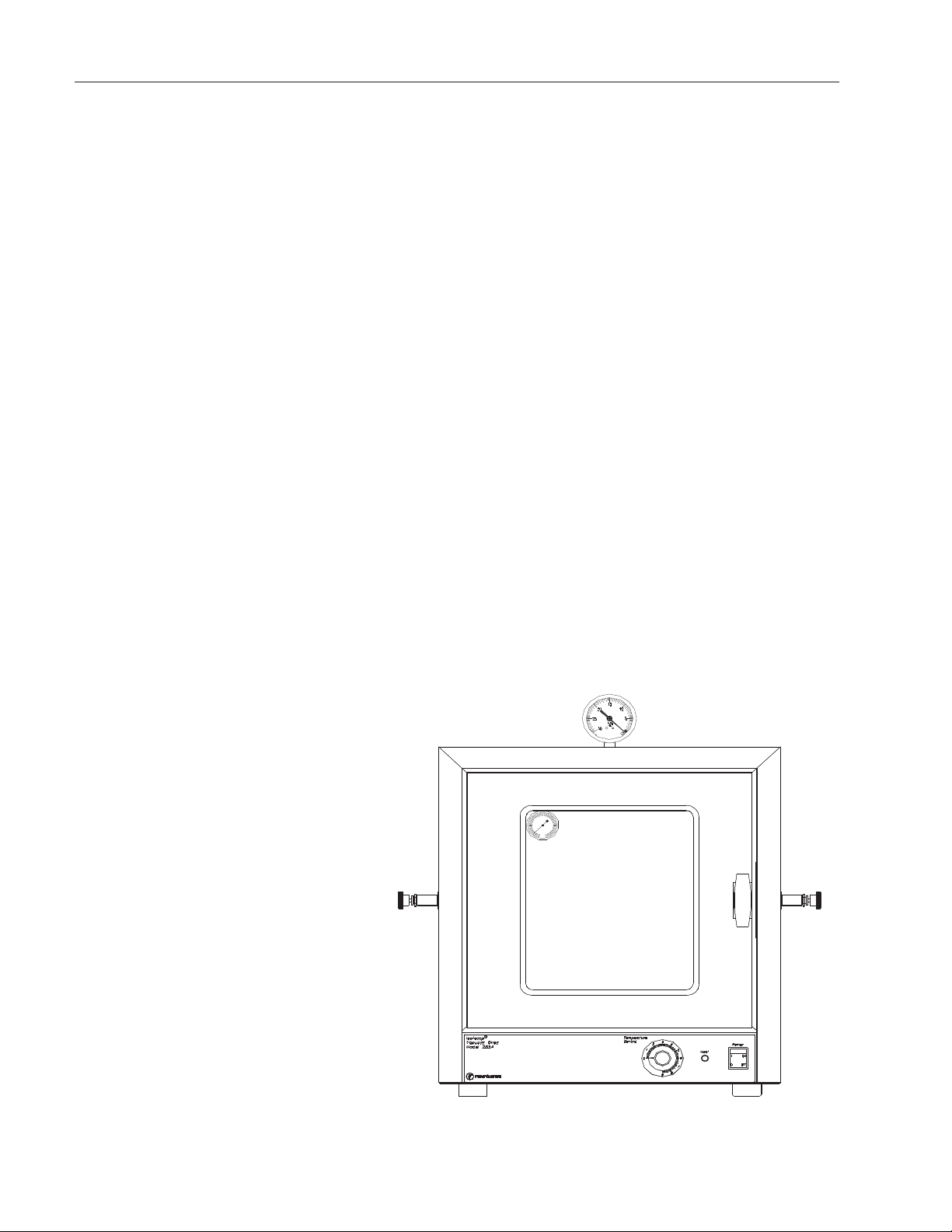

Preparing the Oven

1. Place the oven on a bench or stand at a con-

venient working height. Maintain a minimum of

12 inches of clearance between the oven and

any combustible surfaces.

2. Turn temperature control to low position and

turn power switch off.

3. Check voltage and watts stamped on the data

plate for compatibility before connecting oven to

power source. The data plate can be found

near the power cord.

4. Connect a vacuum pumping system, including a

suitable trap, to the serrated fitting on the valve

designated as vacuum. Use 1/4” ID heavy

walled tubing and secure the connection with a

hose clamp.

5. If desired, connect a purge gas supply to the

remaining serrated fitting. Use a two stage gas

flow regulator if gas is to be supplied by a pres-

surized cylinder.

Temperature Adjustment

1. Turn the power switch on, to supply power to

the oven.

2. Turn the Temperature Control knob fully clock-

wise. The " eating" indicator will glow when the

unit is heating. When the temperature reaches

the desired operating level (as indicated on the

thermometer) turn the Temperature Control knob

counterclockwise until the " eating" indicator

turns off. Allow the temperature to cycle on and

off several times (3 to 4 hours) to make sure the

oven has stabilized. Adjust the Temp. Control

knob up or down as necessary.

3. When temperature is at the desired setting pro-

ceed to operate in any one of the following vac-

uum environments.

7

Operation

Note

Recommended vacuum tubing and

vacuum pumps are listed under the

Accessory Items section of this man-

ual.

Note

When the oven is new and is first

heated, the insulation will become

scorched and some smoke and

burning odor will occur. It is normal

for this condition to last 2 to 3 hours

at high heat.