Isotemp Premium Ovens 1-1Fisher Scientific

Section 1 Introduction

Fisher Scientific Isotemp 700 Series Standard ovens are available in three

sizes: Small, Medium and Large. All ovens provide PID Microprocessor

control at operating temperatures ranging from 50°C (122°F) to 275°C

(527°F).

The forced air ovens provide improved temperature uniformity and

control, as well as faster drying. In these ovens, fresh air enters through an

air intake on the bottom of the oven, then is heated in a plenum below the

chamber. A blower circulates the heated air into the wall plenums and the

oven chamber itself in uniform flow patterns. Exhaust air is vented

through a port at the top of the oven.

Gravity flow ovens inlet air through a port located under the oven floor.

Heat generated convection then gently moves the air in a vertical

circulation pattern. Exhaust air is vented through a port at the oven top.

Temperature readouts and control parameters are shown on red LEDs.

Three additional LEDs indicate when heater power is being applied, an

error condition is encountered, or the temperature is being set.

The Small ovens accommodate a maximum of five shelves. The Medium

ovens hold eight shelves, while the Large ovens each hold eleven.

Isotemp ovens incorporate a variety of safety features. A safety backup is

built into the controller software: if the primary heater control fails, the

backup will maintain control at 5°C above the set point. An alarm LED

then indicates that the backup controller is operating the oven. A circuit

breaker protects the oven from power surges. If primary and backup heater

controls fail, an independent Over Temperature Device will disengage

heater operation.

The silicon rubber gasket supplied with the oven is good for continuous

use up to 250°C and intermittent use to 275°C. This gasket provides a

better seal than the high temperature gasket and is supplied with is

supplied with the unit. An optional high temperature braided gasket is

available for customers using the oven frequently above 250°C. The part

numbers of the supplied and optional gasket are listed below:

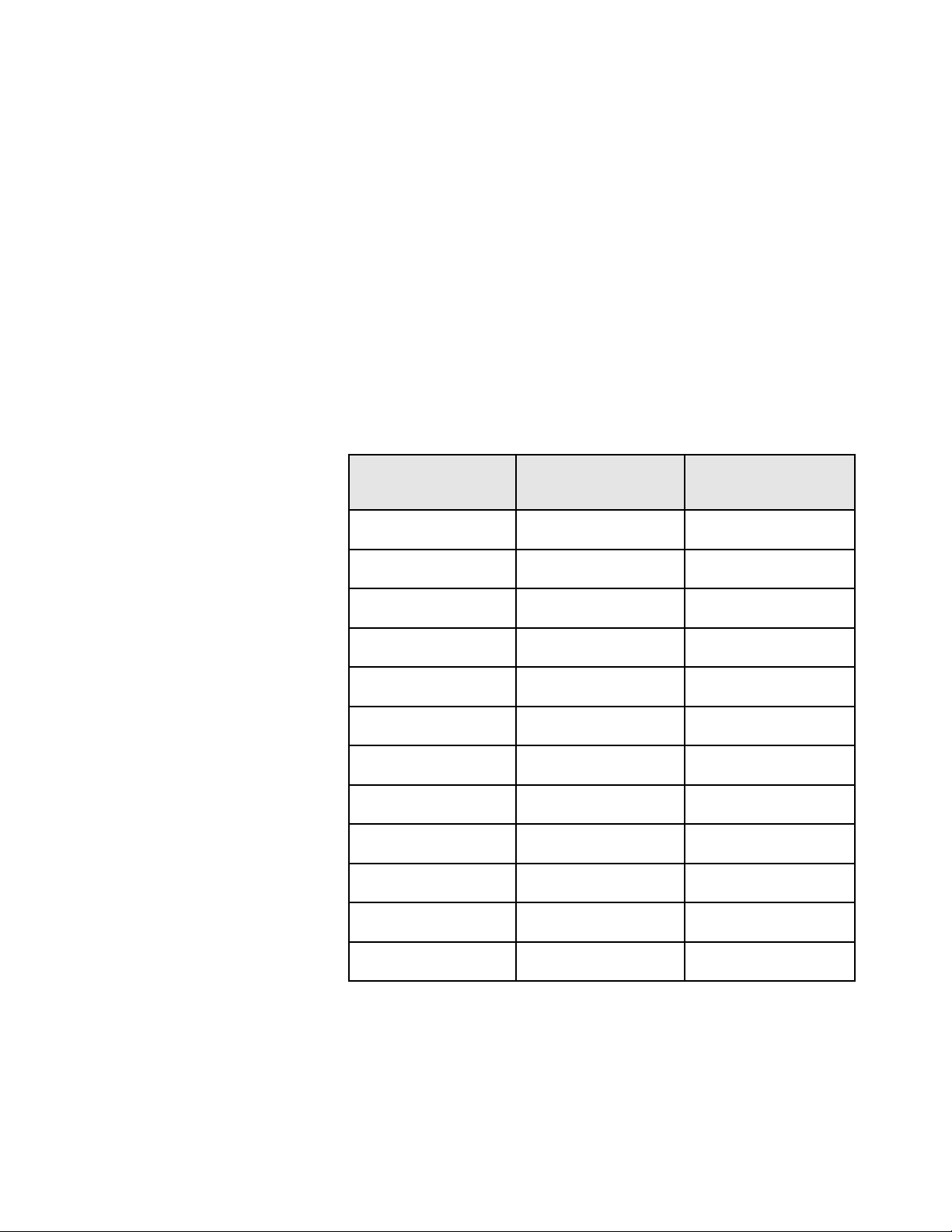

Oven Size Silicon Rubber Gasket Part #

(Supplied with Oven)

Braided Gasket Part #

(High Temp Gasket Optional)

Small SPN 101908 SPN 95782

Medium SPN 101909 SPN 95783

Large SPN 101910 SPN 95784