Fitness Technology 400 Series User manual

Fitness Technology

21 Bishop St.

Skye SA 5072

Australia

+61 8 8331 9229

Mob: 0418 815 400

www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005

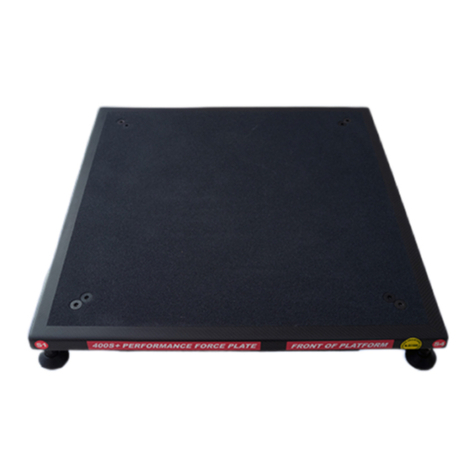

FORCE PLATE

400 Series

Performance Force

Plate

2

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

Introduction:

The 1000Kg Rated Force Plate specifications

1. 795mm x 795mm x 60mm High Aluminium Framed Platform & non slip Carbon Fibre Top.

2. 4 x Load Cells complete with adjustable height feet assemblies that can adjust the height of the

Plate to approx 120mm

3. Maximum Sampling Rate –adjustable in software from 1 –600Hz on all 4 Load Cell channels

via BMS software program.

4. 400S Force Plate + BMS Linear Position Transducer (LPT )is calibrated by users on site via the

BMS software via Tools\Configure\Calibration (tab window)

5. Only Performance Force Plate on the market capable of running the BMS LPT & auto saving all

data files + outputting to Excel via the BMS software program.

6. Only Performance Force Plate on the market capable of running on our new Inner-Balance

software tracking used to measure & record all Anterior Posterior & Medial Linear movements

7. 400S Weight 20.6 Kg (45.3 lbs)

8. 1 x PCB Module operates 4 Load Cells + LPT powered via 5 V DC Computer USB Port only

9. 1 x USB 2.0 communications Cable provides 100% of power required to run the 400S from any

PC or laptop USB Port.

10. 1 x USB 2.0 Extension Cable 3 M Long provided with all 400S units

11. 1 x RJ 45 Connection (located under the Force Plate) with connection lead supplied going to 1K

Ohm Potentiometer on the BMS LPT model PT5A-150-V62-UP-1K-M6-632676A

12. The PCB shown on Page 4 is self contained in the 400S Platform Assembly.

13. To operate the 400S Platform simply installs the software onto your Hard Drive and then

connects the USB Cable plug into your Computer.

14. With the 400S no other power supply or charging of batteries is required.

3

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

FRONT OF PLATFORM

Load Cell Wiring

The four Load Cells connect into the XPV7 Electronics Module are colour coded on the

load cell cables at the terminal blocks for ease of wiring, they are as follows

Load Cell 1. Blue Heat - Shrink shroud as per next page

Load Cell 2. Green Heat - Shrink shroud as per next page

Load Cell 3. Red Heat - Shrink shroud as per next page

Load Cell 4. Yellow Heat - Shrink shroud as per next page

The wiring connection for each individual load cell is as follows.

Ex+ RED Terminal

Block is not

Sig + White on 400 S Plate

Sig - Green Note: Green and White wires maybe reversed.

Ex-Black

Shield (Heat shrink - wire colour may vary)

Installation:

1. Carefully unpack the platform by lifting it out the end of the transport carton.

Make sure all items are present. (Report any discrepancies immediately.)

2. Place the platform onto a flat stable surface.

3. Install each foot into the load cell holes on the four corners of the platform by

rotating the feet to the right. (right hand thread) Adjust height as show below.

4. Connect the USB communication cable as shown below by removing the plug

allowing access to the communications port. (See photos below)

5. The Platform is now ready for use.

6. Install the communications software and the processing software following the

instruction for each module

7. The XPV7 PCB Electronics Module will automatically identify any cable faults.

Should this happen make sure the communication cables are properly installed.

If communication failure continues, then replace the USB cable.

8. For any other problems contact our office for further instructions.

4

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

USB Cable Connections

USB Connector

Lead to RJ45

Connector to

External RJ45

Socket for LPT

cable connection

USB Connector

US8/8 Plug w lead to RJ45 Skt

Pin 2 = PT5A IK Pot V Signal

Pin 4 = USB +5V

Pin 6 = USB Gnd.

Pin 7 = MBU V Signal.

5

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

Installation of 4 x Platform Feet

The Platform cannot be used until the 4 x feet with M12

1.75 pitch threads are installed in each of the four corners.

They screw into the Platform with standard a right-hand

thread

Stainless Steel M12 spacer Nuts are used for levelling and

adjusting the height of the Platform. If required the M12

spacer nuts can be removed but if this is done never

thread the 4 x feet threads thru all the way - back off 5mm.

Refer Trouble shooting Note 5 on Page 7. The Platform

should also always be level when in use.

M12 Spacer

Nut

6

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

1 of the 4 x low profile shear beams bolted in position.

Care and Maintenance of Force Plate

To clean the Force Plate we recommend the use of standard household detergent to wipe

down the external surface area.

Note:

Do not place or allow any water to ingress into the Platform via the load cell holes or

the penetration used for the USB communication port underneath the Platform.

7

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

PRECAUTIONS

Before the Force Platform is used for any purpose, checks must be carried out to

ensure the safety of the individuals using the Platform. Appropriate footwear must

always be worn when using the Platform.

All operators must ensure themselves that the Platform is suitable and safe for the

application or testing purpose, by carrying out a series of tests prior to using the

system.

The Testing Officer or Force Plate Operator acknowledges the decision to use the

Force Plate and it’s suitability for the purpose rests solely with their deliberate

decision to use the device.

Warranty.

The Company warrants that the products are thoroughly examined before shipment and

agrees to make good any part that is proved to be defective due to faulty workmanship.

Defects or failures in equipment which, under proper use, appear therein and arise solely

from faulty materials or workmanship will be remedied by us free of charge provided the

equipment is returned to our Workshop within a period of twelve (12) months from date of

delivery, freight paid both ways. In the case of warranty service to equipment "on site" or at

the purchaser's premises, all traveling and accommodation costs shall be to the

purchaser's account. Damage to product including broken or damaged cabling caused by

maliciousness, negligence or through changes to electrical configuration of equipment or

voltage in excess of rating is specifically excluded from this warranty (the Proof to the

contrary being the onus of the purchaser). Where this occurs then such warranty real or

implied offered by The Company shall immediately come to an end.

The Company extends such warranties as are offered by the original manufacturer of

material. Liability under this warranty applies only to repair or replacement (at the

discretion of the Company) of the original goods supplied. The Company will not be liable

for any damages or delay (general or consequential) whether directly or indirectly caused

by the said defect, and shall not be responsible for any work done, or alterations, or

addition, made to the products by any other party.

8

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

Trouble shooting the 400S Force Plate

If you are unable to receive data from the 400S Force Plate there are a number of simple causes. For

technical reasons not all are detailed in this document:

1. Our system requires you have the correct and latest USB Driver. You may have an older version of

the USB driver which sometimes may not work if your PC also has a virtual COM Port driver loaded.

To fix the you can download new drivers from:

http://www.ftdichip.com/Drivers/CDM/CDM%202.04.06.exe

2. Some PCs have USB ports that are not to the full specification. If you suspect this may be an issue

then a USB hub can be added between the 400S Force Plate and your PC. When adding a USB 2.0

high quality extension lead must connect this Lead before you connect the 400S to the PC .

Then open our BMS software program with the 400S connected and then the PC will register the

presence of the 400S.

3. Are you using a USB extension lead? See 2 above. Until the trouble shooting is complete we

recommend that you disconnect any USB extension leads.

4. Now if the 400S is still not communicating with your PC we have made available a test program

which allows the XPV7 circuit board inside the 400S to be tested. When performing these tests it is

best to remove the cover plate from the underside of the platform to expose the XPV7 circuit board.

The test program is available from

http://www.innervations.com/downloads/TESTXPV7%20Install.exe

5. Fluctuating Force Plate Kg Mass values in the BMS software program - This problem normally

occurs when the 4 x M12 Feet are fully screwed thru into the 4 x Load Cells (Shear Beams).

(a) If the 4 x M12 spacer nuts are used it will not be possible to screw these 4 x Feet in too far.

(b) If these 4 spacer nuts are not used do not screw these 4 feet thru all the way back off the 4 x

Platform feet approximately 5 mm refer Page 5. Only when (a) or (b) has been done proceed to -

Step 1 Now calibrate the plate as per our web site Instructional Footage for Media Player

instructions http://www.fittech.com.au/_en/products/4_force/2_5_instructional/force_2_5.htm then

once calibrations have been completed proceed to

Step 2 - (now when step 1 has followed,) next you should be able in the in the BMS program to set

a 5 sec time test span - then in Collect & Analyse window Zero out the plate then hit then Collect

Data button put a know Mass on the Plate & it should read the correct value of the Mass.

Within 0.1 Kg is a typical acceptable Mass reading,

9

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

6. With the 400S connected to the PC you can now run TEST_XPV7.exe If the XPV7 circuit board

inside the 400S has initialized correctly you should see the version and serial numbers for the XPV7

in the title line of the test program. Further confirmation that the XPV7 is communicating with your

PC is the PCB System Information and PCB A/D Settings which are shown at the bottom of the

test program dialogue box. If this information is not displayed then there is either still a problem with

your PC or the XPV7 is not running. Note the “HEARTBEAT” light at the top of XPV7 should be

flashing when the test program is running. Allow a period of 15 seconds to pass before pressing the

“Start Continuous Data Transfer” Key.

10

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

7. To start receiving data from the 400S press the “Start Continuous Data Transfer” button. If the

equipment is operating correctly you will see “analogue” bars next to each channel and a digital

value on the right hand side. If nothing is displayed this is because the internal error checking in the

XPV7 has detected a fault and is not sending faulty data.

8. If you are not receiving data then press the “Stop Continuous Data Transfer” button.

9. So that you can determine which channel has caused the fault you must click on the “DISABLE

ERROR CHECKING” checkbox then press the “Start Continuous Data Transfer” button. Note, with

a tick the checkbox the caption changes to “DIAGNOSTIC”. Now you should see one or more

channels reading zero.

11

FORCE PLATE 1000 Kg

Capacity

FORCE PLATE 400 Kg Capacity

Fitness Technology, 21 Bishop Street, Skye SA 5072 Australia

Tel: +61 8 8331 9229 Mob: 0418 815 400. www.fittech.com.au

Copyright: Fitness Technology, Adelaide, Australia 21st March 2005. Issue 2.00, 21st Aug 2008

10. To determine the cause of the fault close the test program, disconnect the USB cable, and swap

over the pluggable terminal blocks so that the channel 1 & 2 pair is plugged into channel 3 & 4 and 3

& 4 go into 1 & 2. Now reconnect the USB cable and run the test program and repeat step 8. If the

faulty channel moves (in this case to CH #1) then there is a connection, cable, or load cell fault. If on

the other hand the fault doesn’t move then the XPV7 circuit board is faulty.

11. Next you should compare the A/D Settings at the bottom of the dialogue box, these numbers should

match exactly with what you have on screen. If these numbers do match then there is a hardware

fault on the XPV7 circuit board.

If these numbers don’t match then contact our repair centre for further instructions on resetting these

values.

Table of contents

Other Fitness Technology Fitness Equipment manuals

Popular Fitness Equipment manuals by other brands

Slendertone

Slendertone Pulse 530 instruction manual

AQUATREND

AQUATREND Water Workout Station owner's manual

CYBEX

CYBEX 19100 owner's manual

Rogers Athletic

Rogers Athletic 410343 Product information packet

HeartSine

HeartSine samaritan SAM 350P user manual

Profile Design

Profile Design Sonic Ergo 45AR user manual