INSTALLATION INSTRUCTIONS

MILLENNIUM CISTERN

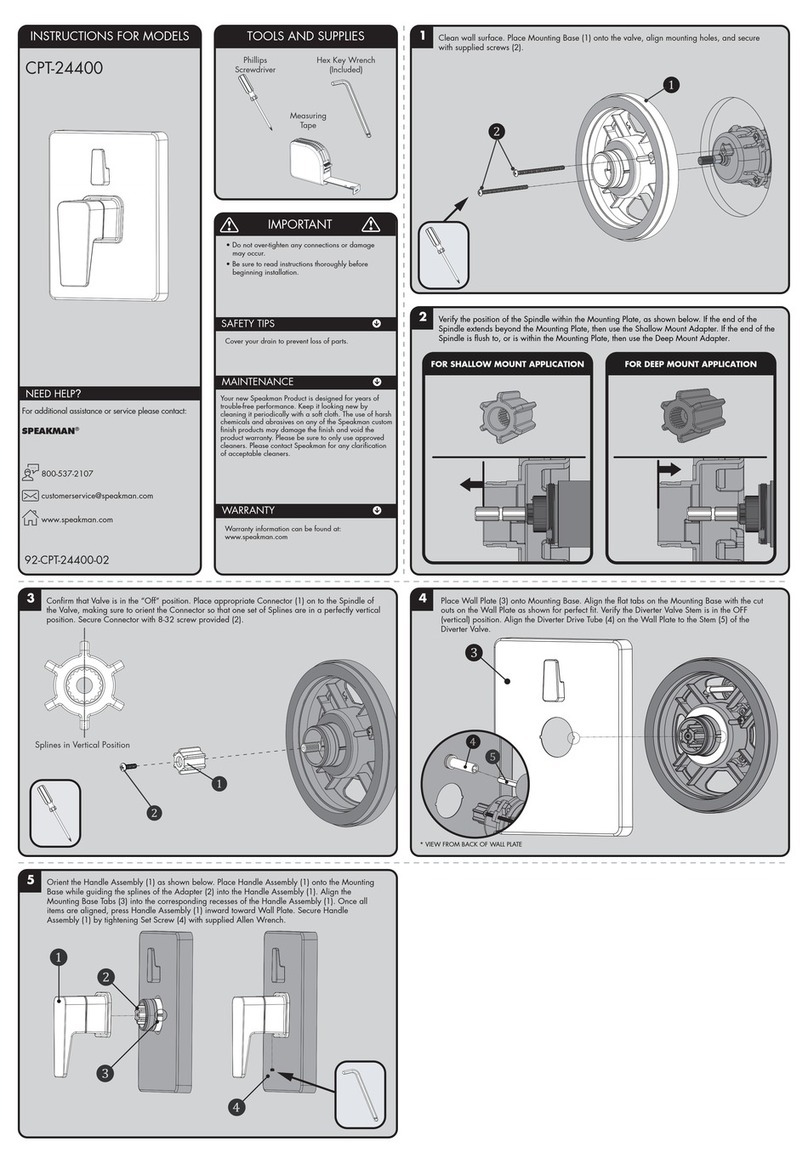

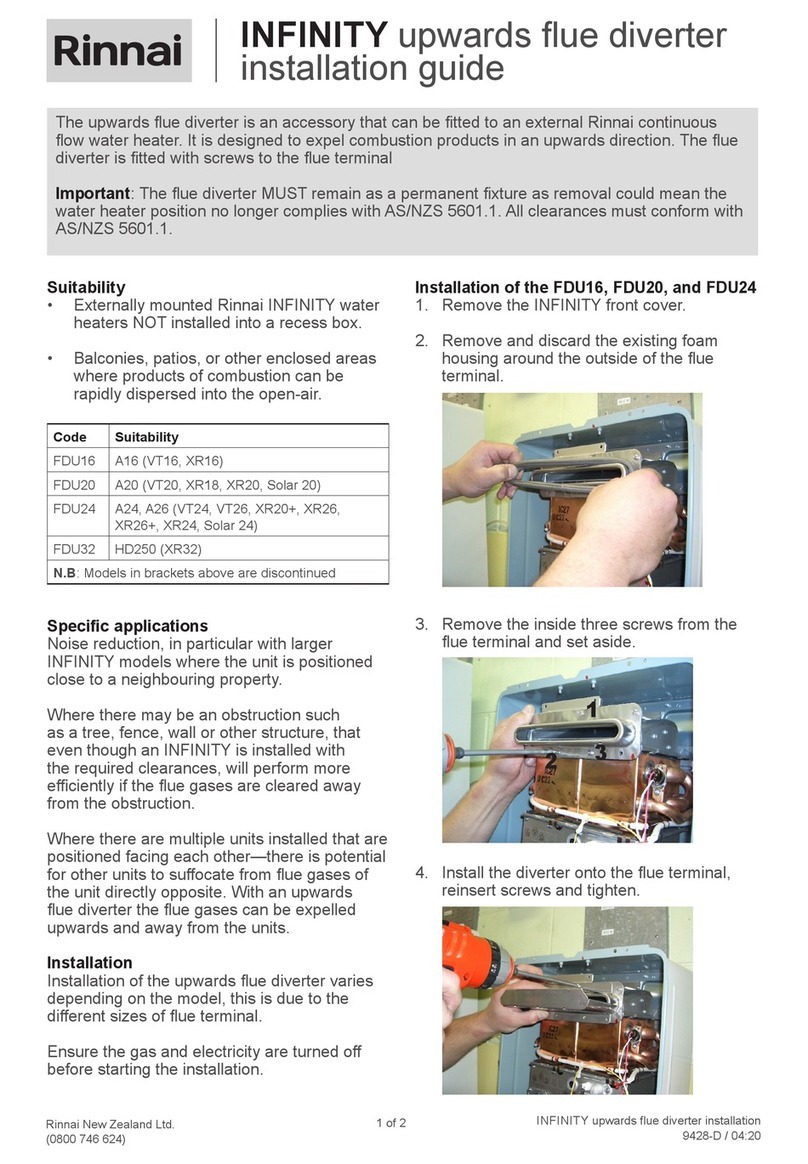

1. Note cistern measurements in the diagrams 1A and 1B, check that the pan is

installed within the dimensions shown, and establish where to hang your cistern.

This cistern includes a flush pipe and two optional flush pipe extensions. The flush

pipe and extensions can be cut to suit your desired wall height and pan fitting.

IMPORTANT: The flush pipe extensions have a narrow end with a

washer to aid in joining pipes together. If cutting is required, the

side without the washer should be discarded.

2. To open the cistern cover, press the top side of the cistern wall with the thumb of

one hand, then lift the side of the cistern cover with the other hand (see diagram

on right).

3. Attach the flush pipe with the longer section in the horizontal position. Place the

pan connector onto the end of the longer section of the flush pipe, and insert into

the back of the pan. If the flush pipe is too long, cut it to the correct size before

inserting it into the pan.

4. Determine the desired height of your cistern, and if the optional flush pipe

extensions will be used for your setup. Note maximum heights for each option.

AS 1172.2:2014

WM-022616

IAPMO R&T

OCEANA PTY LTD

MAX. 180MM 395MM

MAX. 265MM

400MM

130MM

FLUSH PIPE

PAN CONNECTOR

PAN

CONNECTING NUT

SEALING WASHER

BACKNUT V1

MAX. 450MM

WITH 1 PIPE EXTENSION

MAX. 770MMWITH 2 PIPE EXTENSIONS

TO OPEN

CISTERN COVER:

WELS Lic. 0128,

4.4L Full Flush, 2.9L Half Flush,

Average Flush 3.2L, 4 Stars.

We recommend installation by a licensed plumber. Consult our Plumbers

Directory online at https://fixatap.com.au/find-a-plumber or via the QR code:

Ensure the backflow prevention complies with AS/NZS 3500.1 requirements.

See fully labelled diagram, and read through all instructions prior to installing.

Do not use corrosive detergents or solvents containing chlorine or hypochlorite on the tank.

Using these liquids can seriously damage the tank and its accessories, which may lead to leakage.

Water pressure: 0.03MPa - 0.6MPa. Working temperature: 0°C to 50°C. Do not expose the cistern to hot objects.

CHECK IF PAN

IS INSTALLED

WITHIN THE

DIMENSIONS

SHOWN

BACKNUT V1

(USED FOR LOW

LEVEL INSTALLATION,

ARRIVES PRE-INSTALLED)

OPTIONAL FLUSH

PIPE EXTENSIONS

(FOR MID OR HIGH

CISTERN MOUNTS)

BACKNUT V2

(USED FOR MID

OR HIGH LEVEL

INSTALLATION

WHEN FLUSH PIPE

EXTENSIONS ARE USED)

CISTERN COVER

CISTERN RACK

CISTERN

CASING

BUTTON

MOUNTING

BRACKET

FIXING SCREWS

INLET VALVE

OUTLET/FLUSH

VALVE

CISTERN

SEALING WASHER

CONNECTING NUT

FLUSH PIPE

PAN CONNECTOR

WALL PLUG

MAX. 450MM (IF NO EXTENSIONS ARE USED)

FLUSH PIPE

MAX. 745MM (WITH 1 EXTENSION USED)

MAX. 1065MM (WITH 2 EXTENSIONS USED)

MOUNTING BRACKET

OPTIONAL FLUSH

PIPE EXTENSION

OPTIONAL FLUSH

PIPE EXTENSION

TROUBLE SHOOTING

PRODUCT WARRANTY

The product warranty runs for ten years from the date of purchase. Our products come with guarantees that cannot be excluded

under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and for compensation for any

other loss or damage. You are also entitled to have the goods repaired if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

WHAT IS COVERED: This warranty covers any defects in materials or workmanship with the exception of the reasons stated

below. The warranty covers the product used in normal domestic use only.

WHAT IS NOT COVERED: This warranty does not cover wear and tear to working parts, misuse or abuse, or discolourations due

to exposure to sunlight or cleaning chemicals. The warranty does not cover the rubber components such as the wedge washer,

the flush pipe ring, the seating washer, the rubber washers or the pan connector. These rubber components are covered by a

12 month warranty and should be replaced periodically as they wear out. We recommend installation by a licensed plumber.

Warranty may be void if the product is incorrectly installed.

CLAIM PROCEDURE: If you believe you have a legitimate claim, contact FIX-A-TAP® Australia via our website at www.

fixatap.com.au to complete the warranty claim form. Alternatively you can contact our office on (02) 9476 7400. Any written

correspondence should be sent to: FIX-A-TAP® Australia Pty Ltd, Units 1-2, 41 Leighton Place, Hornsby NSW 2077. Please keep

your receipt for proof of purchase. Any expenses incurred in making the claim are the responsibility of the consumer.

ISSUE TROUBLESHOOTING SUGGESTIONS

The inlet valve is on the

wrong side for your mini

tap

The cistern base has holes in both sides. To switch sides, remove the inlet stopper, uninstall the

inlet valve and reinstall both on opposite sides. Ensure that the inlet stopper and inlet valve are

properly secured to prevent leakage of water.

The water level in the

cistern is too high or too

low

The water level can be varied by adjusting the float level on the inlet valve. For small adjustments,

twist the micro float adjustment. For large adjustments, remove the height clip by pressing

downwards, then twist the top part of the valve anti-clockwise to release the height adjusting

teeth. Slide the valve up or down to the correct position, then twist the top part clockwise to lock in.

Ensure the height clip is inserted back into place. See full instructions on page 3 for recommended

standard settings.

Inlet valve fails to access

water

Ensure mini cistern tap and water source are turned on. If water is still not accessible, clean the

white filter located at the bottom of the inlet valve. This filter can be easily removed with pliers.

Rinse thoroughly, then reinsert.

Leakage from the inlet

valve

Replace the rubber washer if required, and tighten the inlet nut. Ensure that the water connector is

in good condition and is adequately tightened.

Leakage from outlet

valve

Ensure that the button prongs are not too long, and that the seating washer is pushing against the

base of the outlet valve. If problem persists, remove valve and rinse thoroughly to clear any debris.

Replace seating washer (see instructions below) and wedge washer if required. Reinstall.

Inadequate draining

when the button is

pressed

The button prongs may be too short. Lengthen the prongs by unscrewing slightly to reduce the

amount of thread in the button and tighten the black nut.

Water released is

insufficient or excessive

Remove the outlet valve by twisting the body until it releases from the base, then adjust the full &

half flush by adjusting the red levers located on the sides of the outlet valve.

To replace the outlet valve seating washer, turn off water, flush toilet, and open the cistern lid. The top part of the outlet valve can

easily be removed without the need to remove the flush pipe. Simply rotate the cylindrical valve in an anti-clockwise direction

until the body is released from the base. Replace the seating washer, then reinstall the outlet valve body, and lock into position

by twisting in a clockwise direction until the valve body is firmly locked into the base.

MAINTENANCE - SEATING WASHER REPLACEMENT

1B

2

1A

4

OVERVIEW

Page 04 Page 01