Cooker hood CPDD, CPDL - Installation and Maintenance Manual

7

FläktGroup DC_8759GB_20190207_R1 We reserve the right to make changes without prior notice

INSTALLATION (FOR INSTALLER AND SERVICE PERSONNEL)

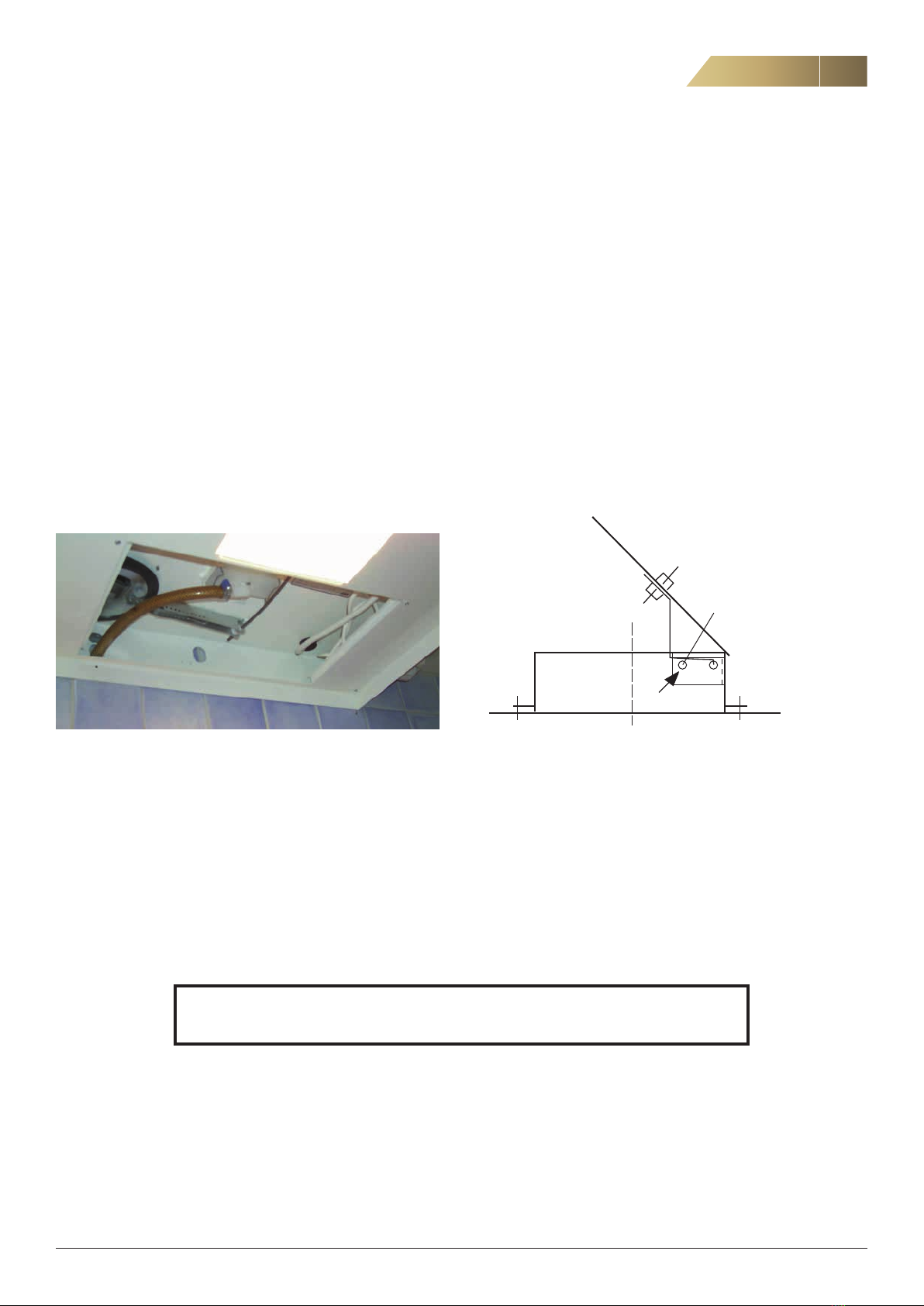

CPDD FOR HEAT RECOVERY UNIT ACF

NOTE! INSTALLATION, COMMISSIONING AND ADJUSTMENT AS DESCRIBED IN THESE

INSTRUCTIONS MUST BE CARRIED OUT BY QUALIFIED AND AUTHORISED PERSONNEL.

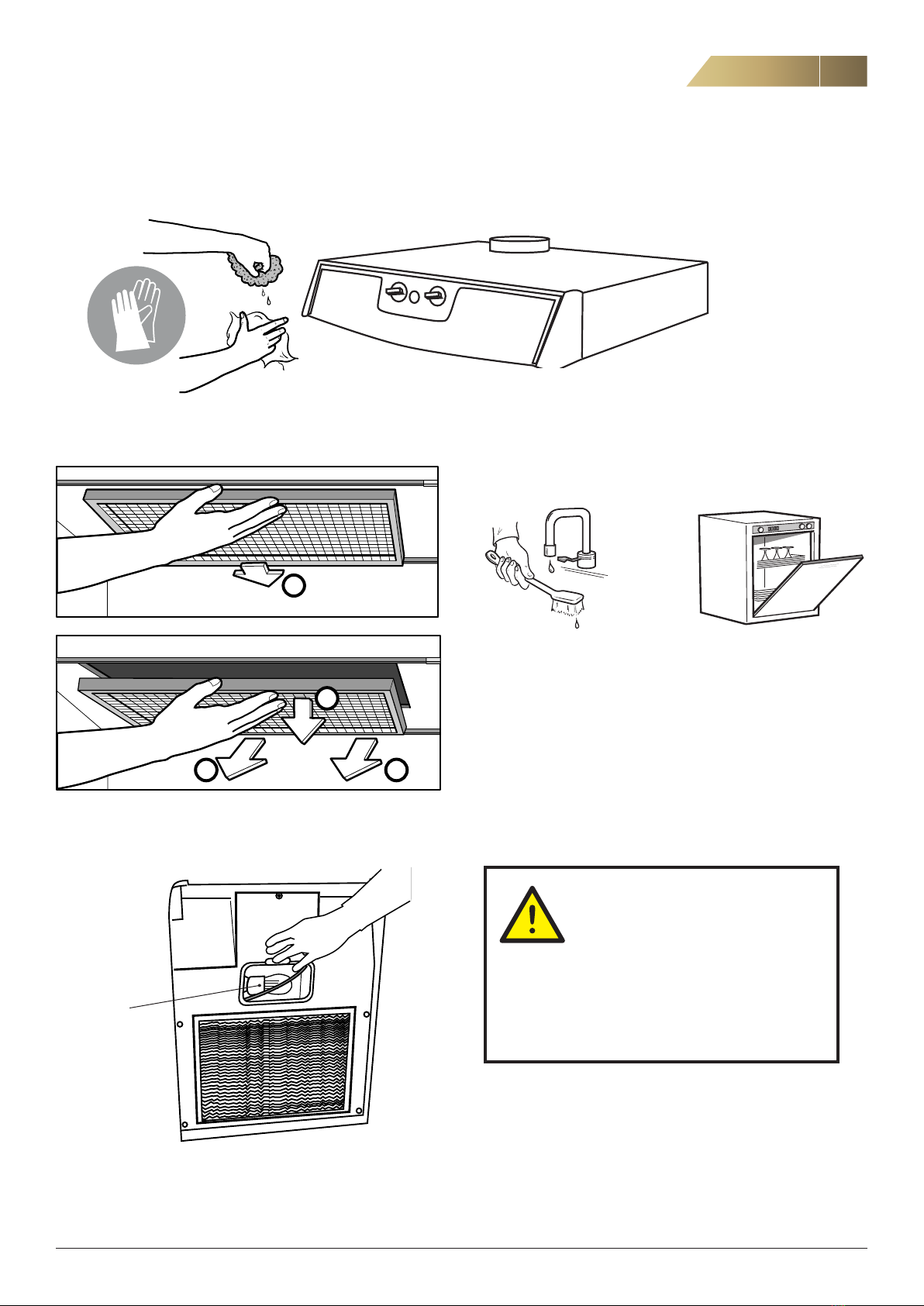

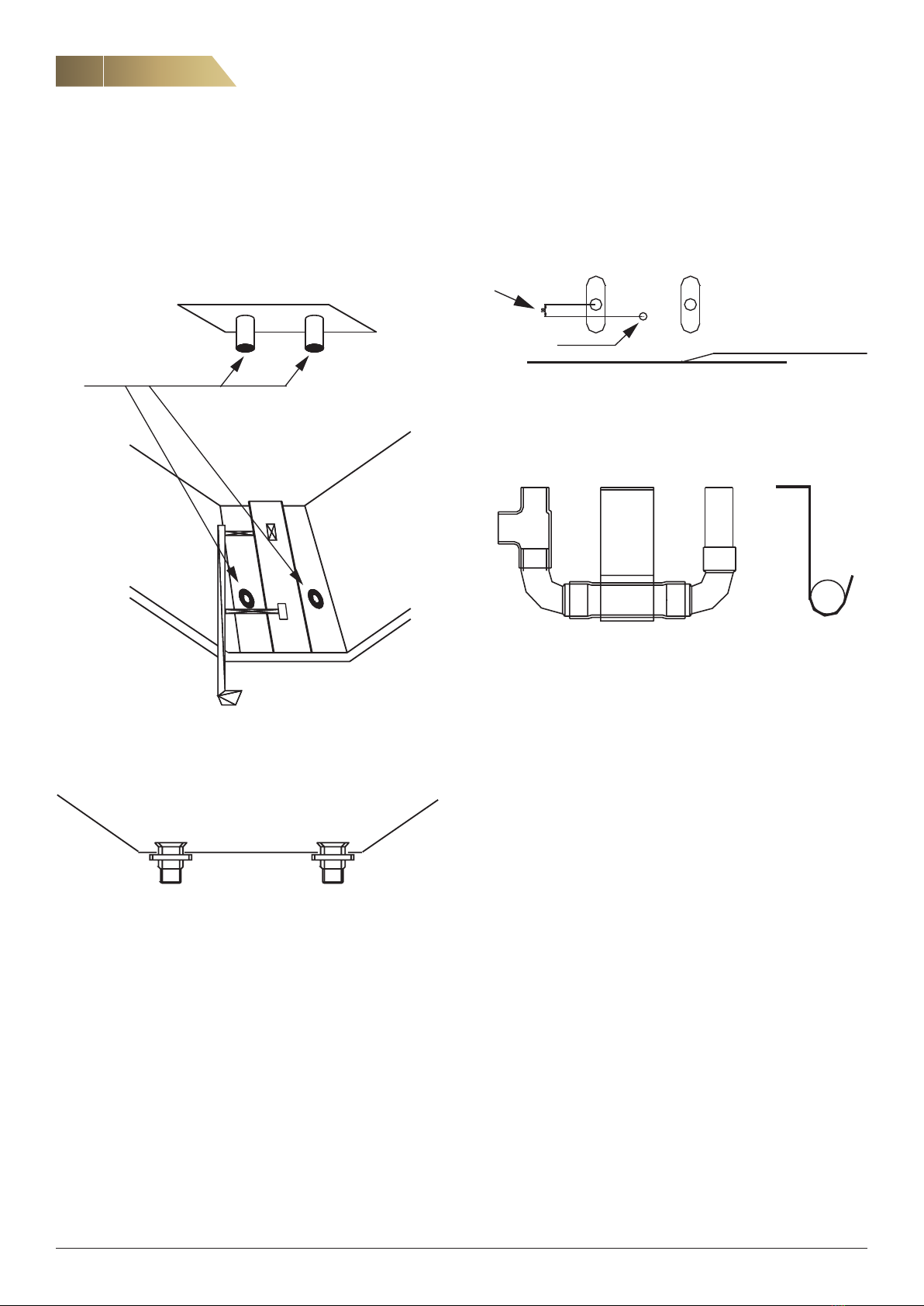

Melting rivet

PROCEDURE

1. Disconnect the unit from the power supply by pulling out the

plug.

If the hood is permanently attached, the work must be per-

formed by a qualified installation engineer.

2. Note the switch position for Normal operating speed.

The switch is on the top of the cooker hood. There are six set-

tings on the switch. The switch is accessed by opening the

door to the ventilation unit.

3. Disconnect the drainage hose from the cooker hood.

4. Remove the BHG hood. The hood is attached with four screws

which are accessed by opening the door to the unit.

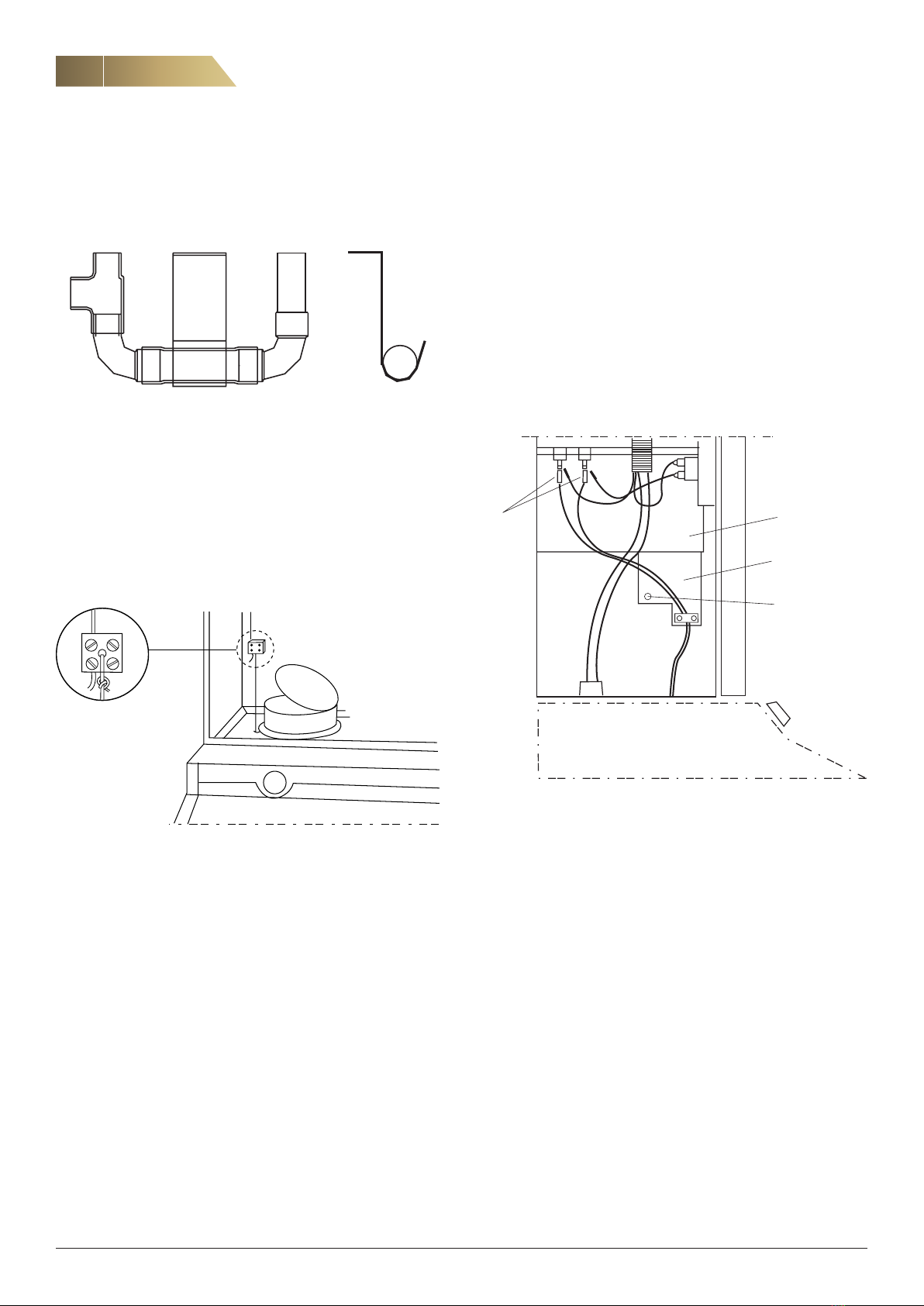

5. Connection to drainage hose.

Alt. 1

a) Make a slit in the wall large enough for the drainage hose to fit

through. The slit should reach from approximately 10 mm below

the centre on the bottom of the unit down to the drainage hose.

B) Position the drainage hose so that it protrudes out of the wall

25 mm below the lower edge of the unit. If a new hose needs to

be installed, it must be armoured to prevent creasing. Position

the hose so that if forms a water trap. Use the old hose’s posi-

tion for reference.

Alt. 2

a) Make a vertical slit in the wall measuring 70 mm. Pull the drain-

age hose upwards until it protrudes roughly 40 mm below the

lower edge of the unit. Adjust the nipple on the drainage cup so

that it points sideways towards the hose. Remove the grease

filter and the cover plate on the new hood and, if necessary,

reposition the cable on the transformer until it is tensioned in

the same way as on the old transformer. By default, the cable is

connected to pin 5, which is 150 V. It is easiest to set the volt-

age before installing the hood.

6. Before installation, prepare the fire damper by fixing it with the

included melting rivet (125 °C). Flatten the end of the rivet using

pliers.

7. Install the cooker hood under the ventilation unit, using the

screws and mounting plate from the old cooker hood. Make

sure the hood creates a tight seal against the unit. Replace the

sealing strip under the unit if necessary.

All cooker hoods must be connected directly or indirectly via the heat recovery unit/extract air fan to earth.