flamco 120 litres Guide

SUPASTOR

UNVENTED CYLINDERS

Installation, commissioning

and maintenance instructions

Direct and indirect enamelled c linders:

120, 150, 180, 210, 250 and 300 litres

Ref:Inst 5C/03

Important:

Please read these instructions carefull before proceeding

with installation. Failure to do so ma invalidate warrant .

Flamco UK Limited.

Unit 4,

St. Michael’s Road,

Lea Green Industrial Estate,

St. Helens

Merseyside WA9 4WZ.

Telephone: 01744 818100.

Fax: 01744 830400.

Email: [email protected]

www.flamco.co.uk

BS EN ISO 9001

Certificate No: FM 34109

R

E

G

I

S

T

E

R

E

D

QUALITY

MANAGEMENT

UKAS

APPROVED

12

WATER BYE-LAWS

Only approved materials, pipes and fittings that comply with water bye-laws should be used.

BUILDING REGULATIONS

The installation of an unvented hot water storage cylinder is regulated by Building Regulations G3. To meet the

requirements of the Regulation, installation of an unvented system should be undertaken by a ‘competent installer’.

IMPORTANT

It is important to note that it is a criminal offence to install an unvented hot water storage system without notifying

your Local Authority.

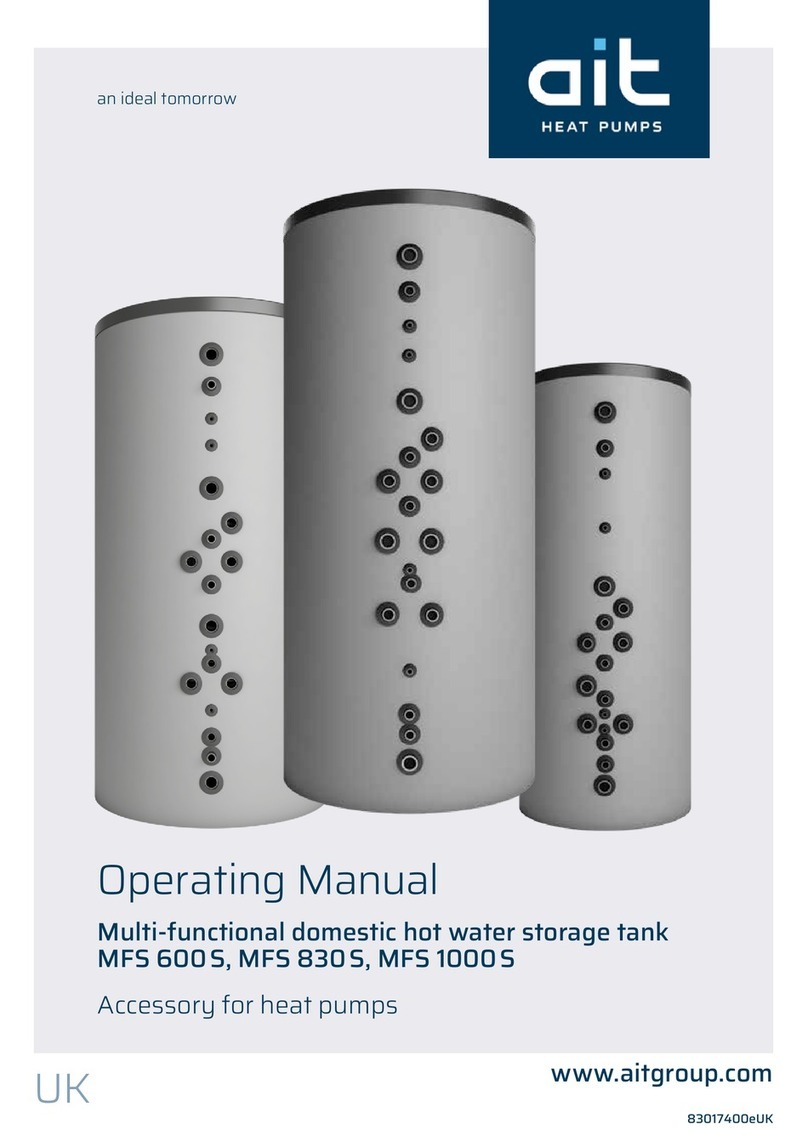

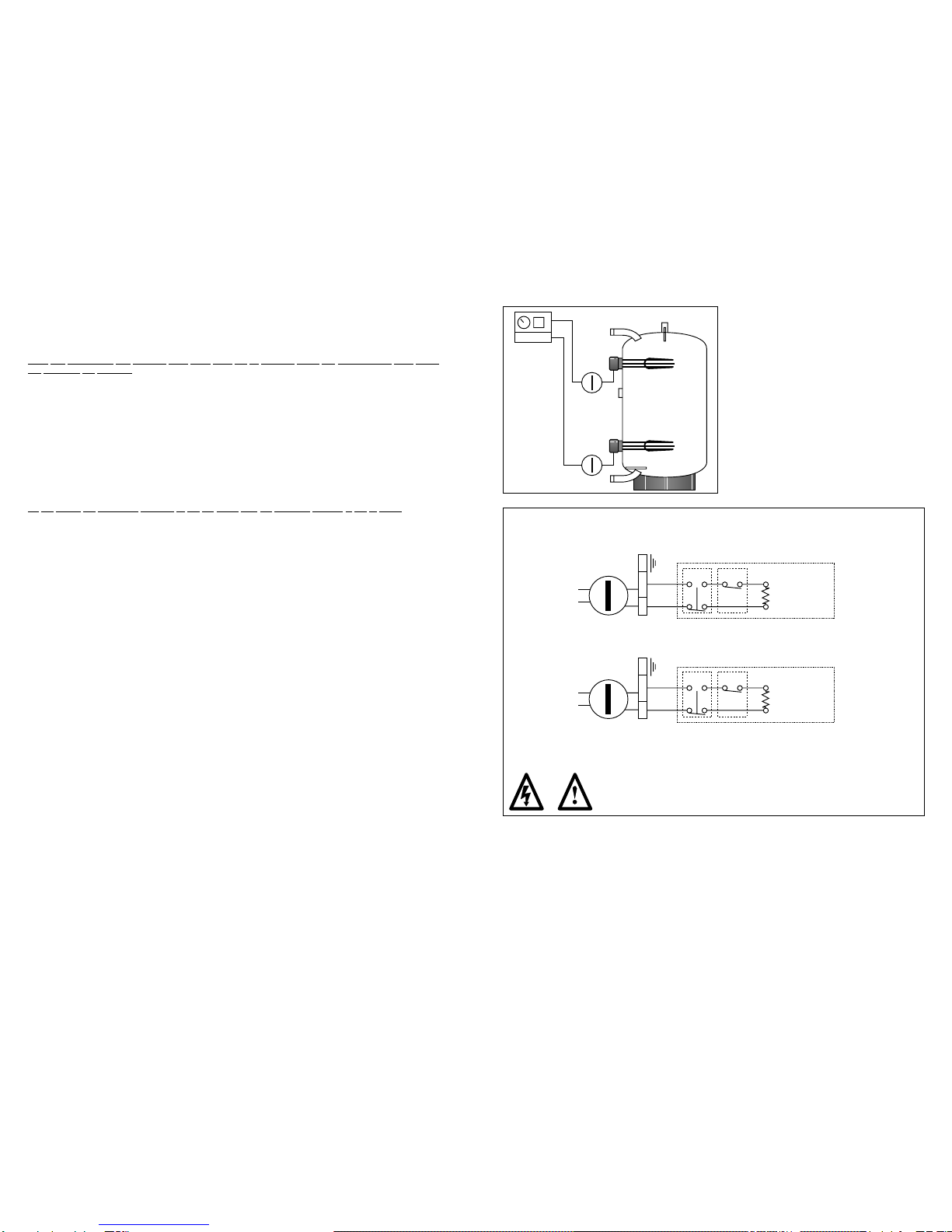

SUPASTOR DIRECT CYLINDER (Diagram A)

The Supastor direct cylinder, available in nominal capacities of 120 litres, 150 litres, 180 litres, 210 litres, 250 litres

and 300 litres, are supplied as:-

One large box containing -

The Supastor unit with factory fitted temperature and pressure relief valve and magnesium anode.

One small box containing -

The unvented kit which consists of a 12 litre expansion vessel, pressure reducing valve set at 3 bar with in-line

strainer, a safety group (expansion relief valve, tundish and single check valve) and two immersion heaters.

SUPASTOR INDIRECT CYLINDER (Diagram B)

The Supastor indirect cylinder, available in nominal capacities of 120 litres, 150 litres, 180 litres, 210 litres, 250 litres

and 300 litres, are supplied as:-

One large box containing -

The Supastor unit with factory fitted temperature and pressure relief valve, cylinder thermostat and magnesium

anode.

One small box containing -

The unvented kit which consists of a 12 litre expansion vessel, pressure reducing valve set at 3 bar with in-line

strainer, a safety group (expansion relief valve, tundish and single check valve), a 2-port motorised valve and one

immersion heater.

SUPASTOR UNVENTED CYLINDERS

Installation, commissioning and maintenance instructions

1. Hot water supply. 2. Immersion heater.

3. Mg anode. 4. Cold water inlet.

5. Temperature/pressure relief valve.

6. Steel cylinder, enamelled inside.

7. Polyurethane foam insulation.

1. Hot water supply. 2. Mg anode. 3. Thermostat.

4. Flow. 5. Immersion heater. 6. Return.

7. Cold water inlet. 8. Temperature/pressure relief valve (3/4”).

9. Steel cylinder, enamelled inside.

10. Polyurethane foam insulation.

10

9

8

7

6

5

4

3

2

1

4

3

2

1

2

7

6

5

Diagram A. Diagram B.

Supastor Direct C linder Supastor Indirect C linder

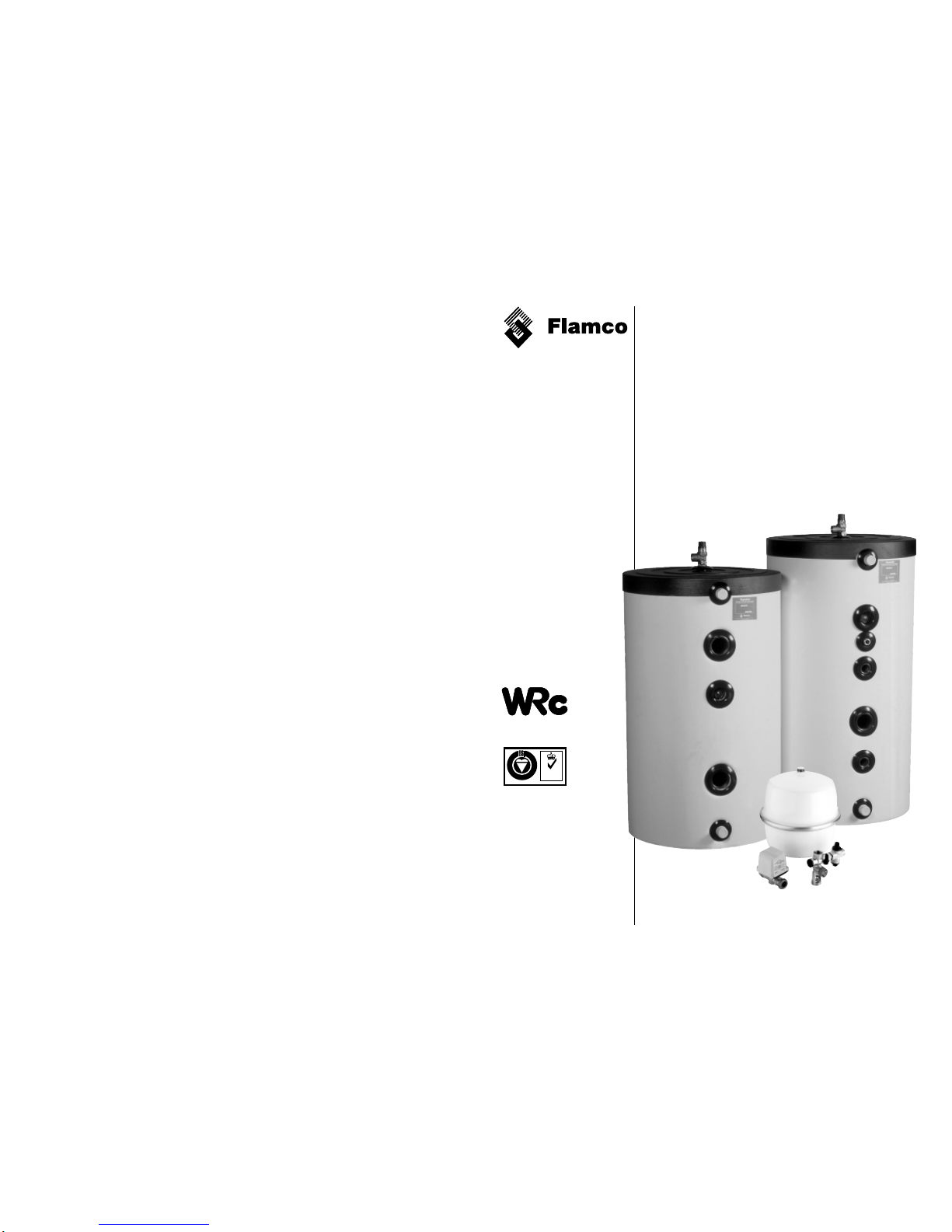

211

Expansion

vessel

To Drain

To Discharge

Safety

group

Cold

mains

in 6 bar expansion

relief valve

3 bar PRV

Hot water

supply

Schematic diagram of Supastor direct unvented hot water controls. Diagram I.

(As diagram C

on page 8).

THE CYLINDER

The cylinder must only be installed in the vertical position. The inlet pipe delivers cold water to the bottom of the

cylinder. An unvented kit is provided which comprises of a Flexcon expansion vessel (to accommodate any increase

in water volume), pressure reducing valve and safety group (expansion relief valve, tundish and single check valve.

IMPORTANT - the discharge from the expansion relief valve must be made and piped away safely.

COLD WATER SUPPLY

The mains water pressure must not exceed 12 bar.

As hot and cold water are both drawn off the same supply, it is important to ensure that the cold water feed is capable

of supplying the full demand. Please identify all the connection ports before making any connections to the cylinder

(See diagrams A and B on page 2).

For maintenance, position an isolating valve between the cold water supply and the cylinder.

All pipework must be flushed clean to avoid an damage to the controls.

INDIRECT CYLINDERS

Indirect cylinders are supplied with a 2-port motorised valve in accordance with Water Board regulations G17.1(b),

and have dual thermostatic controls.

A separate cylinder thermostat is supplied to control the indirect circuit via the motorised valve. In accordance with

Water Bye-Law G20.6, and integral thermal cut-out stat is incorporated within the cylinder stat housing, and is wired

through to the heat source, and operates if the water temperature rises too high. Should the thermal cut-out activate it

can only be re-set manually. Under no circumstances should this be b -passed. The activation indicates afault

which must be rectified b aqualified engineer.Refer to diagram E on page 8 for recommended wiring details.

IMMERSION HEATERS

The cylinder immersion heater(s) are connected through a thermostat which pre-sets the operating temperature. The

required operating temperature can be adjusted at the head of the thermostat. In accordance with Water Bye-Law

G20.6 the immersion heater is pre-wired through a thermal cut-out stat, which operates if the water temperature rises

too high. Should the thermal cut-out activate it can only be re-set manually. Under no circumstance should this be

b -passed. The activation indicates afault which must be rectified b aqualified engineer.Refer to diagram G

on page 9.

FITTING THE IMMERSION HEATER(S)

The electrical installation must be in accordance with the current I.E.E. wiring regulations.

Care must be taken not to cross thread the immersion heater(s) when fitting.

A 220/240V mains supply fused 13 amp is required. Heat resistant cable, round 3 or 4 core 2.5mm2(to BS.6141.

table 8) must be used to connect the electrical supply through the Economy 7 time control switch as shown in

diagram G on page 9.

If the Economy 7 system is not used then a separate 13 amp supply to each element will be required through a

double pole fused isolating switch having a contact gap of at least 3mm on each pole. Make the connection(s) to the

immersion heater(s).

The thermostat(s) on the immersion heater(s) should be adjusted to trip at 60OC. This is the ideal temperature to

prolong the element’s life in hard water areas. Scale on the sheath builds up more rapidly at temperature above 60OC

causing the element to overheat and premature failure could occur. Higher temperatures without additional controls

would result in scalding.

WARNING: THE APPLIANCE MUST BE EARTHED

The earth continuity conductor of the electrical installation must be effectively connected to all exposed parts of other

appliances and services in the room where the unvented cylinder is housed - conformity with the I.E.E. regulations.

SITING THE UNVENTED CYLINDER

As the unvented cylinder is connected directly to the mains cold water supply, the siting is optional. However, for easy

maintenance leave free space for access to the electrical components (immersion heater(s) and anodes). Care

should be taken to ensure the support of the load bearing strength as per the table below.

Supastor Size

Weight full Direct unit

Weight full Indirect unit

300 litre

356 kg

376 kg

250 litre

305 kg

322 kg

210 litre

255 kg

272 kg

180 litre

223 kg

234 kg

150 litre

192 kg

203 kg

120 litre

173 kg

181 kg

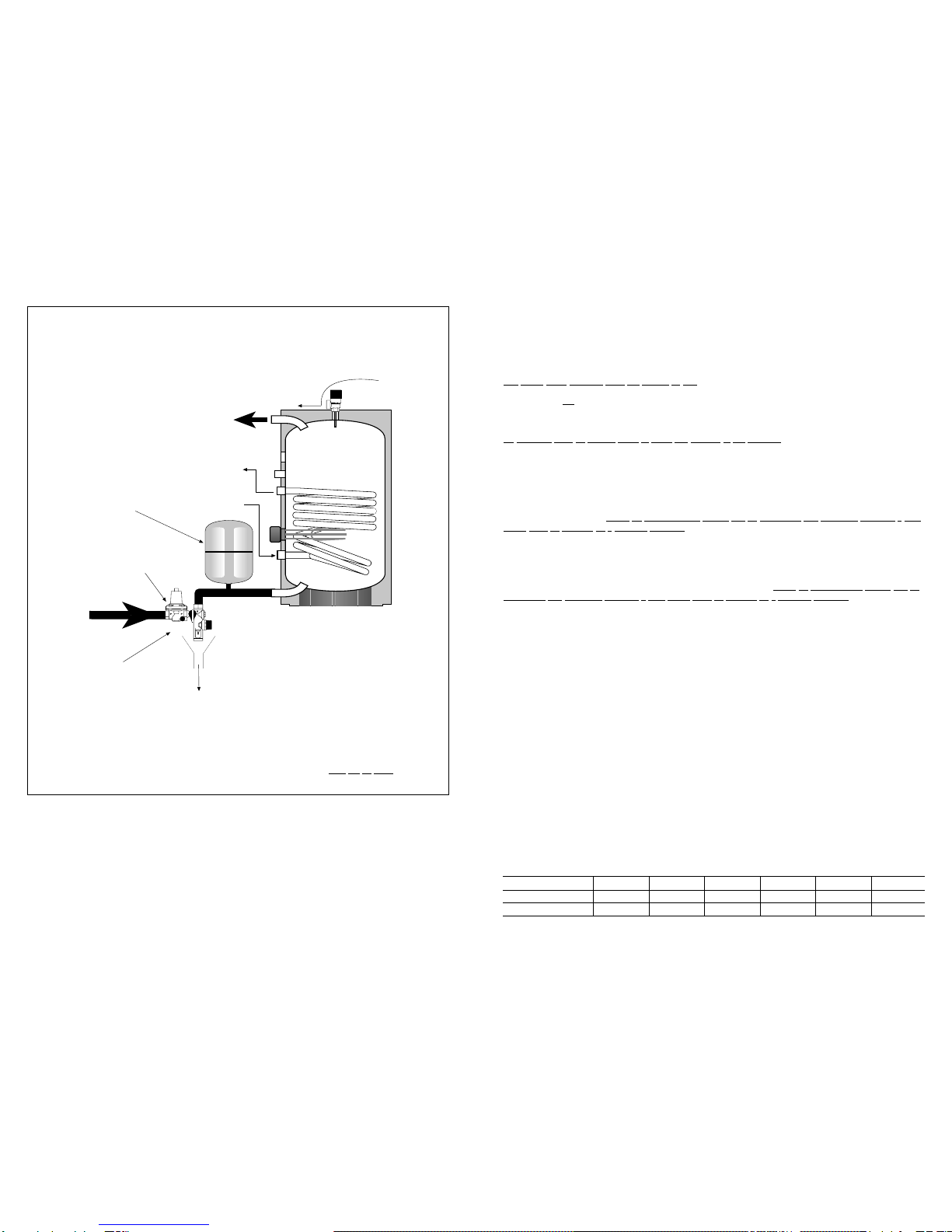

310

Expansion

vessel

To Drain

To Discharge

Safety

group

Cold

mains

in 6 bar expansion

relief valve

3 bar PRV

Heating

flow

Heating

return

Hot water

supply

Schematic diagram of Supastor Indirect unvented hot water controls. Diagram H.

NOTE:

All components must be fitted.

If the system is to be fitted with a 3 port valve, the 2 port valve supplied by Flamco must still be fitted.

(As diagram C

on page 8).

TEMPERATURE AND PRESSURE RELIEF VALVE

The factory fitted temperature and pressure relief valve, sited on top of the unvented cylinder, is a safet device to

back-up and support the thermostat(s) and thermal cut-out(s). It operates when either excess pressure or excess

temperature is sensed. When operated, hot water will be discharged so care must always be taken. The discharge is

connected to a tundish and drain.

Note: The temperature and pressure relief valve must not be removed under an circumstance. Such action

will invalidate the warrant .

DISCHARGE PIPEWORK FROM THE TEMPERATURE AND PRESSURE RELIEF VALVE

The tundish must be vertical and fitted within 300mm of the temperature and pressure relief valve and must be

located near the unvented cylinder. The tundish must also be in a position visible to the occupants, and positioned

away from electrical devices. The discharge pipe from the tundish should be metal and should terminate in a safe

place where there is no risk to persons in the vicinity of the discharge.

Refer to diagram C on page 8.

ALL INSTALLATIONS MUST CONFORM TO BUILDING REGULATIONS G3.

COMMISSIONING

Check for obvious signs of damage to the unvented cylinder and associated controls.

Do not switch the immersion heater(s) or fire the boiler until the unvented c linder is full of water.

1. Open all outlet taps.

2. Turn on mains water supply and allow the unvented cylinder to fill.

3. Close taps in turn after having purged the system of air.

4. Check for leaks around the controls and immersion heater(s). Repeat this check again after the unit has

heated up.

5. Check that no water is passing to discharge through the temperature and pressure relief valve and the expansion

relief valve.

6. Test the operation of the temperature and pressure relief valve and the expansion relief valve by lifting/turning the

manually operated test cap and ensure that water flows through freely and safely to waste.

7. Check that the discharge pipe is plumbed so that it falls continuously and that no taps, valves or other shut-off

devices are installed in the pipe.

8. Check that all thermostats are set to 60OC.

9. DIRECT UNITS: Switch on immersion heater(s) and allow the unit to heat up. Check the operation of the

thermostat(s).

10. INDIRECT UNITS: Fill the indirect (primary) circuit, following the boiler instructions. Switch on the boiler, ensuring

that the programmer is to domestic hot water. Allow the unit to heat up and check the operation of the cylinder

thermostat on the motorised valve.

11. Demonstrate the operation of the unit to the occupier, including the temperature and pressure relief valve and

what to do if it operates.

12. Give this manual to the occupier to retain for future reference and make the occupier aware that periodic checks

of the equipment are essential for safety.

13. Complete the ‘Supastor Service History Book’provided and leave with the occupier.

MAINTENANCE OF THE MAGNESIUM ANODE

The installer should check the magnesium anti-corrosion anode after two years (consult the label on the face of the

unit for correct location). If the heating element is heavily coated with scale we recommend descaling at the time of

this inspection. If the anode is still operational and is not replaced then further annual checks are required. If the

anode is replaced then it does not need re-checking for a further two years.

EXAMINE THE ANODE AND REPLACE IF THE DIAMETER IS LESS THAN 15mm.

Removal of Anode:

1. Close the mains supply service valve.

2. Open hot water taps.

3. Ensure the cylinder is empty.

4. The anode can now be removed.

5. Descale the immersion heater(s) and remove any lime deposit from the cylinder and heating element.

Replace in reverse order.

(continued overleaf

4 9

L

N

L

N

L

N

L

N

Day Element

3kW 220/240V

Pre-wired

Pre-wired

Night Element

3kW 220/240V

Economy 7

TOP ELEMENT

BOTTOM ELEMENT

Thermal

cut-out Thermo

stat

Thermal

cut-out Thermo

stat

Element

Isolating

switch

Isolating

switch

Bottom Element

(Night Store)

Economy 7

controller

Diagram F.

Recommended Direct System

Economy 7

Recommended wiring for Supastor Direct Cylinder - Economy 7

Electrical installation must be carried out by a competent person.

Isolate unit before removing any covers.

Wire using 1.5mm2flexible cable, 85OC rubber insulated HOFR sheathed, complying with BS.6141

Table 8. It must be fully earthed and wired through a double pole isolating switch.

Diagram G.

Check the controls:

1. Check and clean the strainer before refilling the system.

2. Check the pressure in the expansion vessel and top up as necessary.

3. Check the temperature and pressure relief valve manually by turning the top cap.

4. Check the expansion relief valve manually by turning the top cap.

5. Check discharge pipes for both the temperature and pressure relief valve and the expansion relief valve for

obstructions.

SUPASTOR ANODE OPTION

An option is available to replace the magnesium anode with a Flamco impressed current anode.

The installation should be carried out as follows:

Remove the magnesium anode fro the Supastor cylinder, using a 1.1/4”x 3/4”bush insert the Flamco impressed

current anode.

Important:

The Flamco impressed current anode must be earth bonded to the cylinder.

To ensure the correct functioning of the Flamco ‘ICA’the following information relating to safety must be strictly

observed.

1. To avoid annoying gas accumulation within the cylinder, it is essential that the storage water must be drawn from

the cylinder once a month.

2. Never unplug the ‘ICA’when the cylinder is storing water as this will disable the anode protection.

3. The potentiostat is housed in a protective casing and is pre-wired for ease of installation.

4. Only use the original connection leads.

5. Do not under any circumstance alter the length of the connection leads.

6. Site the potentiostat adjacent to the Supastor unvented cylinder.

7. take a 220/240V supply to the Flamco ‘ICA’potentiostat.

The Flamco ‘ICA’connecting calbes are identified as follows:

Black cable = Earth.

Black and white cable = Flamco ‘ICA’connection.

58

Temperature

and pressure

relief valve

Metal dischage pipe

from temperature and

pressure relief valve

to tundish

Tundish

Metal dischage pipe

from tundish with

continuous fall. Discharge

below fixed

grating

Trapped

gulley

500mm

max. 300mm

max.

300mm

min.

L

N

L

N

L

N

L

N

Immersion heater

Single 3Kw element

Pre-wired

Brown

Blue

Orange

Grey

Motorised valve

Optional connections

See Motorised valve

instructions

Live to boiler

C1C21

Safety

Limiter Thermostat

Thermostat and

Safety Limiter

Suggested way of terminating discharge pipe

Diagram C.

Recommended wiring for Supastor Indirect Cylinder

Electrical installation must be carried out by a competent person.

Isolate unit before removing any covers.

Wire using 1.5mm2flexible cable, 85OC rubber insulated HOFR sheathed, complying with BS.6141

Table 8. It must be fully earthed and wired through a double pole isolating switch.

Diagram E.

Element

Isolating

switch

Diagram D.

Recommended

Indirect System

1" pipe

3/4" pipe

FAULT FINDING

FAULT POSSIBLE CAUSES REMEDY

No hot water flow. 1. Mains cold water supply Check and open isolating and/or stop valve.

shut-off. If no water flow check with local water authority.

2. Line strainer blocked. Turn off mains water supply, remove and clean

line strainer.

3. Cold water safety group Check direction of flow arrows on the valve. Refit in

fitted incorrectly. the correct position if necessary.

Reduced flow rate. 1. Low mains water pressure. Check pressure, xonsult local water authority

if necessary.

2. Strainer partially blocked. Turn off mains water supply, remove and clean

strainer.

3. Size of service pipe too small. Pipe size should be increased.

Water from hot 1. Direct immersion heater is Check immersion heater, switch on if necessary.

taps is cold. not switched on.

2. Direct thermal cut-out has Test thermostat operation and wiring, if faulty

operated. correct or replace. Re-set cut-out.

3. Boiler programmer set to Check switch on domestic hot water if necessary.

central heating only.

(Indirect model).

4. Boiler is not functioning. Check boiler operation, if fault suspected consult

(Indirect model). manufacturer’s instructions.

5. Indirect thermal cut-out has Test thermostat operation and wiring, if faulty correct

operated. /replace. Re-set cut-out.

6. Motorised valve jammed or Check wiring and operation of motorised valve,

not wired correctly. if faulty correct/replace as necessary.

(Indirect model).

Discharge from 1. Pressure above 7 bar, Shut down boiler or immersion heater. Check

pressure and failure of pressure reducing pressure reducing valve and thermal controls.

temperature valve. Temperature above Replace if necessary.

relief valve. 90OC, failure of thermal

control.

Discharge from 1. Pressure reducing valve Check pressure from valve. Replace if over 3.5 bar.

expansion relief faulty.

valve. 2. When heater is heating, Check charge in vessel. Re-charge vessel to

faulty expansion vessel 3.5 bar or replace if necessary.

or lost charge.

6 7

GUARANTEE

Flamco UK Limited guarantee that should this water heater prove to be defective by reason of faulty manufacture

during the periods stated below, will replace the defective parts or product free of charge on the condition that:-

The appliance has been correctly installed by a competent installer and used only on the

supply voltage stamped on the rating plate.

The appliance has been used and maintained in accordance with these instructions and

has not been tampered with or otherwise subjected to misuse, neglect or accident.

The appliance has not been taken apart, modified or repaired except by a qualified

service engineer.

Evidence of the date of purchase, in the form of an invoice, receipt or hire purchase

documents, must be included with the appliance when returned under guarantee.

The guarantee will be applicable from the date of purchase or commencement of hire

purchase for the following periods:-

12 months on electrical parts and components.

3 years on the cylinder tank.

Flamco UK Limited

This manual suits for next models

6

Table of contents

Other flamco Water Heater manuals

Popular Water Heater manuals by other brands

Grainfather

Grainfather EZZZ9169 instructions

Waiwela

Waiwela PH2-20R DVSN (Natural Gas) Use & care manual

Quooker

Quooker PRO7 installation guide

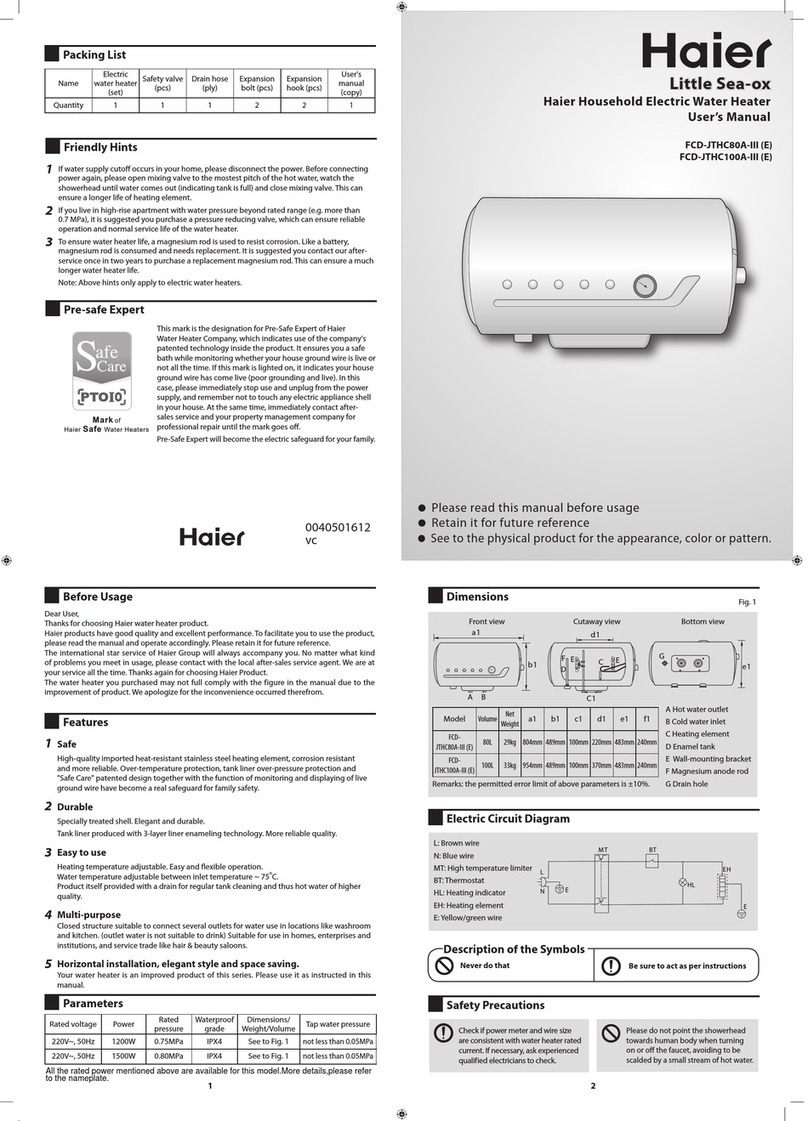

Haier

Haier Little Sea-ox FCD-JTHC80A-III (E) user manual

Siemens

Siemens DG10016R2 Assembly and operating instructions

Ariston

Ariston ABS DACHA R 50 V quick start

Honeywell

Honeywell WV4262B installation instructions

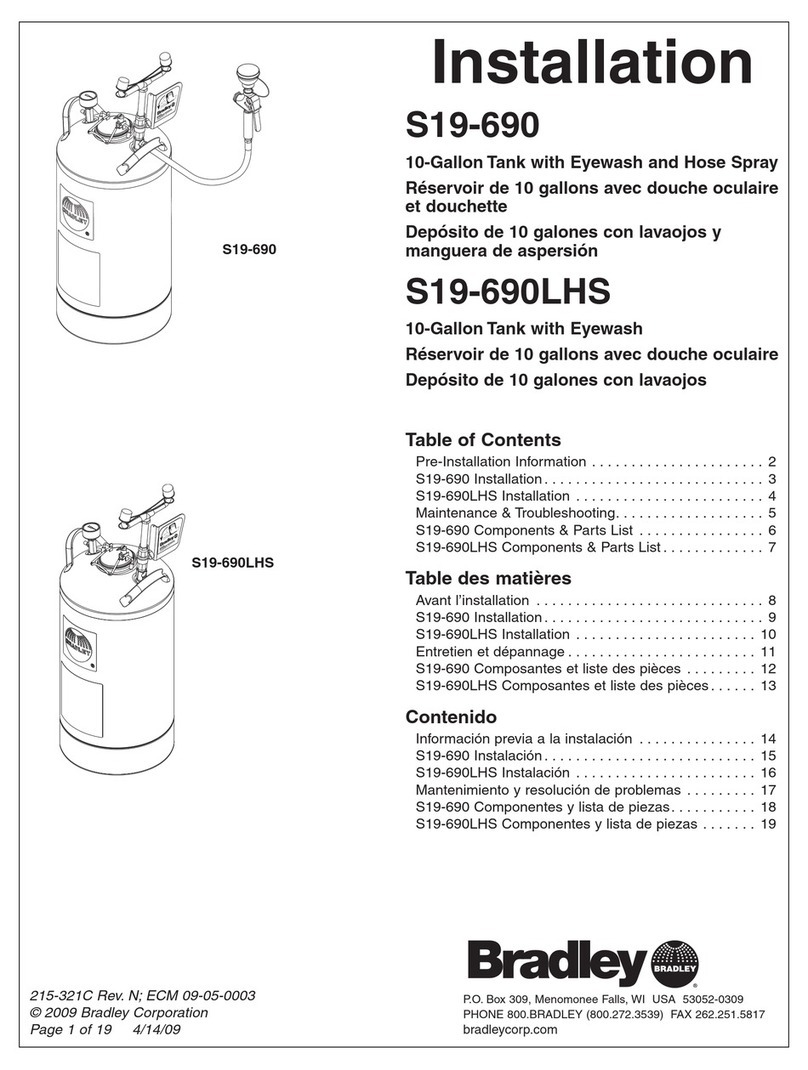

Bradley

Bradley S19-690 Installation

Midea

Midea MWH-38Q instruction manual

RBI

RBI FUTERA XLF Series Installation and operation instructions

Pundmann

Pundmann THERM-9L Assembly, installation and operating instructions

STIEBEL ELTRON

STIEBEL ELTRON MINI 2-1 Operation and installation