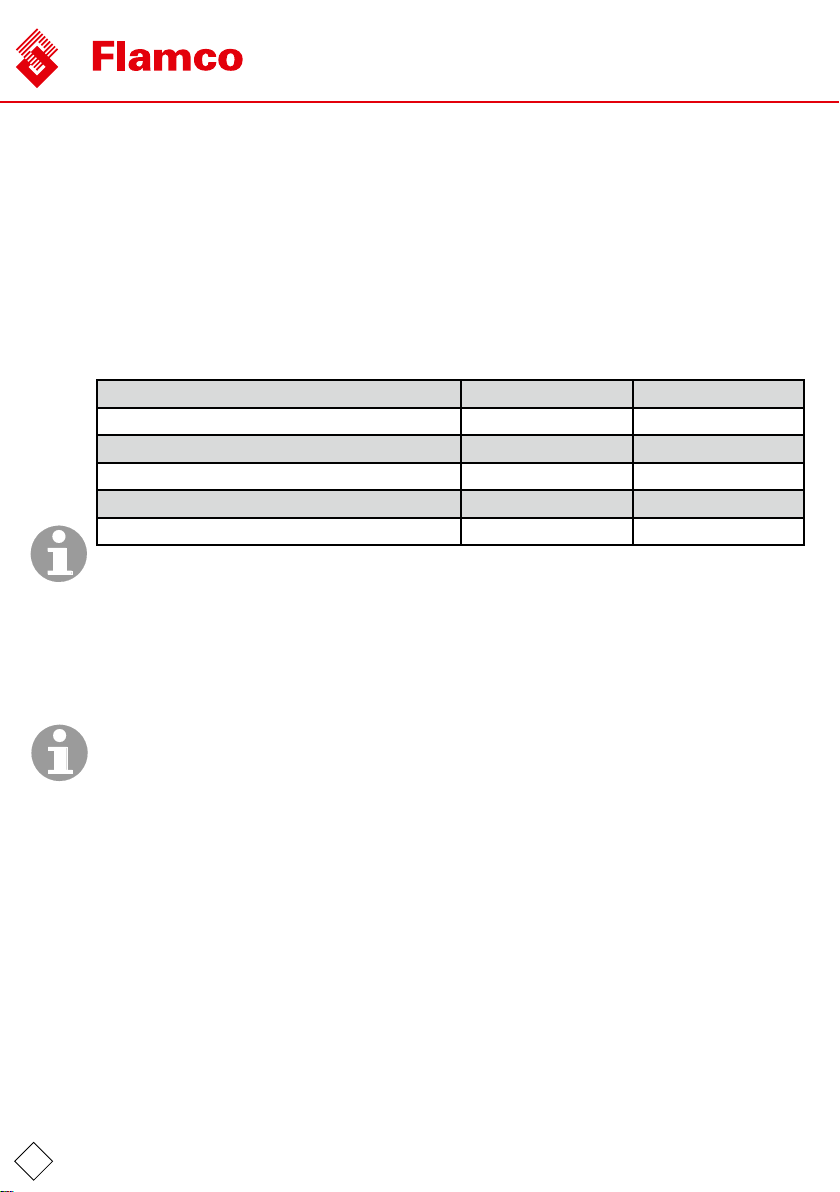

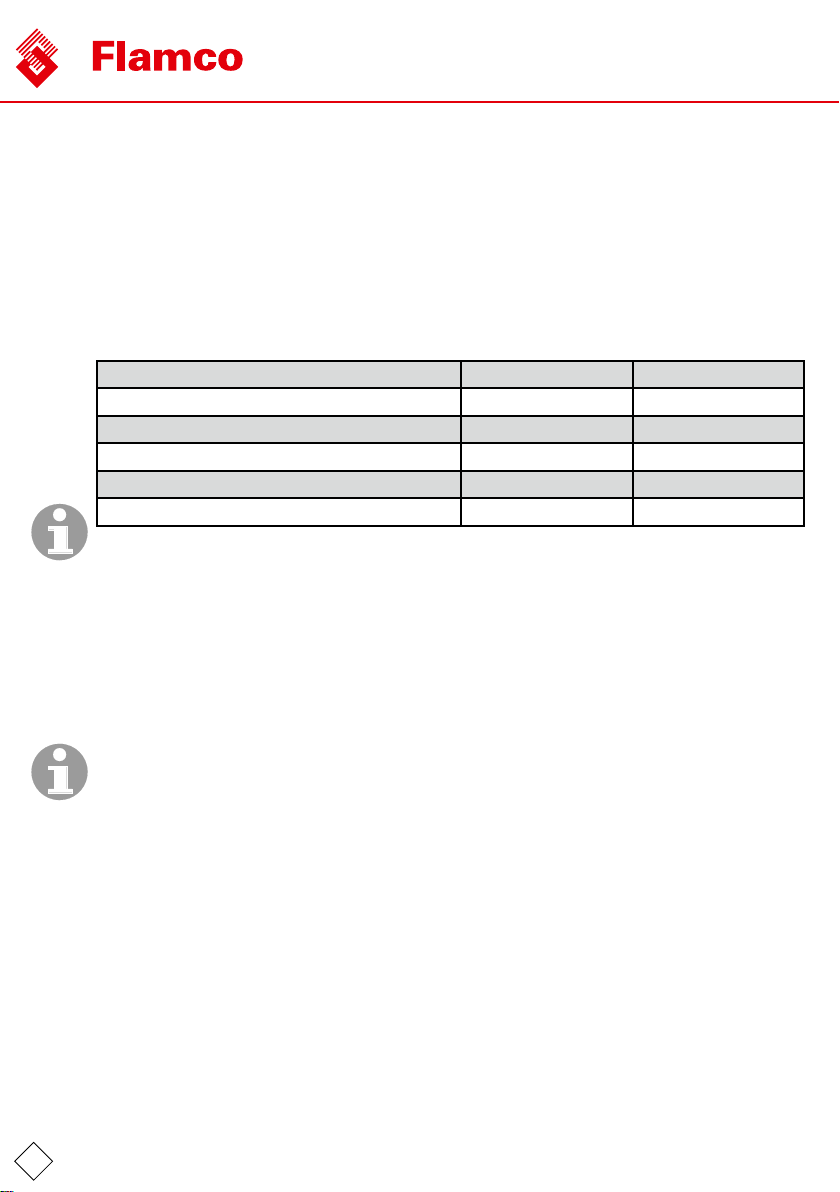

1. General information

Indirectlyheatedstoragewaterheatercylinderwithweldedplain-tubeheatexchangersforfresh

waterheating.Completewiththermalinsulation,inspectionportattheside(TSonly)and

Mganode.Canbecombinedwithanymodernheatingsystem.Premiumenamellingasper

DIN4753/3.Robustandeasy-to-installdesign,equippedwiththermometer(TSonly)and

temperaturesensorport.Baseheightadjustmentasstandardequipmentforbothtypes.

TheupperlevelsystemconnectionsmaketheU/HPparticularlywell-suitedforinstallationbelow

wall-mountedheatingdevices.Incontrasttothis,theTSstoragetankisdesignedforhorizontal

installationwithaboilermountedontopthusminimisingthespacerequirementoftheheating

system.ThesteelsheetcladdingontheTSisdesignedforamaximumboilerweightof300kg.

Permissible operating overpressure U/HP TS

Cylinder 10bar 10bar

Pipecoil 16 bar 10bar

Permissible operating temperature U/HP TS

Cylinder 95 °C 95 °C

Pipecoil 130°C 110°C

Seethetypeplateforothertechnicaldetails.

2. Legend

Seeinstallationschematicfornon-specifiedconnectionwidths.

3. Installing and operating the cylinder

Readthisguidecarefullybeforeinstalling.Intheeventofqueries,pleasecontactourcustomer

servicedepartment(seeContacts).

Installation,commissioningandmaintenanceinlinewithcurrentregulations(includingEN1717,

DIN1988,EN12828,VDI2035,anyapplicableregulationsissuedbylocalutilities,national

regulations)byanexpertinstallerinafrost-freeroomandonsubstratewithsufficientloadbearing

capacitytosupportthefullstoragetank!

AdrainoptionisprovidedatthecoldwaterinletsideoftheTS.Werecommendinstallinga

diaphragmpressure-expansionvessel(observetheseparateinstallationinstructions)inthecold

watersupplyline.TheTWsafetyvalvemustbeinstalledataneasilyaccessiblepositiontoallow

forregularinspection;itmustbefittedwithadrainconnection(seethecoldwaterconnection

schematic).Aplatebearingthefollowinglegendmustbeaffixedclosetothesafetyvalveblow-off

pipeoronthesafetyvalveitselfasappropriate:

WARNING: For safety reasons, water may escape through the blow-off line during heating!

Do not shut off or obstruct the blow-off pipe.

A Magnesium anode

B Drain G½

C Observationport(TSonly)

D Mains water

E Heating cold leg

F Heatinghotleg

G Circulation

H Insulation(solidfoam)

I Hot water

K Thermometer(TSonly)

L Immersion pipe for

temperature sensor

M Installation point

P Baseheightadjustment

Beforecommissioning,checktheearthingoftheMganodeontheTSandflushthecompletewater

heatingsystem.Ifimpressedcurrentanodesareused,observetheoperatinginstructionsincluded.

Unusedconnectionsmustbeprofessionallysealed.

Checktheleaktightnessoftheentiresystemunderoperationconditionsandduringmaintenance;

re-tightentheflangeconnectionifneeded.Checkthesafetyvalveatregularintervals.

Thestoragetankmustbeincludedinequipotentialbonding.

Temperaturecontrol/display:

U/HP:Thetemperaturesensorforcontrollingtheheatsourceisclampedunderthepolycoverin

theverticalimmersionsleeveusingtheclampingspringprovided.Theimmersiondepthdefinesthe

switchingpointofpost-heating.Forstoragetankswithanoperatingtemperatureofabove55°C,

thesensorshouldbepositionedabovethepipecoil.

TS The temperature sensor for controlling the heat source is clamped at the rear of the storage

tankinthehorizontalimmersionsleeveusingtheclampingspringprovided.Theremotesensoron

thethermometerismountedontheobservationport.

Attachtheclampingspringstothesensorstopreventfalsemeasurements.Theimmersionsleeves

are suitable for housing up to three sensors.

If needed, install scald protection at the hot water outlet.

Finally,affixthetypeplateprovided.

4. Further information

Noliabilityisacceptedfordamagecausedbyfailuretoobservetheinstallationandoperating

instructions.

Therequiredmaintenancemeasuresmustbeestablishedbyspecialistsorbytheuseronthebasis

oflocaloperatingconditionsandfiguresbasedonexperience.Thesystemmustbesubjectedto

annual inspections and documentation under the terms of an agreement.

Wearsafetyglovesforinternalcleaning(fortheTS);aftercleaning,theflangesealmustbe

replaced.Thestoragetankmustbeeasilyaccessibleformaintenanceoperations,repairs,and/or

replacement.Theconstructionmeasuresrequiredforthisarenottheresponsibilityofthe

manufacturerortheresponsibledistributor.Furthermore,facilitiesforthesecuredrainageofthe

cylinderintheeventofanywaterleakagemustbeprovidedtoavoidwaterdamage.

Hotwatercanescapethroughthesafetyvalveandondraining:dangerofscalding.Thesystem

operatormustpreventuntrainedpersonsfrombeingputatrisk.

ChecktheMganodeinitiallyafter2yearsandthenannually;replaceasneeded.

Inhard-waterareas,astandarddescalingunitcanbefittedupstreamasnaturallimescale

formationisnotthestoragetankmanufacturer'sresponsibility.

Inprinciple,aminimumconductivityof100µS/cmmustbeadheredto,whiletheotherproperties

ofwaterguaranteedintherelevantlegislationonmainswatermustbemaintained.Pleaseconsult

the manufacturer in borderline cases.

Sedimenttrapsarerecommendedonthedrinkingandhotwatersides.Theymustbeserviced

regularlyinlinewiththesystemconditions.

Avoidelectro-chemicalcorrosioninfluencessuchasmixedinstallations,etc.SClB.

ENG

7