FLAMENT INNOVATIONS BFP-ICARUS User manual

1

BFP-ICARUS Manual

Gen 3 - 4

V1.0 (6/17/20)

2

Table of Contents

Introduction......................................................................................................................................................... 3

Quick Fact Guide.............................................................................................................................................. 4

Quick Start Guide............................................................................................................................................. 5

Unboxing............................................................................................................................................................ 6

Component Names and Locations..................................................................................................................7

Touchscreen Interface.....................................................................................................................................10

Initial Setup and Calibration ........................................................................................................................11

Tools and Accessories..........................................................................................................................12

Leveling the Machine...........................................................................................................................12

Powering the Unit On, Off, and Troubleshooting ..........................................................................13

Bed Height Adjustment and Automatic Leveling.............................................................................15

Automatic Bed Leveling and Baby Z Stepping ..............................................................................16

Moving the Printhead..........................................................................................................................17

System Preheating ...............................................................................................................................18

Filament Loading..................................................................................................................................19

Software and Internet Setup........................................................................................................................21

WiFi Connectivity.................................................................................................................................22

Duet Web Control................................................................................................................................24

Software Slicers and Profiles.............................................................................................................25

Offline File Uploading and Printing.................................................................................................27

Maintenance and Support ............................................................................................................................28

General Maintenance .........................................................................................................................29

General Cleaning.....................................................................................................................29

Oiling and Lubrication .............................................................................................................29

Acrylic Cleaning........................................................................................................................29

PEI Plate Prep and Use............................................................................................................30

Z-Offset Tuning.....................................................................................................................................31

Heater/PID Tuning...............................................................................................................................33

ICARUS Print Out..................................................................................................................................34

Wiring....................................................................................................................................................35

Helpful Links and Documentation ......................................................................................................39

Frequently Asked Questions (FAQ)...................................................................................................40

3

Introduction

To our newest Filament Innovations customer,

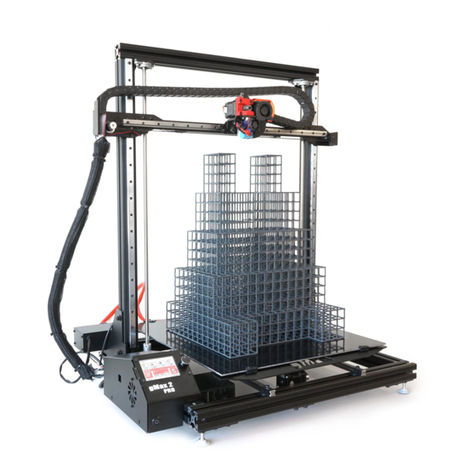

Congratulations on owning your very own BFP-ICARUS 3D Printer! These 3D

Printers are built to fill a clear need in the 3D Printing sector: large-scale,

affordable, and reliable machines. These 3D Printers combine the latest

technology and hardware into one unit. By using this unit, you are

supporting American business and manufacturing, while helping to push

innovation in numerous fields such as medical research, education,

manufacturing, and rapid prototyping.

Filament Innovations is dedicated to making sure that your experience

with our 3D Printers goes smoothly. Extra support is always available

through these easy methods:

Website: https://filamentinnovations.com/pages/support

E-Mail: information@filamentinnovations.com

Phone/Text: (610)640-5699

Tech Hours: M-Th: 8:00am –5:00pm EST

F: 8:00am –12:00pm EST

We thoroughly hope you enjoy using your Filament Innovations 3D Printer.

Please remember your machine was built by hand via trained individuals

in Pennsylvania –supporting American Manufacturing.

Welcome to Industry 4.0!

Happy printing!

The Filament Innovations Team

4

Quick Fact Guide

The following quick fact guide will give you a brief overview of your printer

and its components.

Machine Size:

ICARUS Size: 47 x 29 x 72 (in)

Right Door Swing: 27 (in)

Front Door Swing: 37 (in)

Print Envelope:

ICARUS Print Area: 470 x 381 x 915 (mm)

18.5 x 15 x 36 (in)

Mechanical Components:

X, Y and Z Motion: HiWin Linear Rail and C7 Precision Ballscrews

Motors: CNC Grade Stepper/Servo Hybrid NEMA23s

for X, Y, and 10:1 Geared NEMA23s for Z

Hotend Nozzle: Hardened Tungsten Carbide: 0.6mm

Filament Diameter: 1.75mm

Electronic Components:

Wall Power: 110VAC

Minimum Breaker: 15A

Amperage Draw: 14A

System Voltage:

Printer Electronics: 24VDC & 48VDC

Heated Bed: 110VAC

LEDs: 24VDC White and Blue

Camera: Wyze IP/Internet Webcam

Motherboard: Duet 2 Wifi with Duet Duex2 Expansion Board

Screen: PanelDue7i and Microsoft Surface

5

Quick Start Guide

The following guide allows you to check and monitor the progress of

setting up your ICARUS unit. It is recommended to check each step off

here to ensure everything is done in order and correctly.

1. Remove the four L-brackets from the bottom of the printer that attach

it to the crate. Adjust the casters, so the wheels are on the pallet.

2. Remove the machine from the pallet by gently rolling it off and move

the machine to the general area where it will be used.

3. Remove the shrink wrap from the machine and open the main door.

Inside the printer. Please remove your included filament and any other

boxes you see. Check under the blue bearing plate for boxes.

4. Level the machine using the included bubble level in the toolbox

(located inside the machine at the time of shipping).

5. Plug the 110VAC cord into the wall which is located on the rear right of

the unit, twist the red emergency stop clockwise to disengage it, and

flip the red toggle switch. The unit should now be powered on.

6. From the touch screen, temporarily disable to WiFi by pressing:

Console > Keyboard Icon > Type “M552 S0” > Enter

Note: This step is not relevant if you have the CAT5/6 version.

7. From the touch screen, select and run the following macro by pressing

the Macro button:

Macro > “Bed Leveling” > “Mesh Bed Leveling - RT”

8. Connect to a Wifi Network (page 21). Check that you can connect to

the Duet Web Control interface afterward (detailed in this manual).

Install the webcam, if desired, following the instructions from the Wyze

Cam app on your phone or tablet.

9. Install the slicer profiles from the website and –HAPPY PRINTING

6

Unboxing

The BFP-ICARUS 3D Printer ships in a wooden crate, weighing between 500

- 550 lbs. The crate dimensions are as follows:

ICARUS-X Crate Size: 56 x 48 x 76 (in)

Using the tools and instructions listed below, you should be able to easily

remove your ICARUS from the palette and remove the shrink wrap. The

unboxing process will require two people.

Required Tools Not Included for Unboxing

•Powered Drill with a #2 Philips bit

•Crowbar or Hammer

•Basic metric Allen key set

•19 mm or adjustable wrench

Steps for Unboxing

1. To remove the outside panels, use a crowbar or hammer to remove the

staples around the outside of the box.

2. Once the panels are removed, use a hammer or crowbar to remove

the wooden frame around the printer.

3. Once the crate is open, locate the metal L-brackets securing the

printer to the pallet. Remove the pallet side of the bracket using a drill

and the printer side using a number 4 Allen key

4. Use the 19 mm wrench to raise the stabilizer feet so the wheels are

touching the floor of the crate.

5. You and another person can now remove the printer from the crate by

carefully rolling it off. The printer should still be in the shrink wrap at this

time.

6. Move the printer approximately where it will be operated and remove

all the shrink wrap from the machine. After the shrink wrap is removed,

move the printer into its final position. As a reminder, the filament

chamber is on the right side of the machine and needs an additional

27 inches to open properly.

7

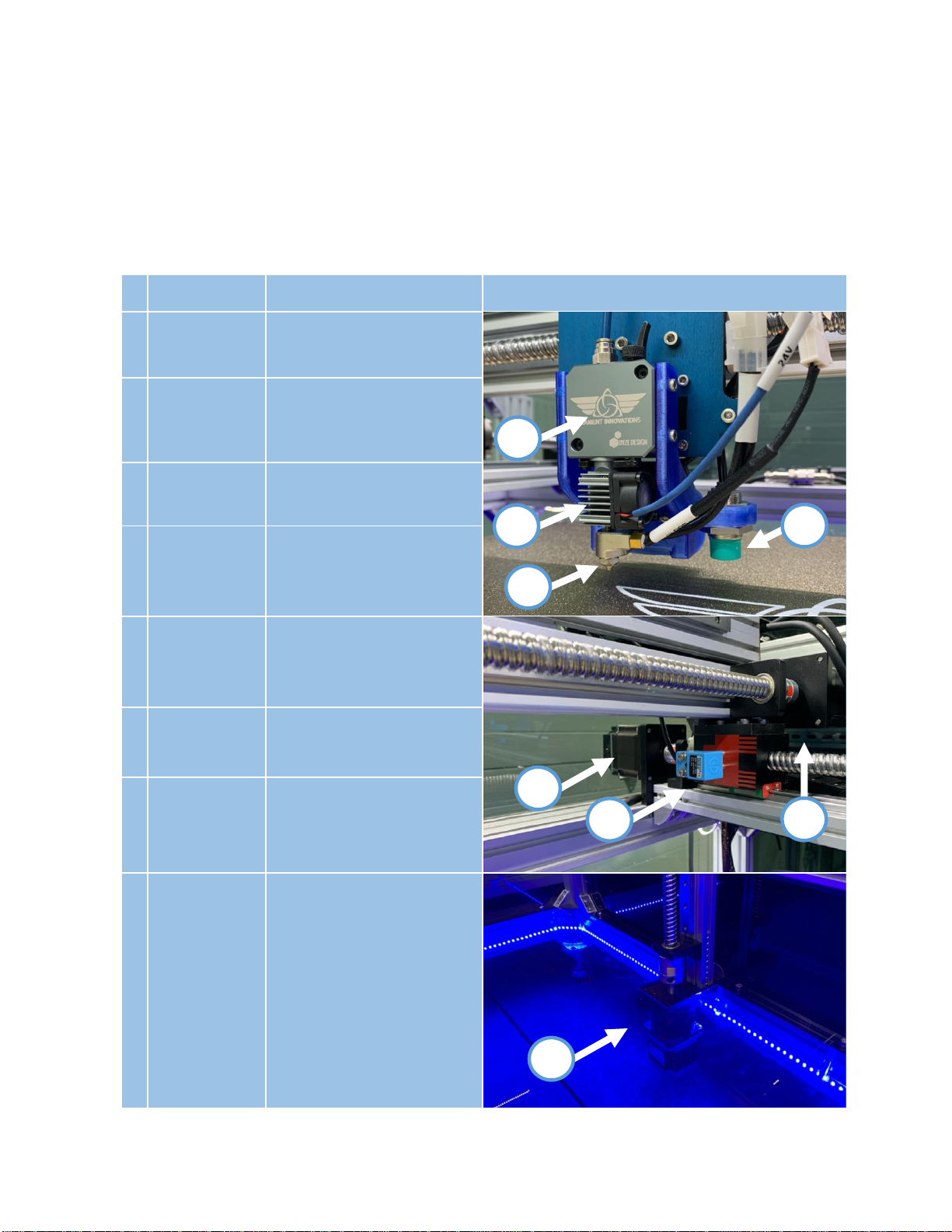

Component Names and Locations

Before we go any farther, let us take a few minutes to understand the

various components of your ICARUS unit. These components will be

referenced later in the manual. At this time, the unit should NOT be

powered on.

#

Component

Description

Image

1

Extruder

Stepper motor that pushes

filament through the

hotend.

2

Hotend

Component that heats up

filament to melting

temperature.

3

Nozzle

Small opening that filament

comes out of to print with.

4

Inductive

Probe

German designed sensor

that detects the distance

from the nozzle to the bed –

teal tip.

5

Endstop

Sensor that detects the x

home position of the printer.

There are two y endstops on

the front of the machine.

6

X Motor

Stepper motor responsible

for moving print head

assembly left to right.

7

Y Motor

Stepper motor responsible

for moving print head

assembly front to back.

There are two of these.

8

Z Motor

One motor on each side

controlling up and down

movement of the bed.

These have a 10:1 gear box

on them to increase power.

There are two of these.

8

7

3

2

4

6

1

5

8

9

Filament

Sensor

Detects when filament has

run out and cleans it as it

passes through. This is found

in the control case on the

right side.

10

Casters

Allows the printer to roll or

be locked in place with

retractable feet. The feet

can be raised and lowered

by rotating the leveling feet.

11

Switch Panel

Controls the printer power:

See the Powering the Printer

On section to see what

each control does.

12

Control Case

Houses all of the electronics

for the printer. This includes

power supply, duet board,

relays, and cooling fans.

13

Duet 2 Wifi

Screen

The interface used to

interact with the printer.

14

Heated Bed

Indicator

Red indicator light that turns

on when the heated bed is

above 40C. The PEI Print

Plate should not be

removed if this light is on

15

Hotend

Indicator

Red indicator light that turns

on when the hotend is

above 40C.

10

9

15

5

12

11

13

1

14

9

16

PEI Print Plate

Removable print surface for

easy remove prints.

17

MIC6 Plate

The plate that is heated by

the heated bed.

18

Insulation

Retains heat from the

heated bed.

19

Leveling

Springs

Adjustable bed levelers.

These are factory set by

Filament Innovations staff.

20

Base Plate

Creates a stable base for

the print bed.

21

Filament

Chamber

Used to house up to 5 spools

of filament at a controlled

temperature and a low

humidity.

22

Temperature

Control

Interface used to control

the temperature of the

filament chamber. This is set

to maintain temperature at

35C.

23

Filament

Chamber

Indicator

Light

A red indicator light that

lights up when the heater is

on to maintain the chamber

temperature.

24

Heater

The 120 V heater that

maintains the temperature

of the dry chamber set by

the temperature control.

25

Main

Chamber

Indicator

Indicates the temperature

and humidity of the main

chamber.

17

19

18

16

20

23

23

21

24

24

22

ffff

25

25

10

Touchscreen Interface

The BFP-ICARUS is equipped with a 7” PanelDue7i LCD touchscreen from

Duet3D to easily interact with the printer. In this section, we will cover the

basics required to understand how to operate your printer using the

touchscreen. For more in depth documentation, refer to the Official

Duet3D Documentation.

Red: Software controlled emergency stop.

Yellow: Heated Bed (Left) and Hotend (Right) icons.

Blue: Current temperature in Celsius.

Orange: Temperature the printer is set to.

Green: Current position of the X, Y, and Z axis in millimeters.

Purple: Home command for each axis. The left icon is a Home All.

to home all three axes. You must Home All before attempting

to use the Move commands. You can individually home each

axis with the other three buttons.

Black: All gCode files for printing that are stored on the onboard 4 GB

MicroSD card. These gCode files are loaded via the Duet

Web control interface on a computer browser.

Brown: The Macro button is used to store custom commands that can

be written and stored via the Duet Web control interface.

Some basic Macros are included to help with setup.

11

Initial Setup and Calibration

Initial Setup and Calibration

12

Tools and Accessories

Your printer has come with the following tools and accessories:

Toolbox Contents

•

Metric Allen Key Set

•

Bubble Level

•

Snips/Pliers

Accessories

•

110VAC Power Cord

•

Filament

•

Wyze IP/Internet WebCam

Leveling the Machine

Using the supplied bubble level, a 19 mm wrench, and the stabilizer feet

on the bottom, level the machine with the earth. Do this by placing the

bubble level on the top of each side of the machine and adjusting the

stabilizer feet as needed. During this, the stabilizer feet will be lowered and

the casters raised in the air. The machine is level when the bubble is

between the two lines, pictured below.

Before Adjusting the Casters: After Adjusting the Casters:

13

Powering the Unit On, Off, and Troubleshooting

The ICARUS printers run on 110 VAC power, the standard USA household

electricity –the unit needs a 15A circuit for operation. The switches on the

front of the control box are responsible for turning on and off the printer.

As a reminder, the function of each control is listed below.

•Red Toggle Switch: Controls power to the printer (Red Arrow)

•Blue Toggle Switch: Controls internal LED lighting (Blue Arrow)

•Emergency Stop: Kills all power in case of emergency. If pressed, turn

the button clockwise to disengage. (Green Arrow)

•Main Power Plug: Plug for 110 VAC power cord. (Yellow Arrow)

Steps for Turning on your ICARUS

1. Use the supplied 110 VAC power cord to plug the printer into a wall

outlet. The unit should be on a minimum 15 amp breaker; however, we

strongly suggest a 20 amp breaker.

2. Ensure that the emergency stop is disengaged. If engaged, turn

clockwise to disengage the button.

3. Flip the red toggle switch to turn on the printer. At this point the screen

and the cooling fans on the control box should turn on. You may also

turn on the LED’s using the blue toggle switch.

REAR

FRONT

14

Steps for Turning off your ICARUS

1. Press the System Cool Down button on the home screen to turn off the

heated bed and hotend.

2. Wait for the red Heated Bed and Hotend indicator lights to turn off.

3. Flip the red toggle switch down to power the unit off.

Troubleshooting the Power

The BFP-ICARUS is a straight forward machine to power on and off,

however there may be times when troubleshooting may occur.

•20amp Breaker –A breaker is located inside the control box, on the

bottom right. If the unit does not turn on, there may have been a

power surge on the electrical line the printer is plugged into. Please

check to see if the breaker has a green(off) or red (on) color on it. If

it is green, please flip the breaker to power the unit back on

•Emergency Stop –Is the emergency stop pressed in? This will cut

power immediately to the unit. Turn this clockwise to disengage it.

•Power Plug –Please check that the plug is fully inserted into the

control case on the back of the machine.

15

Bed Height Adjustment and Automatic Leveling

Keeping a level bed is critical for accurate 3D Printing. Every ICARUS unit

comes equipped with mesh bed leveling to ensure a flat bed. Even

though your bed leveling, and Z-offset is factory set, it is important to

check that no damage occurred during shipping.

Steps for Checking Bed Height and Leveling

1. Every ICARUS unit ships with light tension springs with locks nuts. Check

that all four are on the bed plate, one in each corner with a locknut

underneath it. These are factory set as level and every ICARUS ships

within 200-300 micron bed variance.

2. Use the Home All button to home the X, Y, and Z axes. The printer axes

will now start to move. This is shown in yellow

3. Navigate to the Bed Tilt Compensation macro by going to:

Macros > Bed Compensation > Bed Tilt Compensation

2

3

16

Automatic Bed Leveling and Baby Z Stepping

3D Printing requires a very flat bed surface for large, successful prints.

Because of this, we have included two forms of bed leveling for your

machine. This section of the guide is to inform you of what these two bed

leveling options do.

Inductive Probe: This durable and extremely accurate German

designed sensor is responsible for detecting the metal PEI print plate to

allow for the following functions to be run. This sensor can be found on

the hotend with the circular green cap at the bottom where it senses.

Tilt Compensation: Prior to every print, the ICARUS will automatically

perform a Tilt Compensation which probes the left center and right

center of the print bed. The software will automatically calculate the

deviations of the bed and independently adjust one of the Z motor

ballscrews to level the bed to ensure your print bed is flat every time.

Mesh Bed Leveling: Changes in bed temperatures from printing with

different filaments will slightly effect the levelness of the bed. A Mesh

Bed Compensation is a 5 minute Macro that will probe the bed at

numerous points, twice, and create a virtual height map of the bed. It

is found under:

Macros > Bed Compensation > “Mesh Bed Leveling”.

Run this macro every time you load a new filament to ensure a proper

print surface. There are presets from 50C through 100C bed

temperature, choose the temperature that best suits your printing

needs. Our ICARUS units come pre-calibrated with a mesh variance

under 300 microns.

Baby Step: To ensure you get the perfect first layer every print, the Duet

system allows you to move the print bed up or down at the beginning

of a print to account for small variations in bed leveling from normal

use. When a print is started, a button on the lower right of the

touchscreen called “Baby Step” will allow you to adjust the spacing of

the print head to the print bed in 0.02mm increments. The two arrows

pointing together will raise the print bed to the nozzle. The two arrows

pointing away will lower the print bed from the nozzle.

17

Moving the Printhead

The print head can be moved using the Move tab on the touchscreen.

After selecting the Move button on the home screen on the touchscreen,

the Move window appears. This gives a variety of options for moving the

printer a certain number of millimeters in all directions.

The printer must be homed before it can be

moved manually. If a move button is pressed

without the printer being homed, an error

message will appear. This is necessary to

prevent damage to the machine by moving

the printer too far in one direction.

Moving in the X and Y Direction

The X and Y direction moves the PRINTHEAD. Once the printer is homed, it

can be moved in the X and Y direction freely without fear of moving the

printer too far in either direction.

Moving in the Z Direction

The Z direction moves the BED up and down. More caution has to be

given when moving in the Z direction because it is possible to ram the bed

into the nozzle which can SEVERELY damage the machine. Take extra

caution when moving the Z axis. The negative Z buttons move the print

bed UP while the positive Z buttons move the print bed DOWN.

The diagram below shows what the positive direction of movement is for

each axis. The origin of the x and y axis of the printer is in the front left.

18

System Preheating

In order to preheat the entire system, the desired temperature needs

to be set for the hotend and heated bed individually. Other than

preheating for a print, the heated bed must be preheated for Mesh

Bed Leveling, and the hotend must be preheated when changing

filament. For more information about preheating instructions when

changing filament, see the next section Filament Loading.

Steps to Preheating the Bed and Hotend

1. Press the temperature button in the “Active”

row for the hotend.

2. Use the + and –buttons to select the desired

temperature and then press the “Set”button.

3. Initiate the heating process by pressing the

hotend icon. The hotend will start to heat up.

4. The same process is followed for preheating

the heated bed. Press the temperature button

in the “Active” row for the heated bed, set

the desired temperature, and press the

heated bed icon to initiate the process.

Alternative Method for Preheating

There are also Macros made for system

preheating ABS, ASA, Nylon, PETG, PLA, TPU and

more. When one of these is engaged, the system

will heat the heated bed first and then the

hotend. Find these under

Macros > “Pre-Heating”

Always print at the manufacturer’s suggested

temperatures. Our preheating macros should be

treated as guidelines for that polymer.

1

2

3

19

Filament Loading

To begin printing with your printer, or to change filament, it is important to

know how to load filament into your ICARUS. Follow the two guides below

for Loading Filament for the First Time and Changing Filament.

Loading Filament for the First Time

1. Put the desired spool of filament on

any of the filament holders in the

filament chamber.

2. Preheat the hotend to the correct

temperature for that filament.

3. Cut the end of the new filament at a

45 degree angle to allow it to more

easily be fed through the tube.

4. Push the lever on the extruder to the

left (Green Box) and push the small

lock knob to the right (Blue Box) –this

opens the gear inside the extruder.

5. Start feeding the filament through the

tube, through the sensor, and

continue feeding it until you feel it stop

–it has now entered the extruder.

6. With the hotend heated and

filament in the extruder, release the

filament lever by pushing it to the left

to release it. The lever should now be

tilted to the right (Red Box).

7. On the Duet Screen, press the Extrusion

button to extrude 100mm of filament

at 5mm/s –twice –so you extrude

200mm of filament. If the extruder does

not move, then press the Home All

button to home all the axes as a safety

precaution and repeat this step.

7

1

4

6

3

5

20

Steps to Changing Filament

1. Preheat the hotend to the correct temperature. If you are switching

between different materials (i.e. PETG to PLA), it is suggested to load the

filament at a temperature between the two ranges. This will soften the

PETG enough for getting it out of the hotend and the PLA will not be

burned when you load it.

2. Push the lever on the extruder to the left and engage it into place with

the lock knob.

3. Remove the existing filament by spinning the spool backwards. You can

also remove the blue PTFE tube, at the connector on the hotend, if it is

easier to pull the filament directly out of the extruder.

4. Once the old filament has been pulled out of the tube, put the new

spool of filament on and follow the filament loading steps from the prior

section.

5. When printing, immediately after changing the filament, remember to

preheat the hotend and heated bed to the appropriate temperature

for the new filament.

Once filament has been loaded into the printer, the initial setup and

calibration has been completed. The next section will provide more

information on setting up the software and internet connectivity of the unit.

Other manuals for BFP-ICARUS

1

Table of contents

Other FLAMENT INNOVATIONS 3D Printer manuals