Thank you for choosing ARTILLERY Products. For your convenience, please read this manual carefully before use, and strictly follow the

instructions in the manual. The ARTILLERY team is always ready to provide you with excellent seice.

No matter what problems you encounter, please contact us by telephone and email at the end of the manual. In order to enhance your

experience with our product, you can also acquire knowledge about equipment operation through the following methods:

Included User Guide: You can nd relevant instructions and videos on the USB ash drive.

You can also visit the ARTILLERY ocial website (www.aille3d.com) to nd information regarding software and hardware, contact details,

equipment operation, and maintenance,etc.

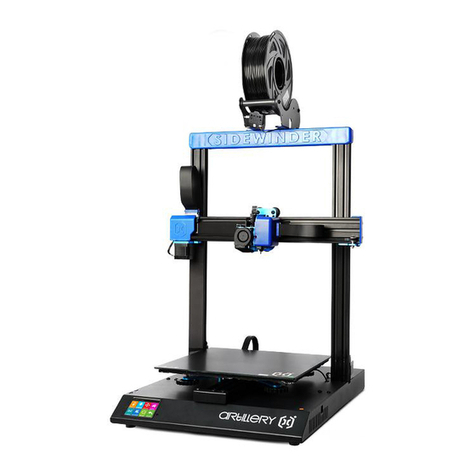

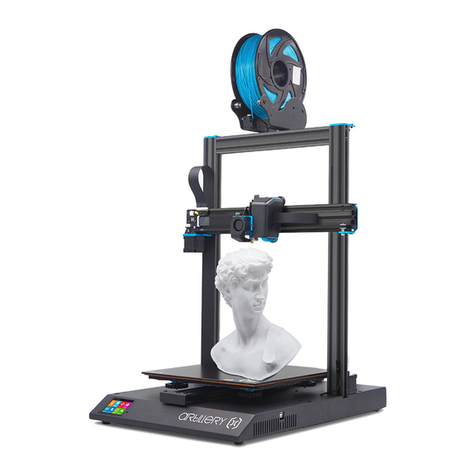

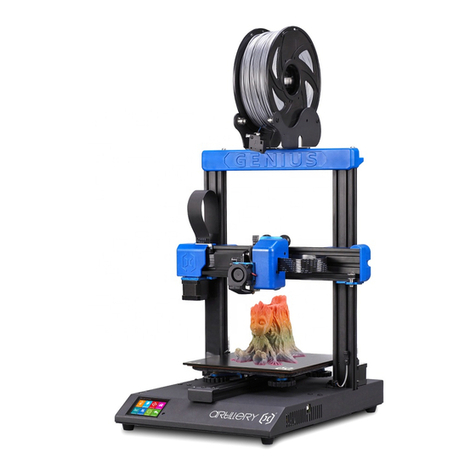

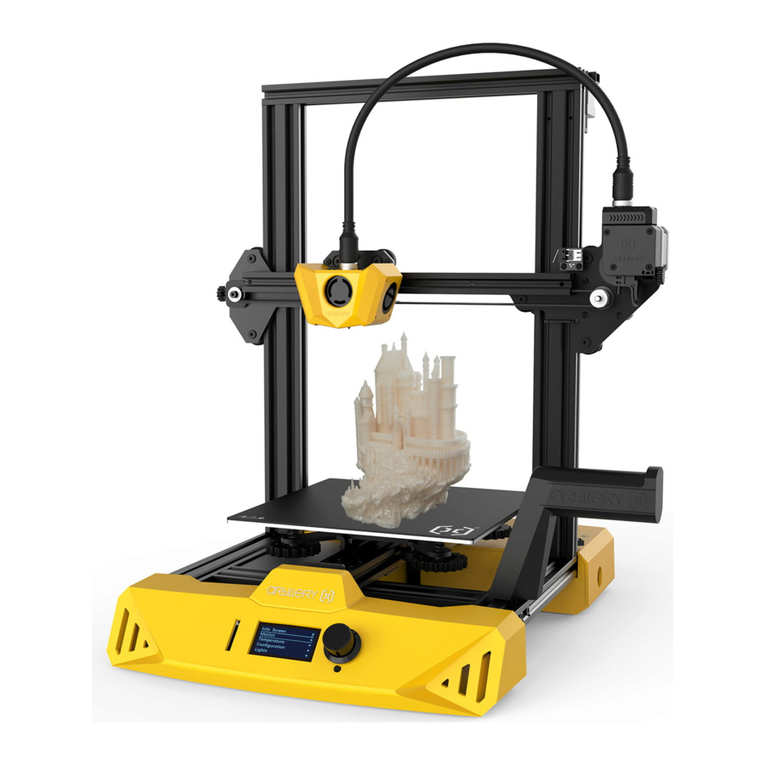

ProductIntroduction

1. Do not attempt to use the machine in any way that is not described in the user manual to avoid personal inju or propey damage.

2. Do not place the machine near ammable or high heat sources. Instead, place it in a well-ventilated, cool, and dust-free environment.

3. Do not place the printer in a vibrating or unstable environment, as machine vibrations can aect print quality.

4. It is recommended to use consumables recommended by the manufacturer to avoid nozzle clogging and machine damage.

5. Do not use other power cords during installation. Please use the power cord provided with the machine and plug it into a three-hole socket

with grounding.

6. Do not touch the nozzle or hotbed while the printer is in operation to prevent burns and personal inju.

7. Do not wear gloves or loose clothing while operating the machine to prevent entanglement or inju from moving pas.

8. After completing a print, clean the residue on the nozzle using tools while taking precautions not to touch the hot nozzle with bare hands.

9. Regularly maintain the printer by cleaning the machine body with a d cloth, removing dust and adhered printing materials or foreign objects

from the guide rails while the power is o.

10. Children under the age of 10 should not use the machine without supeision to avoid personal inju.

11. Users must comply with relevant national and regional laws and regulations, adhere to professional ethics, and fulll safety obligations. It is

strictly prohibited to use our products or equipment for any illegal purposes. Our company takes no responsibility for any legal liabilities

resulting from violations.

12. In case of emergencies, please turn o the power directly.

Instructions