Fletcher-Terry Fletcher Saber 250-A User manual

Owner’s Manual

Fletcher Saber™ 250-A

For Accurate and Efficient Saw Tooth Hanger Installation

Form 032404

The Fletcher

-

Terry Company

65 Spring Lane • Farmington, CT USA 06032-3311

Tel 860.677.7331 or 800.843.3826 • Fax 860.676.8858 • www.fletcher-terry.com

First, we’d like to

congratulate you for adding

the Saber 250-A to your

production line. From now on

your operators will be able to

insert saw tooth hangers with

efficiency, accuracy, and

reliability. It’s easy to use and

designed to require minimal

maintenance. Regardless of

the size of the frame or

thickness of the moulding, the

Saber 250-A will secure a 5-

tooth hanger perfectly placed

and instantly secure.

Next, we ask you to inspect

the two containers that were

used to ship the Saber 250-A.

If damaged, please contact

your carrier and file a claim.

Locate the warranty card that

was shipped with this manual

and return it to The Fletcher-

Terry Company to activate

the warranty.

Now, you’re ready to set up

and operate the Saber 250-A.

Page 2

Page 3

Page 7

Page 12

Page 14

Page 16

Product Warranty

The Fletcher-Terry Company warrants the machine purchased to be free from defects in parts and workmanship for (2) two years from the date of

purchase. The Fletcher-Terry Company warrants that it will repair or replace any such defective machine or replace parts, providing the machine

has been under normal use and service and the defective part or machine is returned to The Fletcher-Terry Company at the purchaser’s expense.

The Fletcher-Terry Company must authorize the return in writing. Proof of purchase must be submitted to validate warranty coverage.

The warranty is in lieu of all other agreements and warranties expressed or implied. THE FLETCHER-TERRY COMPANY DOES HEREBY

EXPRESSLY DISCLAIM ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The Fletcher-Terry

Company does not authorize any company employee or representative to assume for it any other liability than that set forth in this Product

Warranty. The Fletcher-Terry Company shall not be liable for any damages or losses, whether incidental or consequential or direct or indirect,

arising out of the use or abuse of this machine. In any event, THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS OR ANY

OTHER WARRANTY IS LIMITED TO RETU

RN OF THE PURCHASE PRICE PAID FOR THIS MACHINE.

Please read through this manual before operating the Saber™ 250-A. If

after reviewing these pages you still have questions about using the

machine, contact our Customer Service Department: (toll-free)

1.800.843.3826 in the U.S.; outside the U.S. call 860-677-7331;

ÿIt is the employer’s responsibility to enforce compliance with these safety warnings and

procedures by allwho use the Saber 250-A. Keep this manual available so all employees

have access toit and the opportunity to review procedures periodically.

ÿThe intended purpose of the Saber 250-A is to insert saw tooth hangers inpicture frames

of various shapes, sizes, andmaterials. Itmust not be modified or used for any other

application or purpose.

ÿUse safety glasses. The operatorof this machine, and others in the work area,must wear

safety glasses with rigidside shields. Wear ear protection. Ear protection is recommended

in any work environment where repetitive, mechanical machinery is in operation.

ÿOnly connect the Saber 250-Ato an air supply with a coupling that removes all pressure

when disconnected. Always disconnect the machine from the air supply beforeperforming

maintenance, removing a jamor cleaning the Saber 250-A.Even if a hangerstrip is not

visible on the guide, assume that there may be oneor two hangers remainingin the

machine.

ÿUse clean, dry, regulated compressed air at a minimum pressure of 100 PSI at 2 CFM.

The system includes a filter and pressure regulator. Do not connect this machine to an air

supply withmaximum potential pressure greater than 150 PSI.

ÿNever use oxygen, carbon dioxide, combustible gases or any type of bottled gas as a

source for this machine. Explosion and serious injury may result.

ÿNever use the machine if the air supply is compromised, themachine is missing parts, or

repair of the Saber250-A is required. Do not use the machine if the safety warning labels

are missing or unreadable. Donot use the machine ifthe ram safety guard ismissing or

broken. Contact a Fletcher-Terry Customer Service Representative for replacement labels

or parts.

ÿOnly use the parts, supplies,and accessories that are recommendedby Fletcher-Terry.

ÿUse care when loading the hanger strips onto the hangerguide, making sure that you do

not inadvertentlyactivate the T-bar switch.

ÿDo not over-reach or use the Saber 250-A from an awkward or insecure position. Make

sure that the workarea is well lit, freefrom clutter, and set upin a way that promotes

proper ergonomics.

ÿþýü ú

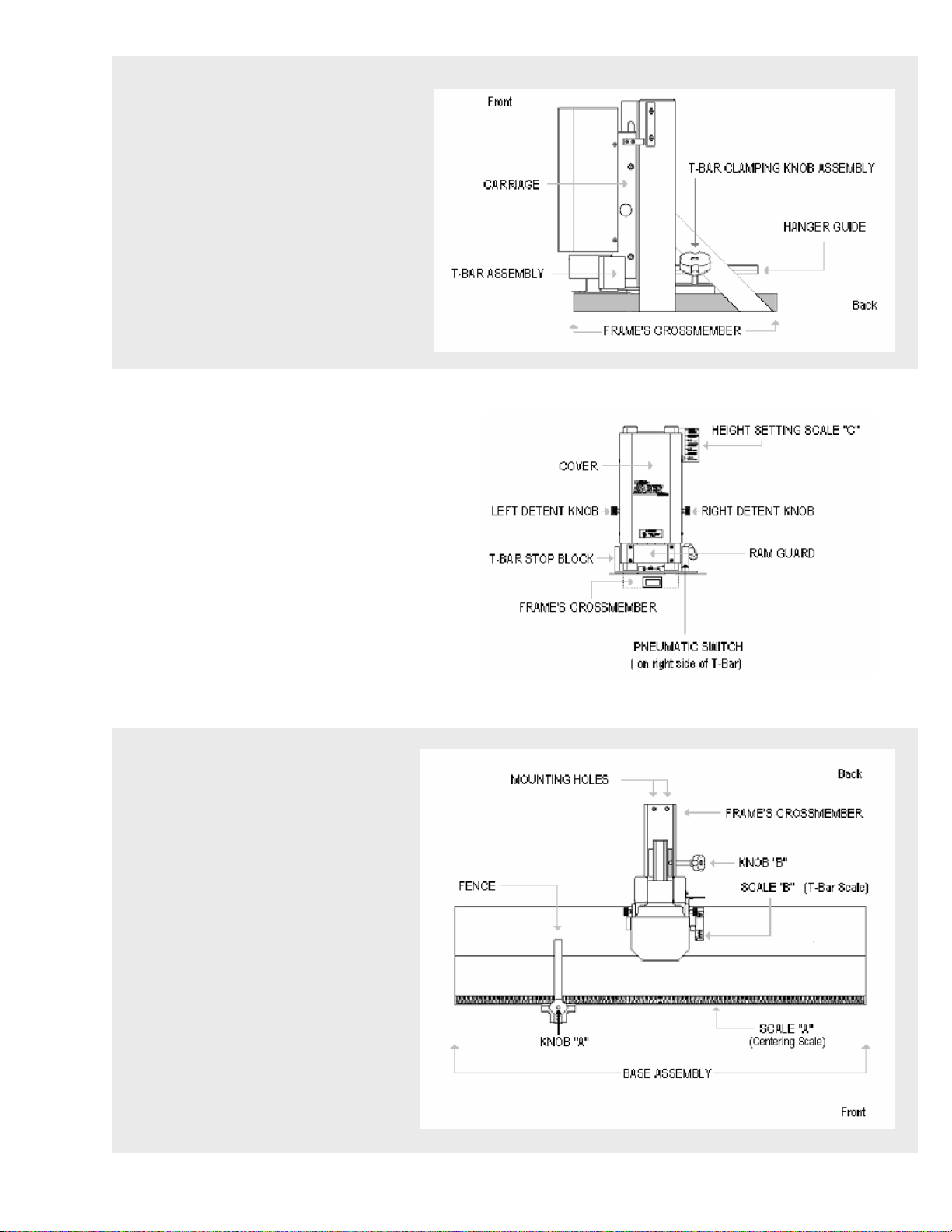

The Saber 250-A has been

shipped to you in two

containers. The longer,

flatter carton contains the

Base (Figure 1).

The other box contains the

Tower Assembly (Figure

2), the Fence (Figure 3),

and a Parts Bag.

You will have found that the

Parts Bag contained:

a) This Owners’ Manual

b) A Warranty Card

c) Flat Head Socket Cap

Screws (2)

d) Hex Key (1)

e) Triangle Template

[for squaring] (1)

All instructions in this manual assume that

you are facing the front of the machine and

that the machine has been placed on

a flat and secure surface.

If anything is missing, please contact a Fletcher-Terry Customer Service Representative at

800.843.3826, at 860.677.7331, or customerservice@fletcher-terry.com.

ÿþýü ú

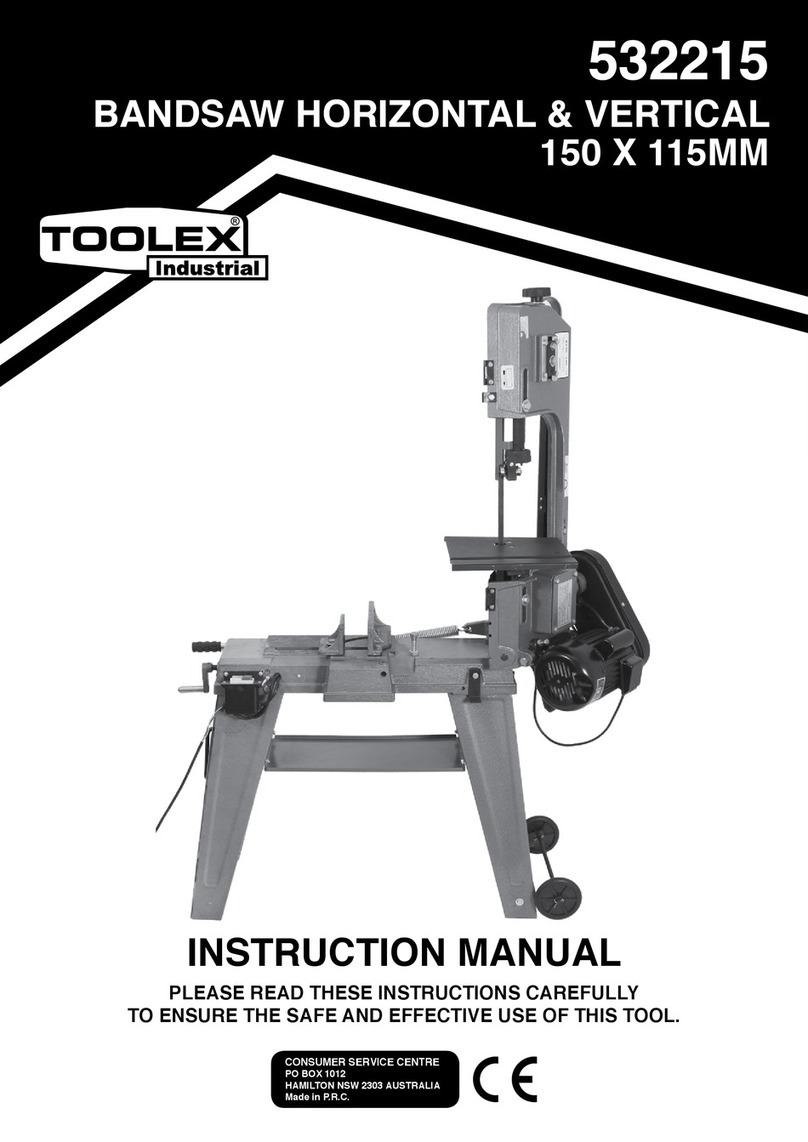

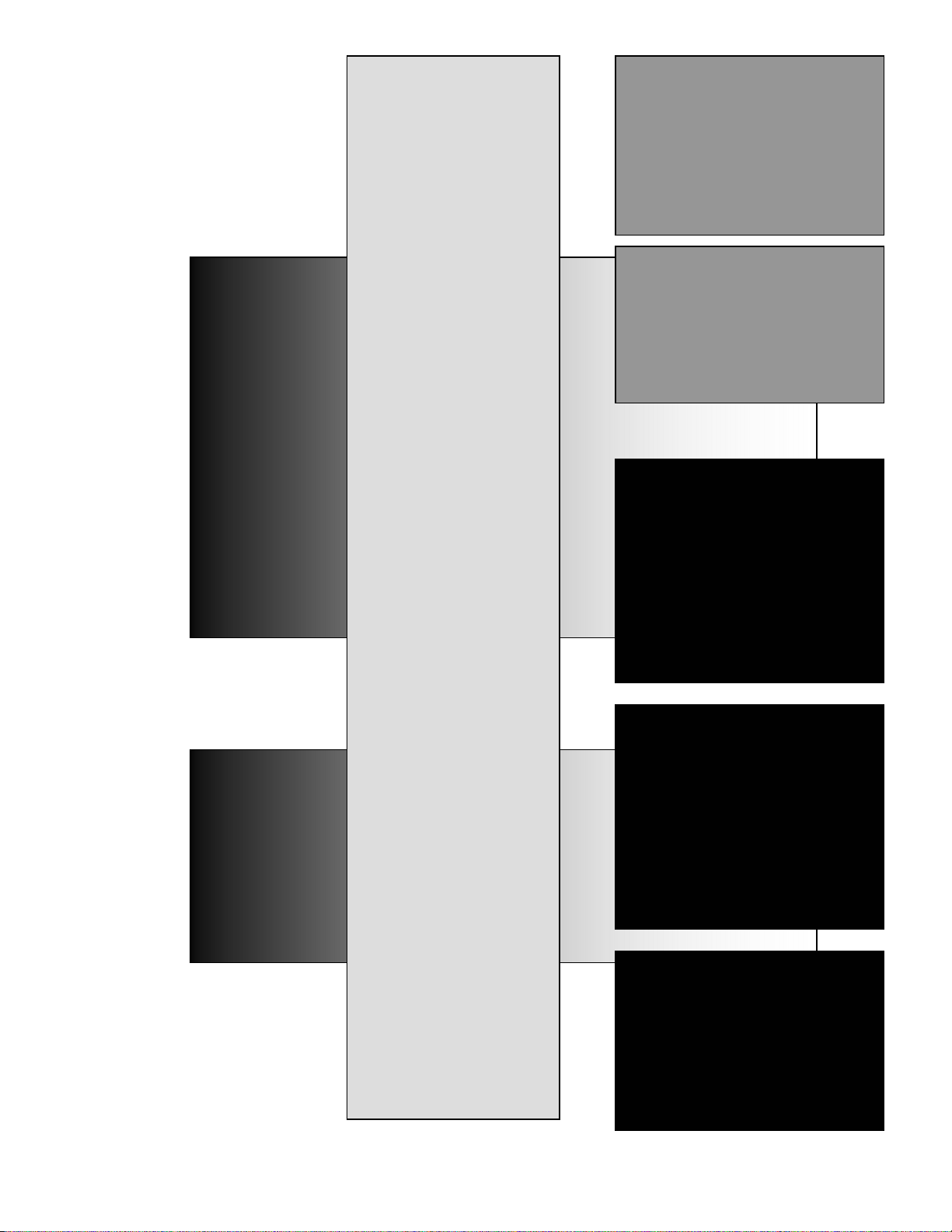

Figure 3 FENCE

VIEW A: FROM RIGHT SIDE

VIEW B: FROM THE FRONT

VIEW C: FROM ABOVE

Figure 4

Figure 5

Figure 6

ÿþýü ú

Before assembling the machine,

determine whether you will

anchor the Saber 250-A to your

work surface. Placing and

securing the machine will be a

matter of personal preference

and it is left to the owner to

decide how best to use the

Saber.

The Saber 250-A should be

placed so that the front of the

machine is facing the operator.

Be sure to leave sufficient room

for attaching the base

assembly. The base assembly

will run along the front edge of

the workstation.

If you decide to anchor the

Saber 250-A to your work

surface, locate the four,

predrilled holes on the

crossmember of the frame

(

Figure 7).

These will allow you

to secure the machine with four

bolts (not included).

Please Note:

When the base is attached

to the tower, a squaring

procedure must be

followed to ensure proper

alignment.

(See Figure 8.)

Figure 7 (Shown with machine’s cover removed)

þýüû ú

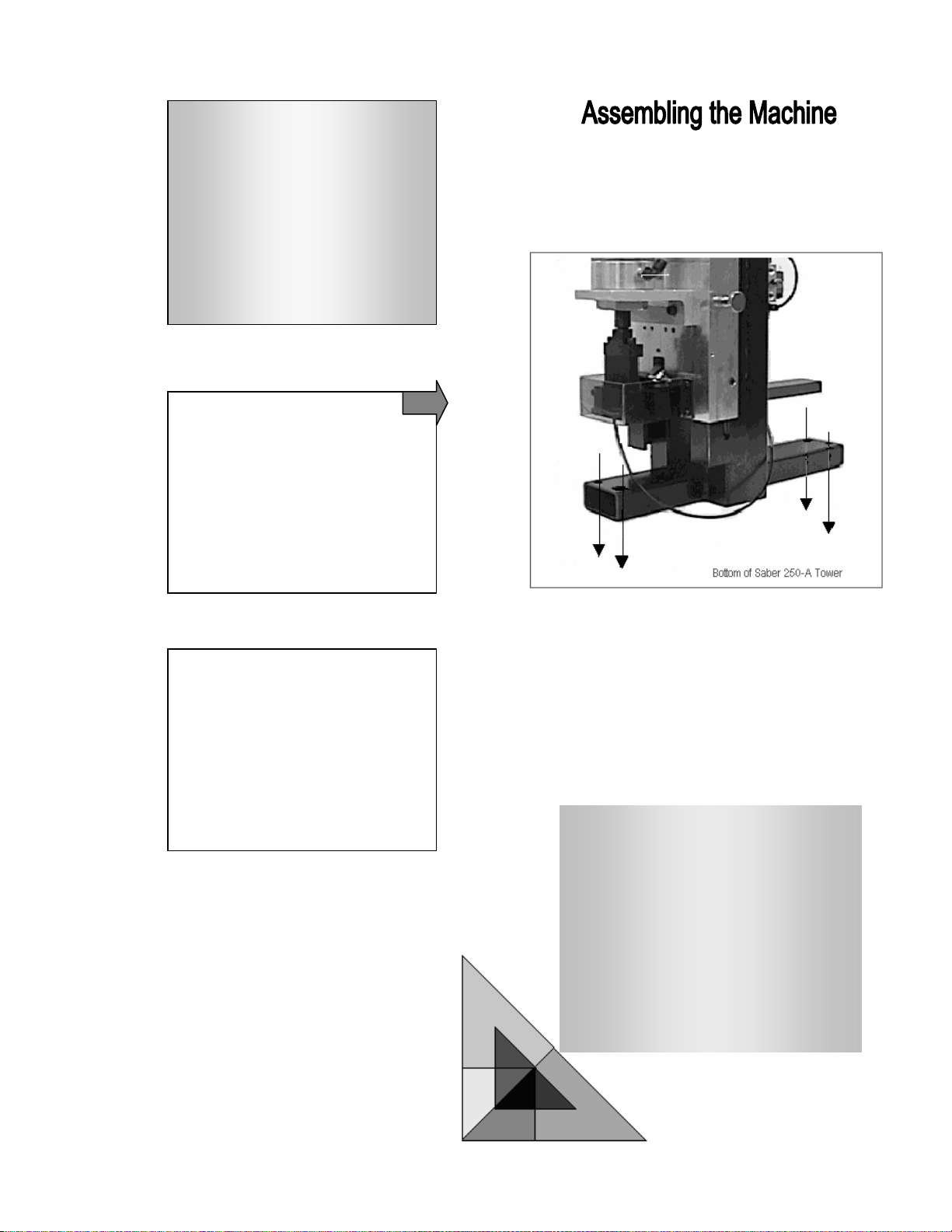

With the machine properly placed (and

optionally mounted to the worksurface),

raise the carriage to its uppermost position

on the tower. Pull out the detent knobs to

release the carriage and guide it upwards

until it locksin place when it reaches the

appropriate location.

Set the T

-

bar to a 2

-

inch depth setting. Do

this by loosening the T-bar clamping knob

and moving the entire T-bar assembly until a

2-inch setting is reflected on the T-bar scale.

Tighten the knob.

Place the enclosed

triangle template

squarely against the

fence and across the T-

bar assembly. Use a

piece of material or

matting (approximately

1/8” thick) as a platform

under the template to

ensure that thetriangle

will bump up against the

fence and the T-bar

assembly.

Attach the base to the tower assembly by placing it atop

the machine’s crossmember. Align the screw holes and

insert screws. Loosely tighten the left, but do not tighten

the right screw. The right screw will not be tightened until

the squaring procedure is complete. Attach the fence

assembly and position it at the 10” mark on Scale A.

Gentl

y move the base assembly until the

triangle is perfectly squared tothe fence and

T-bar. When you have done so, tighten the

right screw and then the left.

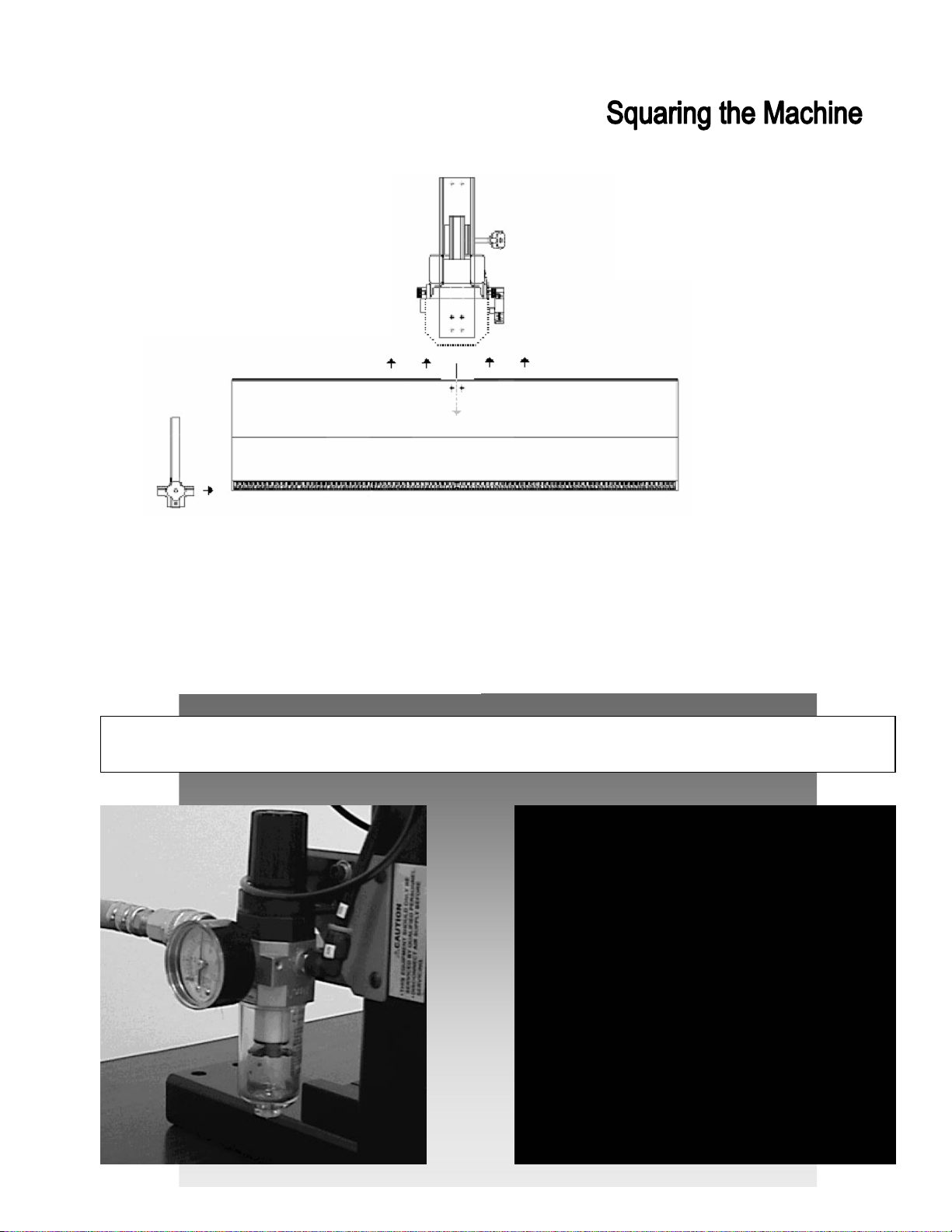

THE MACHINE IS NOW PROPERLY SQUARED AND YOU MAY ATTACH YOUR SOURCE OF COMPRESSED AIR TO

THE FILTER / REGULATOR AT THE LEFT REAR OF THE SABER 250-A

Establishing a Proper Air Supply:

Attach your compressed air hose to the machine

using clean, dry air (minimum 100 PSI with the

regulator set at 75 PSI).

You may choose to adjust pressure depending

on the size and material of the frame. This may

be especially important if using the small frame

adapter. (See “Optional Equipment”)

Certain safety precautions are required when

using pneumatic tools in order to prevent injury

to the user and others in the area. Read and

follow all instructions and safety warnings in

this manual.

ÿþýü ú

Figure 9

Figure 8

A. Load the Hanger Strip

B. Measure the Frame and Adjust the Machine

C. Activate the Saber 250-A

Saw tooth hanger strips

contain 25 collated hangers.

Individual hangers are

barbed to ensure maximum

hold when inserted into a

frame.

The hanger strip is loaded

onto the guide, barbs

pointing downwards and

teeth facing the machine’s

operator, i.e., the front of the

Saber 250-A.

Once the strip is loaded onto

the guide, the operator

pushes the strip forward

toward the front of the

machine until the hanger

strip stops.

The required hanger strips (part

number 08-810) may be ordered

by contacting the Fletcher-Terry

Customer Service Department at

800.843-3826; outside the U.S.,

call 860.677.7331; or

customerservi[email protected]

ÿþ üûúù ø÷ö õúôóöò ñøòðï

Figure 10 (Top View)

úóö

Coming Up:

Page 9: A quick review and instructions for taking measurements andadjusting the Saber 250-A.

Page 10: Some examples, product notes and safety tips.

Page 11: How to drive a sawtooth hanger using the Saber 250-A.

ÿþ üûúùø÷û öõû ô÷úóû úòñ ðñïøùö öõû üúîõíòû

The Saber 250-A requires

the operator to determine

three measurements before

proper placement of a saw

tooth hanger can be made:

a. The width of the

frame;

b. The hanger’s

placement from

the top of the

frame to the

centerline of the

hanger;

c. The height or

thickness of the

frame.

Figure 11

úû

Taking measurements and adjusting the Saber 250-A:

ÿA. How wide are the frames you will be processing?

i. Measure the width from outside the left edge to outside the right edge of the frame.

(measurement “a” in Figure 11)

ii. Locate the Fence assembly and loosen it by twisting Knob A, counterclockwise.

iii. Slide the Fence until its edge is aligned with the mark on the Centering Scale,

Scale A, that corresponds to the frame’s width.

iv. Tighten Knob A.

ÿB. Where do you want the hanger to be inserted, relative to the top

edge of the frame?

i. Measure or approximate the distance between the top edge of the frame and the point

at which you wish to insert the hanger. (measurement “b” in Figure 11)

ii. Loosen the T-Bar Clamping Knob, Knob B, by turning it counterclockwise.

iii. Move the T-Bar Assembly by gently pushing or pulling the unit along its track.

iv. Align the T-Bar so that measurement “b” is reflected on the T-Bar scale, Scale B,

located on the Base Assembly.

v. Tighten Knob B.

ÿC. How high is the frame at its greatest thickness?

i. With the frame laying flat on a surface, determine its height at its thickest cross-section.

(measurement “c” in Figure 11)

ii. The Carriage of the Saber 250-A is spring-loaded and slides up and down the tower of

the machine.

iii. Firmly pull out the left and right Detent Knobs at the same time.

iv. You will notice that doing so will free the Carriagetoglideupordownasyouwish.

v. This movement of the Carriage will cause the Height Setting Pointer to move along the

Height Scale, Scale C, at the upper right hand corner of the machine.

vi. The Carriage will lock into any one of six (6) pre-set positions that correspond to a

range of heights.

vii. Find the range that includes measurement “c.”

viii. Feel for the locking location at that range by gently releasing the Detent Knobs at or

near the correct setting.

ix. Fully release any pressure on the Detent Knobs to lock the Carriage in place at the

appropriate height setting.

Example “a”

A frame measures 10 inches

across. After loosening the fence

with Knob A, move the fence so

that the Centering Scale (Scale A)

reads 10 inches. Tighten the knob

tolockthefenceinplace.

Example “b”

After assessing where a hanger

should be placed on a certain

frame, the operator measures the

distance from the top edge of the

frame to that spot and finds it to be

two inches (2”). The operator then

moves the T-bar assembly to 2"

on Scale B and then locks the T-

bar assembly in place by turning

knob B.

Example “c”

A frame measures 2.3” high at its

greatest thickness. Using the

Detent Knobs, the operator locks

the carriage into place at the 1.5”

to 2.5” setting as marked on the

Height Settings Scale (Scale C).

Please Note:

The Height Scale

(Scale C) shows six (6)

different height ranges.

Choose the one that will

accommodate

measurement “c.”

2.5” to 3.5”

2.0” to 3.0”

1.5” to 2.5”

1.0” to 2.0”

0.5” to 1.5”

0.5” to 1.0”

ÿþýü ú

Safety Tips:

It is recommended that the

hanger be driven at the thickest

portion of the frame. The further

it is driven from a thick portion,

the more likely it becomes that

the frame will kick upward when

the hanger is inserted.

Set the carriage so that there is

a minimum clearance of 0.25"

from frame to the bottom of the

ram guard. Keep in mind that

the machine will operate

properly with greater

clearances, but there is less

room for errors or injury when

this space is kept to a minimum.

Please Note:

While this manual uses non-

metric measurements in all of

its examples, the Saber 250-A

has both imperial and metric

scales.

Let’s Review:

ÿYou have read and

understand the safety

instructions listed

inside the front cover of

this manual.

ÿYou are familiar with

the operating

procedures and safety

guidelines of your

employer.

ÿYou are wearing safety

glasses prior to working

with this equipment.

ÿYou have assembled

the Saber 250-A and

have created an

uncluttered work area

for the machine.

ÿIt is securely positioned

(possibly mounted) on

your work surface.

ÿYou are familiar with

the major components

of the Saber 250-A and

know that three

measurements must be

taken before adjusting

the machine to yourrun

specifications.

ÿThe machine has been

connected to your

source of clean, dry,

compressed air,

accordingtothe

specifications listed on

the bottom of page 6,

and in compliance with

your company’s

operating procedures.

The Saber 250-A has been

designed to deliver precise

installation of saw tooth hangers

with great reliability. If, for any

reason, a hanger jams, the

machine will not fire.

Uneven pressure on the T-Bar

will automatically interrupt the

operation of the ram. The

slightest release of pressure will

do the same. This design

feature prevents injury and

unintended firing.

ÿþýü úù

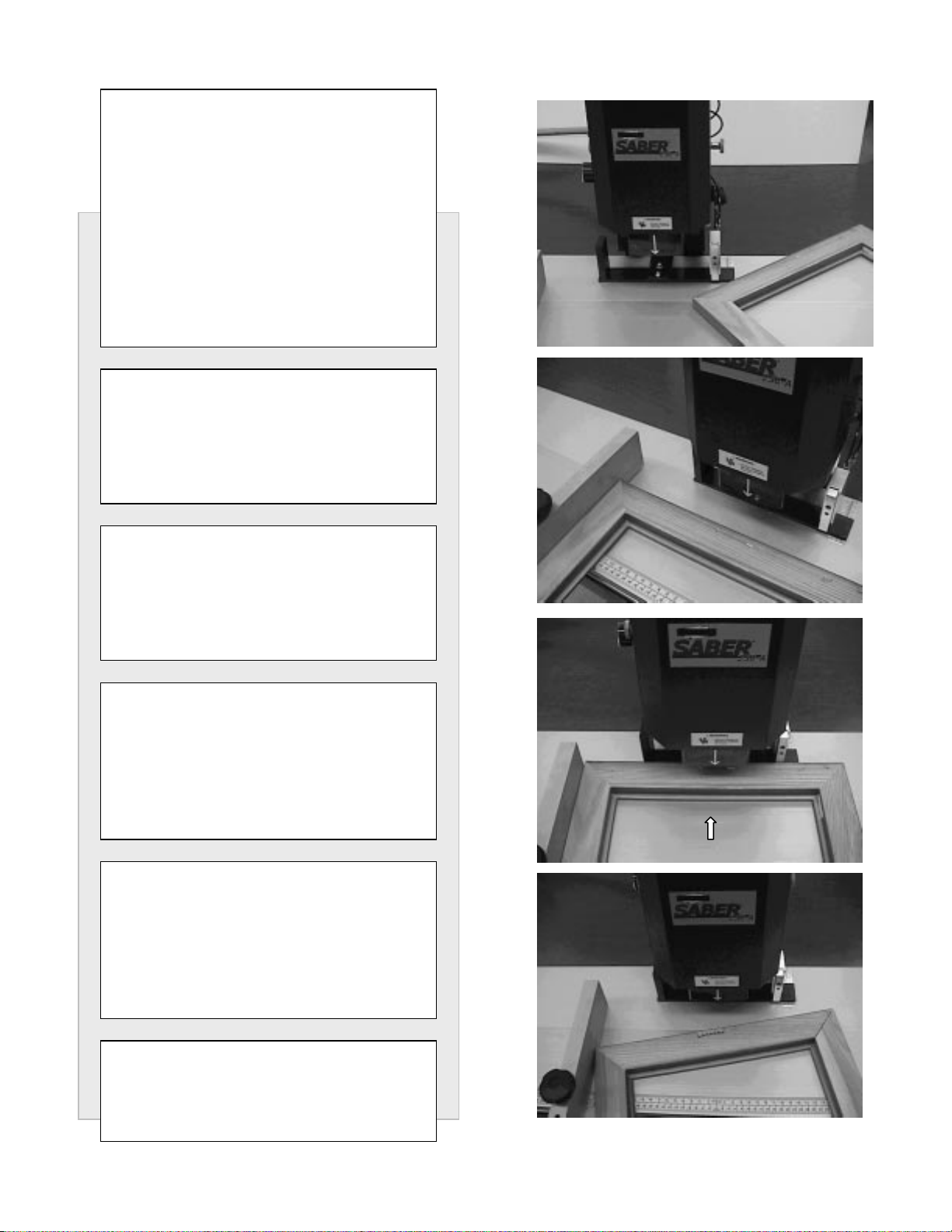

Once all three measurements

(a, b, and c) have been taken

and the machine has been

readied with these measures

being reflected on Scales A, B,

and C, the operator is now

ready to insert the saw tooth

hanger.

ÿþ

The frame is inserted backside-

up with its left edge pressed

against the left fence.

þ

The top edge of the frame is

leveled against the T-Bar

assembly.

þ

The operator then pushes the

frame squarely into the machine

(against the T-Bar), thereby

triggering the pneumatic switch.

þ

When the pneumatic cylinder is

activated, the machine’s ram

will insert the hanger into the

frame at the proper location.

This process can be repeated

25 times per hanger strip.

þ

ÿÿ

The Saber 250-A can be outfitted with one or more of the following optional devices:

A. Small Frame Adapter

(Part # 04-553)

:For frames that are too small to be processed

using the standard T-Bar assembly and pneumatic switch.

B. Foot Pedal

(Part # 04-552)

:To give the machine operator an alternative method for

activating the Saber 250-A.

C. Additional Fence Assembly

(Part # 04-551)

:The Saber 250-A comes equipped with

a universal fence assembly that is used for squaring the left edge of a picture frame. It

may also be used to square the right edge of a picture frame that requires two side-by-

side saw tooth hangers. When two hangers must be inserted into the top piece of a

picture frame, a second fence assembly may be ordered (to attach on the right side of

the base) in order to provide the operator with a step-saving method of installing the

hangers.

Using a Small Frame

Adapter to Insert

Hangers

The sizes of some frames

are such that they will be too

small to be effectively

handledby the standard T-

Bar assembly of the Saber

250-A. Therefore, The

Fletcher-Terry Company has

designed an optional adapter

that will accommodate such

frames.

The adapteris fittedon the

T-Bar stop block on the T-

Bar assembly. The adapter’s

bracket is securely tightened

to the Saberby turning Knob

D. Do not over-tighten. The

procedure for inserting the

hanger is unchanged.

Note: Add ¼” to measurement

“b” to compensate for the

thickness of the Actuator Bar

when setting the T-bar Scale.

That is, if you wish to place the

hanger ¼” from the top edge of

the frame, add ¼” and set Scale

Bto½”.

ÿþ üûúùù ø÷úûö ÿõú

ô

óö

÷

úö

Inserting Two Hangers Per Frame Using a Second Fence.

ÿThe fence designed for the Saber-250-A may be attached to the base on either the left or the right side of the

machine. When inserting a single hanger, the fenceis positioned to the left. If aframe’s size necessitates a

two-hanger configuration, a second fence assembly may be used to streamline the process.

ÿThe secondfence is the identical twin to the standard fence. They can be used interchangeably. They are

attachedto the base the same way and are positionedso that there is a fence to the leftof “zero”on the

centering scale, and there is oneto the right of thismark.

The procedure for inserting two hangers usingthe second fenceis similar to the procedure for insertingone:

ÿMeasurements are taken and the machine isadjusted toreflect them. Whereasa single hanger is centered on

a frame,two hangers must be lined up horizontally at an equal distance fromthe center (or at an equal

distance from the frame’s edge).

ÿThe operator manually determines the placement of thefirst hanger and takes thatmeasurement. The

essential thing to remember is that the placement and measurement of the second hanger must mirror that of

the first.Both fences must be positioned so that theircorresponding edges areset to the same mark on either

side of “zero.” (See Figure 13 above.)

ÿThe installation processis completed by firstinserting the right hanger. (Square the frame to the left fence

before pressing it against the pneumatic switch to activate thehanger.) Repeat this process for the left hanger

by squaring the frame against the right fence.

Using an Optional Foot

Pedal.

Use of thefoot pedal is a matter of

the personal preference of the

machine operator. It is assembled

according to the instructions enclosed

with the item.

Figure 13

ÿþ üûûú ùø÷öõ

þ ÷÷úûöõ üøø øõ

ùöø

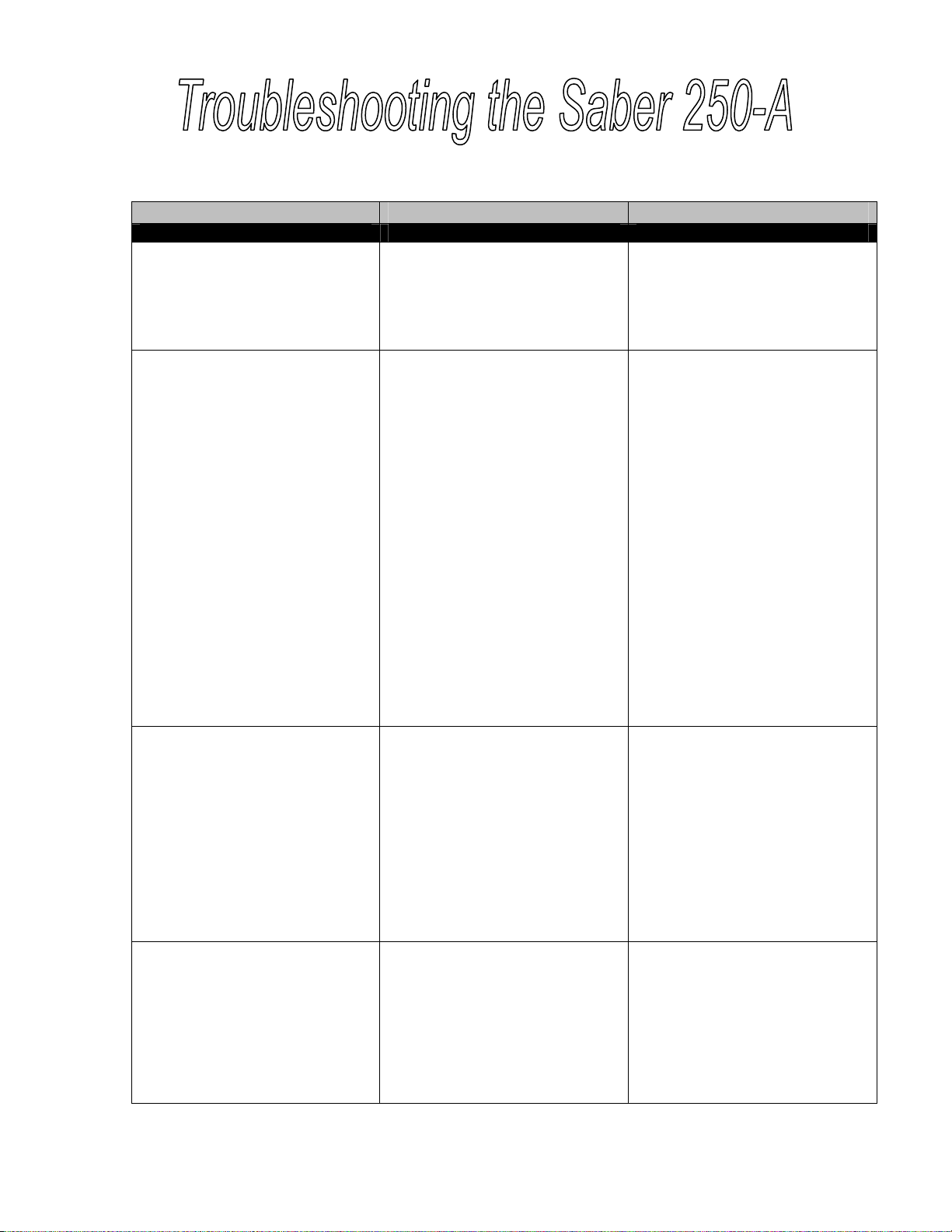

Problem or Issue Possible Reason Action

The machine fires prematurely. The top edge of the frame is

pressing against the activation

switch before the side edge is

squared on the fence.

Alwayspositionthesideedgeof

the frame before pushing the top

edge against the T-Bar (i.e., the

pneumatic switch).

A hanger is jammed in the

machine. In the unlikely event of a jam, one

of two things may have

happened. The hanger strip has

been placed on the magazine

incorrectly, or the hanger strip

was bent or damaged during

shipping or handling.

The operator must manually

remove the jam by first

disconnecting the air supply, then

freeing the remaining hanger

strip from the rear of the

machine, and finally ejecting the

jammed hanger. Only one hanger

can ever be jammed because of

the machine’s design.

To remove the hanger strip,

locate the ram guard above the

T-bar assembly and push up on

the orange release lever.

Remove the hanger and then

make sure the hanger strip is

reloaded properly before

reconnecting the air supply. (See

page 6.)

There is no air pressure. The source of compressed air is

disconnected or improperly

connected to the Saber 250-A.

Re-check your air source and

hose connections to make sure

that you have correctly attached

the Saber 250-A to your existing

air supply system.

If the pneumatic drive still does

not work properly, contact your

Fletcher-Terry Customer Service

Representative for further advice.

There is insufficient air pressure. Pressure settings are not

properly set.

The machine is being used on

material, or in a way for which it

is not designed.

Check your company’s

compressed air source to make

sure that it is in proper working

order. Verify that all settings are

consistent with the

recommendations listed on page

6 of this manual.

ÿþýü úù

Hanger is not fully installed. (a) There is too much clearance

between the picture frame and

the ram tip at its extended

position.

(b) There is not enough air

pressure.

(a) Using the detent knobs on

either side of the drive carriage,

lower the height setting to an

appropriate range. A ¼”

clearance is sufficient.

(b) Increase air pressure until the

hanger is fully installed.

Hanger is not centered (left-

right). The fence is not positioned

properly. Refer to page 9 in order to review

measurement settings.

Hanger is not centered (up-

down). The hanger need not be centered

vertically on the top edge of the

frame. However, if the hanger is

not placed where the operator

wants it, there is likely a problem

with the measurements reflected

on the scale on Scale B.

Refer to page 9 in order to review

measurement settings.

Hanger strip does not feed

properly. (a) The hanger strip may be

slightly bent or twisted.

(b) The flow control valve is

closed or clogged.

(a) The hanger strip can be fed

with minimal misshape, however,

it should be manually corrected if

possible. If the strip is badly bent,

the strip needs to be replaced.

(b) Adjust the flow control valve

to let more air into the indexing

cylinder.

Frame will not release. There may have been less than

¼” clearance between the ram tip

and the picture frame.

Using the detent knobs on both

sides of the carriage, raise the

ram to an appropriate height

setting range. A ¼” clearance is

necessary to avoid trapping the

frame.

For assistance, contact The Fletcher-Terry Company Customer Service Department at

800.843.3826, 860.677.7331, or customerservice@fletcher-terry.com.

ÿþýü úù

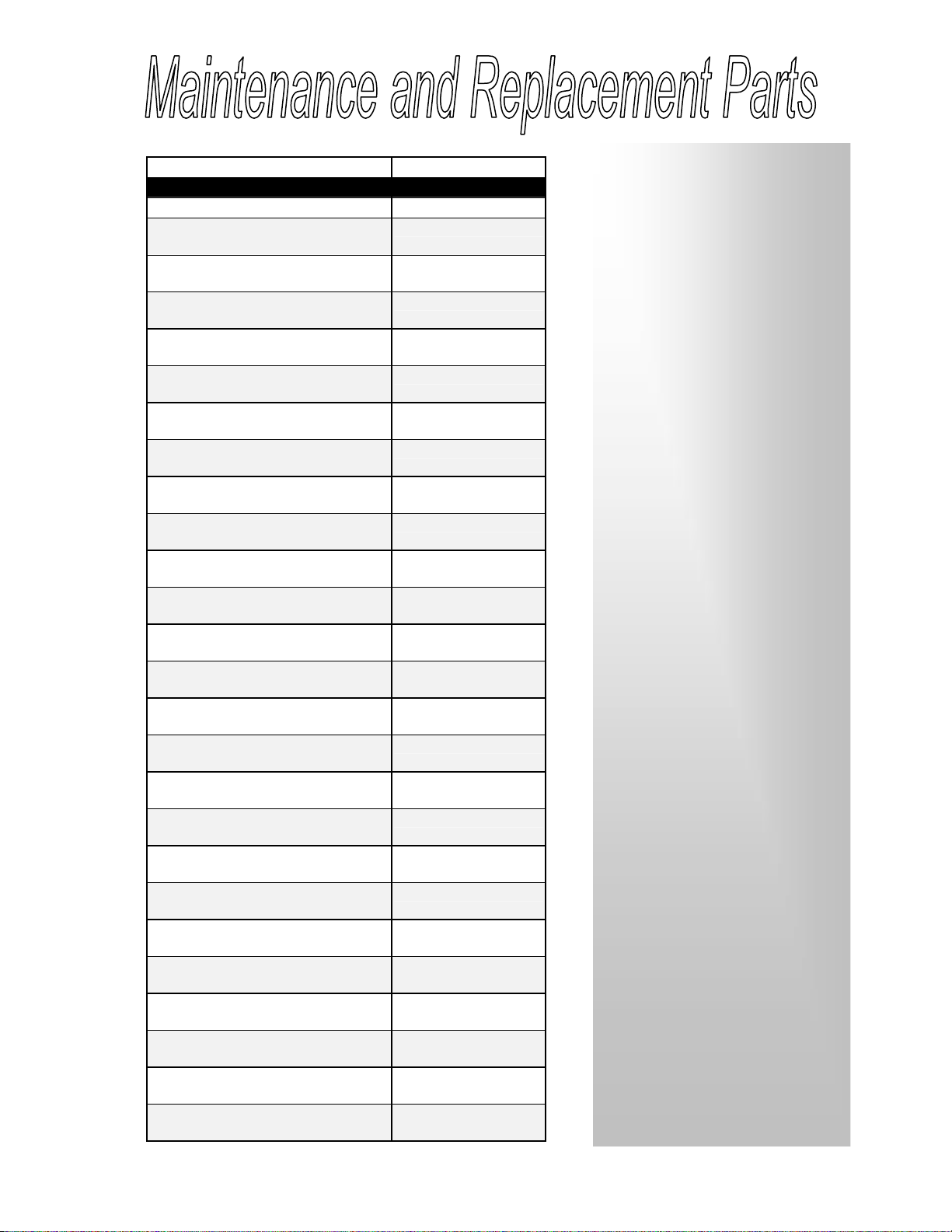

Description Part Number

Air Regulator 18-000

Air Valve 18-001

Air Limit Valve 18-002

Indexing Cylinder Assembly 18-003

Main Air Cylinder 18-004

Carriage Spring –

5/8" Dia. x 5" LG 18-005

Carriage Spring –

1/2" Dia. x 5" LG 18-006

Height Adjustment Knob 18-007

T-Bar Shoe 12-349

T-Bar Clamping Knob Assembly 18-008

Hanger Ram Tip Assembly 18-009

Hanger Shear Nose Assembly 18-010

Ram Guard

(With Arrow Labels) 18-011

Button Head Socket Cap

Screw, #8-32 x 1/2" LG (4) 12-848

Detent Height Settings Bracket &

Scale 18-012

Detent Height Settings Pointer 18-013

Base Assembly (With Scales) 18-014

Flat Head Socket Cap Screw,

#10-32 x 5/8" LG (2) 18-015

Hex Key (Base-To-Frame

Assembly Screws) 18-016

Front Cover Assembly

(With Labels) 18-017

Button Head Socket Cap

Screw, #8-32 x 1/2" LG (4) 12-848

Warning Label

(Guards in Place) 18-018

Caution Label

(Servicing) 18-019

Air Volume Chamber 18-020

Triangle Template (Square) 12-625

ÿThe Saber 250-A is an

efficient and reliable machine,

designedto be operated

safely and maintained with

minimal effort.

ÿKeeping the workarea clean

and clutter-free will allow the

operator to work quickly and

will prevent accidental

damage tothe machine and

production materials.

ÿA clean dry cloth should be

used to wipe down the

machine; the surface of the

base assembly should be

protected from dents and

abrasions. While the machine

will operate properly despite

such marks, it is up to the

operator to safeguard the

condition of your company’s

product by taking care of the

base and fence(s).

ÿThere are no parts to service

or replaceas part of a

regularly scheduled plan. In

fact, there is very little

likelihood that a part will need

replacement.

ÿPlastic safety guards, safety

labels, replacement knobs,

scalesandtheramtipcanbe

ordered from The Fletcher-

Terry Company.

ÿThe machine’s parts and

order numbers are listed to

the left. Please referto the

drawingson page 4to make

sure you are ordering the

correct item.

ÿþýü úù